Catalog

PREFACE X-NET INTRODUCTION ............................................................................................................................................ 3

1X-NET FIELDBUS ............................................................................................................................................................. 4

1-1. FUNCTION SUMMARIZE .......................................................................................................................4

1-1-1. Introduction ...........................................................................................................................4

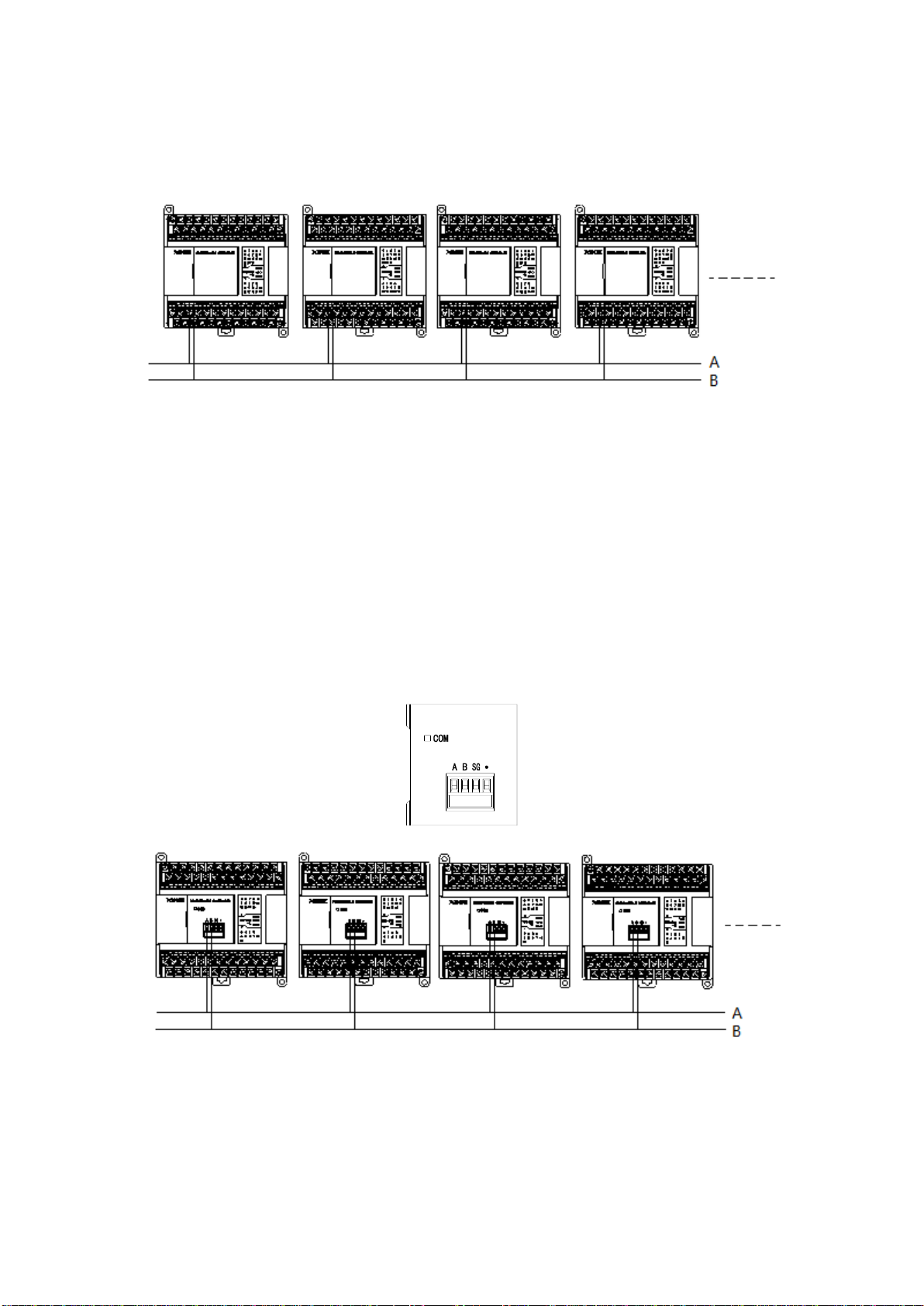

1-1-2. Wiring mode ..........................................................................................................................4

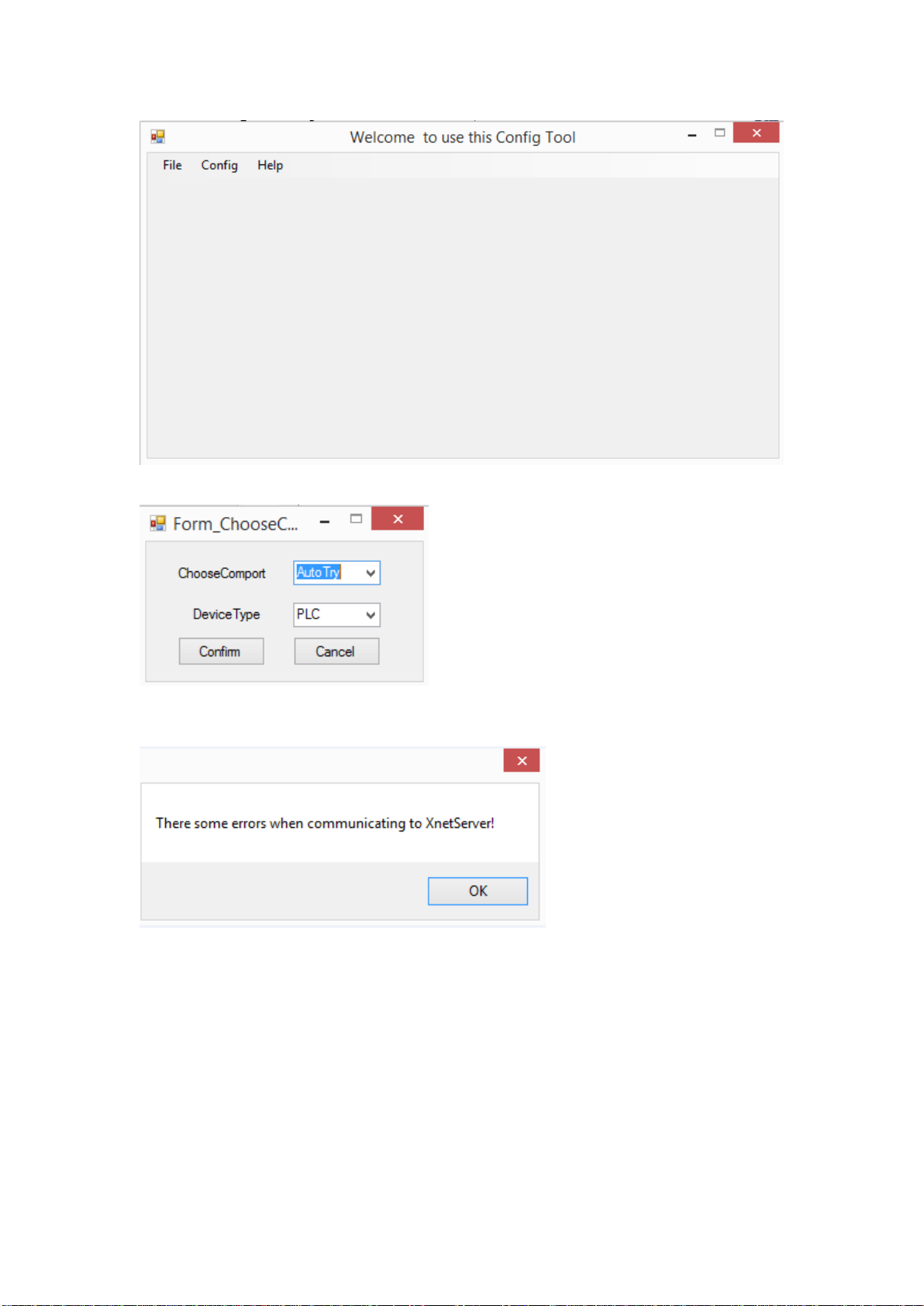

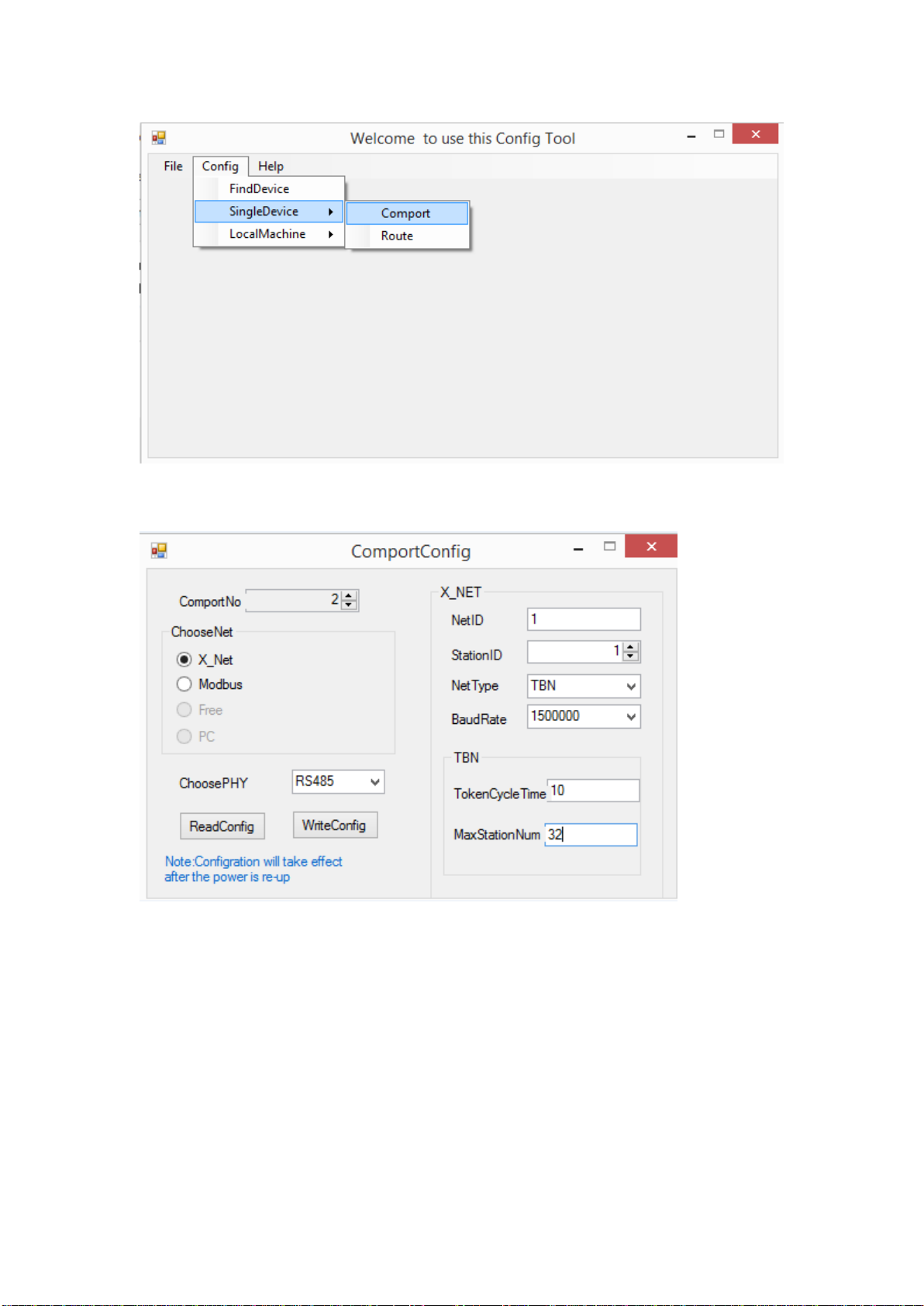

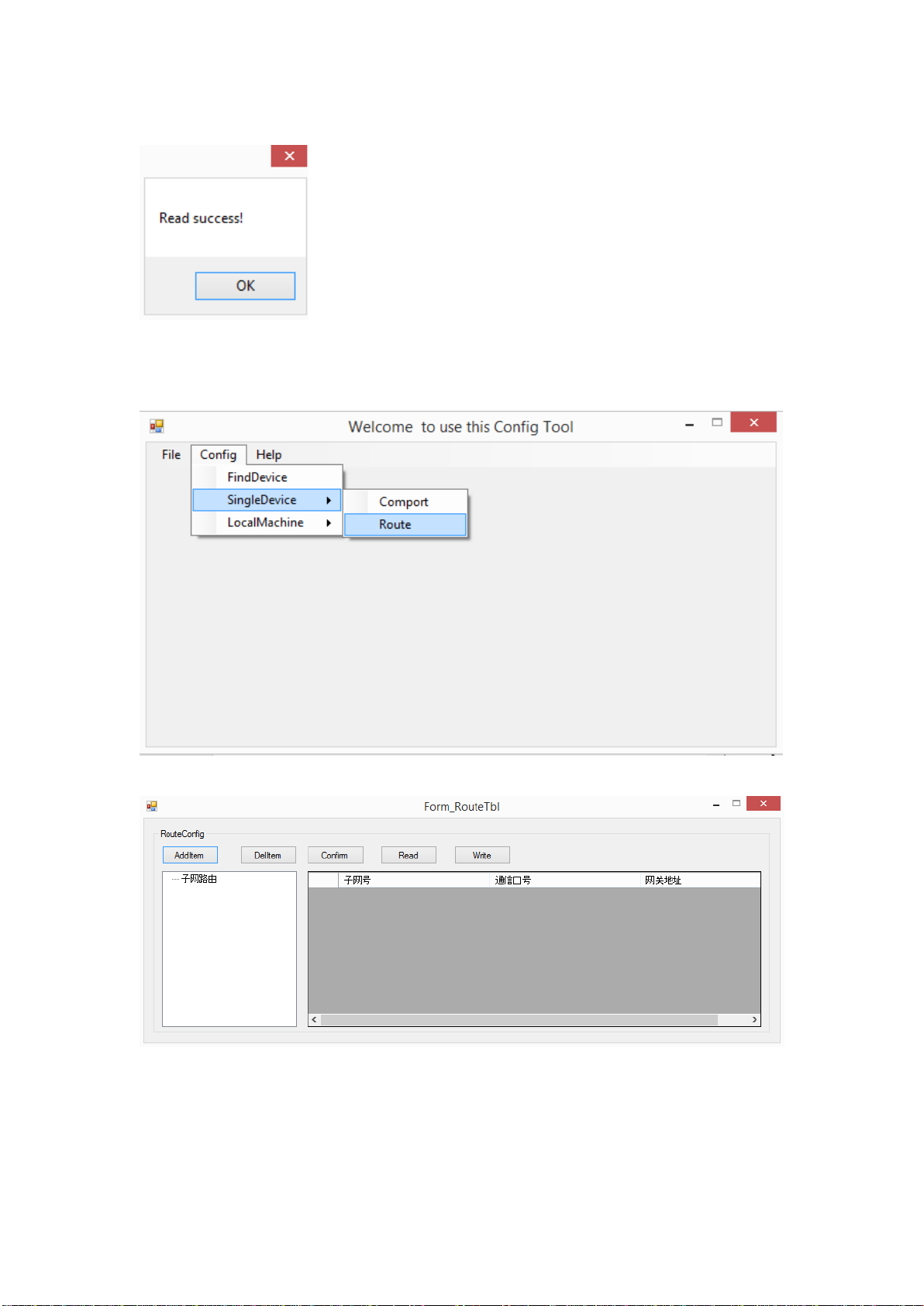

1-1-3. XINJEConfig software .............................................................................................................6

1-2. COMMUNICATION INSTRUCTION ..........................................................................................................10

1-2-1. Read bit [BIT_READ].............................................................................................................11

1-2-2. Write bit [BIT_WRITE] ..........................................................................................................12

1-2-3. Read register [REG_READ] ...................................................................................................13

1-2-4. Write register [REG_WRITE].................................................................................................14

1-3. COMMUNICATION ADDRESS................................................................................................................15

1-4. X-NET COMMUNICATION APPLICATION ................................................................................................22

1-5. COMMUNICATION REGISTER ...............................................................................................................26

2X-NET MOTION FIELDBUS ...............................................................................................................................................29

2-1. FUNCTION SUMMARY ........................................................................................................................29

2-1-1. Special vocabulary ...............................................................................................................29

2-1-2. Fieldbus wiring.....................................................................................................................29

2-1-3. PLC software ........................................................................................................................30

2-2. INSTRUCTIONS .................................................................................................................................30

2-2-1. Incremental position motion [MOTO] ..................................................................................30

2-2-2. Absolute position motion [MOTOA] .....................................................................................35

2-2-3. Multi-speed running [MOTOS] .............................................................................................38

2-2-4. Stop running [MOSTOP] .......................................................................................................45

2-2-5. Continue running [MOGOON] ..............................................................................................47

2-2-6. Synchronous run [MOSYN] ...................................................................................................48

2-2-7. Release synchronous run [MOUSYN]....................................................................................51

2-2-8. Write in present position [MOWRITE] ..................................................................................52

2-2-9. Read present position [MOREAD] ........................................................................................54

3 TEACHING FUNCTION .....................................................................................................................................................55

3-1. SFD REGISTER SETTING......................................................................................................................55

3-2. RETURN THE ORIGIN..........................................................................................................................57

3-3. JOGGING ........................................................................................................................................64

3-4. IN-CIRCUIT EMULATION......................................................................................................................68

3-5. PROTECTION....................................................................................................................................68

4SYSTEM COIL AND REGISTER...........................................................................................................................................69

5ERROR MESSAGE............................................................................................................................................................74

APPENDIX 1 XINJE CONFIG SOFTWARE .................................................................................................................................77

APPENDIX 2 SERVO PARAMETERS.........................................................................................................................................80