HE MODERN MOTOR CYCLE unquestionably provides one of the

most healthy, economical and pleasant means of transport. In

addition by reason of its superb braking, high power to weight ratio and

ease ofcontrol it is, ifused with due care, one of the safest vehicles on the

road.

It is our sincere desire that every owner should obtain from his mount

the service, comfort and innumerable miles of low cost travel that we have

earnestly endeavoured to build into it.

It must be borne in mind however, that although of simple design and

construction, it is nevertheless a highly specialised piece of engineering

and must in consequence be intelligently and efficiently maintained in

order to provide unfailing reliability.

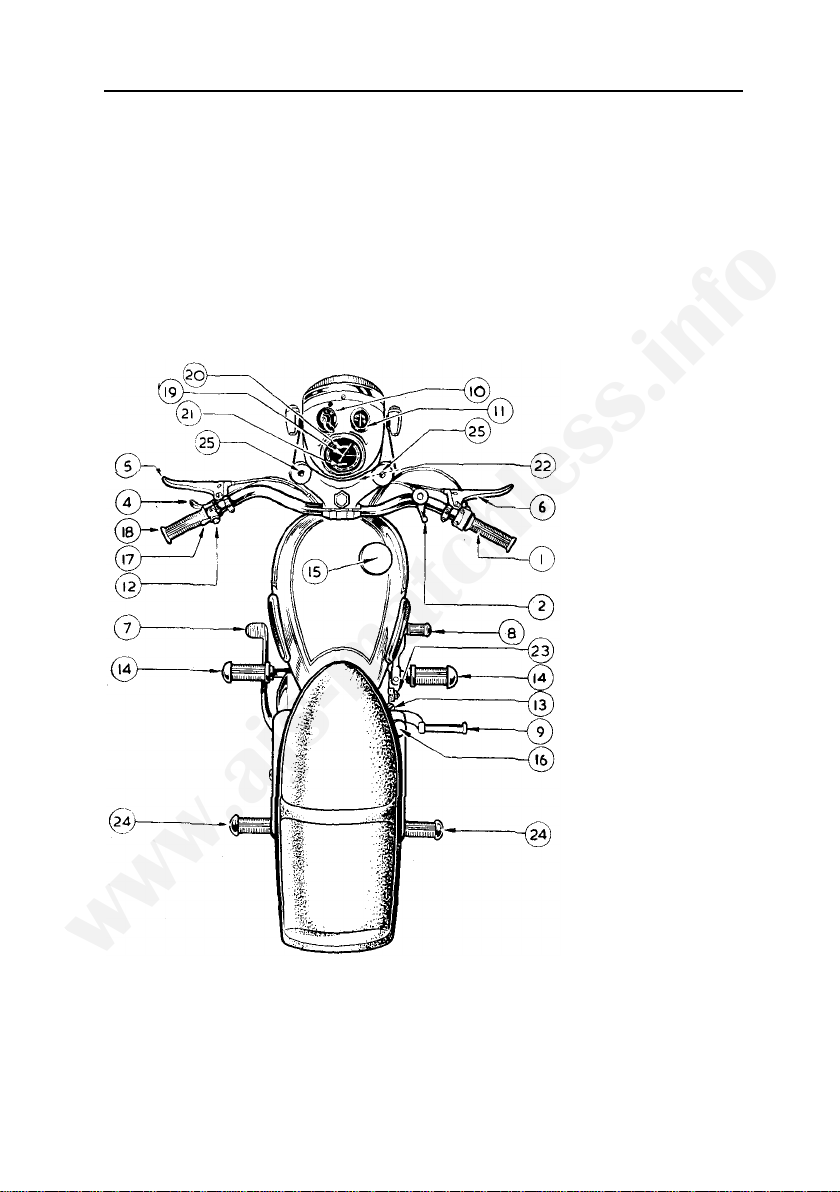

In this book we provide non-technical instructions for carrying out all the

maintenance operations likely to be called for in normal service, together

with assisting illustrations.

To owners of long experience we tender apologies for the elementary

nature of some of the contents of this handbook, but owners whether

novice or expert are advised to read the contents from beginning to end.

We are at all times pleased to give owners the full benefit of our wide

experience in matters relating to motor cycles of our manufacture and

elsewhere will be found details of the particulars required when making

enquiries of our Service Department.

Safety on the Road

N the interest of Safety on the Road a few words of warning will not

be out of place.

The outstanding manoeuverability of a motor cycle over all other vehicles

on the road makes it necessary to exercise caution at all times.

There are unfortunately a few motor-cyclists whose reckless driving

constitutes a menace not only to themselves but also to other road users

resulting in the totally false impression in some quarters that motorcycling

is a dangerous pastime.

Take a pride in your riding technique and never rely upon the other fellow

doing the right thing.

Your example of careful, courteous and unobtrusive riding will materially

contribute to road safety and to the reputation of a fine sporting pastime.

T

I