2

(29” pure flat). When the TV set needs to be fixed, please follow the inspection procedures of

high voltage in item 4.11 under this instruction ”Inspection of high voltage”. It is suggested that

the value of high voltage be recorded as part of maintenance work. It is most essential at the

same time to use precise and dependable high voltage meter.

1.1.2 This set is equipped with X-ray over radiation (FS) protection circuit to prevent over radiation

of X-ray in the case of abnormal increase of B+ voltage in the set. Whenever fixing the set,

FS circuit must be checked according to the inspection procedures as in item 4.11.5 of this

instruction, ”X-ray radiation protection test” to make sure the circuit functions well.

1.1.3 The only source of TV set producing X-ray is CRT. To avoid X-ray radiation during the whole

process, the exact same type of CRT designated in the detail list must be replaced, when

there is a need to change CRT.

1.1.4 When deciding on the same type of 4, as some components of this TV set are related to the

safety characteristic, please read the “Points of attention for products safety” before changing

the components, for the sake of safety.

1.2 Safety measures

1.2.1 When the TV set is working, the high voltage will be as high as approximately 31kV. When

adjusting the set after removing the cover or opening the back cabinet there will be risk of

electric shock, so

a) Before detaching the anode cap, please discharge it several times by grounding the anode

of CRT to earth many times to avoid electric shock.

b) Before moving the CRT, its anode must be thoroughly discharged. The CRT is a high

vacuum part. Once broken, its fragments will fly out violently. Therefore it must be very

careful in dismantling and loading it.

1.2.2 There are a lot of electronic and mechanical components in PCB that have safety related

features. They are indicated with shadow in the circuit diagram. Please carefully read the

detail list before changing these components.

1.2.3 If the fuse is blown, please change it for the one designated in the list of components.

1.2.4 When changing resistors of 1w or bigger than 1w in PCB, make sure to separate them from

the PCB by10 mm.

1.2.5 Make sure that the wire stays far away from the high voltage or high temperature

components.

1.2.6 Check for the AC leakage current of the metal components exposed out of the cover such as

antenna terminal, screw, metal surface and control axis. Make sure that the cabinet of TV set

is absolutely safe in operation, free from any risk in electric shock. Insert the power supply

plug directly into the 220v AV socket (No isolate transformer will be applied during the test).

Use an AC voltage meter with sensitivity of 5 kΩor higher per volt to measure the leakage

current according to the following steps:

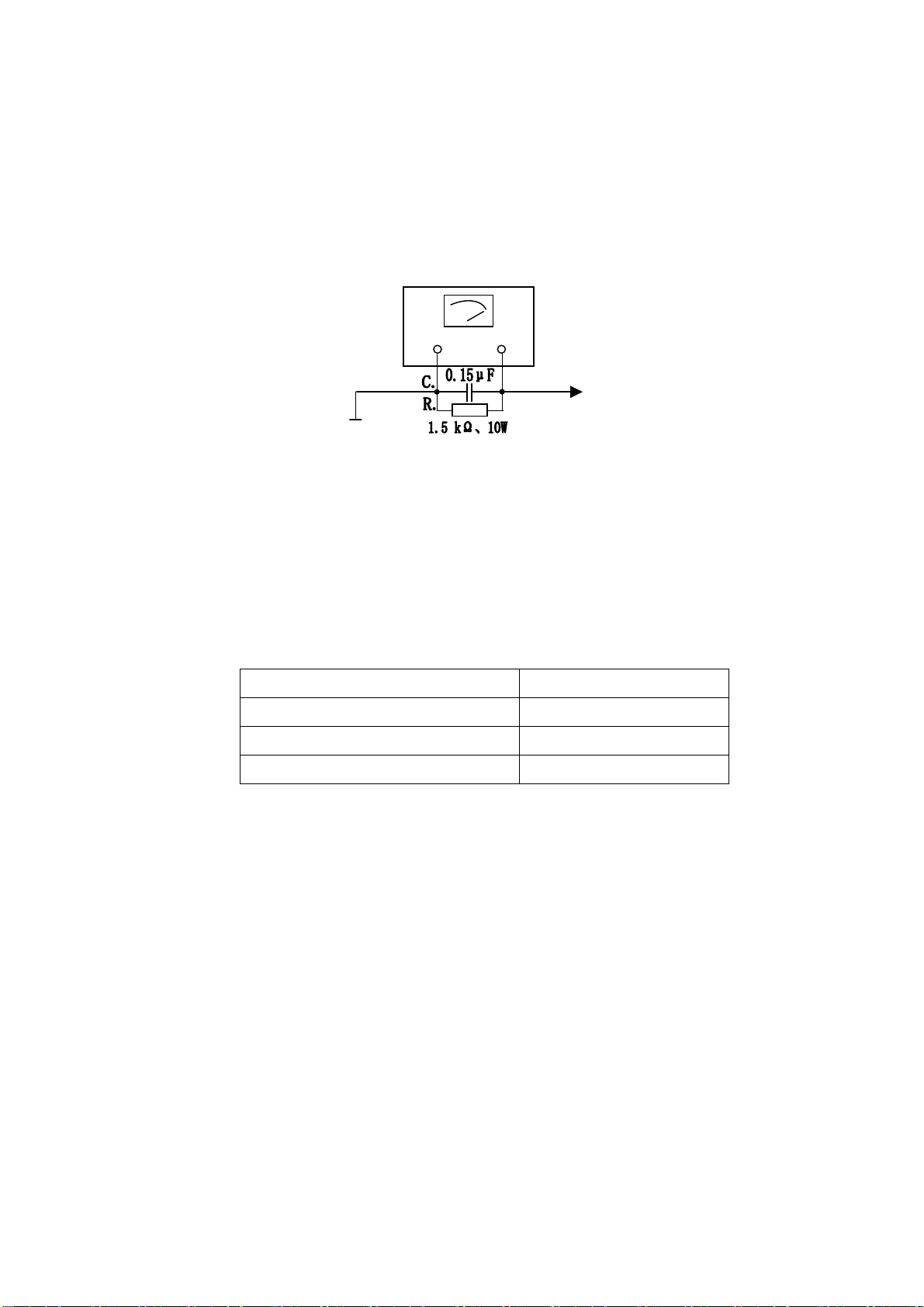

First, connect in parallel a resistor of1.5 kΩ,10 W resistor and a 0.15 μF capacitor (AC type)