Maintenance

Motor maintenance is generally limited to cleaning and lubrication (where applicable). Cleaning should be limited to

exterior surfaces only. Removing dust buildup on motor housing ensures proper motor cooling. Greasing of motors

is only intended when fittings are provided. Many fractional motors are permanently lubricated and should not be

lubricated after installation. Motors supplied with grease fittings should be greased in accordance with manufacturer’s

recommendations. With motor temperatures under 104ºF (40ºC), the grease should be replaced after 2000 hours of

running time as a general rule.

Wheels require very little attention when moving clean air. Occasionally, oil and dust may accumulate causing

imbalance. When this occurs, the wheel and housing should be cleaned to ensure smooth and safe operation.

All fasteners should be checked for tightness each time maintenance checks are performed prior to restarting unit.

A proper maintenance program will help these units deliver years of dependable service.

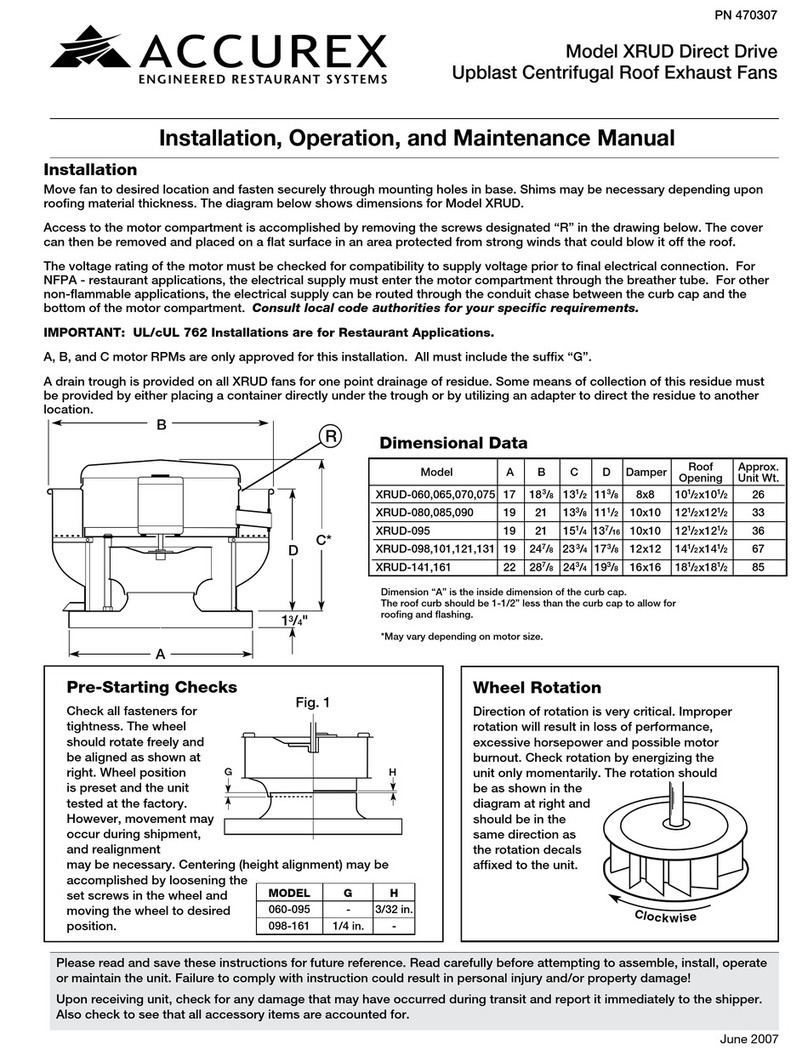

Unit Size A B C D

60-75 105⁄8163⁄4141⁄287⁄8

80-95 131⁄4193⁄4171⁄2117⁄8

100 185⁄8213⁄4191⁄2137⁄8

120 185⁄8233⁄4211⁄2157⁄8

130 185⁄8253⁄4231⁄2177⁄8

140 191⁄2273⁄4251⁄2197⁄8

160 231⁄231 281⁄2227⁄8

All dimensions are in inches.

Vibration Isolator Dimensional Data

CA

A

C

Access

Panel

BA

A

AccessPanel

BD

D

B

B

AccessPanel

Fig. 1

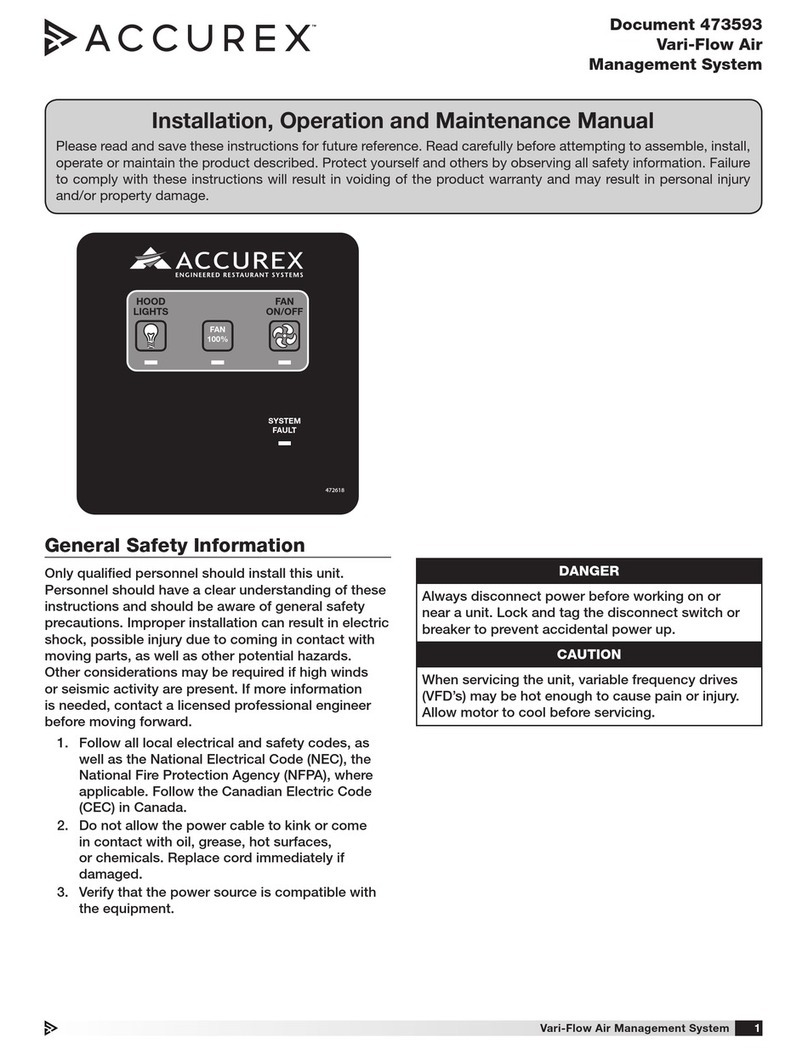

Pre-Starting Checks

Check all fasteners for tightness. The

wheel should rotate freely and be aligned

as shown in Fig. 3. Wheel position is

preset and the unit tested at the factory.

However, movement may occur during

shipment, and realignment may be

necessary. Centering (height alignment)

may be accomplished by loosening the set

screws in the wheel and moving the wheel

to desired position.

Overlap 1/4 in.

Gap 1/8 in.

XID

100-160

XID

60-95

Fig. 3

PN 470389

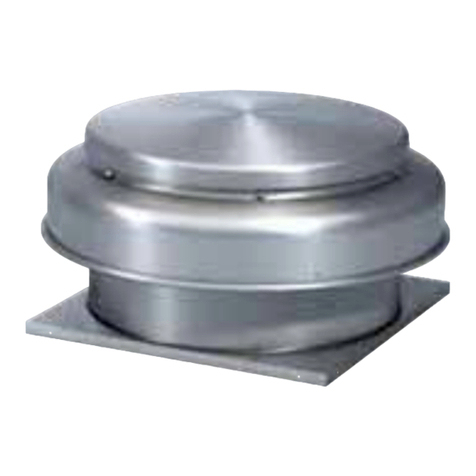

Installation

Move fan to desired location and determine position of access panels, discharge, and motor. Make sure inlet and

outlet have at least 2.5 times the wheel diameter (duct diameter) before any obstructions like an elbow or transaction.

Attach fan to suitable framework as specified (hanging or base vibration isolators are recommended). See chart below

for dimensions of vibration isolator centerlines (Fig.1). See Fig. 2 for physical dimensions.

The voltage rating of the motor must be checked for compatibility to supply voltage prior to final electrical connection.

Electrical lead-in wires are then connected to the factory supplied safety disconnect switch. All wiring must conform to

local and national codes.

Installation, Operation, and Maintenance Manual

Model XID Direct Drive

Centrifugal Inline Fans

Please read and save these instructions for future reference. Read carefully before attempting to assemble, install, operate

or maintain the unit. Failure to comply with instruction could result in personal injury and/or property damage!

Upon receiving unit, check for any damage that may have occurred during transit and report it immediately to the shipper.

Also check to see that all accessory items are accounted for.

June 2007

A1in.

C sq.

B sq.

B sq.

1in.

C sq.

XID Dimensional Data

Fig. 2

Unit Size A B C Material Thickness

(ga.)

Approx. Unit

Weight (lbs.)

60-75 13 12 87⁄820 25

80-95 16 15 117⁄820 40

100 21 17 137⁄820 60

120 21 19 157⁄820 75

130 21 21 177⁄820 90

140 22 23 197⁄818 105

160 26 26 227⁄818 130

All dimensions are in inches.

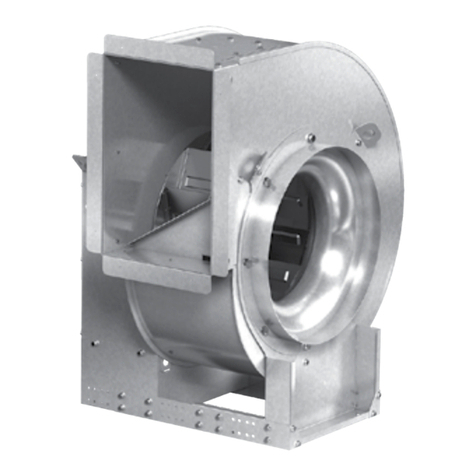

Wheel Rotation

Direction of wheel rotation is

critical. Reversed rotation will

result in poor air performance,

motor overloading and possible

burnout. Check wheel rotation

(all XID fans have CW wheel

rotation when viewed from top

of fan) by momentarily energizing the unit.

Rotation should be clockwise as shown in Fig. 4 and

correspond to the rotation decal on the unit.

Fig. 4