aci PM2.5-ROOM Installation instructions

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 1

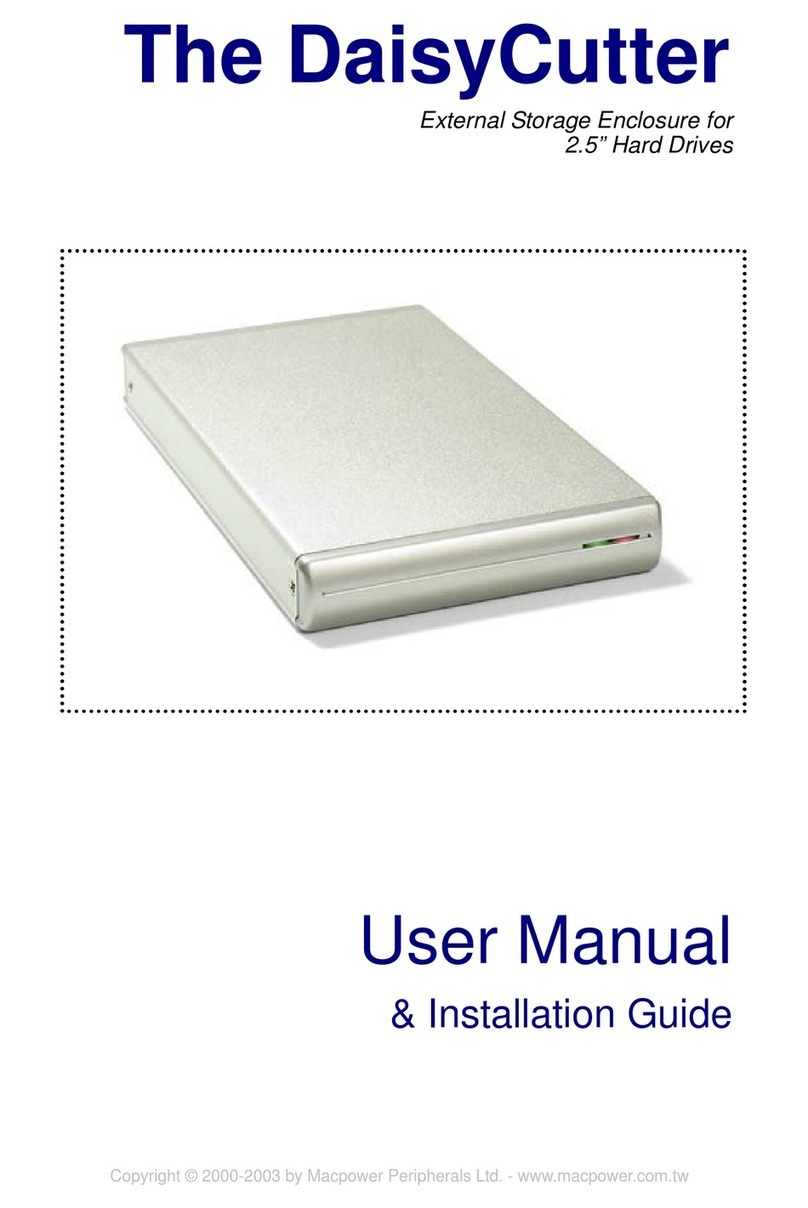

FIGURE 1: ENCLOSURE

DIMENSIONS

PM2.5-ROOM

Installation & Operation Instructions Phone: 1-888-967-5224

Website: workaci.com

GENERAL INFORMATION

“Particulate matter” (PM) is the general term used to

describe solid particles and liquid droplets found in

the air. The PM2.5 series of transmitters are designed

to detect particles less than 2.5 µm in diameter

include smoke, smog, bacteria, ne dust and liquid

droplets, and report the particle concentration of the

monitored environment. The unit utilizes a laser

particulate matter sensor to detect particle sizes

from 0.3 ~ 2.5 µm. The sensor has good long-term

stability with an accuracy 10% reading or 10 µg/m3.

The room unit features eld selectable outputs, 4-20

mA, 0-10 VDC, and Modbus RTU (RS485), relay, and

display.

The sensor has two jumper selectable working

modes for monitoring PM. The Normal Mode

monitors the environment continuously and Auto

Mode reduces the measuring time to extend service

life. The sensor default is set to Auto Mode.

IMPORTANT PRECAUTIONS

• This product uses a laser particulate matter

sensor. It is strictly prohibited to be

disassembled. It is dangerous if the human

body is exposed to the laser directly.

• If the environment exceeds the measurement

range for an extended period, it may lead to a

decrease of the measurement accuracy.

• The performance of the sensor may be

decreased due to excessive dust and oil mist,

etc. in extreme environments. (ie: high

humidity, high temperature)

• Avoid strong light into the housing.

• Avoid vibration.

MOUNTING INSTRUCTIONS

For optimal temperature readings, follow these

tips:

• Avoid air registers, diusers, vents, and

windows

• Avoid conned areas such as shelves, closed

cabinets, closets, and behind curtains.

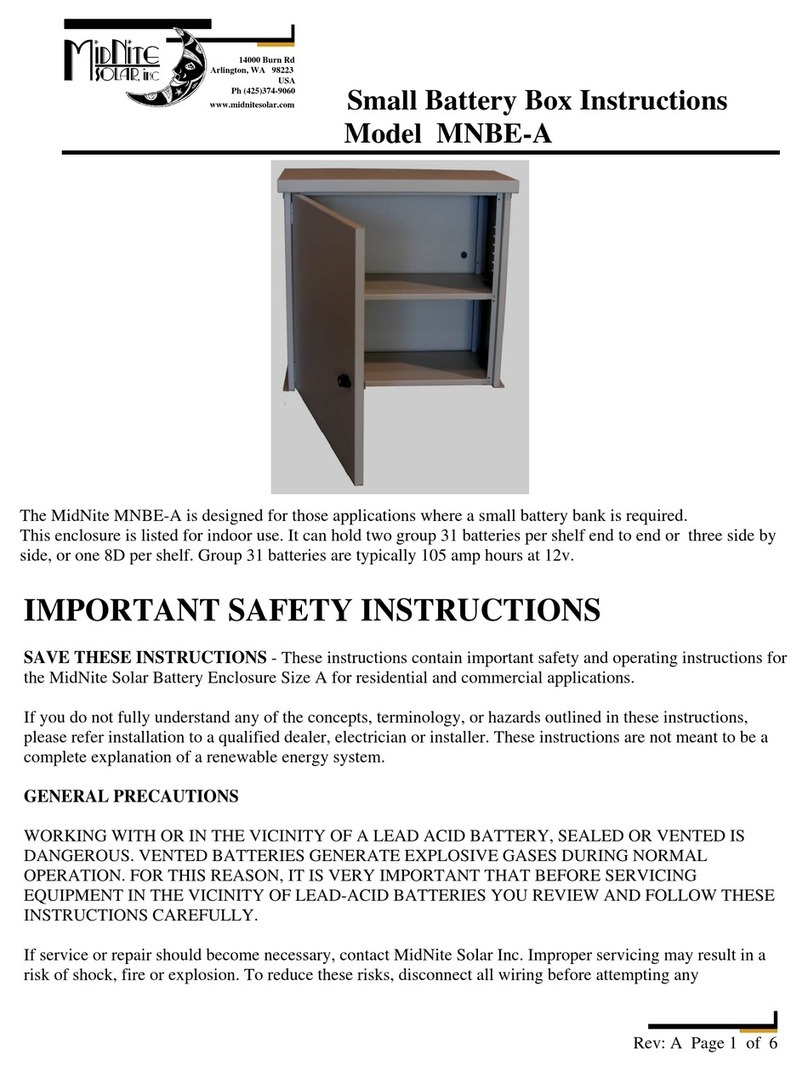

FIGURE 2: OPENING COVER

Separate the cover from the base by inserting a

at head screwdriver into the top slot marked

“OPEN”. Pry the cover forward.

Attach the base directly to the wall or to a

standard 2”x 4”junction box using (2) #6-32 x 1”

screws.

3.268"

(82.00 mm)

1.205"

(30.60 mm)

4.79"

(121.55 mm)

.984"

(25.00 mm)

• Eliminate and seal all wall and conduit

penetrations. Air migration from wall

cavities may alter readings.

• Do not install near heat sources. eg:

lamps, radiators, direct sunlight,

copiers, chimney walls, walls concealing

hot-water pipes

Version: 1.0

I0000941

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 2

FIGURE 3: BACKPLATE

Refer to the wiring instructions to make necessary

connections. After wiring, attach the cover to the

base by snapping the top of the cover on rst and

then the bottom.

Take care when mounting. Check local code for

mounting height requirements. Typical mounting

heights are 48-60”(1.22-1.52m) o the ground and

at least 1.5’(0.5m) from the adjacent wall. The

sensor should be mounted in an area where air

circulation is well mixed, and not blocked by

obstructions.

WIRING INSTRUCTIONS

PRECAUTIONS

• DO NOT RUN THE WIRING IN ANY CONDUIT

WITH LINE VOLTAGE(24/120/230VAC).

• Remove power before wiring. Never

connect or disconnect wiring with power

applied.

• It is recommended that you use an isolated

UL-listed Class 2 transformer when

powering the unit with 24 VAC. Failure to

wire the devices with the correct polarity

when sharing transformers may result in

damage to any device powered by the

shared transformer.

• IF THE 24 VDC OR 24VAC POWER IS SHARED

WITH DEVICES THAT HAVE COILS SUCH AS

RELAYS, SOLENOIDS, OR OTHER

INDUCTORS, EACH COIL MUST HAVE AN

MOV, DC/AC TRANSORB, TRANSIENT

VOLTAGE SUPPRESSOR (ACI PART:

142583), OR DIODE PLACED ACROSS THE

COIL OR INDUCTOR. THE CATHODE, OR

BANDED SIDE OF THE DC TRANSORB OR

DIODE, CONNECTS TO THE POSITIVE SIDE

OF THE POWER SUPPLY. WITHOUT THESE

SNUBBERS, COILS PRODUCE VERY LARGE

VOLTAGE SPIKES WHEN DE-ENERGIZING

THAT CAN CAUSE MALFUNCTION OR

DESTRUCTION OF ELECTRONIC CIRCUITS.

ACI recommends 16 to 26 AWG twisted pair wires

or shielded cable for all transmitters.

ACI recommends using BELDEN 3105 for communi-

cation(Modbus) wiring. This wire has 120 ohm

input impendence.The terminal blocks allow for (1)

or (2) wires to be connected in each position for

daisy chaining. Daisy chain the RS-485 wiring and

do not use “Star” or “T” wiring. Avoid running

communication wires next to AC line voltage wires.

These can be sources of noise that can aect signal

quality.

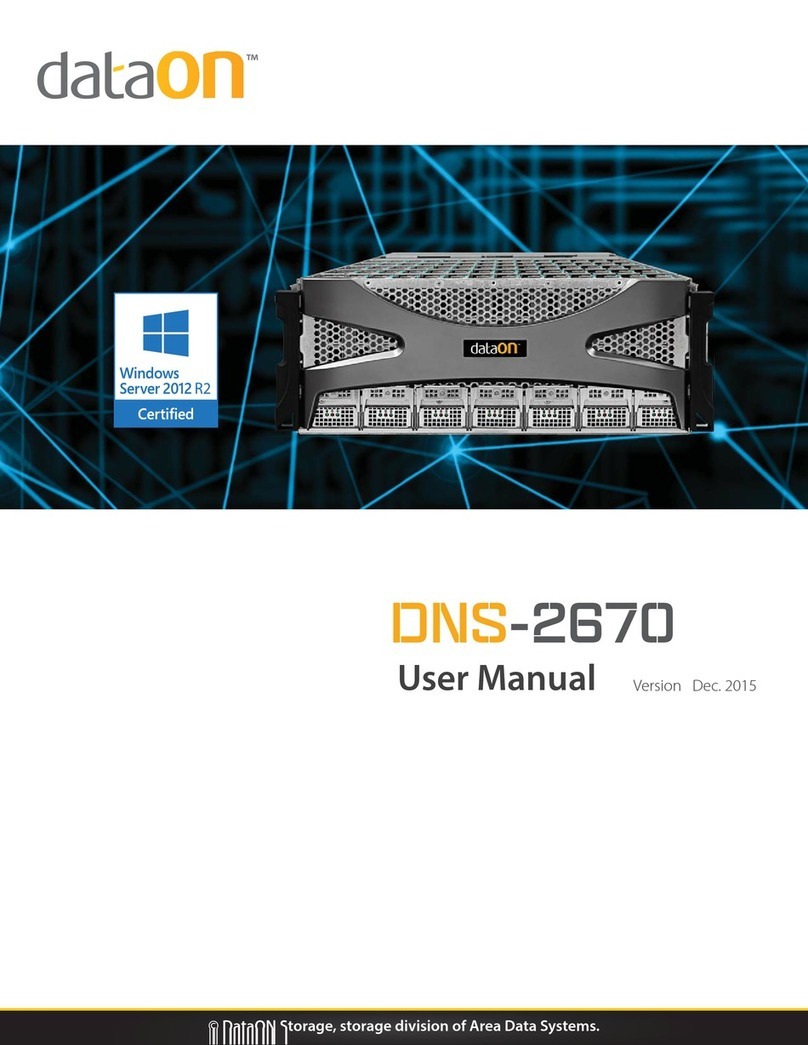

FIGURE 4: WIRING

Note: Dierent models have

dierent electrical terminals.

Terminal 3 is 0-10VDC output

Terminal 4 is 4-20mA output.

POWER SUPPLY

24VDC

24VAC

RS485

Vout mA

A

B

NO

(Normally Open)

Relay Output

C

(Common)

1 2 3 5 94 6 10

Version: 1.0

I0000941

MENU ADJUSTMENTS

1. Button denition

Set/Save Bit Select/decrease Adjust/increase

Users can adjust the parameters.

The backlight of LCD will be o after 30s without any key’s operation.

Note: the LCD will display "----" when the settings are successful, and display "Err" when failed.

2. Operation instruction

Users can adjust transmitter parameters. Push button to enter programming. "P000" will be displayed. Push

button to select the Column and push button to cycle 0-9 settings. Select dierent Codes to enter

corresponding parameter group settings.

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 3

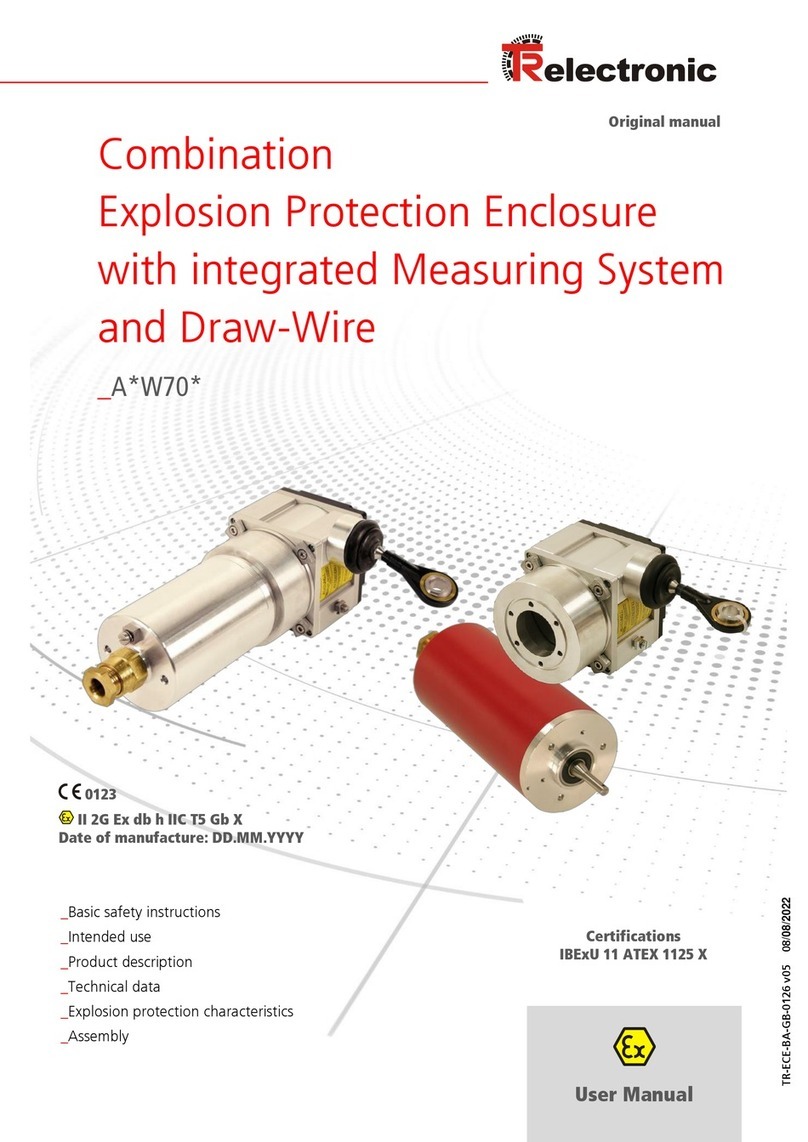

FIGURE 5: MODE SELECTION

MODE SELECTION

There are two working modes, automatic mode (AUTO) and continuous mode (NORMAL). AUTO mode

will automatically reduce the measuring time to extend the service life of the sensor when the dust

concentration changes very slightly. Use MODE jumper to choose the mode. The factory default mode is

AUTO.

Notes:

-P999 Reset: Once entered, rST is displayed. Press button . All factory default settings will be restored.

-P161 1 Point Calibration: The current value is displayed. Press button to increase an oset. Press

button to decrease an oset. The single point oset is shown. After 2 seconds, the new reading(Current

Value + Oset) is shown. Press button to accept changes.

-P401 Relay Settings: Once entered, the current Mode is shown. Followed by Parameter #1, Par. #2, Par.

#3, Par. #4

3. System Error signal

DEVICE CONFIGURATION THROUGH MODBUS RTU

MODBUS RTU INTERFACE

The Modbus Remote Terminal Unit (RTU) data link protocol uses EIA-485 as a two-wire, daisy chain

network. A branch is a discrete chain of devices connected to a controller. The max number of devices per

segment is (32), as per the Modbus specications. 4000 ft (1219.2 m) is the maximum recommended length

for a segment, which includes all devices from the controller to the last device in the daisy chain.

Each branch must have all devices connected with (A) connected to (A) and (B) connected to (B). If a

shielded cable is used, this is not to be connected to the devices. The shield cable should only be

connected on one end to earth ground, usually at the controller.

Each device must be congured for the correct baud rate and have a unique address in each branch. The

baud rate for the branch is set by the controller.

EOL TERMINATION RESISTANCE SELECTION

RS-485 requires that the last device in a chain have a termination resistor. This is controlled using a jumper

in the center and right pins(120 Ω) position marked on FIGURE 7. When the jumper is set to 120 Ω, a 120 Ω

resistance is added in parallel to the data line. When the jumper is set to left and center pins(disabled), the

resistance is not added. By default, the jumper is placed in the disabled position.

A typical Modbus RTU mode message frame is shown below. In the Modbus RTU mode, the messages

between frames are separated by at least 3.5 characters time’s silent interval. If the silent interval between

two characters is more than 3.5 characters time, the former character was transferred successfully, and the

current character’s transmission starts.

ADDRESS SELECTION

Modbus can locate up to 256 dierent addresses, including valid addresses from 1-247. Address 0 is for

broadcast and address 248~255 are reserved for special addresses.

Slave address can be set with compatible Modbus RTU software or via Menu selection(see above for Menu

Adjustments). Default address is 1.

BAUD RATE, DATABITS, PARITY, AND STOPBITS SELECTION

Baud rate is set to 9600, but can also be congured to 4800 via the register or via Menu selection(see above

for Menu Adjustments).

The device that requests information is called the Modbus Master and the devices giving the information

are Modbus Slaves. The Modbus sensors are slave devices and the number of Data Bits needs to be the

same as in the Master device conguration. ACI’s Modbus RTU sensors utilize 8 data bits during

communication exchange.

Parity default setting is NONE. Stopbit default setting is 1. Both settings can adjusted via the register or via

Menu selection(see above for Menu Adjustments).

FUNCTION

The function code is the second data in the frame.Valid function codes are from 0~127 (01H~7FH). See the

relevant Modbus standard. It supports 03H/06H function codes, shown as the following Modbus Poll

software. The detail register addresses are in: 6 General registers table.

BROADCAST MODE TO WRITE DATA TO SLAVE

Using broadcast mode, customer can write data to all slaves connected to the network. Address of

broadcast mode to write data is 0.

For example: change slave address with broadcast mode, customer can set a new slave address. Note: since

this operation will modify all the addresses of the slavers to the same address, it is NOT applicable for

network of more than one slave.

Code

P999

P401

P483

P484

P485

Description

Factory Reset

Relay Settings(see below for sub menu)

RS485 Baud Rate

RS485 Parity

RS485 Address

Default Value

NA

Mode:2

Set Point: 100

Dead Band: 5

On Delay: 3 (S)

O Delay: 1 (S)

9600

0(None)

1

Parameters

(see below for sub menu)

4800, 9600

0(None), 1(Odd), 2(Even)

1-255 (1-32 recommended)

AUTO

MODE

NORMAL AUTO

MODE

NORMAL

SPECIAL MODE TO READ DATA FROM SLAVE

With the special mode, customer can read the register data under the circumstance of NOT knowing the

slave address.

Address of special mode read data: 255(0xFF)

Note: this operation is applicable for ONLY ONE slave in the network.

Version: 1.0

I0000941

MENU ADJUSTMENTS

1. Button denition

Set/Save Bit Select/decrease Adjust/increase

Users can adjust the parameters.

The backlight of LCD will be o after 30s without any key’s operation.

Note: the LCD will display "----" when the settings are successful, and display "Err" when failed.

2. Operation instruction

Users can adjust transmitter parameters. Push button to enter programming. "P000" will be displayed. Push

button to select the Column and push button to cycle 0-9 settings. Select dierent Codes to enter

corresponding parameter group settings.

FIGURE 6: EOL TERMINATION

Relays parameters and descriptions:

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 4

3. System Error signal

DEVICE CONFIGURATION THROUGH MODBUS RTU

MODBUS RTU INTERFACE

The Modbus Remote Terminal Unit (RTU) data link protocol uses EIA-485 as a two-wire, daisy chain

network. A branch is a discrete chain of devices connected to a controller. The max number of devices per

segment is (32), as per the Modbus specications. 4000 ft (1219.2 m) is the maximum recommended length

for a segment, which includes all devices from the controller to the last device in the daisy chain.

Each branch must have all devices connected with (A) connected to (A) and (B) connected to (B). If a

shielded cable is used, this is not to be connected to the devices. The shield cable should only be

connected on one end to earth ground, usually at the controller.

Each device must be congured for the correct baud rate and have a unique address in each branch. The

baud rate for the branch is set by the controller.

EOL TERMINATION RESISTANCE SELECTION

RS-485 requires that the last device in a chain have a termination resistor. This is controlled using a jumper

in the center and right pins(120 Ω) position marked on FIGURE 7. When the jumper is set to 120 Ω, a 120 Ω

resistance is added in parallel to the data line. When the jumper is set to left and center pins(disabled), the

resistance is not added. By default, the jumper is placed in the disabled position.

A typical Modbus RTU mode message frame is shown below. In the Modbus RTU mode, the messages

between frames are separated by at least 3.5 characters time’s silent interval. If the silent interval between

two characters is more than 3.5 characters time, the former character was transferred successfully, and the

current character’s transmission starts.

ADDRESS SELECTION

Modbus can locate up to 256 dierent addresses, including valid addresses from 1-247. Address 0 is for

broadcast and address 248~255 are reserved for special addresses.

Slave address can be set with compatible Modbus RTU software or via Menu selection(see above for Menu

Adjustments). Default address is 1.

BAUD RATE, DATABITS, PARITY, AND STOPBITS SELECTION

Baud rate is set to 9600, but can also be congured to 4800 via the register or via Menu selection(see above

for Menu Adjustments).

The device that requests information is called the Modbus Master and the devices giving the information

are Modbus Slaves. The Modbus sensors are slave devices and the number of Data Bits needs to be the

same as in the Master device conguration. ACI’s Modbus RTU sensors utilize 8 data bits during

communication exchange.

Parity default setting is NONE. Stopbit default setting is 1. Both settings can adjusted via the register or via

Menu selection(see above for Menu Adjustments).

FUNCTION

The function code is the second data in the frame.Valid function codes are from 0~127 (01H~7FH). See the

relevant Modbus standard. It supports 03H/06H function codes, shown as the following Modbus Poll

software. The detail register addresses are in: 6 General registers table.

BROADCAST MODE TO WRITE DATA TO SLAVE

Using broadcast mode, customer can write data to all slaves connected to the network. Address of

broadcast mode to write data is 0.

For example: change slave address with broadcast mode, customer can set a new slave address. Note: since

this operation will modify all the addresses of the slavers to the same address, it is NOT applicable for

network of more than one slave.

ERROR CODE

Err

Er4

POSSIBLE PROBLEMS

Key input error

The sensor’s reading is abnormal

SOLUTION

Input correct code

Check if the sensor is in good connection with the PCB

J8

120Ω

END OF LINE

TERMINATION DISABLED

END OF LINE

TERMINATION ENABLED

J8

120Ω

Mode

0

1

2

3

4

Mode Description

Disable Relay

Activate Relay Below

Set Point

Activate Relay Above

Set Point

Activate Relay Between

High and Low Limits

Activate Relay Outside

High and Low Limits

PARA. #1

N/A

Set Point

Set Point

Low Limit

Low Limit

PARA. #2

N/A

Dead

Band

Dead

Band

High Limit

High Limit

PARA. #3

N/A

Actuate

Delay(S)

Actuate

Delay(S)

Actuate

Delay(S)

Actuate

Delay(S)

PARA. #4

N/A

Restore

Delay(S)

Restore

Delay(S)

Restore

Delay(S)

Restore

Relay(S)

Denition

Relay OFF

Relay ON

Relay ON

Relay OFF

Relay OFFRelay OFF

Low limit High limit

Dead band

Set point

Relay OFF Relay ONDead band

Set point

Relay OFF Relay ONRelay ON

Low limit High limit

SPECIAL MODE TO READ DATA FROM SLAVE

With the special mode, customer can read the register data under the circumstance of NOT knowing the

slave address.

Address of special mode read data: 255(0xFF)

Note: this operation is applicable for ONLY ONE slave in the network.

Version: 1.0

I0000941

MENU ADJUSTMENTS

1. Button denition

Set/Save Bit Select/decrease Adjust/increase

Users can adjust the parameters.

The backlight of LCD will be o after 30s without any key’s operation.

Note: the LCD will display "----" when the settings are successful, and display "Err" when failed.

2. Operation instruction

Users can adjust transmitter parameters. Push button to enter programming. "P000" will be displayed. Push

button to select the Column and push button to cycle 0-9 settings. Select dierent Codes to enter

corresponding parameter group settings.

MODBUS MESSAGE

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 5

CRC Check

16 bits

Data

N x 8 bits

Address

8 bits

Function

8 bits

Start

≥3.5 char

End

≥3.5 char

3. System Error signal

DEVICE CONFIGURATION THROUGH MODBUS RTU

MODBUS RTU INTERFACE

The Modbus Remote Terminal Unit (RTU) data link protocol uses EIA-485 as a two-wire, daisy chain

network. A branch is a discrete chain of devices connected to a controller. The max number of devices per

segment is (32), as per the Modbus specications. 4000 ft (1219.2 m) is the maximum recommended length

for a segment, which includes all devices from the controller to the last device in the daisy chain.

Each branch must have all devices connected with (A) connected to (A) and (B) connected to (B). If a

shielded cable is used, this is not to be connected to the devices. The shield cable should only be

connected on one end to earth ground, usually at the controller.

Each device must be congured for the correct baud rate and have a unique address in each branch. The

baud rate for the branch is set by the controller.

EOL TERMINATION RESISTANCE SELECTION

RS-485 requires that the last device in a chain have a termination resistor. This is controlled using a jumper

in the center and right pins(120 Ω) position marked on FIGURE 7. When the jumper is set to 120 Ω, a 120 Ω

resistance is added in parallel to the data line. When the jumper is set to left and center pins(disabled), the

resistance is not added. By default, the jumper is placed in the disabled position.

A typical Modbus RTU mode message frame is shown below. In the Modbus RTU mode, the messages

between frames are separated by at least 3.5 characters time’s silent interval. If the silent interval between

two characters is more than 3.5 characters time, the former character was transferred successfully, and the

current character’s transmission starts.

ADDRESS SELECTION

Modbus can locate up to 256 dierent addresses, including valid addresses from 1-247. Address 0 is for

broadcast and address 248~255 are reserved for special addresses.

Slave address can be set with compatible Modbus RTU software or via Menu selection(see above for Menu

Adjustments). Default address is 1.

BAUD RATE, DATABITS, PARITY, AND STOPBITS SELECTION

Baud rate is set to 9600, but can also be congured to 4800 via the register or via Menu selection(see above

for Menu Adjustments).

The device that requests information is called the Modbus Master and the devices giving the information

are Modbus Slaves. The Modbus sensors are slave devices and the number of Data Bits needs to be the

same as in the Master device conguration. ACI’s Modbus RTU sensors utilize 8 data bits during

communication exchange.

Parity default setting is NONE. Stopbit default setting is 1. Both settings can adjusted via the register or via

Menu selection(see above for Menu Adjustments).

FUNCTION

The function code is the second data in the frame.Valid function codes are from 0~127 (01H~7FH). See the

relevant Modbus standard. It supports 03H/06H function codes, shown as the following Modbus Poll

software. The detail register addresses are in: 6 General registers table.

BROADCAST MODE TO WRITE DATA TO SLAVE

Using broadcast mode, customer can write data to all slaves connected to the network. Address of

broadcast mode to write data is 0.

For example: change slave address with broadcast mode, customer can set a new slave address. Note: since

this operation will modify all the addresses of the slavers to the same address, it is NOT applicable for

network of more than one slave.

SPECIAL MODE TO READ DATA FROM SLAVE

With the special mode, customer can read the register data under the circumstance of NOT knowing the

slave address.

Address of special mode read data: 255(0xFF)

Note: this operation is applicable for ONLY ONE slave in the network.

Version: 1.0

I0000941

MENU ADJUSTMENTS

1. Button denition

Set/Save Bit Select/decrease Adjust/increase

Users can adjust the parameters.

The backlight of LCD will be o after 30s without any key’s operation.

Note: the LCD will display "----" when the settings are successful, and display "Err" when failed.

2. Operation instruction

Users can adjust transmitter parameters. Push button to enter programming. "P000" will be displayed. Push

button to select the Column and push button to cycle 0-9 settings. Select dierent Codes to enter

corresponding parameter group settings.

Page 5

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 6

3. System Error signal

DEVICE CONFIGURATION THROUGH MODBUS RTU

MODBUS RTU INTERFACE

The Modbus Remote Terminal Unit (RTU) data link protocol uses EIA-485 as a two-wire, daisy chain

network. A branch is a discrete chain of devices connected to a controller. The max number of devices per

segment is (32), as per the Modbus specications. 4000 ft (1219.2 m) is the maximum recommended length

for a segment, which includes all devices from the controller to the last device in the daisy chain.

Each branch must have all devices connected with (A) connected to (A) and (B) connected to (B). If a

shielded cable is used, this is not to be connected to the devices. The shield cable should only be

connected on one end to earth ground, usually at the controller.

Each device must be congured for the correct baud rate and have a unique address in each branch. The

baud rate for the branch is set by the controller.

EOL TERMINATION RESISTANCE SELECTION

RS-485 requires that the last device in a chain have a termination resistor. This is controlled using a jumper

in the center and right pins(120 Ω) position marked on FIGURE 7. When the jumper is set to 120 Ω, a 120 Ω

resistance is added in parallel to the data line. When the jumper is set to left and center pins(disabled), the

resistance is not added. By default, the jumper is placed in the disabled position.

A typical Modbus RTU mode message frame is shown below. In the Modbus RTU mode, the messages

between frames are separated by at least 3.5 characters time’s silent interval. If the silent interval between

two characters is more than 3.5 characters time, the former character was transferred successfully, and the

current character’s transmission starts.

ADDRESS SELECTION

Modbus can locate up to 256 dierent addresses, including valid addresses from 1-247. Address 0 is for

broadcast and address 248~255 are reserved for special addresses.

Slave address can be set with compatible Modbus RTU software or via Menu selection(see above for Menu

Adjustments). Default address is 1.

BAUD RATE, DATABITS, PARITY, AND STOPBITS SELECTION

Baud rate is set to 9600, but can also be congured to 4800 via the register or via Menu selection(see above

for Menu Adjustments).

The device that requests information is called the Modbus Master and the devices giving the information

are Modbus Slaves. The Modbus sensors are slave devices and the number of Data Bits needs to be the

same as in the Master device conguration. ACI’s Modbus RTU sensors utilize 8 data bits during

communication exchange.

Parity default setting is NONE. Stopbit default setting is 1. Both settings can adjusted via the register or via

Menu selection(see above for Menu Adjustments).

FUNCTION

The function code is the second data in the frame.Valid function codes are from 0~127 (01H~7FH). See the

relevant Modbus standard. It supports 03H/06H function codes, shown as the following Modbus Poll

software. The detail register addresses are in: 6 General registers table.

BROADCAST MODE TO WRITE DATA TO SLAVE

Using broadcast mode, customer can write data to all slaves connected to the network. Address of

broadcast mode to write data is 0.

For example: change slave address with broadcast mode, customer can set a new slave address. Note: since

this operation will modify all the addresses of the slavers to the same address, it is NOT applicable for

network of more than one slave.

Register Address

40001, 00000

40002, 00001

40003, 00002

……

40014, 00013

……

40016, 00015

40017, 00016

40018, 00017

40019, 00018

40020, 00019

40021, 00020

40022, 00021

……

40029, 00028

40030, 00029

R/W

R

R

R

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

Type

Signed

Signed

Signed

Signed

Signed

Signed

Signed

Signed

Signed

Signed

Signed

Signed

Signed

Denition

Product code

PM2.5 Value

PM10 Value

RS485-Modbus RTU slave address

Function register

Relay Control Mode

Back up

Set point (mode 1 or 2) low limit

(mode 3 or 4) regional

Dead band (mode 1 or 2) high

limit(mode 3 or 4)

Start delay

Stop delay

Baud rate

Parity

Remarks

PM series Product code: 9070

PM2.5 = Value , ug/m³

PM10 = Value , ug/m³

Default slave address =1, (RTU,9600,n,8,1)

Write 40016=21845 to reset to factory

default setting

0: O

1: Relay activated Below the set point.

2: Relay activated Higher than set point.

3: Relay activated in the set range

4: Relay activated outside the set range

Relay control parameters set

Baud rate: 9600(default) or 4800

Parity : 0: NONE, 1: ODD, 2: EVEN

Note: 1. 40001 is PLC mode ADDRESS (BASE 1); 00000 is PROTOCOL ADDRESS (BASE 0).

2. Function register 40016: Use the 06 function code to write password (21845) to the register 40016 to

return to the factory set.

MODBUS RTU

SPECIAL MODE TO READ DATA FROM SLAVE

With the special mode, customer can read the register data under the circumstance of NOT knowing the

slave address.

Address of special mode read data: 255(0xFF)

Note: this operation is applicable for ONLY ONE slave in the network.

Version: 1.0

I0000941

Page 6

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 7

WARRANTY

The ACI PM Room Series are covered by ACI’sTwo (2)Year Limited Warranty, which is located in the front of ACI’S

SENSORS & TRANSMITTERS CATALOG or can be found on ACI’s web site: www.workaci.com.

W.E.E.E. DIRECTIVE

At the end of their useful life the packaging and product should be disposed of via a suitable recycling

centre. Do not dispose of with household waste. Do not burn.

PRODUCT SPECIFICATIONS

16-28VAC/16-35VDC (Reverse Polarity Protection)

4-20 mA: 500 Ohms maximum | 0-10 VDC: 2K Ohms Minimum

0~500μ g/m3

4-20mA(Default), 0-10VDC

N.O. rated 3A @ 30VDC, 3A @250VAC

100μ g/m3

+/-10μg/m3 @ 0~100μg/m3, +/-10% reading @

100~500/600µg/m3@25°C/50%RH

1 μg/m3

In continuous service mode, sample time <1s, response time <10s

15 minutes

MTBF more than 3 years in continuous service mode, service life up to 8-10

years in auto (intermittent)

service mode

Modbus RTU; EIA RS-485

1-247

4800 or 9600

None/Even/Odd

1

8

Screw Terminal Blocks / 16 AWG (1.31 mm2) to 22 AWG (0.33 mm2)

0.45 lbf-in (0.5 Nm) nominal

32 to 122°F (0 to 50°C)

-30 to 70°F (-34 to 21°C)

10 to 95% RH, non-condensing

IP30

ABS Plastic / UL94V-0

Supply Voltage:

Output Load Resistance:

Measurement Range:

Output:

Relay:

Relay Trip Point:

Accuracy:

Resolution:

Response Time:

Warm Up Time:

Service Life:

Communication Protocol:

Sensor Addresses:

Supported Baud Rates:

Parity:

Stop Bits:

Databits:

Connections / Wire Size:

Terminal Block Torque Rating:

Operating Temperature Range:

Storage Temperature Range:

Operating Humidity Range:

Enclosure Protection:

Enclosure Material / UL Flammability:

Version: 1.0

I0000941

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 8

Automation Components, Inc.

2305 Pleasant View Road

Middleton, WI 53562

Phone: 1-888-967-5224

Website: workaci.com

Page 7

Version: 1.0

I0000941

Table of contents