Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 2

Version: 6.0

I0000647

FIGURE 3: SENSOR PROBE/

ENCLOSURE REMOVAL

Note: The mounting bracket can be removed from

the shield if needed for easier access. Loosen the

two Phillip screws holding the probe retaining clip

until the sensor probe/enclosure is loose enough

to remove as shown in Figure 3.

• Finger tighten the assembly around the

mounting pole. With a level, make sure the solar

radiation shield is level, and tighten the hex nuts

with a wrench.

Surface Mounting

• Loosen the two Phillip screws holding the probe

retaining clip until the sensor probe/enclosure is

loose enough to remove as shown in Figure 3.

• Attach the mounting bracket directly to the wall

or post(Hardware not included).

• Slide the sensor probe/enclosure back into the

shield. Tighten the two Phillip screws holding

the probe retaining clip until the sensor probe/

enclosure is tight.

Install the PG11 watertight tting supplied

with the sensor if not using conduit. The outer

knockout ring (PG 11/16) on housing should not

be removed when using a ½" NPT conduit tting.

The 4X enclosure has (4) screws. Conrm gasketed

cover is fastened securely in order to prevent any

moisture being introduced into housing.

Refer to Wiring Instructions) to make necessary

connections.

WIRING INSTRUCTIONS

PRECAUTIONS

• Remove power before wiring. Never connect

or disconnect wiring with power applied.

• When using a shielded cable, ground the

shield only at the controller end. Grounding

both ends can cause a ground loop.

• Do not run the temperature sensor wiring in

any conduit with line voltage (24/120/230

VAC) if utilizing resistance temperature signal.

• It is recommended you use an isolated UL-

listed class 2 transformer when powering the

unit with 24 VAC. Failure to wire the devices

with the correct polarity when sharing

transformers may result in damage to any

device powered by the shared transformer.

• If the 24 VDC or 24VAC power is shared

with devices that have coils such as relays,

solenoids, or other inductors, each coil must

have an MOV, DC/AC Transorb, Transient

Voltage Suppressor (ACI Part: 142583), or

diode placed across the coil or inductor. The

cathode, or banded side of the DC Transorb

or diode, connects to the positive side of the

power supply. Without these snubbers, coils

produce very large voltage spikes when de-

energizing that can cause malfunction or

destruction of electronic circuits.

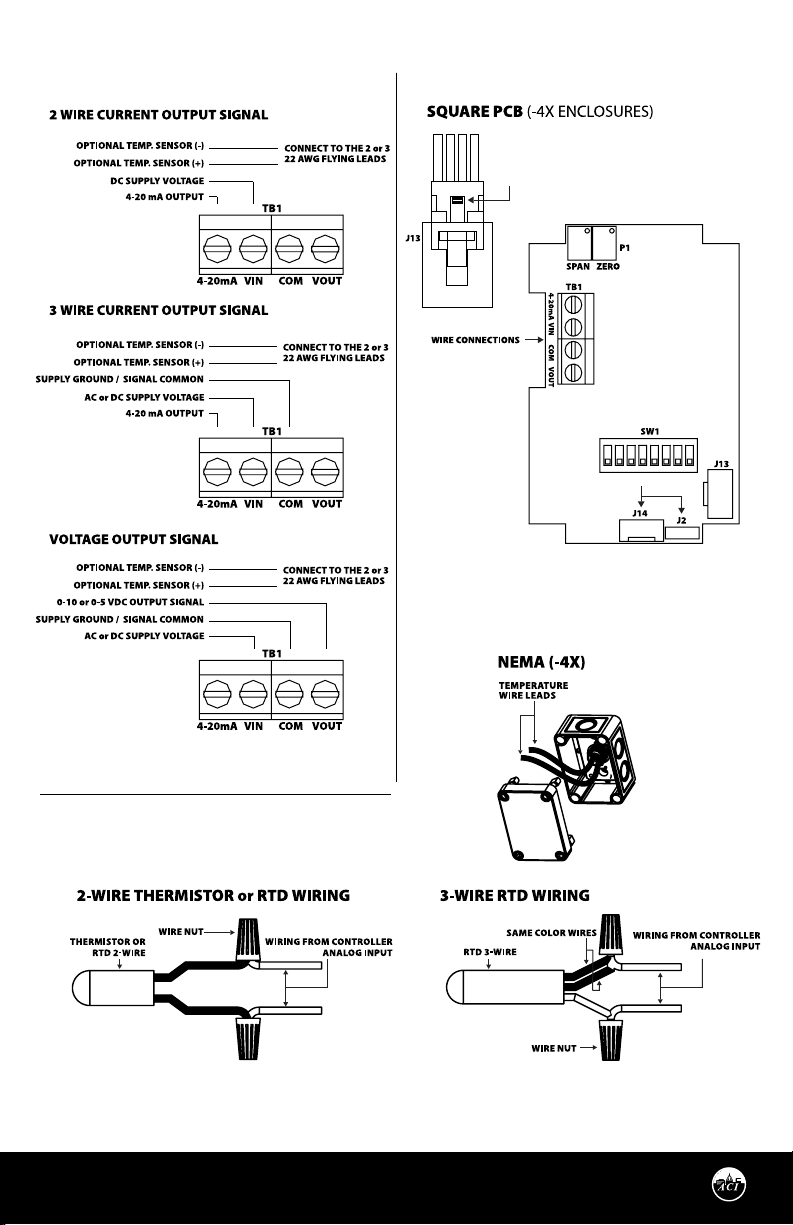

RELATIVE HUMIDITY WIRING

INSTRUCTIONS

Open the cover of the enclosure. ACI recommends

16 to 26 AWG twisted pair wires or shielded cable

for all transmitters. Twisted pair may be used for

2-wire current output transmitters or 3-wire for

voltage output. Refer to FIGURE 4 (p. 3) or wiring

diagrams.

TEMPERATURE WIRING INSTRUCTIONS

ACI recommends 16 to 26 AWG twisted pair wires

or shielded cable for all temperature sensors.

ACI recommends a separate cable be pulled for

Temperature signal only. Temperature Signal

wiring must be run separate from low and high

voltage wires (24/120/230VAC). All ACI thermistors

and RTD temperature sensors are both non-

polarity and non-position sensitive.

All thermistor type units are supplied with (2)

ying lead wires, and all RTD’s are supplied with

(2) or (3) ying lead wires – see FIGURE 6 (p. 3).