AccuTemp EDGE ALTLGB Operating instructions

THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE. READ, UNDERSTAND AND FOLLOW THE

INSTRUCTIONS AND WARNINGS CONTAINED IN THIS MANUAL.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS OR LIQUIDS IN THE VICINITY OF THIS OR

ANY OTHER APPLIANCE.

ESURE DE SÉCURITÉ

NE PAS ENTREPOSER NI UTILISER DE´ESSENCE NI AUTRES VAPEURS OU LIQUIDES INFLAMMABLES À PROXIMTÉ DE

CET APPAREIL OU DE TOUT AUTRE APPAREIL.

POST IN A PROMINENT LOCATION

INSTRUCTIONS TO BE FOLLOWED IN THE EVENT THE USER SMELLS GAS. THIS INFORMATION SHALL BE

OBTAINED BY CONSULTING YOUR LOCAL GAS SUPPLIER. AS A MINIMUM,TURN OFF THE GAS AND CALL YOUR

GAS COMPANY AND YOUR AUTHORIZED SERVICE AGENT. EVACUATE ALL PERSONNEL FROM THE AREA.

WARNING: IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, INJURY, OR DEATH. READ THE INSTALLATION, OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR SERVICING THIS EQUIPMENT.

AVERTISEMENT: L’INSTALLATION, LE RÉGLAGE, LA MODIFICATION, LA RÉPARATION OU L’ENTRETIEN INCORRECT

DE CET APPAREIL PEUT CAUSER DES DOMMAGES MATÉRIELS, DES BLESSURES OU LA MORT. LIRE ATTENTIVEMENT

LES INSTRUCTIONS D’INSTALLATION, DE FONCTIONNEMENT ET D’ENTRETIEN AVANT DE PROCÉDER À SON

INSTALLATION OU ENTRETIEN.

GAS-FIRED

INSULATED SELF-CONTAINED TILTING KETTLE - ALTLGB

INSULATED SELF-CONTAINED STATIONARY KETTLE - ALLGB

OWNERS MANUAL AND INSTALLATION INSTRUCTIONS

Made in U.S.A.

MODEL # ALLGB-60 with optional 3” draw-oMODEL # ALTLGB-20 with optional 3”draw-o

Table of Contents

Uncrating & Inspecting the Equipment 1

Safety Precautions 2

Gas/Combustion Precautions 2

Pressure Testing Precaustions on Gas Units 2

Positioning Precautions 2

Electrical Precautions 3

General Use Precautions 3

Warning & Operating Plates 3

Product Improvements 3

Section I: Installation 4

Positioning the Unit 4

Fig. 1.1 Minimum Clearances 4

Draft Hood Installation 4

Leveling and Securing the Unit 4

Electrical Connection 5

Gas Connection 5

Fig. 1.2 Configuration of Gas Connection 5

Checking for Gas Leaks 6

Gas Control - Pressure Verification 6

Fig. 1.3 Pressure Regulator Specification Pressures 6

How to check inlet pressure - with other equipment on

the same line - turned on and turned off 6

Fig. 1.4 Inlet Pressure Tap 7

How to check outlet pressure - with other equipment on

the same line - turned on and turned off 7

Fig. 1.5 Outlet Pressure Tap 7

Completing the “Installation Checklist” 7

Section II: Startup & Operation 8

Initial Cleaning 8

Removing & Cleaning the Draw-off Valve 8

Control Functions 9

Fig. 2.1 Control Panel Features 9

Summary of Control Functions 9

Shutting Down the Unit 10

How to Start Cooking 10

Section III: Service and Maintenance 11

Servicing 11

Replacing Primary ermostat 11

Replacing Ignition System Control 12

Replacing the Gas Burner or Burner Orifices 13

Replacing the Pilot/Igniter Assembly 13

Actuator Maintenance Adjustment 14

Actuator Tension Adjustment 14

Actuator - Repacking with Grease 14

Actuator Replacement 14

Fig. 3.1: Actuator Components & Assembly 15

Fig. 3.2: Removing/Installing Actuators 15

Gas Control System 16

Maintenance of the Gas Control System 16

Control Knob Settings 16

Frequency of Maintenance Required 16

Fig. 3.3: SV9501/9502 Gas Control 16

When to Replace the Gas Control 16

Adjusting the Pilot Flame 16

Fig. 3.4: Pilot System for the SV9501/9502 Smartvalve Gas

Control 16

Identifying Unsatisfactory Pilot Flames 17

Fig. 3.5: Examples of Problem Pilot Flames 17

Filling Steam Jacket 17

Safety Relief Valve 18

Installation Instructions 18

Operating Instructions 18

Maintenance and Testing 18

Section IV: Caring for Stainless Steel 19

Sanitizing 19

Section V: Troubleshooting 21

Troubleshooting - General Problems 21

Troubleshooting - SV9501/9502 Gas Control System 21

Fig. 5.1: e SV9501/9502 Smartvalve 21

Troubleshooting Chart 21

Fig. 5.2: e SV9501/9502 Smartvalve Troubleshooting

Sequence 22

Checking the Grounding 22

Checking the Ignition Cable 22

Checking and adjusting Gas Input and Burner Ignition 22

Section VI: Parts List 23

General Parts List 23

Actuator Parts List & Assembly 24

Fig. 6.1: Actuator Assembly Diagram 24

Compression Draw-off Parts List & Assembly 25

Fig. 6.2: Compression Draw-off Assembly Diagram 25

For Your Use & Review 26

Installation Checklist 26

Maintenance & Service Log 27

Wiring Diagrams 28

120V/1Phase 28

240V/1Phase 29

120V/1Phase (Tilting Gas Units Only) 30

Product Warranty 31

Uncrating & Inspecting the Equipment

INSPECTION:

This appliance was carefully inspected before shipment from the factory. The transportation company assumes

full responsibility for safe delivery to the customer until customer acceptance of the package. Careful inspection

of the packaging and the appliance should be completed before acceptance from the transportation company.

CONTACT INFORMATION:

Toll Free 800 480-0415

Oce 260469-3040

Fax 260469-3045

Web Site www.accutemp.net

1

Safety Precautions

Installation of the equipment must be done by a

qualied technician, knowledgeable of and experienced

in the installation of commercial gas and electrical

cooking equipment.

Retain this manual for future reference.

Gas/Combustion Precautions

Your installation must conform to local codes or in the

absence of local codes, with the current National Fuel Gas

Code ANSI Z223.1/NFPA 54 (latest edition), or the National

Gas and Propane Installation Code, CSA B149.1 (latest

edition), as applicable.

Appliances equipped with casters the installation

must be made with a connector that complies with the

Standard for Connectors for Movable Gas Appliances, ANI

Z21.69•CSA 6.16 (latest edition), and a quick-disconnect

device that complies with the Standard for Quick-

DisconnectDevices for UseWithGasFuel,ANSIZ21.41•CSA

6.9 (latest edition). The appliance must be limited in its

movement by a restraining device attached to the frame

of the appliance and an adjacent wall. Adequate means

must be provided to limit the movement of the appliance

without depending on the connector and the quick-

disconnect device or its associated piping.

AVIS: Les appareils sur roulettes doivent être pourvus

des roulettes fournies, d’un tuyau de raccordement

conforme à la norme ANSI Z21.69 ou CAN/CGA-6.16

et d’un raccord à débranchement rapide satisfaisant

les exigences de la norme ANSI Z21.41 ou CAN1-6.9.

Ils doivent aussi être munis d’un dispositif de retenue

pour empêcher toute transmission de tension au tuyau

de raccordement confromément aux instructions du

fabricant.

Appliance MUST be connected ONLY to the gas type

identied on the attached rating plate.

This unit is not suitable for connection to Type B Gas

Vent.

Ne convient pas au raccordement à un conduit

d’évacuation de type B.

FOR YOUR SAFETY: Do not store or use gasoline or

other ammable vapors or liquids in the vicinity of this or

any other appliance.

ESURE DE SÉCURITÉ: Ne pas entreposer ni utiliser

de´essence ni autres vapeurs ou liquides inammables à

proximté de cet appareil ou de tout autre appareil.

Always disconnect from the power supply and close

the main gas valve before servicing.

The ignition system controls of this equipment have

been factory set for either natural (manufactured) or LP

gas. Do not attempt to use an ignition system control set

for natural (manufactured) gas with LP gas or an ignition

system set for LP gas with natural (manufactured) gas.

Ignition system controls cannot be eld converted from

one gas type to the other.

The lighting sequence on this appliance is automatic;

do not attempt to manually light the main burner.

It is your responsibility to post, in a prominent location,

instructions to be followed in the event the user smells

gas. This information must be obtained from your local

gas supplier. Until it is obtained, post the label that came

with this manual.

IMPORTANT! In the event gas odor is detected, do the

following.

Observe the posted instructions.

Shut down the unit at the main shut-o valve.

Contact the local gas company or supplier—from a

phone away from the building—for emergency service

and follow the supplier’s instructions.

If the gas supplier cannot be reached, call the re

department.

Do not use any phone in the building.

Do not light or start any appliance.

Do not touch any electrical switch.

Pressure Testing Precautions on Gas Units

The equipment and its individual shut-o valve must be

disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in

excess of 1/2 psig (3.45 kPA).

The equipment must be isolated from the gas supply

piping system by closing its individual manual shut-o

valve during any pressure testing of that system at test

pressures equal to or less than 1/2 psig (3.45 kPA).

Positioning Precautions

The unit must be placed on a non-combustible oor,

under an exhaust hood, with a re retardant system

and all connections and placement must comply with

all applicable local and national codes. Your ventilation

hood, when installed, must conform to ANSI/UL 705 and

ANSI/NFPA 96 (latest edition).

Installer sur un plancher incombustible seulement.

Installer en dessous d’une hotte de ventilation

seulement.

Adequate make-up air must be provided for exhaust

2

Safety Precautions

systems in the area where the equipment is to be installed.

No frame or restriction shall be constructed around

the equipment that will restrict air movement into

the equipment’s combustion area or prevent proper

combustion.

Keep the appliance area free and clear from

combustibles. Failure to do so may cause re or property

damage.

Adequate clearance for servicing and proper operation

must be maintained.

The appliance must be restrained to prevent tipping

when installed in order avoid the splashing of hot liquid.

The means of restraint may be the manner of installation

or by separate means.

Electrical Precautions

This equipment must be electrically grounded in

accordance with local codes or, in the absence of local

codes, with the National Electrical Code, ANSI/NFPA No.

70 (latest edition) or the Canadian Electrical Code, CSA

C22.1 (latest edition), as applicable.

Never attempt to operate the equipment during a

power failure.

This appliance is equipped with a three prong

(grounding) plug for your protection against shock

hazard and should be plugged directly into a properly

grounded three-prong receptacle. Do not cut or remove

the grounding prong from this plug.

Cet appareil est pourvu d’une che à trois broches

dont une mise à la terre assurant une protection contre

les chocs électriques. La prise dans laquelle elle esst

branchée doit être correctement mise à la terre. Ne pas

couper ni enlever la broche de mise à la terre de la che.

General Use Precautions

Always instruct employees on the proper use of this

equipment.

Never attempt to move this equipment when it is full of

hot oil or another hot liquid.

Never operate this equipment during a power failure.

This equipment is intended for other than household

use.

Non destiné à l’usage domestique.

Warning & Operating Plates

All warning and operating plates on the equipment

should be in place at all times. If plates are damaged or

lost, replace them immediately.

Product Improvements

Be aware that as continuous product improvement

occurs, specications may be changed without notice.

3

Section I: Installation

IMPORTANT! Installation of the equipment must be done by a qualied technician, knowledgeable of and experienced

in the installation of commercial gas and electrical cooking equipment. It is the responsibility of the owner and installer

to comply with all applicable local and national codes and regulations when installing the unit.

All internal wiring of the equipment is supplied complete and ready for nal connection. A wiring diagram is supplied

behind the cover of the unit’s control console. OEM’s Engineering Department must approve any mechanical or electrical

changes.

Positioning the Unit

Position the unit where you intend to use it. A minimum

of fteen (15) inches must be provided for servicing

of controls. Remember to also consider the required

clearances of any other adjoining pieces of equipment.

Fig. 1.1 Minimum Clearances

Model Back of Unit Sides of Unit Vent

ALLGB(F) 10 6 6

ALTLGB(F) 10 6 6

Draft Hood Installation

Leveling & Securing the Unit

The feet of the unit may be adjusted so that the kettle is

properly leveled.

The ue vent shipped with the kettle is the correct height

and shape to give maximum performance. Do not

change the diverter in any way.

WARNING:

The unit must be placed on a non-combustible oor,

under an exhaust hood, with a re retardant system

and all connections and placement must comply with

all applicable local and national codes. Your ventilation

hood, when installed, must conform to ANSI/UL 705 and

ANSI/NFPA 96 (latest edition).

Installer sur un plancher incombustible seulement.

Installer en dessous d’une hotte de ventilation

seulement.

Adequate make-up air must be provided for exhaust

systems in the area where the equipment is to be installed.

No frame or restriction shall be constructed around

the equipment that will restrict air movement into

the equipment’s combustion area or prevent proper

combustion.

Adequate clearance for servicing and proper operation

must be maintained

Warning: This unit is not suitable for connection to Type B

or any other type gas vent. It is required that ue gases be

vented to a ventilating hood. This unit must be installed

under a ventilation hood.

Ne convient pas au raccordement à un conduit

d’évacuation de type B.

Installer en dessous d’une hotte de ventilation

seulement.

Warning: Hot liquids can cause severe burns. Avoid

contact. Under all circumstances, oil must be removed

from the fryer before attempting to move it to avoid

spills, and the falls and severe burns that could occur. This

fryer may tip and cause personal injury if not secured in a

stationary position.

Appliances equipped with casters the installation must

be made with a connector that complies with the

Standard for Connectors for Movable Gas Appliances, ANI

Z21.69•CSA 6.16 (latest edition), and a quick-disconnect

device that complies with the Standard for Quick-

DisconnectDevicesforUseWithGasFuel,ANSIZ21.41•CSA

6.9 (latest edition). The appliance must be limited in its

movement by a restraining device attached to the frame

of the appliance and an adjacent wall. Adequate means

must be provided to limit the movement of the appliance

without depending on the connector and the quick-

disconnect device or its associated piping.

AVIS: Les appareils sur roulettes doivent être pourvus des

roulettes fournies, d’un tuyau de raccordement conforme

à la norme ANSI Z21.69 ou CAN/CGA-6.16 et d’un raccord

à débranchement rapide satisfaisant les exigences de la

norme ANSI Z21.41 ou CAN1-6.9. Ils doivent aussi être

munis d’un dispositif de retenue pour empêcher toute

transmission de tension au tuyau de raccordement

confromément aux instructions du fabricant.

Appliances must be a room temperature, empty of all

liquids, and if tted with legs, lifted during movement to

avoid damage and possible bodily injury.

4

Section I: Installation

WARNING:

Your installation must conform to local codes or in

the absence of local codes, with the current National Fuel

Gas Code ANSI Z223.1/NFPA 54 (latest edition), or the

National Gas and Propane Installation Code, CSA B149.1

(latest edition), as applicable.

Do not store or use gasoline or other liquids with

ammable vapors in the vicinity of this equipment.

Always disconnect the fuel source before servicing.

The ignition system controls of this equipment have

been factory set for either natural (manufactured) or LP

gas. Do not attempt to use an ignition system control set

for natural (manufactured) gas with LP gas or an ignition

system set for LP gas with natural (manufactured) gas.

Ignition system controls cannot be eld converted from

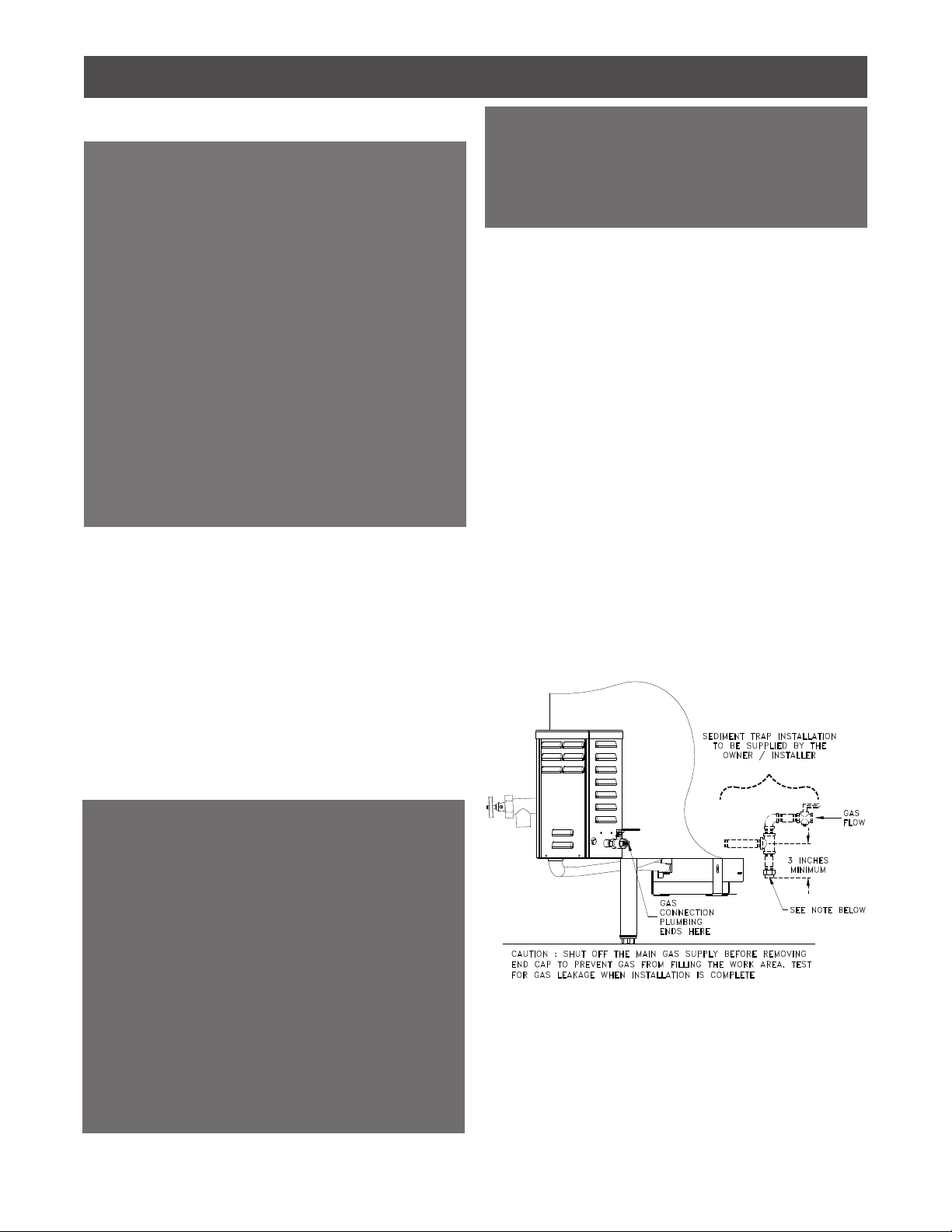

1. Shut o the main gas supply

before beginning the gas

connection.

2. Properly congure the gas

supply line to be used (see Fig.

1.2). The gas supply line must

be a minimum of 3/4” npt pipe.

It is your responsibility to ensure

that the supply line installed

is large enough to achieve

the proper pressure and allow

the required volume of gas to

ow. A sediment trap must

be installed to protect against

contamination of the ignition

system control. Install a manual

shut-o valve between the gas

supply line and the sediment

trap to allow for maintenance of

the trap.

Fig. 1.2 Conguration of Gas Connection

3. In making the connections, use a good quality joint

compound. If LP gas is supplied, a joint compound

resistant to LP gas should be used. Connect the supply

line to the ball valve at the rear of the unit. Tighten the

connection securely.

Electrical Connection

A power cord is provided on the back of the unit, for

connecting to the electric power supply. The installer

should verify the electrical requirements of the unit to

make sure your power supply line is capable of powering

the equipment properly. This information is listed on the

unit’s nameplate.

Standard 120 Volt Model: Connect a 120-volt, 60 Hz,

single (1) phase power cord.

Optional 240 Volt Model: Connect a 240-volt, 60 Hz,

single (1) phase power cord.

Gas Connection

WARNING: Electrical Grounding Instructions

This appliance is equipped with a three-prong

(grounding) plug for your protection against shock

hazard and should be plugged directly into a properly

grounded three-prong receptacle. Do no cut or remove

the grounding plug from this plug.

AVERTISSEMENT: Mise à la terre

Cet appareil est pourvu d’une che à trois broches

dont une mise à la terre assurant une protection contre

les chocs électriques. La prise dans laquelle elle esst

branchée doit être correctement mise à la terre. Ne pas

couper ni enlever la broche de mise à la terre de la che.

Also, it is required that an electrical cut-o device,

such as a fused disconnect switch or equivalent, be

installed in the power supply line between the main

power supply and the unit.

The pilot ame on this equipment is lit automatically

and requires electrical power to operate. The unit will not

operate if the power is o.

one gas type to the other.

It is your responsibility to post, in a prominent

location, instructions to be followed in the event the

user smells gas. This information must be obtained

from your local gas supplier.

5

Section I: Installation

To check inlet pressure - with other equipment on

the same line turned on and turned o:

Check the inlet pressure with all equipment on the same

gas supply line turned on and turned o.

1. Shut o the gas supply and remove the cover panel of

the control console. Remove the inlet pressure tap and

connect the pressure gauge or manometer (See Fig. 1.4).

2. Turn the gas supply back on. Light the main burner.

Turning the primarythermostat dial above room

temperature lights the main burner.

3. Record the inlet pressure readings on the Installation

Checklist for Warranty Validation. Be sure to take readings

with other equipment on the same line turned on and

turned o.

4. Reverse the procedure in step 2 to turn o the main

burner and shut o the gas supply before disconnecting

the manometer or pressure gauge.

5. Replace the inlet pressure tap plug.

Important! Always shut o the gas supply at the manual

valve in the gas supply piping to the unit (or at the tank

for LP gas), before removing the inlet pressure tap plug to

connect or disconnect a pressure gauge or manometer.

Inlet Pressure Too High? If natural gas pressure exceeds

7” water column or LP gas pressure exceeds 14” water

column, then a pressure-regulating valve must be

installed in the gas supply line.

Inlet Pressure Too Low? If natural gas pressure is below

5” water column or LP gas pressure is below 12” water

column, then the installer must determine the problem.

Too much equipment may be on the same line or a larger

gas supply line may be required.

Inlet pressure must be correct before checking the outlet

pressure.

Fig. 1.3 Pressure Regulator Specication Pressures

(in Inches Water Column)

Gas Valve

Type

Type of

Gas

Nominal Inlet

Pressure Range

Factory Set

Nominal Out-

let Pressure

Adjustment

Setting Range

Intermittent

Pilot

Natural 5.0 - 7.0”w.c. 3.5”w.c. 3 - 5

LP 12.0 - 14.0”w.c. 9.0”w.c. 8 - 12

Checking For Gas Leaks

WARNING:

Do not permanently supply gas to the unit until the gas

lines have been pressure tested. Faulty operation and

even equipment damage will result if the gas supply falls

below requirements.

The equipment and its individual shut-o valve must be

disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in

excess of 1/2 psi (3.5 kPA).

The equipment must be isolated from the gas supply

piping system by closing its individual manual shut-o

valve during any pressure testing of that system at test

pressures equal to or less than 1/2 psi (3.5 kPA).

1. Turn on the main gas supply. With burner o, douse

the pipe connections up stream of the ignition system

control with a rich soap and water solution. Bubbles

indicate a gas leak. If a leak is detected, tighten pipe

connections. Replace the part if the leak cannot be

stopped.

2. With main burner in operation, douse pipe joints

and control inlet and outlet with rich soap and water

solution. If another leak is detected, tighten joints and

pipe connections. Replace the part if the leak cannot be

stopped.

Gas Control - Pressure Verication

Using a pressure gauge or a manometer, the installer must

record the gas pressure at both the inlet and outlet of the

ignition system control—rst with all equipment on the

same gas line turned on, then with all equipment turned

o. These readings are necessary for your installation and

warranty records. Gas pressure input and output ratings

for your equipment are listed on the unit’s nameplate.

Acceptable pressure ranges are provided below. Do not

exceed these ratings. NOTE: Since outlet pressure is

dependent upon proper inlet pressure, inlet pressure must

be checked rst.

6

Section I: Installation

Completing the“Installation Checklist”

With all of the preceding installation steps completed, the

primary aspects of the installation have been completed.

This manual contains an Installation Checklist that must

be lled out to show that certain key elements of the

installation have been performed properly.

IMPORTANT! TheInstallation Checklistmust becompleted

for your warranty to be valid. Do not neglect this step.

Outlet Pressure Tap

Fig. 1.5 Outlet Pressure Tap

To check outlet pressure - with other equipment

on the same line turned on and turned o:

Check the outlet pressure with all equipment on the same

gas supply line turned on.

1. Be sure the ignition system control knob is in the

OFF position. Remove the outlet pressure tap plug and

connect the pressure gauge or manometer (See Fig. 1.5).

Turn the ignition system control knob to the ON position.

2. Turn the gas supply back on and light the main burner

by following Step 2 in the previous procedure for checking

the inlet pressure.

3. Record the outlet pressure readings by following Step 3

in the Check inlet pressure procedure for checking the

inlet pressure.

4. Turn OFF the main burner and shut o the gas supply

before disconnecting the manometer or pressure gauge

by reversing the procedure in Step 2 in the previous

procedure for checking the inlet pressure.

5. Replace the outlet pressure tap plug

6. Replace the cover panel of the control console and turn

the gas supply back on.

Important! Always shut o the gas supply at the manual

valve in the gas supply piping to the unit (or at the tank

for LP gas), before removing the outlet pressure tap plug

to connect or disconnect a pressure gauge or manometer.

Outlet pressure too high or too low? If the outlet pressure

is too high or too low, but the inlet pressure is nominal,

the outlet pressure can be adjusted by the installer using

the following procedure.

• Remove the pressure regulator adjustment cap screw.

Inlet Pressure

Tap

Fig. 1.4 Inlet Pressure Tap • Using a screwdriver, turn the inner adjustment screw

clockwise to increase pressure and counterclockwise to

decrease pressure to the infrared burners.

• When proper outlet pressure has been achieved,

replace the pressure regulator adjustment cap screw.

The unit will not operate properly if the cap screw is not

in place.

Proper outlet pressure cannot be achieved? If following

the above procedure fails to attain proper outlet pressure,

and the inlet pressure is nominal, then the ignition system

control needs to be replaced.

7

Section II: Startup & Operation

Warning:

Always disconnect power before cleaning (or servicing)

the unit.

The control console is not waterproof. Never spray the

control console, electrical controls, ignition system

controls, or connections with water. Clean these areas by

wiping them with a clean, damp cloth.

When cooking, never allow water or foodstu to come in

contact with any electrical components.

Before operating your equipment, it must be cleaned

thoroughly. Refer to section IV: Caring for Stainless Steel

for instructions.

Important! Disconnect all electrical power before

cleaning the unit.

Clean the unit thoroughly with a mild detergent

solution. Always“wipe”

around the control

console (never spray).

Never rinse control

consoles with a spray

hose or let water come

in contact with any

electrical and control

components.

For routine cleaning,

Accutemp’s optional

“Care Kit” accessories

help you thoroughly

clean all surfaces,

including the inside of

the lid and the inside

of the draw-o valve.

During washing, excess

water in the kettle may be drained away through the

draw-o using the optional drain hose attachment.

Use the “Care Kit” to clean hard to reach places like inside

the lid and inside the draw-o valve. Rinse and drain

away wastewater easily through the optional drain hose.

Take care when removing the draw-o valve for

cleaning. The draw-o hex bonnet nut and valve stem

are surprisingly heavy. Do not drop them, since this can

cause damage to the stem creating leaks. Also be sure

to remove all water from the kettle before removing the

draw-o valve.

1. Make sure the stem is in the open position.

2. Unscrew the hex bonnet nut.

3. Carefully remove the nut and stem assembly

Removing & Cleaning the Draw-O Valve:

Initial Cleaning

8

Section II: Startup & Operation

4. Thoroughly clean the body and tube using the draw-

o cleaner brush provided with the Legion Care Kit.

5. When through, rinse with clean water and re-assemble,

taking care not to over-tighten the draw-o. It is designed

to be hand-tightened only.

We’ve already started the unit up during installation. Now

we’ll examine all control functions, step by step, for a full

understanding.

IMPORTANT: After installation or service and prior to

operating the unit, make sure the following are done,

otherwise the unit will not operate.

Make sure the ignition system control knob is in the

ON position.

Make sure the main electrical power and the gas

supply to the unit have both been turned on.

Fig. 2.1 Control Panel Features

Rocker Switch (On - O). Energizes the unit for operation.

Primary Thermostat Dial (Temperature). Allows the user

to set the cooking temperature of the unit.

Unit Power On Indicator Light (Green). Illuminates upon

depressing the rocker switch to the ON position. This

indicates the unit has been energized.

Heater Power On Indicator Light (Red). Illuminates upon

turning the thermostat dial to show that the infrared

burners are operating. Note: If the temperature of the

unit is already above the set temperature, the red heater

power on light will not come on.

Low Water Indicator Light (Amber). It alerts the user that

the water level in the steam jacket has fallen below the

recommended operating level and that the low water

relay has been activated, turning o the burner as a

safety precaution until the low water condition has been

remedied (Refer to Section III, Service & Maintenance,

Item 4, Filling Steam Jacket). Once the water level has

been increased to normal working levels the low water

relay will reset and permit normal operation.

Control Functions Summary of Control Functions:

9

Section II: Startup & Operation

Tilt Switch (ALTLGB & ALTLGB-F only). Automatically shuts

o the kettle when tilted. Care should be taken when

tilting unit lled with hot product.

Shutting Down the Unit:

Normal (Routine) Shutdown. Turn the primary thermostat

dial to the lowest temperature setting and press the

rocker switch to OFF.

Complete System Shutdown. Perform normal shut down

as described above. Then, turn the ignition system control

knob (located inside the control console, clockwise to OFF.

Do not force the knob. The appliance will completely shut

o. To resume normal operation, turn the ignition system

control knob to the ON position and set the primary

thermostat dial to the desired temperature setting.

How to Start Cooking:

1. Press the rocker switch to ON position, turn the primary

thermostat clockwise to the desired temperature. This

will cause the red indicator light to come on, showing that

the burner is operating.

2. Close the lid to speed up the heating process.

3. Once the unit has cycled (the red indicator light goes

out), you can start cooking immediately. However, to

guarantee the most even, stable heat you may want to let

it cycle several times.

4. If a new temperature is desired during a cooking

operation, simply turn the thermostat to the new

setting. Again, allow several cycles to ensure proper heat

stabilization.

5. To shut down the unit, turn the thermostat dial to OFF

and press the rocker switch to OFF.

10

Section III: Service and Maintenance

This section covers the basics of servicing and maintaining

your equipment. A “Maintenance and Service Log” is

included in this manual for your use in recording all

maintenance and service performed.

IMPORTANT: Service must be done by a qualied

technician experienced with commercial gas and electric

cooking equipment. Use only OEM supplied parts.

Unauthorized or generic parts can cause bodily injury and

equipment damage. If the unit ever needs repair during

the warranty period, prior authorization is required. Also

refer to the sections of this manual entitled Service Calls

and also Important Warranty Information.

Servicing

Warning: Always disconnect the power supply and shut

o manual gas valve before cleaning or servicing.

Re-Calibrating Thermostats (Do Not Attempt)

IMPORTANT! If thermostat is defective or not working

properly, it must be replaced (without breaking the seal)

and returned to Accutemp. The warranty is voided if the

seal is broken or any attempt is made to recalibrate a

thermostat. See below for replacement instructions.

1. Disconnect the unit from its power supply.

2. Turn o the manual gas valve

at the rear of the unit.

3. Remove the control

console panel.

4. On the existing primary

control thermostat control-

ler (Item 1), mark and dis-

connect the sensor (probe)

leads (Item 2) from terminal

1 and 2. For 120 VAC oper-

ation, mark and disconnect

the black wire(s) from termi-

nals 4 and 7 and white wire

from terminal 5. For 208 to

240 VAC operation, mark

and disconnect the black

wire(s) from terminals 3 and

7 and white wire from terminal 5. Mark and disconnect the

red wire from terminal 6. Mark and disconnect the black

wire from terminal 6.

5. If replacing the primary control thermostat controller

(Item 1), remove the knob on the front panel by loosening

the setscrew and loosen the rubber-coated nut to release

the controller from the front panel.

6. Reconnect the wires from the sensor (probe) leads to the

Replacing Primary Thermostat

11

Section III: Service and Maintenance

new controller and secure to front panel with mounting

nut and replace knob securing with setscrew.

7.Replace control console panel and secure in place.

8. If replacing the sensor (probe) (Item 2),drain water in

jacket below the sensor location.

9. Refer to step 4 to disconnect leads from primary con-

trol thermostat controller.

9. Remove sensor (Item 2) from kettle jacket using a

18mm deep well socket.

10. After installing new sensor, reconnect the wires from

the new sensor (probe) to the controller.

11. Replace control console panel and secure in place.

12. Rell kettle with pure distilled water. Refer to Fill-

ing Steam Jacket of this section for instructions.

B) Replacing the Ignition System Control

Disconnect power and turn o main gas supply before

starting.

To replace the gas control valve (Item 4);

1.Disconnect the controls connector and the igniter

connector from the gas control valve (Item 4).

2. Disconnect the pilot tube (Item 3) from the gas control

valve (Item 4).

3. Loosen exible gas hose nut (Item 7), using a crescent

wrench or 1 1/8 open end wrench, located under the

control console.

4. Remove the manual gas valve, reducing bushing and

nipple from gas control valve

5.Remove 1/4-20 bolts (Item 6) from rear of control

console to loosen bracket holding gas valve.

6.Remove gas control valve from control console.

Note: You may need to rotate valve slightly to allow

clearance for elbows and bracket attached to valve.

Make note of positioning of valve in control console when

removing to insure correct placement of new valve.

7.Reverse steps to secure new gas control valve in place.

12

Section III: Service and Maintenance

(C) Replacing the Gas Burner or Burner Orices

Refer to steps 1 through 3 of Replacing the Ignition

System Control then,

Remove 3 1/4-20 bolts from burner shroud (Item 8). Let

the shroud/gas burner assembly drop down, then pull

out from underneath the kettle.

Remove 3/8 nut and at washer located in center of

burner assembly (Item 9).

Lift burner out of shroud.

Reverse steps to replace new burner.

D) Replacing the Pilot/Igniter Assembly

Refer to steps in C) Replacing the Gas Burner or Burner

Orices then,

Turn gas burner over and loosen 2 1/4-20 bolts to remove

bracket from burner (Item 10).

Lift bracket away from burner and remove 1 slotted screw

from bracket which holds the igniter to the bracket.

Remove pilot tube using a 7/16 open end wrench (make

sure not to lose the orice inside the igniter).

Reverse steps to replace the new igniter.

13

Section III: Service and Maintenance

Actuator Maintenance and Adjustment

A) Actuator Tension Adjustment

The lid on the ALLGB and ALLGB-F(standard on 60 gallon

and up) can operate with spring-loaded actuators. If the

lid can be raised to any position, and it remains in that

position, the actuators are adjusted properly. Should the

tension need adjustment after shipping, or at any time

in the future, the following procedure can be performed.

Raise the unit’s lid completely. Removal of the stop nut

may be needed to raise the lid completely.

Remove the tube closure cap on the actuator. With a 3/4”

deep hex socket, turn the adjusting nut (located inside

the actuator sleeve) clockwise to increase the tension or

counterclockwise to decrease tension. Rotate the nut

one turn at a time and test the lid’s operation. When the

adjustment is complete, replace the tube closure cap on

the actuator sleeve.

B) Actuator: Re-Packing With Grease

The lid actuator(s) of your unit must be re-packed with

grease every six months to ensure proper operation.

Perform the following steps. Refer to Figure 3.1 and to

Figure 3.2.

1. Raise the lid of the unit fully.

2. Remove the tube closure cap.

3. Remove the self-locking 1/2-13 hex nut on the actuator

rod.

4. If the components inside the actuator sleeve do not

slide out easily, remove the bolt, which secures the

actuator sleeve to the frame lug. Put aside the bolt, nut,

and lock washer for re-assembly later.

5. Grasp the actuator sleeve and pull down away from the

actuator rod. The components inside the actuator sleeve

will slide out.

6. Pack the spring (or springs) with Bel-Ray No-Tox Clear

Grease #2. The grease must be liberally applied between

each coil.

7. After re-packing with grease, reassemble the

components back inside the actuator sleeve and slide the

sleeve back over the actuator rod.

8. Reconnect the actuator assembly to the frame lug

using the bolt, nut, and lock washer previously set aside.

9. Adjust the tension of the actuators using the procedure

described earlier in this section.

C) Actuator Replacement

Should the actuators on your unit ever require

replacement, use the following procedure. Refer to Figure

3.1 and to Figure 3.2.

1. Raise the lid of the unit fully.

2. Remove the tube closure cap.

3. Using a deep socket tool, loosen the self-locking hex

nut on the actuator rod (by turning it counterclockwise)

to eliminate pressure on the springs.

4. From the pivot arm of the actuator, remove the acorn

nut, bolt, lock washer, and spacer and retain them for

mounting the new actuator(s).

5. From the frame lug (at the other end of the actuator)

remove the acorn nut, bolt, and lock washer and retain

them for mounting the new actuator(s).

6. Mount the new actuators using the bolts, nuts, lock

washers, and spacers set-aside in the above steps.

Note: The actuator rod must be free to pivot during use.

Therefore, when tightening the hex bolt into the acorn

nut, tighten it completely, and then back o a half turn.

7.Afterthe newactuator(s)are installed,adjust thetension

using the procedure described earlier in this section.

14

Section III: Service and Maintenance

404486-001

404486-002

Parts List

TITLEPART NUMBER

QTY

ITEM

SLEEVE WELDMENT404483-00111

ACTUATOR ROD & LUG

455880

1

2

WASHER NYLON 1.355 X .5240850533

NYLON SHOULDER WASHER40850624

SPRING 8" X 1 1/4" X 5/8"

4085311

5

NUT SS LOCK 1/2-13

40559116

ACTUATOR END-CAP PLUG404485

17

ACTUATOR COVER STOP45669518

Parts List

TITLEPART NUMBER

QTY

ITEM

SLEEVE WELDMENT404483-00111

ROD ACTUATOR LUG45587912

WASHER NYLON 1.355 X .5240850533

NYLON SHOULDER WASHER40850624

NUT SS LOCK 1/2-13

40559116

SPRING 8" X 1 1/4" X 5/8"

40853115

ACTUATOR END-CAP PLUG404485

17

ACTUATOR COVER STOP45669518

346

17

5

8

283467404486-002 [60G - 150G INSULATED, & 80G -150G UN-INSULATED]

15

404486-001 [20G - 40G INSULATED, & 20G -60G UN-INSULATED]

2

Figure 3.1: Actuator Components & Assembly

Fig. 3.2: Removing/Installing Actuators

15

Section III: Service and Maintenance

Gas Control System

Fig. 3.3: SV9501 / 9502 Gas Control

When to Replace the Gas Control:

√ The gas control does not perform properly on checkout

or troubleshooting.

√ The gas control knob is hard to turn.

√ The gas control is likely to have operated more than

200,000 cycles.

√ The control is wet or looks as if it has been wet.

B) Adjusting the Pilot Flame

The pilot ame was adjusted at the factory. Should it ever

need adjusting, follow the instructions below.

Fig. 3.4: Pilot System for the SV9501/9502

SmartValve™ Gas Control

Proper Setting: The ame should envelope 3/8” to 1/2”

(10 mm to 13 mm) of the igniter sensor tip.

1. Turn o the thermostat dial.

2. Disconnect the lead to the MV terminal on the gas

control.

3. Re-light the pilot by turning up the thermostat to call

for heat.

4. Remove the pilot adjustment cover screw from the gas

control (see Fig. 3.3).

5. Turn the inner pilot adjustment screw clockwise to

decrease or counterclockwise to increase the pilot ame.

When done, replace the cover screw and tighten it rmly.

A). Maintenance of the Gas Control System

Your equipment came with an intermittent pilot gas

control system. The systems is as follows:

The SV9501/9502 SmartValve™ System Control combines

gas ow control and electronic intermittent pilot

sequencing functions into a single unit. The Q3450

SmartValve™ System pilot burner provides pilot ame

ignition and sensing for the SV9501/9502 Systems. It

consists of a replaceable igniter-ame rod assembly,

bracket assembly, pilot target, ground electrode, orice

assembly, compression tting and spring clip. The igniter

lights the pilot burner. The ame rod proves the pilot

ame and the pilot ame lights the main burner.

Control Knob Settings:

OFF. Prevents pilot and main gas ow through the

ignition system control.

ON. Permits gas ow into the control body and, under

control of the thermostat, to the pilot and main burners.

Frequency of Maintenance Required:

Cycling Frequency. Appliances that may cycle 20,000

times annually should be checked monthly.

Intermittent Use. Appliances that are used seasonally

should be checked before shutdown and again before

the next use.

Consequence of Unexpected Shutdown. Where the cost

of an unexpected shutdown would be high, the system

should be checked more often.

Dusty, Wet, or Corrosive Environment. Since these types

of environments can cause the gas control to deteriorate

more rapidly, the system should be checked more often.

16

Section III: Service and Maintenance

Filling Steam Jacket

Warning!

After start-up use pure, chloride free, distilled water only

(referred to as “water” in the following text). Do not use

tap water to rell to correct water level.

Appliance failure caused by incorrect water quality is not

covered under warranty.

Allow kettle to cool. Never attempt to add water to a hot

kettle.

Place the thermostat in the o position. Press the rocker

switch to the OFF position. Disconnect power at the

customer supplied electrical cut-o device.

Open the air vent by turning selector screw counter-

clockwise (See Fig. 3.6) until air blows through valve to

release any residual steam contained in the steam jacket

OR open the petcock by turning the lever to vertical (See

Fig. 3.7) to release any residual steam contained in the

steam jacket.

Remove sight glass and place a funnel in the inlet elbow.

Pour water into funnel. Continue adding water until the

Fig. 3.5: Examples of Problem Pilot Flames

C) Identifying Unsatisfactory Pilot Flames

Much can be determined by the appearance of the pilot.

The size, color, shape, sound, and movement of the ame

are all indicators. Refer to the chart below to identify and

correct possible problems.

water in the jacket is visible in the sight glass. DO NOT FILL

BEYOND THE TOP OF THE SIGHT GLASS LEVEL.

Remove funnel, replace sight glass in inlet elbow, securely

turn selector screw on Dole Air Valve clockwise as far as it

will go to return to automatic venting and restore power to

the kettle.

CAUTION: Drain the steam jacket if the kettle is to be stored

in an unheated area. Water freezing in the steam jacket

may cause damage to the unit. Drain is located behind the

control-housing panel.

Fig. 3.7: Filling Steam Jacket - Commercial Units

17

Section III: Service and Maintenance

Safety Relief Valve

Installation Instructions

This valve must be mounted in a vertical, upright position

directly to a clean, tapped opening located at the top of

the equipment. Under no circumstances should there be

a ow restriction or valve of any type between the safety

relief valve and the pressure vessel.

Be certain that all connections - including the valve inlet -

are clean and free from any foreign material.

Use pipe compound sparingly, or tape, on external

threads only.

The Btu/hr or lb/hr rating of the safety valve must equal

that of the equipment to which it is installed.

Warning! The safety relief valve may discharge large

amounts of steam and/or hot water during operation.

Therefore, a discharge line must be installed to reduce

the potential for bodily injury and property damage that:

√ is connected from the valve outlet with no obstructions

and directed downward to a safe point of discharge.

√ allows complete drainage of both the valve and the

discharge line.

√ is independently supported or securely anchored so as

to avoid applied stress on the valve.

√ is as short and straight as possible.

√ terminates freely to atmosphere when any discharge

will be clearly visible and is at no risk of freezing.

√ terminates with a plain end that is not threaded.

√ is constructed of a material suitable for exposure to

temperatures of 375° F or greater.

√ is of a pipe size equal to or greater than that of the valve

outlet over its entire length.

Do not cap, plug, or otherwise obstruct discharge pipe

outlet!

Operating Instructions

DO NOT ALLOW water to ow through a safety relief

valve as sediment or debris may be deposited on seating

surface if adding water to a kettle. Excessive deposits

may prevent the valve from operating properly and a

dangerous pressure buildup and equipment rupture may

result.

Maintenance and Testing

CAUTION! Make certain discharge pipe is properly

connected to valve outlet and arranged to contain and

safely dispose of boiler discharge before testing (see

“Installation Instructions”).

Under normal operating conditions a“try lever test” must

be performed every two months. Under severe service

conditions, or if corrosion and/or deposits are noticed

within the valve body, testing must be performed more

often. A“try lever test”must also be performed at the end

of any non-service period.

Test at or near maximum operating pressure by holding

the test lever fully open for at least 5 seconds to ush the

valve seat free of sediment and debris - then release lever

and permit the valve to snap shut.

If lift lever does not activate, or there is no evidence of

discharge, discontinue use of equipment immediately

and contact a licensed contractor or qualied service

personnel.

18

This manual suits for next models

3

Table of contents

Other AccuTemp Kettle manuals