CAUTION - FOR RESIDENTIAL KITCHEN USE ONLY

Do Not Use to exhaust hazardous or explosive materials or vapors.

NEVER

voids between walls.

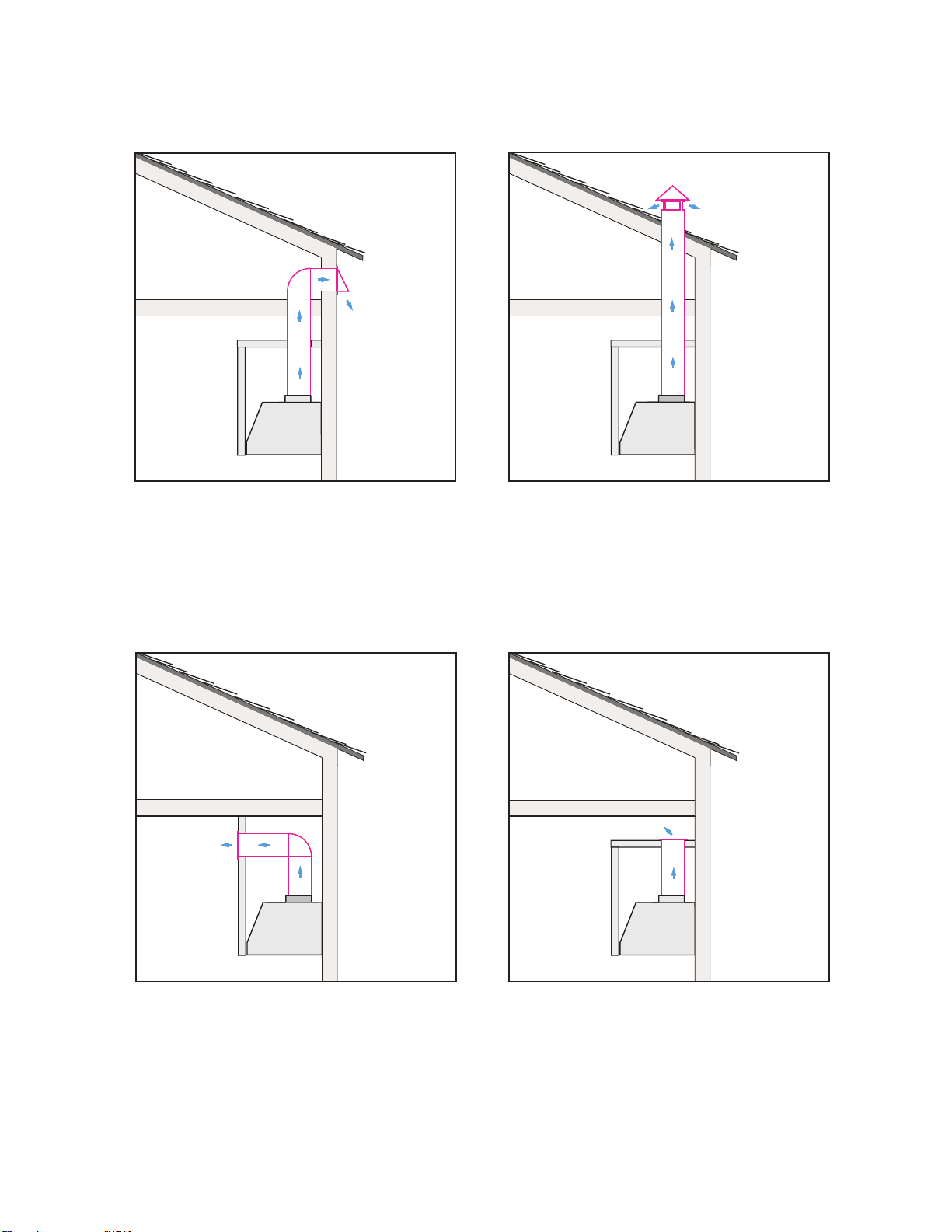

Ducted installation must exhaust outside. Recirculating installations must exhaust back

into the living space.

WARNING: ELECTRICAL SAFETY

This appliance must be connected to a properly grounded, dedicated 120v 60hz 15amp

circuit by a qualified electrician in accordance with all applicable codes and regulations.

Never use any external speed control device.

Never use any extension cord or temporary wiring.

The appliance must be protected by a properly sized circuit breaker or time delay fuse.

CAUTION - DURING INSTALLATION

All installation work and electrical wiring must be done by qualified people in accordance with

all applicable codes and standards, including fire rated construction.

(chimney) of the fuel burning equipment to prevent backdrafting.

Follow the cooking equipment manufacturer’s guidelines and safety standards such as those

published by the National Fire Protection Association (NFPA) and the American Society of

Heating, Refrigeration, and Air Conditioning Engineers (ASHRAE) as well as all local code

authorities.

WARNING: TO REDUCE RISK OF A RANGETOP GREASE FIRE:

a. Never leave the cooking surface unattended. Boil overs, spills and splatter may ignite or

create smoke. Heat oils slowly on low or medium heat settings.

b. Always turn the hood on before you begin cooking.

c. Clean the hood frequently. Keep filters, fans and surfaces free of grease.

d. Use pan sizes appropriate for each burner.e.prepared.

e. Use high heat only when necessary.

f. Use cookware and utensils designed for the cooking style, type and amount of food.

safety first

4