6

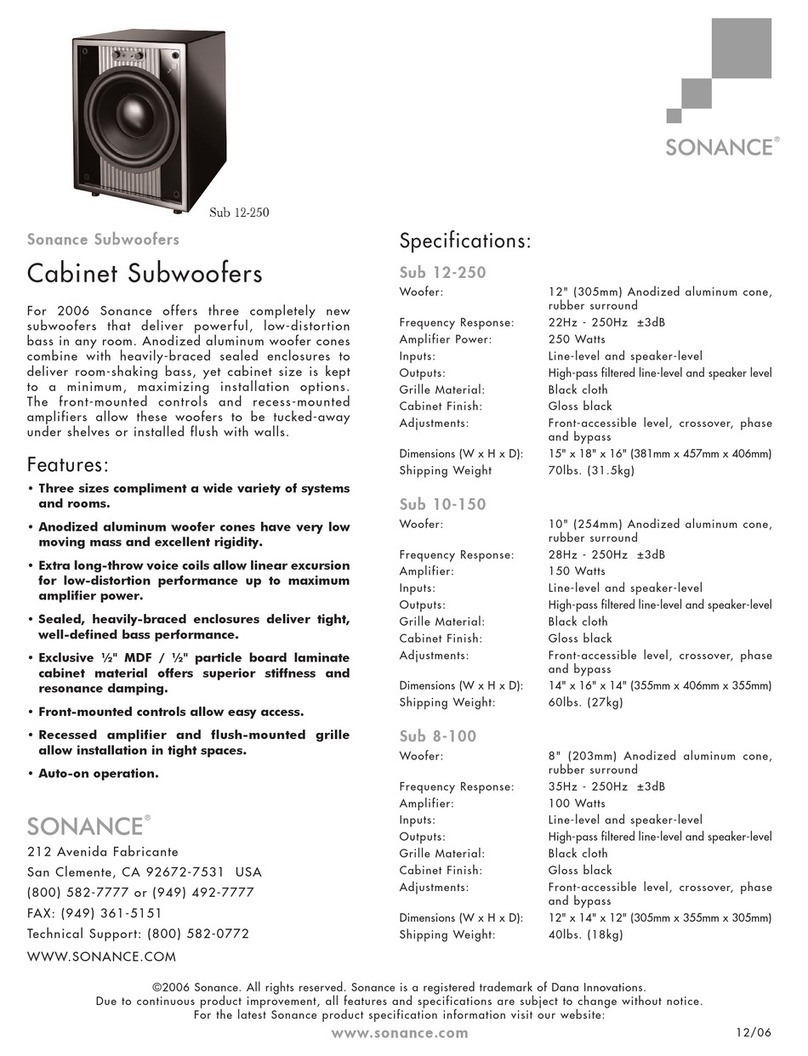

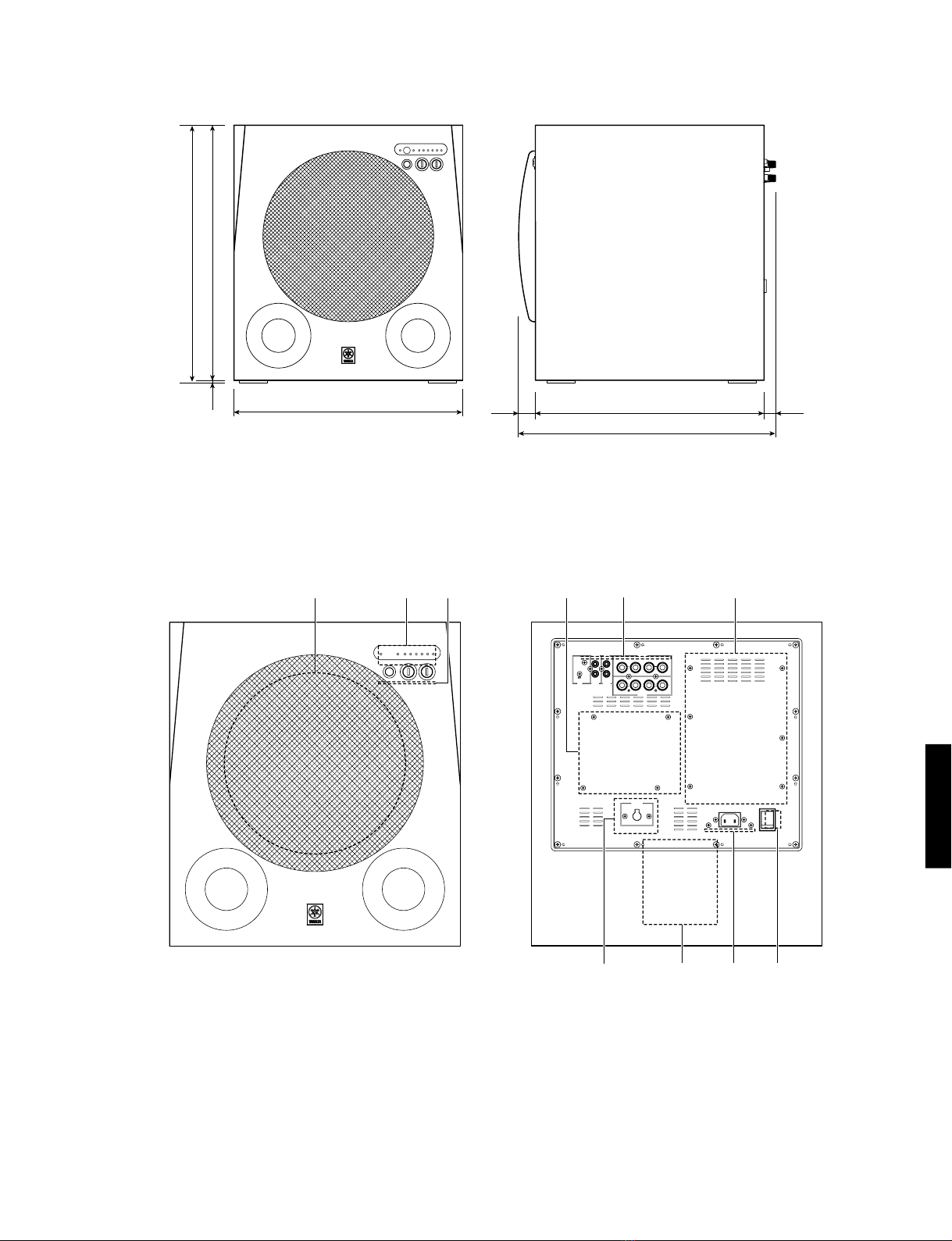

Soavo-900SW

Soavo-900SW

■SPECIFICATIONS/参考仕様

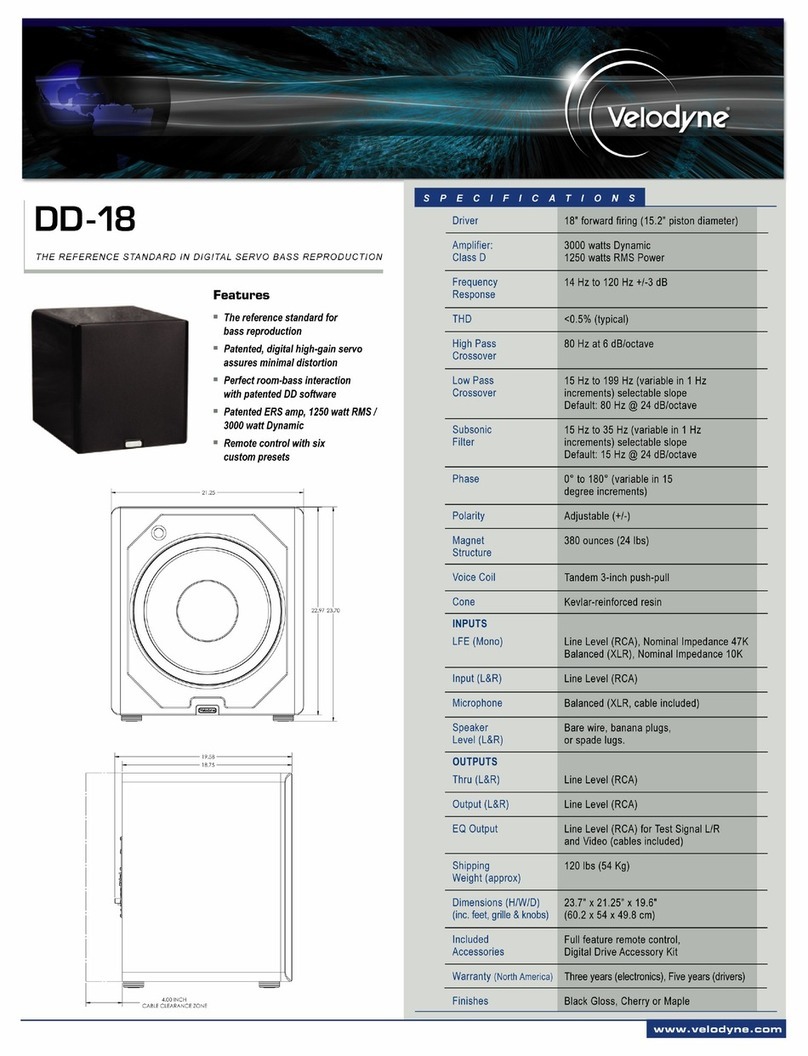

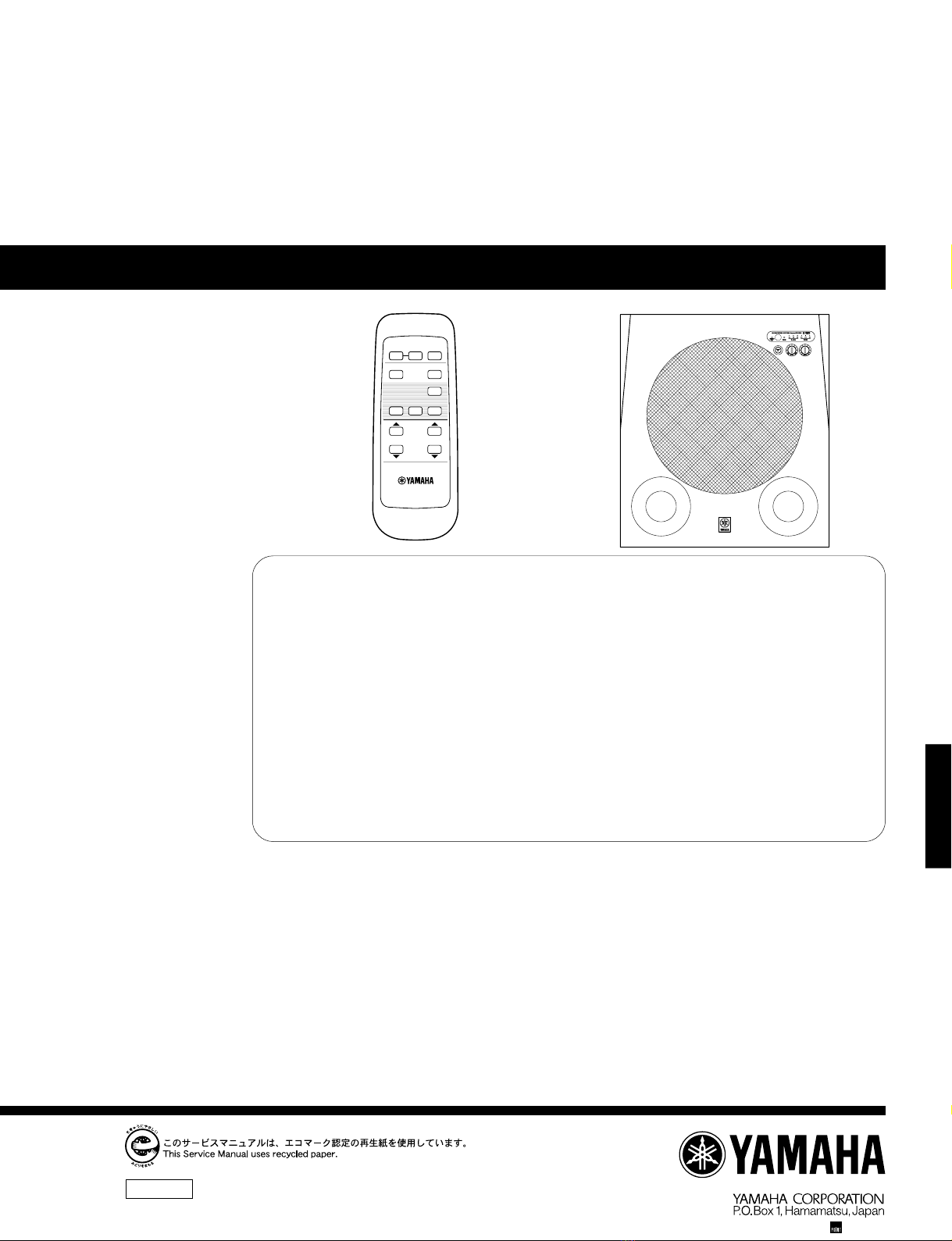

■REMOTE CONTROL PANEL

POWER

STANDBY

SLEEP

PHASE

MEMORY

PRESET

HIGH CUT VOLUME

231

B.A.S.S.

WH64300

Type / AdvancedYamaha Active ServoTechnology

II

Output Power /

100 Hz, 4 ohms, 10 % T.H.D ............................. 600 W

Input Sensitivity / (50 Hz, 600 W/4 ohms, L+R)

INPUT (SP) .......................................................... 1.2 V

INPUT (PJ) ......................................................... 70 mV

Input Impedance /

INPUT (SP) .................................................2.2 k-ohms

INPUT (PJ) ...................................................12 k-ohms

Frequency Response / 18 Hz to 160 Hz

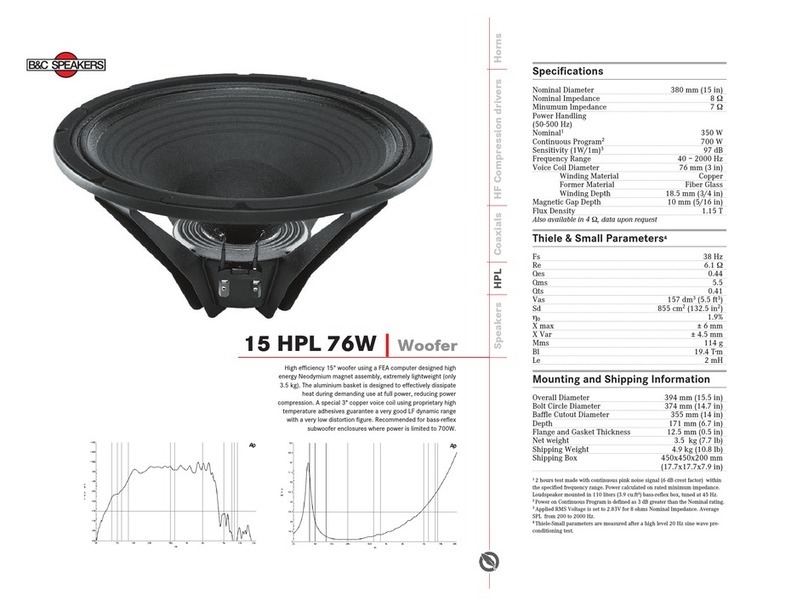

Driver / 25 cm (10”) cone woofer

Magnetic shielding type

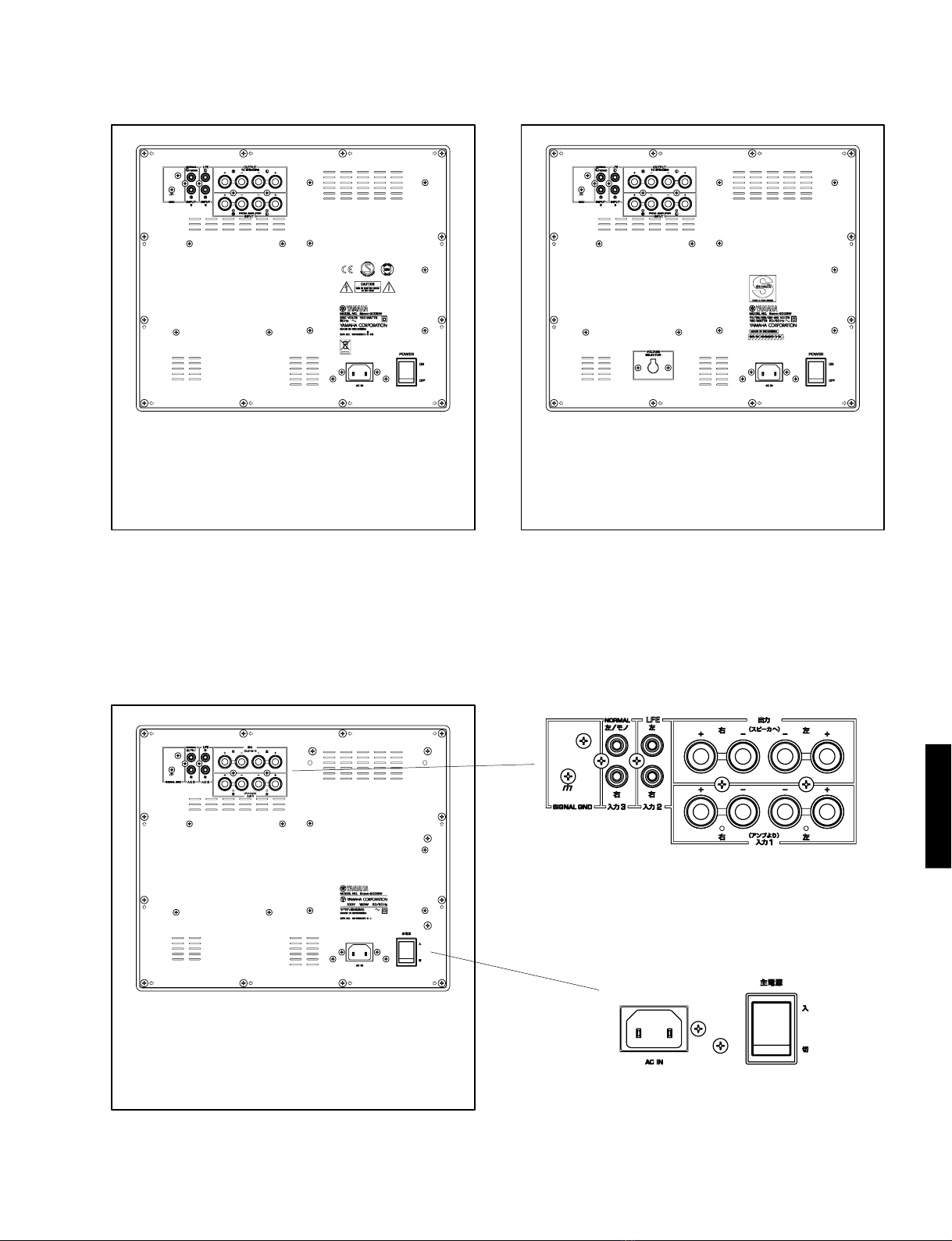

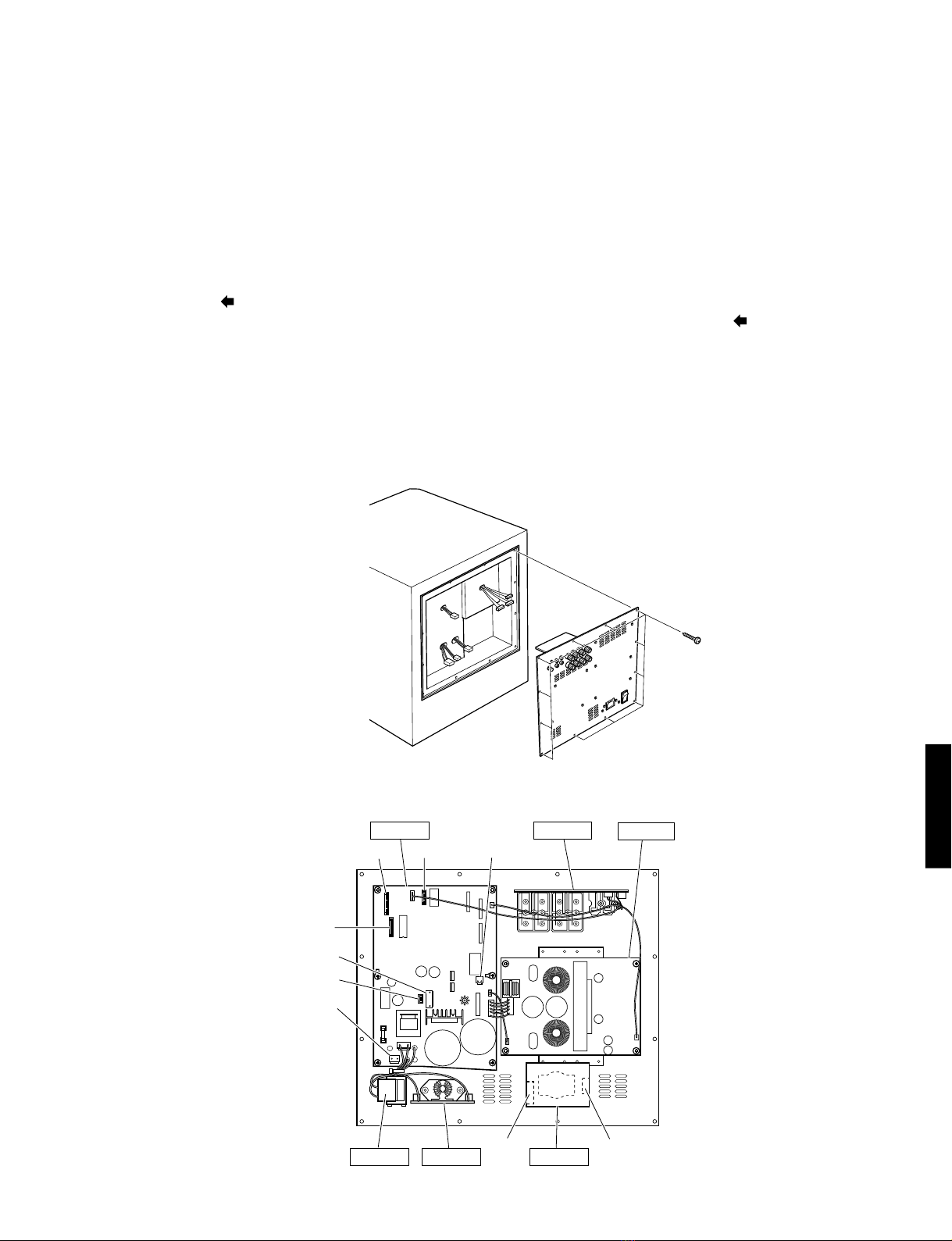

Input Section /

INPUT 1............................................. Speaker terminal

INPUT 2, 3................................................ RCA pin jack

Operation Section /

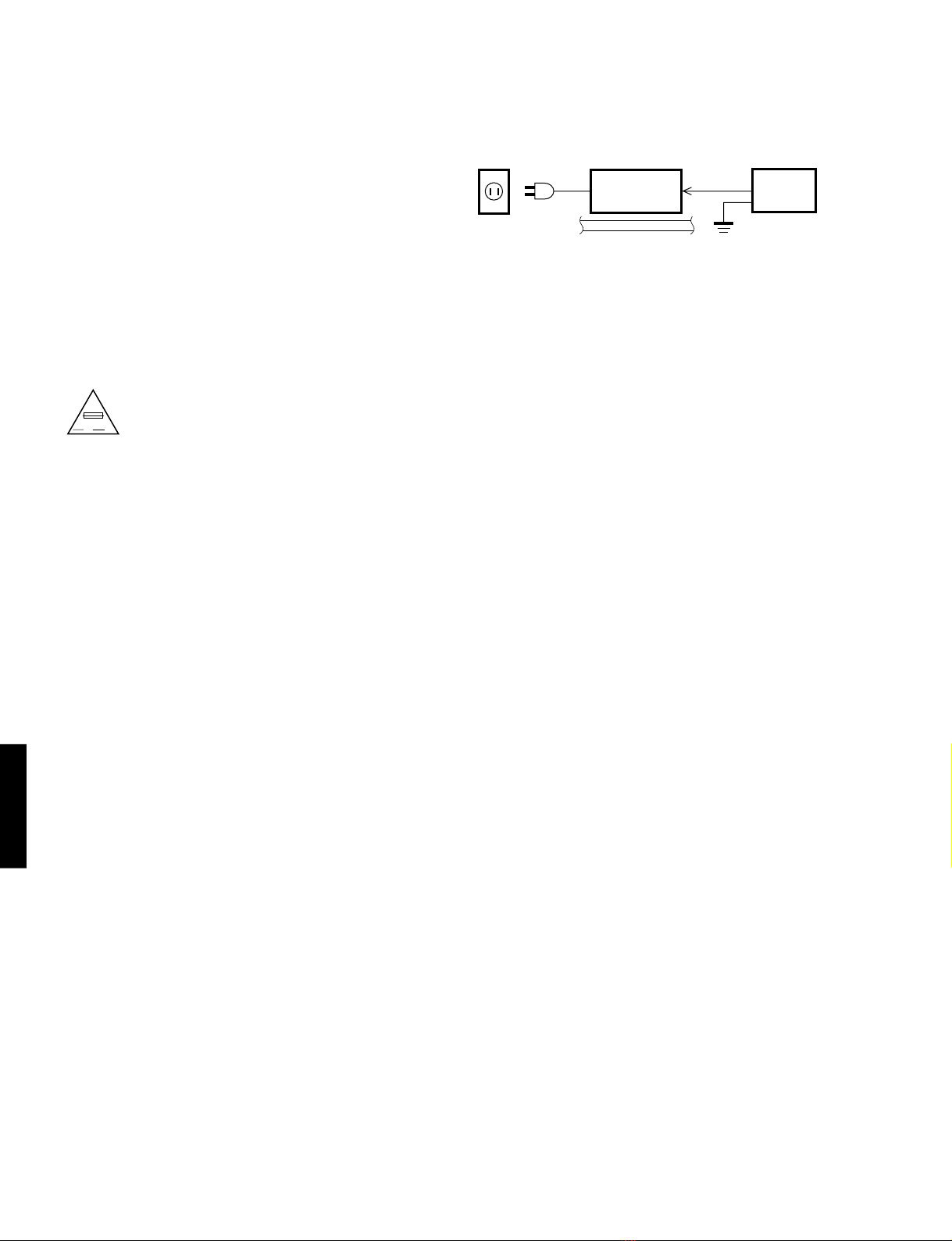

Top Panel.......... STANDBY/ON switch,Volume control,

H-CUT control, LED indicator

Rear Panel...............................................Power switch,

Voltage selector (R, L models)

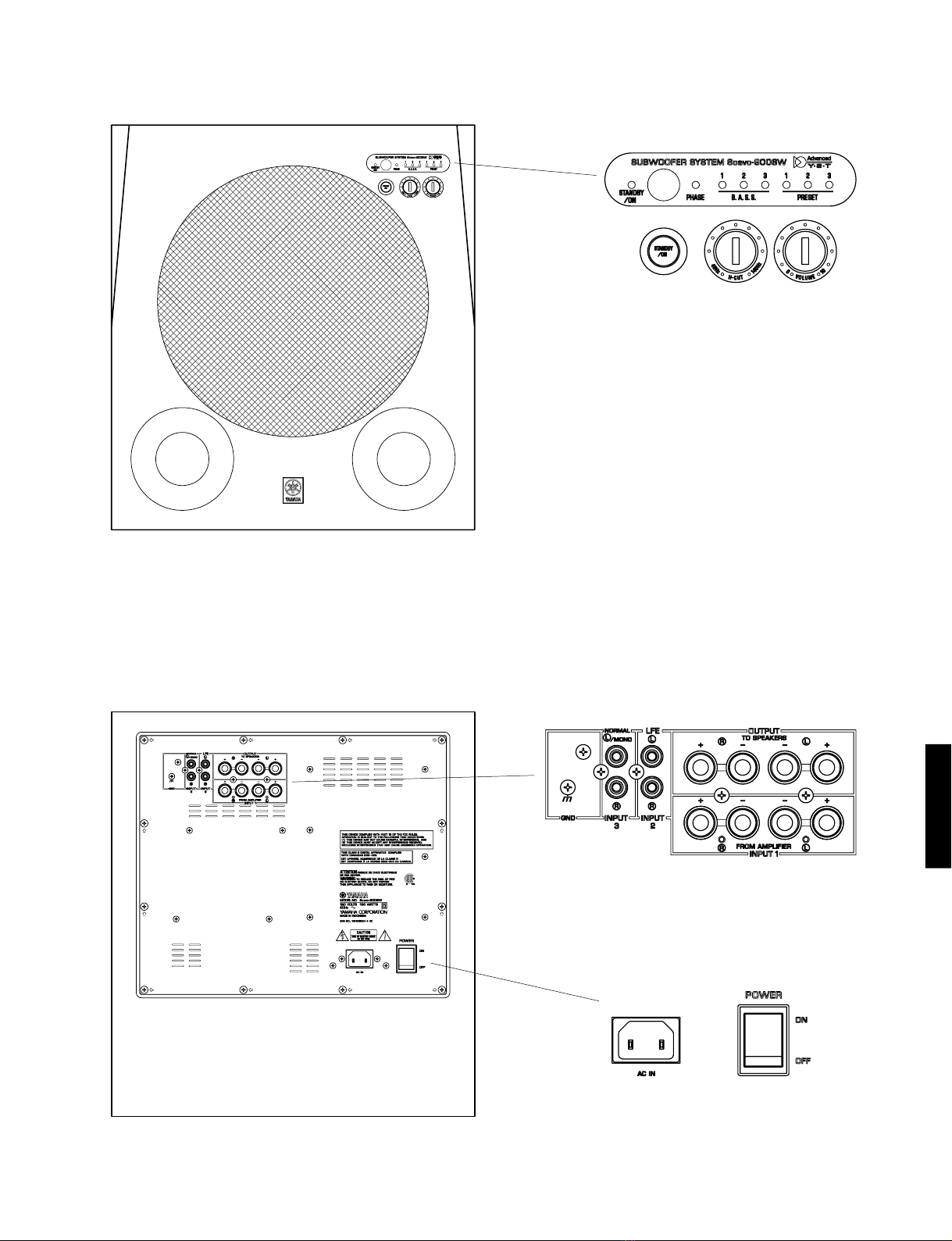

Power Supply /

U, C models.........................................AC 120V, 60 Hz

R, L models .... AC 110, 120, 220, 230-240 V, 50/60 Hz

T model ...............................................AC 220V, 50 Hz

K model ...............................................AC 220V, 60 Hz

A model ...............................................AC 240V, 50 Hz

B, G models.........................................AC 230 V, 50 Hz

J model...........................................AC 100V, 50/60 Hz

Power Consumption /

U, C, R, T, K, A, B, G, L models.......................... 180 W

J model............................................................... 120 W

Standby Power Consumption /

..................................................0.5 W (reference data)

Dimensions (W x H x D) /

.................................... 410 mm x 461 mm x 461.5 mm

(16-1/8”x 18-3/16”x 18-3/16”)

Weight / ...................................... 32 kg (70 lbs.9 oz.)

Finish / Birch color (MN)

Brown color (MB)

Dark brown color (MD)

Black color (BL)

Accessories / ............................... Power cable x1,

Remote control x1, Battery x2,

Speaker cable (4 m) x1 (J model),

Subwoofer cable (5 m) x1 (J model)

* Specifications subject to change without notice.

U ....... USA model

C ....... Canadian model

R ....... General model

T ....... Chinese model

K ....... Korean model

A ....... Australian model

B ....... British model

G ....... European model

L ....... Singapore model

J ....... Japanese model