York YP8C Quick start guide

Other York Furnace manuals

York

York TM9M Quick start guide

York

York G8C Series User manual

York

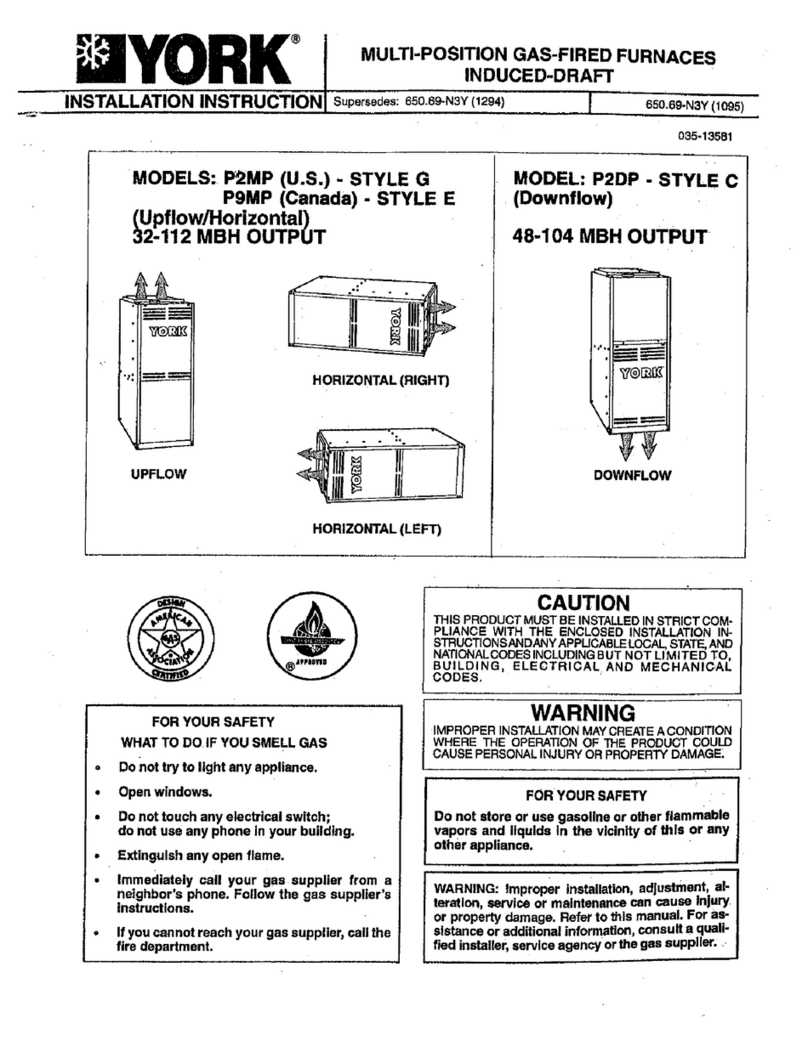

York P2MP Series User manual

York

York AFFINITY PS8 Quick start guide

York

York PS9A12N040UP11 Quick start guide

York

York TM9Y120D20MP11 Quick start guide

York

York MBC-MBH 50 User manual

York

York P*DH Quick start guide

York

York LC8 Guide

York

York GY9 Quick start guide

York

York GY8S*UH Series Quick start guide

York

York PV9 Quick start guide

York

York G8C Series Quick start guide

York

York LX SERIES TM8V User manual

York

York P2MP Series User manual

York

York P*DU-"V" Manual

York

York YP9C Series Quick start guide

York

York AFFINITY PV9 Quick start guide

York

York G8C07516(MU,MD)C12 Quick start guide

York

York TM9V080B12MP11 Quick start guide

Popular Furnace manuals by other brands

Armstrong

Armstrong EG7H SERIES Installation and maintenance instructions

Payne

Payne PG92ESA Installation, start-up, operating and service and maintenance instructions

SUPREME

SUPREME FEM10-M2301CM-A Installation instructions and homeowner's manual

Ingersoll-Rand

Ingersoll-Rand S9V2B080D4VSAC/D Installer's guide

Johnson Controls

Johnson Controls TM9T User's information manual

Fluke

Fluke 9118A user manual

Lennox

Lennox EL195UHE Elite Series Unit information

Intertherm

Intertherm M7RL Series user manual

HDG

HDG Pelletmaster 15 Operation manual

Pinnacle

Pinnacle Aero Bella AB-716C-QH User's manual and operating instructions

Nortek

Nortek MG2S Series installation instructions

VERDER

VERDER CARBOLITE GERO ABF 8/28 Installation, operation and maintenance instructions

Goodman

Goodman GMV9 Installation & operating instructions

SUPREME

SUPREME SUP10-M2301C Installation instructions and homeowner's manual

Dettson

Dettson AMT400B34-SM1PMA Installation instructions and homeowner's manual

Evcon

Evcon DGD 60 MBH installation instructions

Trane

Trane S8B1A026M2PSAB Installer's guide

Hart Sceintific

Hart Sceintific 9113 user manual