Contents

1. Introduction............................................................................................................................................................2

Features...........................................................................................................................................................2

Cautions...........................................................................................................................................................3

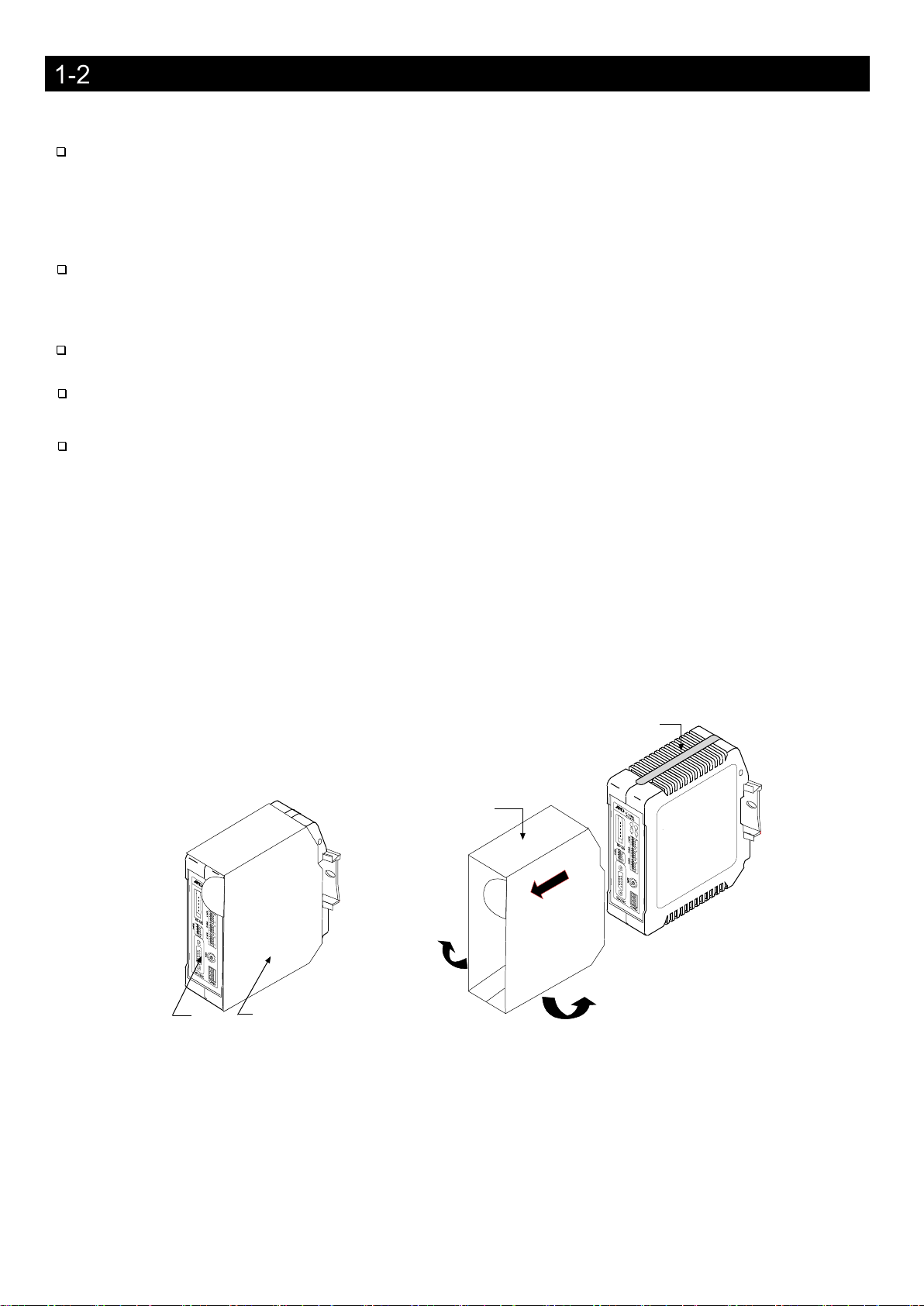

2. Composition and Names .......................................................................................................................................4

AD-8551R ........................................................................................................................................................4

Accessories......................................................................................................................................................4

3. Specifications ........................................................................................................................................................5

Dimensions ......................................................................................................................................................5

Applicable models............................................................................................................................................6

4. Power Terminal......................................................................................................................................................7

Power-supply voltage ......................................................................................................................................7

Connecting example........................................................................................................................................8

Internal connection status................................................................................................................................8

5. RS-485 Interface ...................................................................................................................................................9

RS-485 specifications......................................................................................................................................9

Connections...................................................................................................................................................10

6. RS-232C Interface...............................................................................................................................................11

RS-232C specifications .................................................................................................................................11

Connecting cable...........................................................................................................................................11

7. Switch ..................................................................................................................................................................12

How to operate the switch .............................................................................................................................12

Factory setting ...............................................................................................................................................12

RS-485 function settings ...............................................................................................................................13

RS-232C function settings.............................................................................................................................15

Fixed decimal point function..........................................................................................................................16

8. LED (status, error display)...................................................................................................................................17

9. Communicaiton in Modbus RTU Mode ...............................................................................................................18

Preparing for communication ........................................................................................................................19

Data address .................................................................................................................................................20

Detailed information on Holding Register 1...................................................................................................21

Detailed information on Holding Register 2 (only for AD-4212C/AD-4212D)..............................................................22

Communication format ..................................................................................................................................23

Operating example (When connected to the AD-4212C/AD-4212D) ...........................................................25

10. Communication in Command Mode..................................................................................................................27

Preparing for communication ......................................................................................................................27

Communication format ................................................................................................................................28

11. Troubleshooting .................................................................................................................................................29

Modbus RTU mode communication check..................................................................................................29

Command mode communication check ......................................................................................................30