5

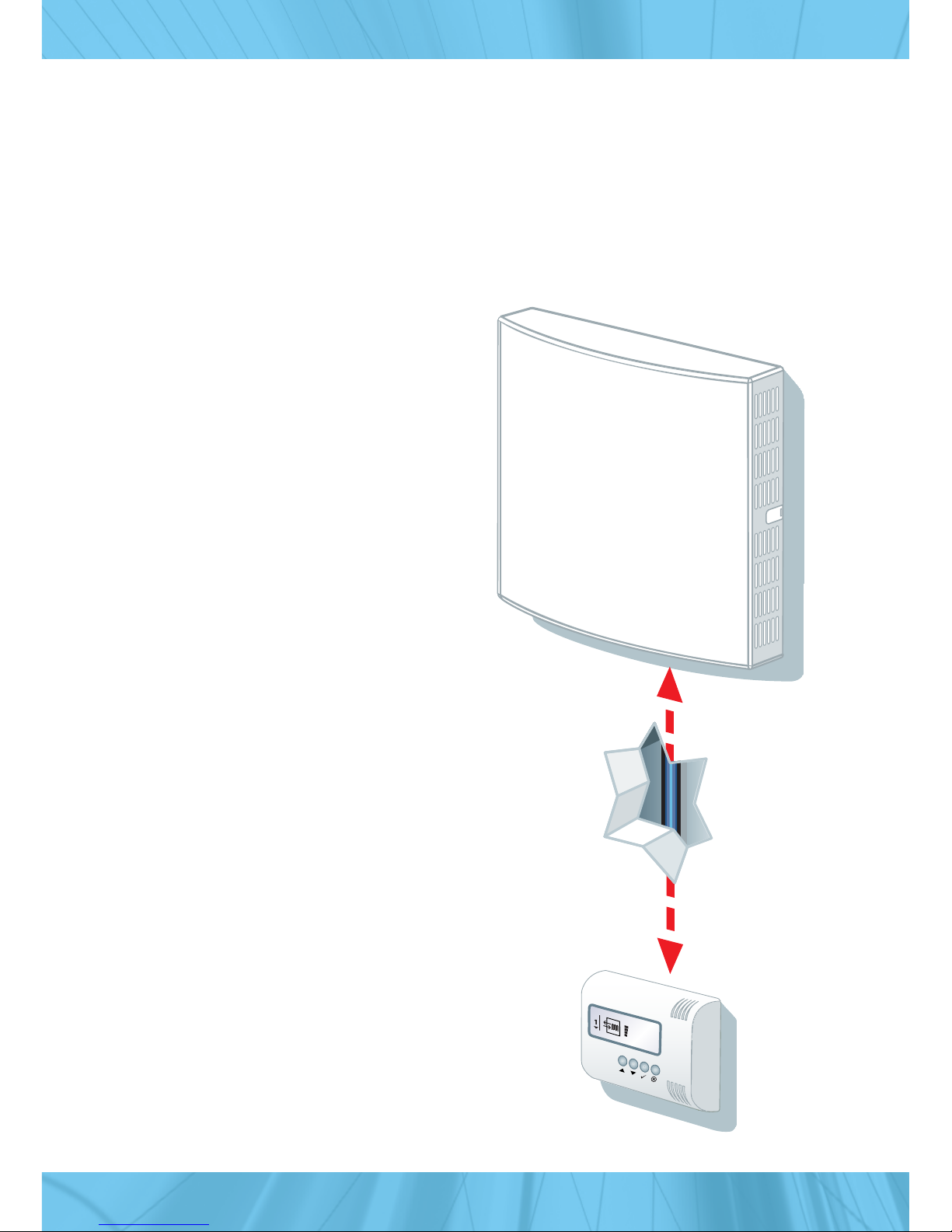

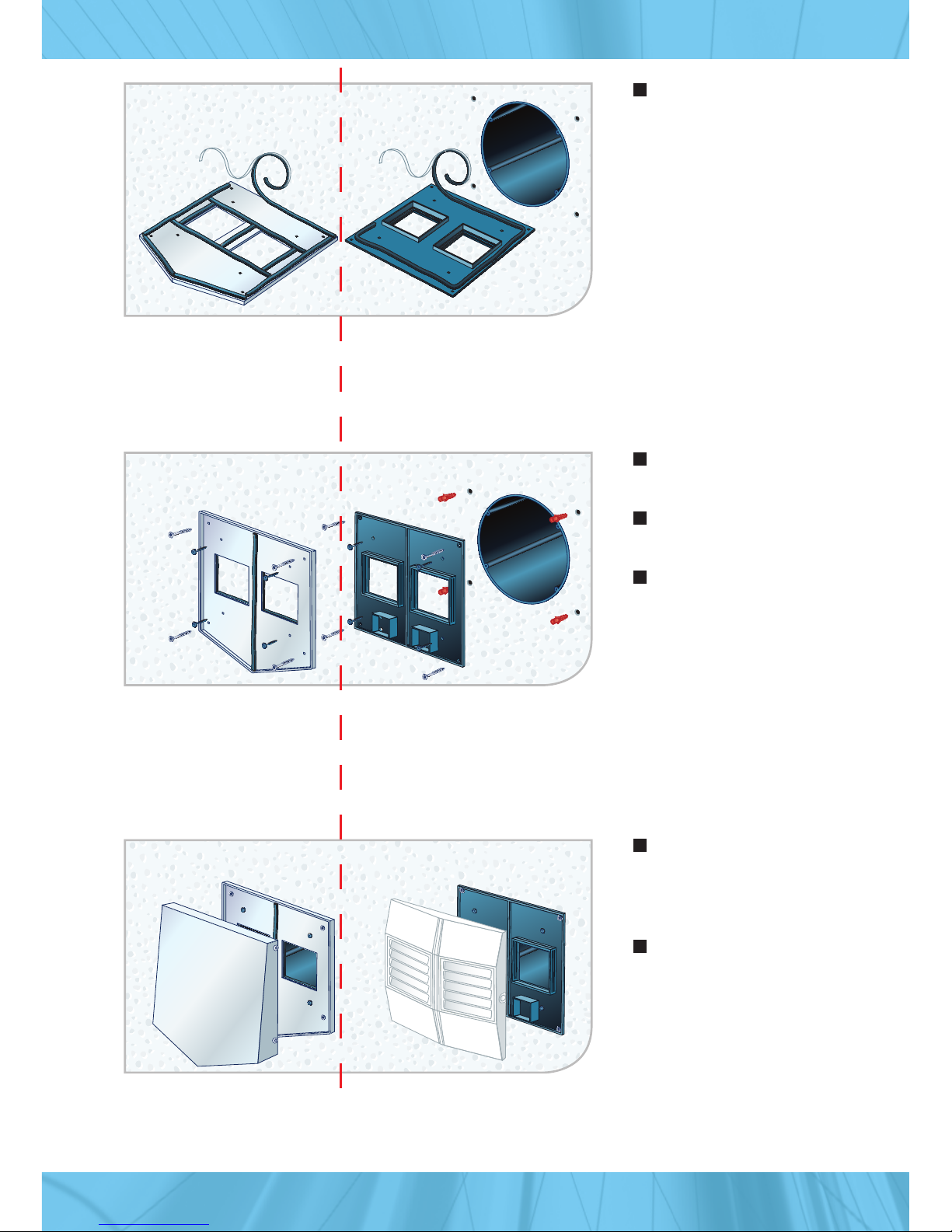

4.2 Ventilation unit installation

4. Installation

4.1 Installation instructions

On-site preparation:

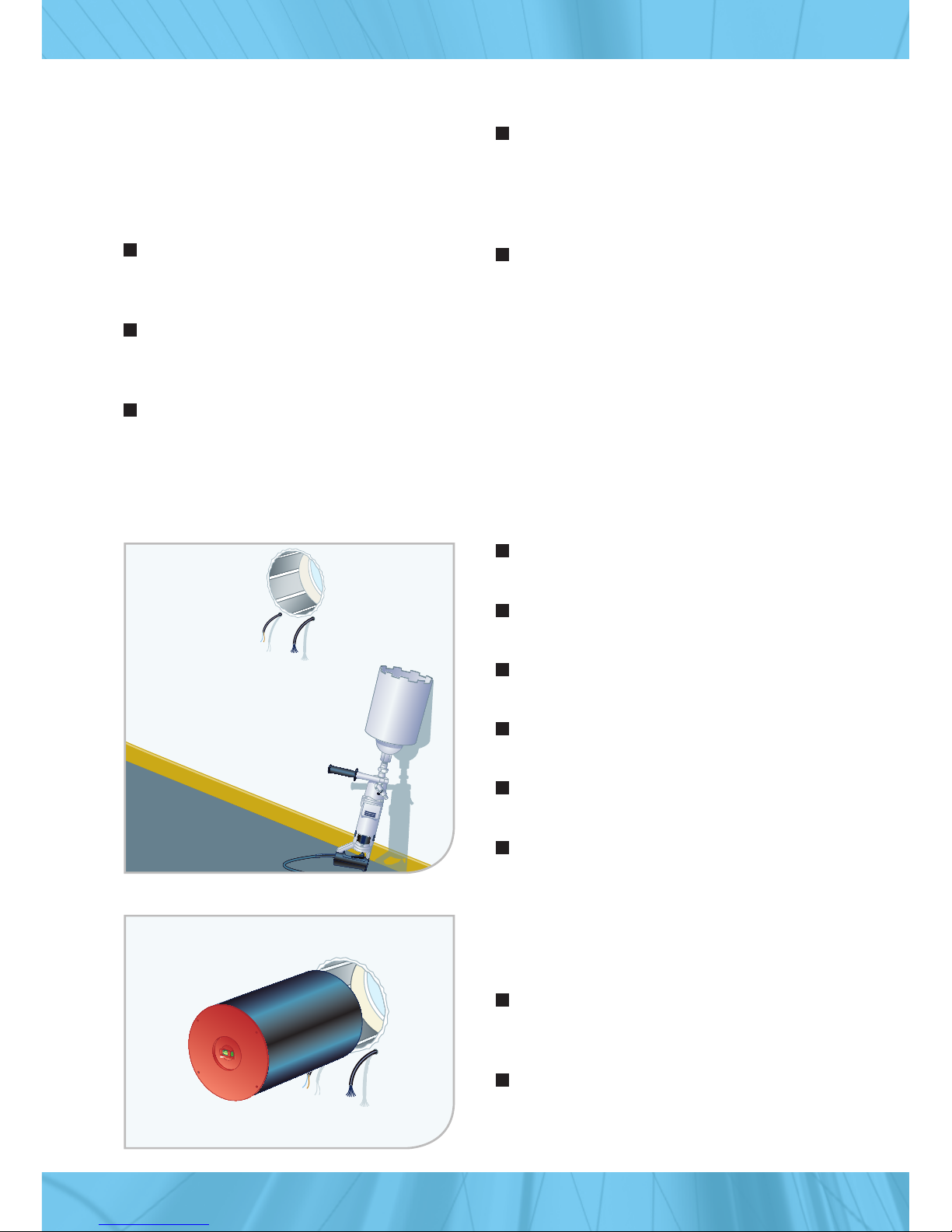

A core drilling of 290 to max. 300 mm

must be drilled in order to install the

Vario-Vent DUO.

The electrical supply of 230 volt must be

laid properly according to the specifica-

tions.

A 6 x 0,1 mm²control line must be in-

stalled between the Vario-Vent DUO and

the control panel.

Make a core drilling of 300 mm diameter

with a 1% decline toward the outside.

Cable for left side:

2 x 0,75 mm²for 230 volt

Cable for right side:

6 x 0,1 mm² to the control panel

Optional: additional cable right side:

min. 2 x 0,1 mm² additional input.

Take the measurements from the drilling

template.

Connection cables must be installed by

the customer on site.

A separate 2 x 0,1 mm²control line must

be available when using the additional

input. This is an additional switching

input that can be used with the software

as opened or closed.

For the exact measurement please use

the included drilling template.

Please examine the Vario-Vent DUO after it

is unpacked for any external damage that

may have occurred during transport. If you

notice any damages please contact us on

our service number located on the type

label. Please let us know the extent of

damage and the serial number of the

ventilation unit.

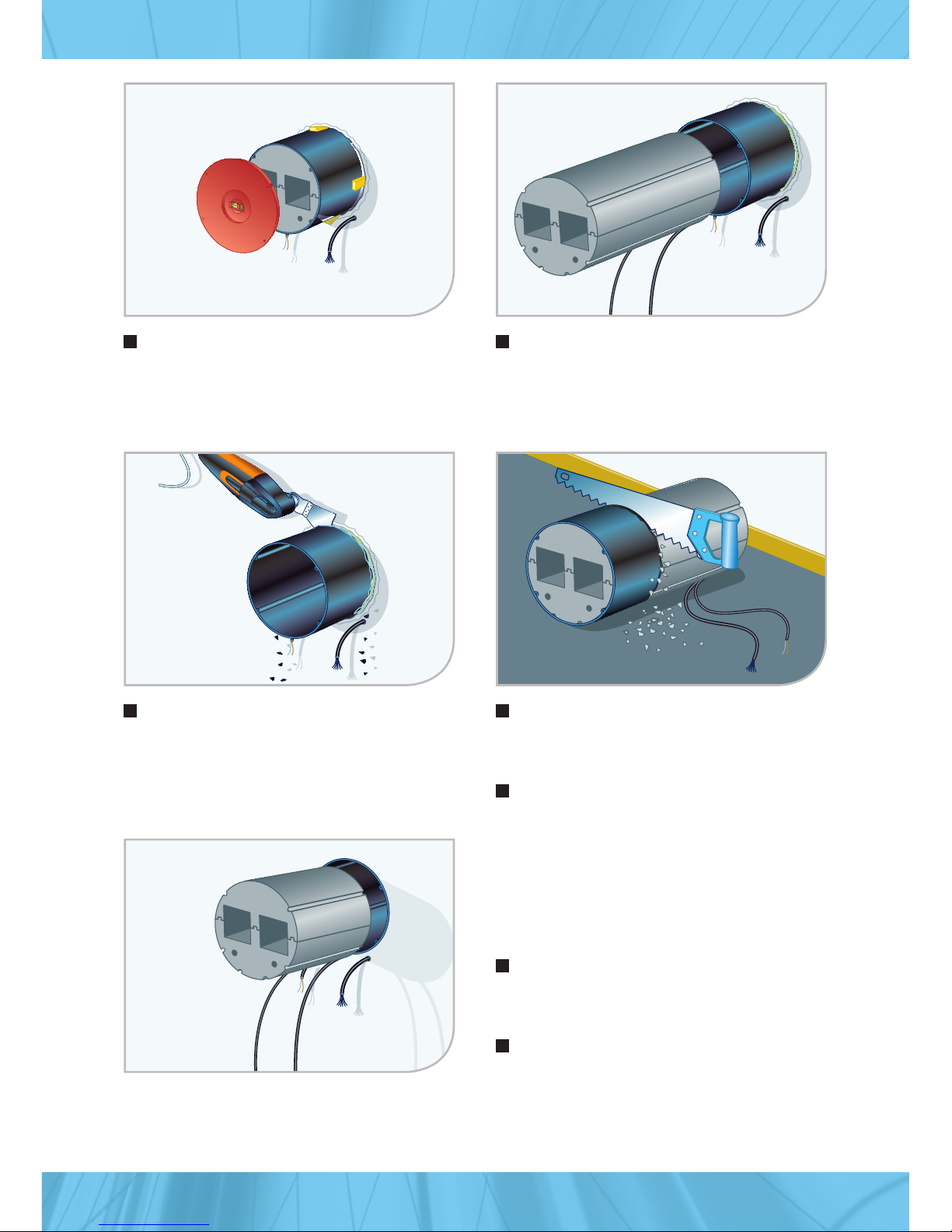

Insert the casting tube from the inside

to the outside. The casting tube must

be flush to the exterior finish wall.

The ventilation unit must be inserted

into the casting tube. The ventilations

fans must be pointed toward the

exterior wall.

Inside

Inside