ZepSolar ZS Span User manual

ZS Span™

Installation Manual for Rail-Based Applications - U.S.

Document #800-0329-001 Rev F

File Generated July 3, 2013

© 2013/EN Zep Solar, Inc. reserves the right to make specifications changes without any prior notice. All rights reserved.

www.zepsolar.com

Document #800-0329-001 Rev F File Generated July 3, 2013 Page 2

ZS SPAN INSTALLATION MANUAL FOR RAIL-BASED APPLICATIONS - U.S.

Notices

This manual contains safety, installation, configuration and troubleshooting instructions for ZS

Span. Zep Solar, Inc. recommends that you save this manual in a readily accessible location,

should any questions arise regarding ZS Span.

Copyright and Trademark Information

Copyright © 2012, 2013 by Zep Solar, Inc. All rights reserved.

ZEP™, ZS Comp™, ZS Aero™, ZS Seam™, ZS Trap™, ZS Wave™, ZS Span™, ZS Tile™, and the Zep

logo are trademarks of Zep Solar, Inc. Zep Solar® is a registered trademark of Zep Solar, Inc. All

other trademarks are the property of their respective owners.

Warranty Notice

Warranty void if hardware not certified by Zep Solar, Inc. is attached to the Zep Groove of a Zep

Compatible PV module frame.

© 2013/EN Zep Solar, Inc. reserves the right to make specifications changes without any prior notice. All rights reserved.

www.zepsolar.com

Document #800-0329-001 Rev F File Generated July 3, 2013 Page i

ZS SPAN INSTALLATION MANUAL FOR RAIL-BASED APPLICATIONS - U.S.

Contents

1 Introduction ___________________________________________________________1

1.1 ZS Span Overview...................................................................................................................................................................1

1.2 General Safety Precautions ................................................................................................................................................2

1.3 Zep Compatible™ ................................................................................................................................................................... 3

2 ZS Span Components __________________________________________________ 5

2.1 ZS Span Cutaway View........................................................................................................................................................ 5

2.2 ZS Span Core Components ................................................................................................................................................ 6

2.3 ZS Span Accessory Components..................................................................................................................................... 8

2.4 ZS Span Tools .......................................................................................................................................................................10

3 Array Design_________________________________________________________ 11

Step 1: Gather Project Data ............................................................................................................................................... 11

Step 2: Obtain Spacing and Cantilever Allowances.................................................................................................. 12

Step 3: Create Array Layout and Bill of Material....................................................................................................... 13

3.1 Using the Zepulator Online Design Tool .....................................................................................................................14

3.2 Using the Span Tables....................................................................................................................................................... 16

3.3 Alternative Layout Possibilities...................................................................................................................................... 17

4 Layout Concepts _____________________________________________________ 19

4.1 Drop-In Direction.................................................................................................................................................................19

4.2 Engineering Rules................................................................................................................................................................20

4.3 Grounding/Earthing.............................................................................................................................................................25

4.4 Thermal Expansion ............................................................................................................................................................. 27

4.5 Roof Zones..............................................................................................................................................................................30

5 Installation Process __________________________________________________ 33

Step 1: Mark Out Array Layout on Roof.........................................................................................................................34

Step 2: Install Roof Attachments ...................................................................................................................................35

Step 3: Ground Prep ..............................................................................................................................................................36

Special Inset: Spanner Bar 1x 3x 4x Lengths..........................................................................................................39

Step 4: Attach Spanner Bars .............................................................................................................................................40

Step 5: Install Array Skirt ..................................................................................................................................................42

Special Inset: Grip Installation.....................................................................................................................................46

Step 6: Install First Row of Modules..............................................................................................................................47

Special Inset: Interlocks.................................................................................................................................................53

Special Inset: Wire Management .................................................................................................................................55

© 2013/EN Zep Solar, Inc. reserves the right to make specifications changes without any prior notice. All rights reserved.

www.zepsolar.com

Document #800-0329-001 Rev F File Generated July 3, 2013 Page ii

ZS SPAN INSTALLATION MANUAL FOR RAIL-BASED APPLICATIONS - U.S.

Step 7: Complete the Array................................................................................................................................................57

Step 8: Ground the Array.....................................................................................................................................................58

Special Inset: Installing Side Skirt and Corner Caps...........................................................................................59

Special Inset: Universal Box Brackets and Other Accessories.........................................................................62

6 Installation Supplement ______________________________________________ 63

6.1 Servicing an Array................................................................................................................................................................63

6.2 Array Skirt Options..............................................................................................................................................................65

6.3 Removing the First-Row Array Skirt ............................................................................................................................68

6.4 Hybrid Interlocks................................................................................................................................................................. 71

6.5 Backwards Compatibility ..................................................................................................................................................73

Special Inset: Component Versioning ........................................................................................................................74

Special Inset: Interlock Versions and Alignment Marks ....................................................................................76

Special Inset: Array Skirt Version Compatibility.................................................................................................... 77

Special Inset: Array Skirts and Caps ..........................................................................................................................78

7 Regulatory Information _______________________________________________ 79

7.1 UL and ETL Listings............................................................................................................................................................79

© 2013/EN Zep Solar, Inc. reserves the right to make specifications changes without any prior notice. All rights reserved.

www.zepsolar.com

Document #800-0329-001 Rev F File Generated July 3, 2013 Page 1

1 Introduction

ZS Span™, from Zep Solar, Inc., is an integrated roof mounting solution for installing PV arrays on tile roofs. ZS

Span offers the following benefits: rapid installation, reduced roof penetrations, reduced parts count, low sys-

tem weight, precision alignment, enhanced aesthetics, resistance to theft, redundant auto-grounding hardware,

portrait and landscape options, and an easy-to-use design tool with array-level BOM calculations.

1.1 ZS Span Overview

Figure 1.1 ZS Span for Tile Roofs

© 2013/EN Zep Solar, Inc. reserves the right to make specifications changes without any prior notice. All rights reserved.

www.zepsolar.com

Document #800-0329-001 Rev F File Generated July 3, 2013 Page 2

ZS SPAN INSTALLATION MANUAL FOR RAIL-BASED APPLICATIONS - U.S.

1.2 General Safety Precautions

Follow all instructions in this manual and the PV module installation manual. The installer is ulti-

mately responsible for ensuring that all installations are performed in compliance with applicable

codes and standards, as well as industry best practices.

1.2.1 Installation Safety

• The installation process requires working on sloped and elevated building surfaces, in out-

door weather conditions, using tools and heavy components designed for the generation of

electricity.

- Use properly anchored fall protection equipment.

- Use caution to prevent objects from falling or dropping off the roof area.

- Cordon off ground areas directly beneath the roof work area when possible.

• Always use personal protection equipment such as safety glasses, gloves, etc. as neces-

sary.

• Do not perform installations in excessively wet, windy, or inclement weather conditions.

• When working in hot weather, work crews should take care to prevent symptoms of over-

heating or deyhdration.

• Use proper lifting and carrying techniques when handling heavy components at the job

site. If conditions are challenging for moving PV modules to the roof area, use a mechani-

cal lift.

• Follow best practices when working around high-voltage electrical equipment.

• Do not anchor fall protection equipment to roof mounts, or any other inappropriate roof

structure.

• Ensure that Zep Solar components are properly engaged with the PV modules.

• Do not subject the PV modules to excessive loads or deformation such as twisting or

bending.

• The installer is responsible for:

- Following all applicable regional and local codes, standards, and regulations

- Ensuring that all personnel are properly trained, equipped, and licensed

- Obtaining all required permits and inspections

- Verifying that the roof structure can support the array under live load conditions.

- Verifying that the system is installed over a properly rated fire-resistant roof covering

1.2.2 Electrical Specifications

• These instructions describe the correct installation of the Interlock, the Ground Zep, and

other listed components into a PV module that has a Zep Compatible frame.

• Product listing information is shown for each component in the Components chapter and

in the Requirements chapter. For the most up-to-date listing information, please refer to

the product datasheets on the Zep Solar web site.

• Zep Solar components are only suitable for PV modules with a series fuse rating of 15

Amps or less.

• Each array of PV modules must be earthed with a solid copper wire that is connected

between the Ground Zep and a suitable earth ground. The ground wire and torque specs

are identified in “Ground the Array” on page 58.

© 2013/EN Zep Solar, Inc. reserves the right to make specifications changes without any prior notice. All rights reserved.

www.zepsolar.com

Document #800-0329-001 Rev F File Generated July 3, 2013 Page 3

ZS SPAN INSTALLATION MANUAL FOR RAIL-BASED APPLICATIONS - U.S.

1.3 Zep Compatible™

Zep Solar mounting solutions are based on the Zep Groove, a patented module frame profile

designed to mate easily and precisely with Zep components. Module frames with the Zep Groove

are considered "Zep Compatible", and are offered by PV module manufacturers who have estab-

lished a licensing agreement with Zep Solar, Inc. Please visit www.zepsolar.com for an updated

list of Zep Compatible partners.

Figure 1.2 Zep Groove and Rockit

Key and Tongue. The Key and Tongue concept informs all Zep Compatible designs. The Key side

inserts into the Zep Groove, similar to inserting a key into a lock. On the other side, the Zep Groove

allows PV modules to “drop in” easily onto the Tongue of the Rockit.

Figure 1.3 Module Drop-In Example

Zep Compatible PV module

Zep Groove cross

section

Key side

For example, the “Rockit” is a hardware feature used to secure PV modules to

the roof attachments. The Rockit fits into the Zep Groove on both sides: The

Key side inserts, while the Tongue side receives.

Zep Groove

Tongue side

Zep Compatible PV module

Rockit

In the next row, modules are “dropped in” on the Tongue side (the receiving

side). Each Tongue provides an in/out adjustability with the Zep Groove, allow-

ing for optimized placement of each module.

1

First, the Key side of the Rockit

is inserted into the Zep Groove.

2 3 4

© 2013/EN Zep Solar, Inc. reserves the right to make specifications changes without any prior notice. All rights reserved.

www.zepsolar.com

Document #800-0329-001 Rev F File Generated July 3, 2013 Page 4

ZS SPAN INSTALLATION MANUAL FOR RAIL-BASED APPLICATIONS - U.S.

Another example of the use of Key and Tongue in a Zep Compatible design is seen with the Inter-

lock, a component that couples and bonds two modules together. Here, the Key and Tongue are

differently shaped, but they still fit into the Zep Groove in the same manner as the Rockit.

Figure 1.4 Zep Groove and Interlock

Auto Grounding. The Key and Tongue sides of Rockits and Interlocks establish an electrical

bonding connection between both modules and other Zep Solar components such as the Array

Skirt. The rotation of the Key side into the Zep Groove, and the rotation of the next row of PV mod-

ules onto the Tongue side, acts to establish an equipotential bond for all UL listed components by

cutting through the surface coating (tested for both anodized and painted coatings) on the Zep

Groove.

Note: All components shown as UL Listed to UL 2703 are listed for bonding.

Interlock back is Key side

Other Zep Solar components such as the Interlock also use the Key and Tongue concept.

Interlock front is Tongue

side

Key side is inserted into

Zep Groove

The fasteners on the Interlock (the

“Interlock Zeps”) are tightened one-

quarter turn to lock securely into the

Zep Groove.

Open

Closed

Rotation seen from Key side

See “Interlocks” on page 53 for more information on the Interlock.

© 2013/EN Zep Solar, Inc. reserves the right to make specifications changes without any prior notice. All rights reserved.

www.zepsolar.com

Document #800-0329-001 Rev F File Generated July 3, 2013 Page 5

2 ZS Span Components

2.1 ZS Span Cutaway View

Cam Foot

Array Skirt

Adjustable Mighty Hook

Zep Groove

Ground Zep

Corner Cap

T-Lock

Spanner Bar

Spanner Clamp

Interlock

© 2013/EN Zep Solar, Inc. reserves the right to make specifications changes without any prior notice. All rights reserved.

www.zepsolar.com

Document #800-0329-001 Rev F File Generated July 3, 2013 Page 6

ZS SPAN INSTALLATION MANUAL FOR RAIL-BASED APPLICATIONS - U.S.

2.2 ZS Span Core Components

Cam Foot

Interlock

Provides a structural and electrical bond between

modules. See “Backwards Compatibility” on page 73

for additional information regarding Interlock

versions.

Listed by UL to UL 2703.

Secures PV Modules to the Spanner Bar, and

enables fine-tuned leveling. Create an electrical

bond between modules on both Key and Tongue

sides. Also creates bond with Spanner Bar.

Listed by UL to UL 2703.

Part No. 850-1388

Part No. 850-1413

Hybrid Interlock

Ground Zep

Used on Cam Foot base where the Cam Foot location

conflicts with the installation of an Interlock. Creates

electrical bond between modules on both Key and Tongue

sides.

Listed by UL to UL 2703.

Provides a single point for grounding/earthing

the PV Array. One Ground Zep can ground an

array up to 33 x 33 feet.

Listed by UL to UL 467 and UL 2703. ETL

listing conforms to UL STD 467.

Part No. 850-1281

Part No. 850-1172

© 2013/EN Zep Solar, Inc. reserves the right to make specifications changes without any prior notice. All rights reserved.

www.zepsolar.com

Document #800-0329-001 Rev F File Generated July 3, 2013 Page 7

ZS SPAN INSTALLATION MANUAL FOR RAIL-BASED APPLICATIONS - U.S.

ZS Span Core Components, Continued

Adjustable Mighty Hook

Provides a roof mounting attachment point for the array.

Shown above are 2-piece and 3-piece product versions.

Spanner Clamp

Attaches Spanner Bar to Adjustable

Mighty Hook or other roof attachment.

Listed by UL to UL 2703.

Splice Kit

Splices lengths of Spanner Bar together for

use in large arrays. Creates electrical bond

between Spanner Bars when fully spliced

together. Two Splices per join.

1x 3x 4x Spanner Bar

Attaches to Adjustable Mighty Hook or other roof attachment to pro-

vide a mounting channel for the Cam Feet. Pre-cut lengths dimen-

sioned by module width for 1, 3, or 4 modules.

Note: Some regions may continue to stock the previous version of

the 1x for all Spanner Bar needs. See “Backwards Compatibility” on

page 73 for more information.

Part No. 850-1403

Part No. 850-1396 Part No. 850-1194

Part No. 850-1400 - 4x

Part No. 850-1399 - 3x

Part No. 850-1398 - 1x

Part No. 850-1401

© 2013/EN Zep Solar, Inc. reserves the right to make specifications changes without any prior notice. All rights reserved.

www.zepsolar.com

Document #800-0329-001 Rev F File Generated July 3, 2013 Page 8

ZS SPAN INSTALLATION MANUAL FOR RAIL-BASED APPLICATIONS - U.S.

2.3 ZS Span Accessory Components

Array Skirt

End Cap

Grip

Conceals hardware for an aesthetic appearance on all sides of the array, and

also serves as a jig during installation to keep the first row of modules straight.

Also serves as a structural component when attached to modules via the Key

side of a Cam Foot Rockit with Interlocks connectiong sections of Array Skirt.

Listed by UL to UL 2703.

Used to cover the ends of the Array

Skirt on the front row of modules for

a more aesthetic appearance.

Listed by UL to UL 2703.

Used to secure Array Skirt after attaching the

Array Skirt to the first row of Cam Feet.

Listed by UL to UL 2703.

* When properly installed, these Accessory Hardware Components are capable of creating an electrical bond

with adjacent Zep Solar hardware components. See “Installation Process” on page 33 for details.

Outside Corner Cap

Used to bridge the corners when Array

Skirt is applied all around the perime-

ter of the array, for a more aesthetic

appearance.

Listed by UL to UL 2703.

Part No. 850-1421

T-Lock

Attaches the Array Skirt to the module

frame along the non-leading edges of

the array. Creates an electrical bond

between Array Skirt and module.

Listed by UL to UL 2703.

Array Skirt profile view

AC/DC Cable Clip

Snaps into the Zep Groove to secure array

wiring, and to adjust wire tension. Fits a

variety of cable sizes.

Inside Corner Cap

Used to bridge inside corners when

Array Skirt is applied all around the

perimeter of the array, for a more aes-

thetic appearance.

DC Wire Clip

Snaps into the Zep Groove to

secure array wiring, and to adjust

wire tension, with parallel and 90

degree clips. Fits wires 5.2mm-

7.6mm in diameter.

© 2013/EN Zep Solar, Inc. reserves the right to make specifications changes without any prior notice. All rights reserved.

www.zepsolar.com

Document #800-0329-001 Rev F File Generated July 3, 2013 Page 9

ZS SPAN INSTALLATION MANUAL FOR RAIL-BASED APPLICATIONS - U.S.

ZS Span Accessory Components, Continued

Universal Box Bracket

Allows attachment of electrical boxes to Zep Compatible PV

module frame, thereby eliminating additional roof penetra-

tions.

Jam

Secures the Universal Box Bracket to the

module frame.

Part No. 850-1258

Jam

Groove Adapter Bracket

Mounts to selected microinverters and provides an electrical

bond and a mechanical connection to a Zep Compatible PV

module frame.

UL Listed to UL 2703.

© 2013/EN Zep Solar, Inc. reserves the right to make specifications changes without any prior notice. All rights reserved.

www.zepsolar.com

Document #800-0329-001 Rev F File Generated July 3, 2013 Page 10

ZS SPAN INSTALLATION MANUAL FOR RAIL-BASED APPLICATIONS - U.S.

2.4 ZS Span Tools

Zep Tool

Flat Tool

The Zep Tool performs the following functions:

• Install and remove Interlock

• Install and remove Ground Zep

• Adjust height of Cam Feet using #30 Torx Bit attachment

The Flat Tool does everything that the Zep Tool can do,

except for adjusting the Cam Foot height. In addition, the

Flat tool performs these additional functions:

• Secure Cam Foot base in Spanner Bar groove

• Remove Interlock from between two modules

850-1412

#30 Torx Bit Attachment

Inserts into top of Rockit for the Cam Foot and the

Hybrid Interlock, for raising and lowering of the

array at the attachment points. Base attaches to

the handle end of the Zep Tool.

© 2013/EN Zep Solar, Inc. reserves the right to make specifications changes without any prior notice. All rights reserved.

www.zepsolar.com

Document #800-0329-001 Rev F File Generated July 3, 2013 Page 11

3 Array Design

Zep Solar, Inc. seeks to encourage efficient design of PV arrays by providing tools and resources necessary for

installers and integrators to successfully design system that meet local structural codes. The Zepulator online

design tool and Span Tables are available on the Zep Solar web site to enable custom array designs. Additional

information on fine-tuning array designs can be found in training videos, also available on the Zep Solar web site.

Step 1: Gather Project Data

Array design begins by identifying specific information that applies to the project, including:

• Site information such as wind speed and terrain characteristics

• Building characteristics such as purlin/battenspacing, roof pitch, and roof type

• PV array details such as PV module manufacturer, mounting area, and desired orientation

Within each specified roof type, users can select a preferred Zep Solar approved roof attachment

when using the Zepulator. The Span Tables and Certification Letters are only valid for hardware

specifically tested and approved by Zep Solar, Inc. for use within each country.

NOTE: Input variables may vary from one country to the next. To see variables for

other countries supported in the Zepulator, select another country for the

project on the Project page.

© 2013/EN Zep Solar, Inc. reserves the right to make specifications changes without any prior notice. All rights reserved.

www.zepsolar.com

Document #800-0329-001 Rev F File Generated July 3, 2013 Page 12

ZS SPAN INSTALLATION MANUAL FOR RAIL-BASED APPLICATIONS - U.S.

Step 2: Obtain Spacing and Cantilever Allowances

After gathering the project data, the designer can either look up the allowances in the Span Tables,

or s/he can enter the project information into the Zepulator in order to obtain the maximum allow-

able spacing and cantilever distances. (The terms “spacing” and “span” are interchangeable.)

Figure 3.1 Spacing and Tile Reveal

Spacing terminology is dependent on Spanner Bar direction. Most of the examples in this

manual show Spanner Bars running North-South. However, if the Spanner Bars run East-West,

then the Tile Hook spacing will refer to the the dimension that is a multiple of the spacing between

rafters, and the Spanner Bar spacing will be a multiple of the Tile Reveal. See “Engineering Rules”

on page 20 for more details.

Maximum achievable vs. maximum allowable spacing. The maximum allowable spacing is an

absolute maximum based on Zep Solar’s engineering values. The maximum spacing achievable in

practice is a mulitple of either rafters or tile sizes, and may be smaller than the maximum allow-

able spacing. Cantilever allowances are based on the maximum allowable spacing, not the maxi-

mum achievable spacing.

NOTE: It is strongly recommended that both and designers and installer crews attend

hands-on training classes with Zep Solar, Inc., and also view the online videos

available on the Zep Solar web site at www.zepsolar.com.

Spanner Bar spacing is a multiple of

the distance between rafters

Down-roof

Tile Hook spacing is a

multiple of the Tile Reveal

Tile reveal

Showing Spanner Bars Running North-South

Tile Hook

Cam Foot

Spanner Bar

Interlock

PV module

Array Skirt

© 2013/EN Zep Solar, Inc. reserves the right to make specifications changes without any prior notice. All rights reserved.

www.zepsolar.com

Document #800-0329-001 Rev F File Generated July 3, 2013 Page 13

ZS SPAN INSTALLATION MANUAL FOR RAIL-BASED APPLICATIONS - U.S.

Figure 3.2 Cantilever

Spans are site and project-specific. Field installers should keep the span allowances in mind for

each job, as they may need to re-configure an array due to unexpected conditions at the job site.

Cantilever is also site and project-specific. Cantilever refers to the amount of overhang that a

module or Spanner Bar can have beyond its last support point. Please refer to “Engineering Rules”

on page 20 for more information on cantilever rules for ZS Span.

Step 3: Create Array Layout and Bill of Material

Array Layouts and a Bill of Material can be created using the Zepulator online design tool or using

a CAD program. The designer may also choose to generate an initial layout in the Zepulator and

then further refine the design using another program. Zep Solar, Inc. provides downloadable CAD

blocks on the Zep Solar web site for Zep Solar components. Note that the Bill of Material created

by the Zepulator does not include hardware pricing, since that may depend on the distribution

channel and other factors.

Down-roof

Module Cantilever: Cam

Foot center to module

edge.

Spanner Bar cantilever: Tile Hook

to module edge (with supporting

Cam Foot)

© 2013/EN Zep Solar, Inc. reserves the right to make specifications changes without any prior notice. All rights reserved.

www.zepsolar.com

Document #800-0329-001 Rev F File Generated July 3, 2013 Page 14

ZS SPAN INSTALLATION MANUAL FOR RAIL-BASED APPLICATIONS - U.S.

3.1 Using the Zepulator Online Design Tool

The Zepulator online design tool is available from the Zep Solar web site, or directly at

www.zepulator.com.

Figure 3.3 Zepulator Online Design Tool

Access the Zepulator from the Home

page of the Zep Solar web site

Each tab contains a set of inputs for

your project

Home tab is for opening saved

projects or creating new projects Click Continue to save changes on

any input screen.

Layout tab is for selecting module

details, orientation, and mounting

area.

Project tab includes the site address,

country, and contact person

Site tab includes topography,

weather, and other site-specific data

that may vary by country

Building tab includes inputs for roof

type, attachment method, and rafter

spacing

Use the Summary page to view, edit,

or print the Bill of Material and

Engineering Calculations.

1

2

3

4

Place your cursor in a field to display

an explanation.

5

© 2013/EN Zep Solar, Inc. reserves the right to make specifications changes without any prior notice. All rights reserved.

www.zepsolar.com

Document #800-0329-001 Rev F File Generated July 3, 2013 Page 15

ZS SPAN INSTALLATION MANUAL FOR RAIL-BASED APPLICATIONS - U.S.

3.1.1 Zepulator Layout Example

After all information is entered or selected, click the Update button on the Layout tab to see a

suggested layout similar to the one shown below. Note that the Zepulator optimizes the layout to

minimize the number of roof penetrations.

Figure 3.4 Example Zepulator Array Layout (ZS Span, US)

The array layout accounts for each ZS Span component listed on the Bill of Material.

NOTE: In cases where a Cam Foot coincides with an Interlock location, you may need

to substitute a Hybrid Interlock. However, shifting the array slightly left or right

(in the direction perperpendicular to the Spanner Bar direction) can sometimes

eliminate the need for Hybrid Interlocks altogether.

The Zepulator does not show Hybrid Interlocks on the layout, although it will

include Hybrid Interlocks in Additional Truck Stock to ensure adequate hard-

ware supply if needed.

Ground Zep

Tile Hook roof

attachment

PV module

Rafters

Interlock

Down-roof

The Zepulator centers the array in the specified

roof mounting area.

Cam Foot

© 2013/EN Zep Solar, Inc. reserves the right to make specifications changes without any prior notice. All rights reserved.

www.zepsolar.com

Document #800-0329-001 Rev F File Generated July 3, 2013 Page 16

ZS SPAN INSTALLATION MANUAL FOR RAIL-BASED APPLICATIONS - U.S.

3.2 Using the Span Tables

In addition to the Zepulator online design tool, Zep Solar, Inc. provides complete Span Tables that

are included with the Engineering Certification Letters for each country. These tables represent

tested structural values for every combination of hardware that is approved for use with Zep Com-

patible roof mounted PV arrays. The Engineering Certification Letter may also be provided to build-

ing officials when submitting for a permit, or for use by independent engineering consultants.

Figure 3.5 Span Table Example (ZS Span - US)

Wind speed

Roof pitch

Specific option for

roof attachment

hardware

Roof zone

Maximum allowable East-

West span (across rafters)

Snow load

Module orientation

Tile shape

Drop-in direction

Exposure category

Maximum allowable North-South span

(up the rafter), shown in increments of

2, 3, and 4 Tile Reveals, assuming a 14-

inch reveal.

Table of contents

Other ZepSolar Rack & Stand manuals

Popular Rack & Stand manuals by other brands

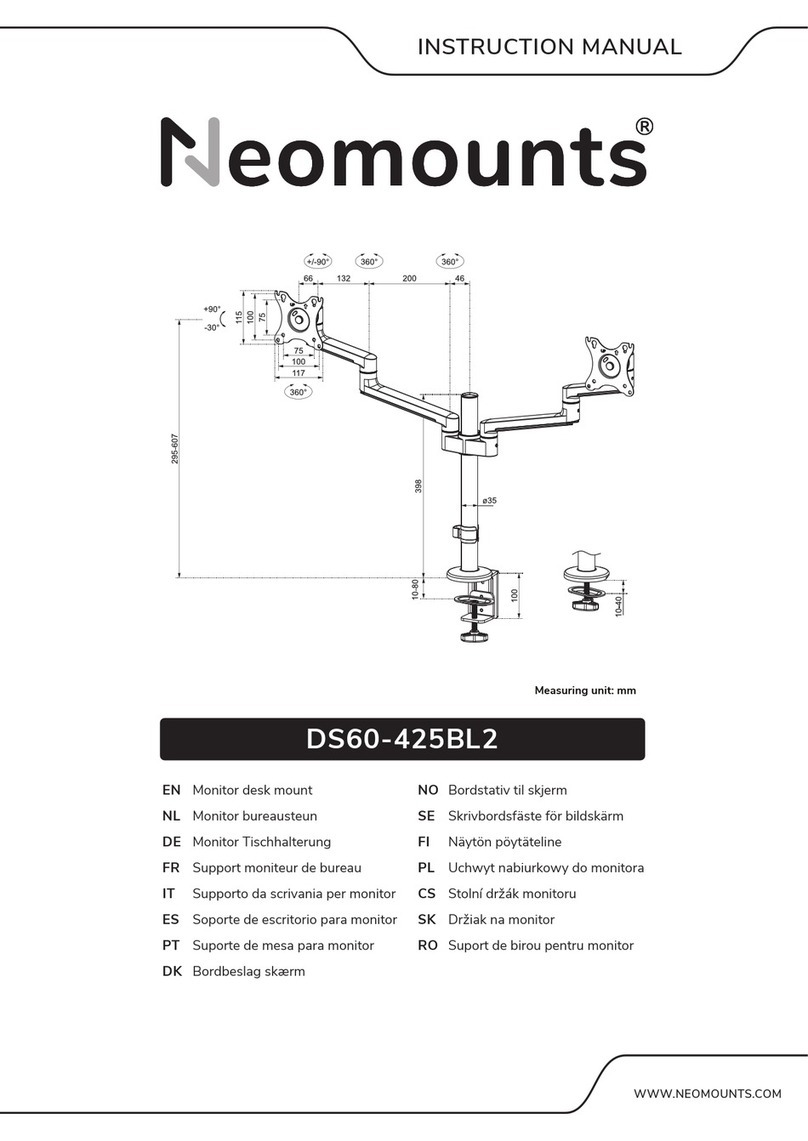

NeoMounts

NeoMounts DS60-425BL2 instruction manual

CHIEF

CHIEF PSMA800 installation instructions

Wali

Wali CS203 installation manual

Classic Exhibits

Classic Exhibits SUPERNOVA VK-4048 Setup instructions

DCU Tecnologic

DCU Tecnologic 70100010 installation manual

peerless-AV

peerless-AV Paramount PP740 Installation and assembly