CRX-M170

CRX-M170

5

■ FM SECTION

Tuning Range (50 kHz steps) . . . . . . . . . 87.50 to 108.00 MHz

Signal to Noise Ratio (Mono) . . . . . . . . . . . . . . . . . . . . . .65 dB

Sensitivity (S/N 30 dB) . . . . . . . . . . . . . . . . . . . . . . . . 1.0 µV/m

■ AUDIO SECTION

Minimum RMS Output Power Per Channel

1 kHz, 0.1% THD, 6 ohms . . . . . . . . . . . . . . . . . . .25 W + 25 W

Input Sensitivity/Impedance

Tape, AUX 1, AUX 2 . . . . . . . . . . . . . . . . 300 mV/47 k-ohms

Output Level

REC OUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280 mV

SUB WOOFER (50Hz) . . . . . . . . . . . . . . . . . . . . . . . . . 2.0 V

Headphone Jack Rated Output

CD, etc. (32 ohms) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.0 V

Frequency Response

CD, etc (20Hz to 20kHz) . . . . . . . . . . . . . . . . . . . . . . ±0.5 dB

Total Harmonic Distortion

CD, etc. 1 kHz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.03%

Signal to Noise Ratio (IHF-A-Network)

CD, etc. (300 mV, Input Shorted) . . . . . . . . . . . . . . . . .98 dB

Tone Control Characteristics

BASS Boost/cut . . . . . . . . . . . . . . . . . . ±10 dB (100 Hz)

TREBLE Boost/cut . . . . . . . . . . . . . . . . . . ±10 dB (10 kHz)

■SPECIFICATIONS

■ AM SECTION

Tuning Range (9 kHz steps) . . . . . . . . . . . . . . .531 to 1629kHz

Signal to Noise Ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . .35 dB

Sensitivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .600 µV/m

■GENERAL

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . AC 230V, 50 Hz

Power Consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75 W

Standby Power Consumption . . . . . . . . . . . . . . . . . . . . .0.9 W

Dimensions (W x H x D) . . . . . . . . . . . . . .215 x 110 x 359 mm

(8-7/16" x 4-5/16" x 14-1/8")

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.4 kg (9 lbs. 11 oz)

Finish . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Silver color

Accessories . . . . . . . . . . . . . . . . . . . . . . AM loop antenna x 1

Indoor FM antenna x 1

Indoor DAB antenna x 1

Remote Control x 1

Battery (size "AAA", "R03", "UM-4") x 2

* Specifications subject to change without notice.

B ....... British model

■ DAB SECTION

Tuning Range (BAND

III

) . . . . . . . . . . . . 174 MHz to 240 MHz

Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 ohms (nominal)

Sensitivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .–96 dBm

Selectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35 dB typ.

Audio Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . Stereo, 2.0 Vp-p

Digital Out . . . . . . . . . . . . . . . . . . . . . . 24 bit/48 kHz resolution

■ CD PLAYER SECTION

Signal to Noise Ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . .90 dB

Total Harmonic Distortion . . . . . . . . . . . . . . . . . . . . . . 0.007%

Separation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90 dB

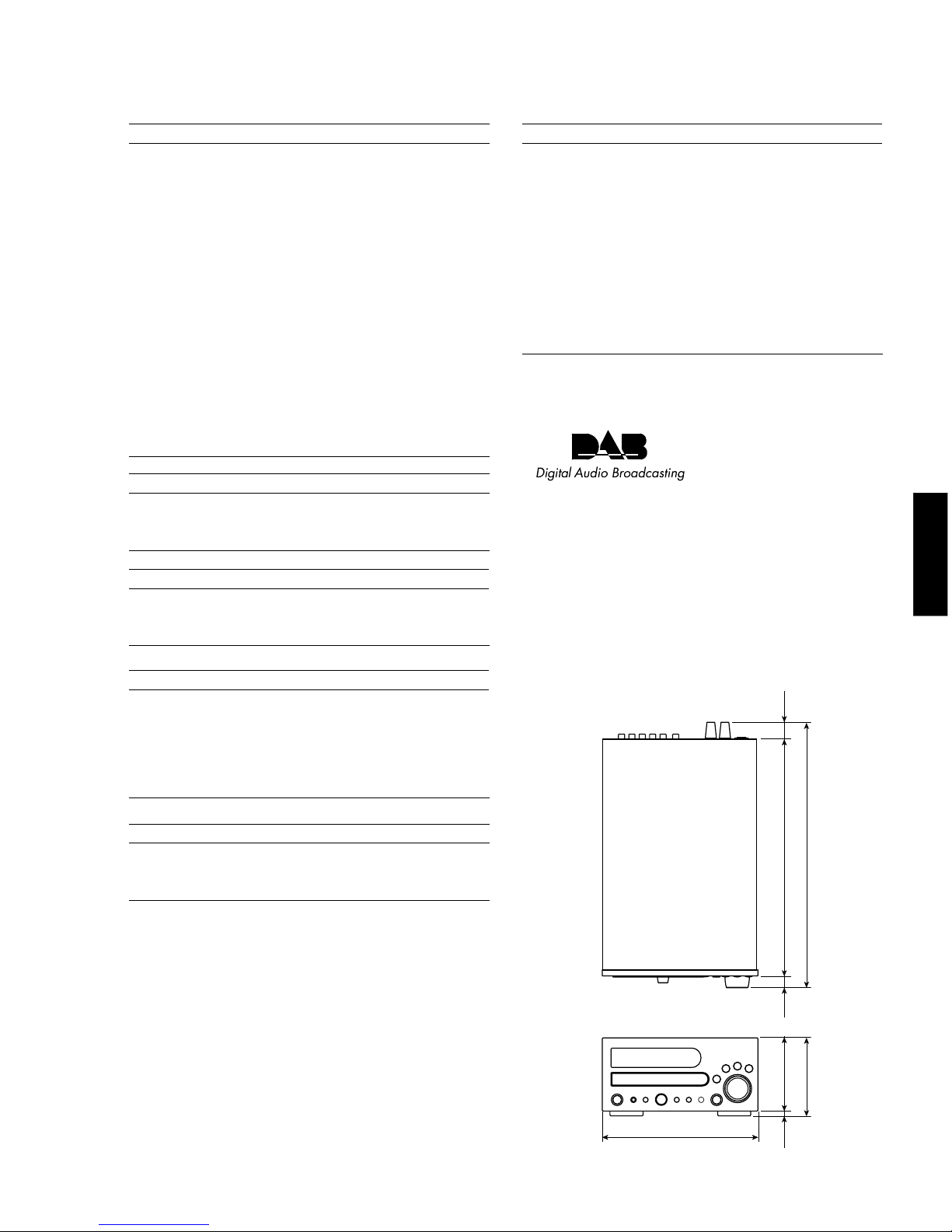

● DIMENSIONS

Unit : mm (inch)

215 (8-7/16")

110 (4-5/16")

101 (4") 320 (12-5/8")9

(3/8") 17

(11/16") 22

(7/8")

359 (14-1/8")

DAB (Digital Audio Broadcasting), also known as digital

radio, is a new way of radio broadcasting. DAB is

broadcast using digital signals instead of analog signals,

resulting in near CD-quality sound. Analog signals (i.e.

AM/FM) are susceptible to interference (i.e. distortion and

noise) caused by electrical equipment, weather conditions,

tall buildings, mountains, etc.; digital signals are not.

Thus, with DAB, there is virtually interference-free

reception and no hiss or crackle.