1. Safety instructions

1.1. General Machinery

Read and understand the entire manual before assembling or operating machinery.

Always use correct safety equipment including hearing protection, eye protection and

respiratory protection.

Wear suitable clothing. Remove loose clothing, remove jewellery such as rings and necklaces

and keep loose hair tied back or contained.

Keep machinery and work area clean and tidy and free of trip hazards.

Do not use machinery when tired or under the influence of prescription drugs, non-prescription

drugs or alcohol.

All machinery operators must be properly trained in the operation of the equipment and suitably

supervised.

Do not reach over an operating machine and ensure footing is secure.

Check machine for damaged components and maintain as necessary.

Only use original manufactures accessories and spare parts.

Do not force the machine or exceed its capacity.

Do not leave the machine running when unattended and ensure the machine has come to a

stop before walking away following machine operation.

Ensure machine is securely mounted or where mobile bases are utilised ensure wheels are

locked prior to operating the machine.

Keep children and visitors away from operating machines and consider childproofing the

workshop area.

Do not use machine in wet or damp areas or in areas that may have flammable or noxious

fumes.

Ensure there is sufficient lighting around the machine and on the machine workface.

If the machine is powered using an extension cord ensure that the extension cord is the correct

amperage and the cord is correctly sized for the length of extension cordage. Ensure cord is

installed in a manner that ensures it cannot be damaged. Inspect cord prior to starting the

machine.

Disconnect power before servicing the machine.

1.2. Grinders

Make sure that the grinder is turned off and has come to a complete rest before moving the belt

tension adjuster, loosen or adjust support arms or tool rest or carrying out cleaning or inspection

of the belt grinder.

Never start or operate a grinder that is damaged or excessively worn.

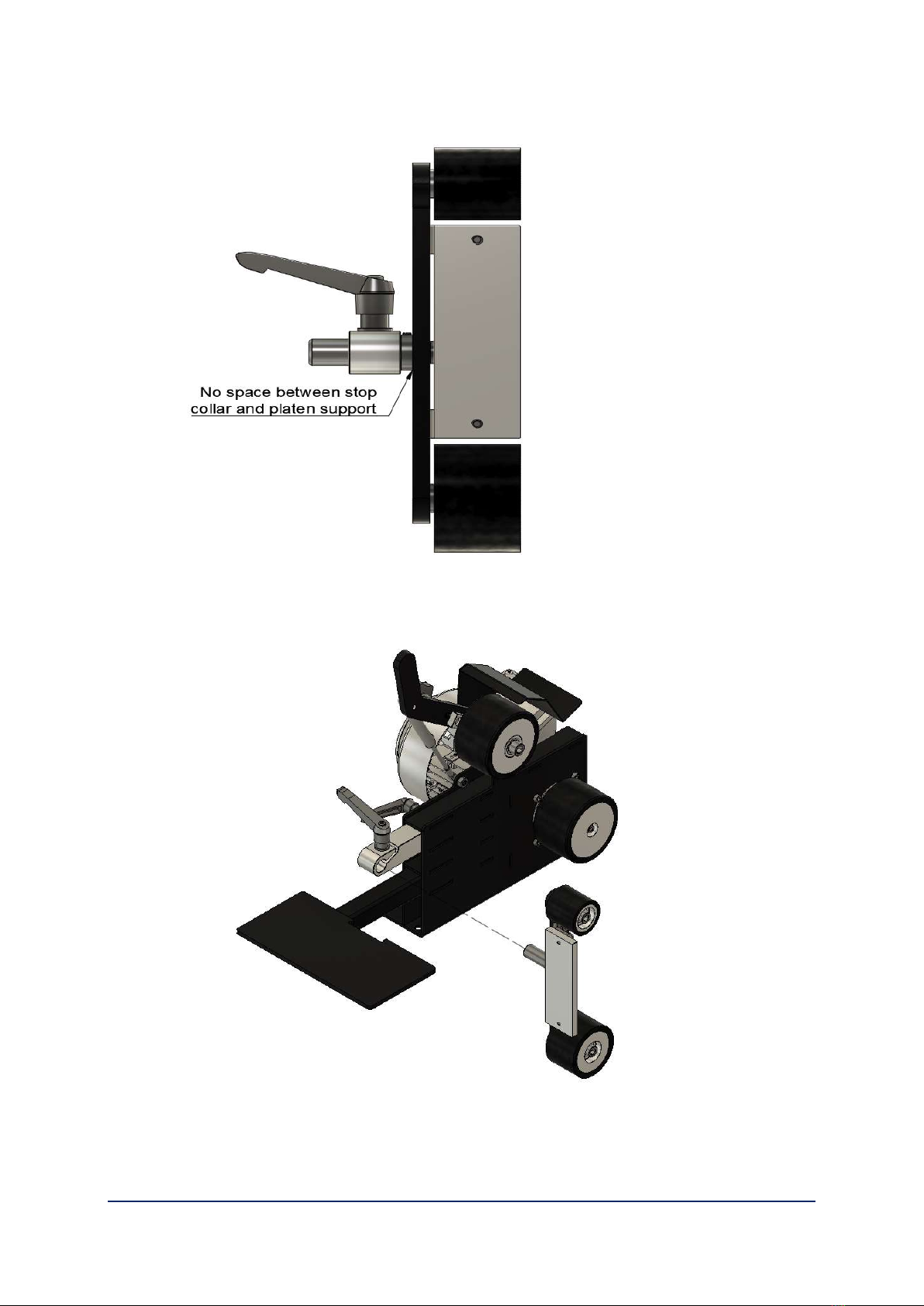

Ensure all lock levers are sufficiently tightened prior to operating the grinder.

Do not operate the grinder with damaged or torn belts or damaged or torn abrasives on disc

grinders.

Ensure belts that are marked with a direction of travel on the reverse side are correctly

orientated on the belt grinder.