Page 4

POWERING TECHNOLOGY

Manual No. sli-15-5 sli15-man-rev5-0718.indd

FIGURES

Figure 1-1 Input Current Absorption .............................................................................................................5

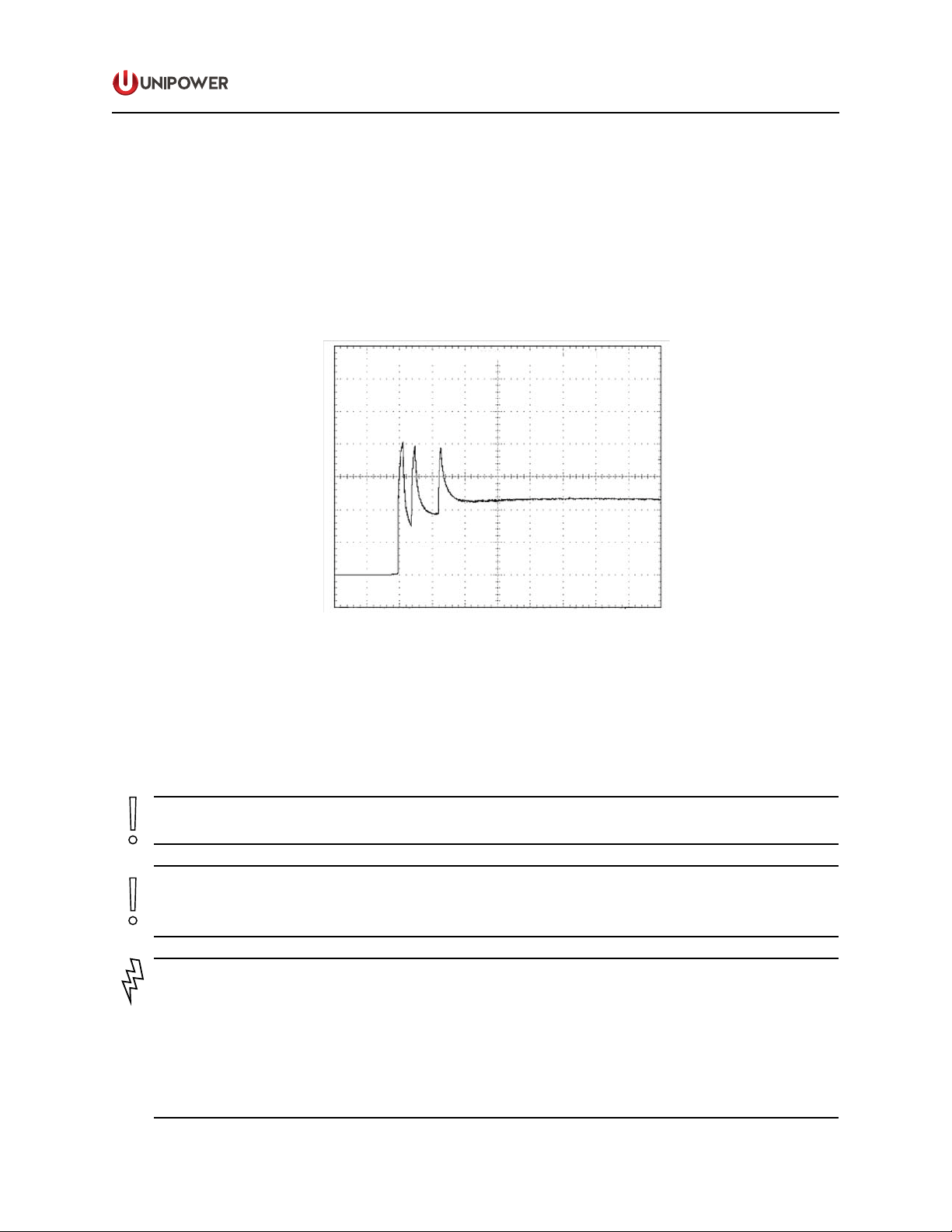

Figure 1-2 Input Breaker Delay .....................................................................................................................6

Figure 4-1 Fitting Mounting Brackets .........................................................................................................10

Figure 4-2 Mounting Dimensions................................................................................................................11

Figure 4-3 Rear View...................................................................................................................................11

Figure 4-4 Input Connection Bus Bars ........................................................................................................11

Figure 4-5 DC Input Clips in sub-rack ........................................................................................................12

Figure 4-6 Plug Connections .......................................................................................................................12

Figure 4-7 Screw Terminal Connections .....................................................................................................12

Figure 4-8 AC Output Connections for n-inverters in parallel conguration - plug connectors .................13

Figure 4-9 AC Output Connections for n-inverters in parallel conguration - screw terminals .................13

Figure 4-10 AC grid input connections for parallel conguration - plug connectors..................................14

Figure 4-11 AC grid input connections for parallel conguration - screw terminals ..................................14

Figure 4-12 Signal Connector Type .............................................................................................................15

Figure 4-13 Parallel Conguration Signal Connections ..............................................................................16

Figure 4-14 Parallel Adapter for Standalone Units......................................................................................17

Figure 4-15 Parallel Adapter for Hot-Plug Units.........................................................................................18

Figure 4-16 Signal Connections for 3-phase Y Output Conguration.........................................................19

Figure 5-1 Front Panel Display/Touch Pad..................................................................................................27

Figure 5-2 Startup and Status Menu ............................................................................................................29

Figure 5-3 Main Menu Structure .................................................................................................................30

Figure 5-4 Settings Menu Navigation..........................................................................................................32

Figure 5-5 Settings Menu Structure.............................................................................................................33

Figure 5-6 Protections Sub-menu Structure.................................................................................................36

Figure 5-7 Transfer Switch Sub-menu Structure .........................................................................................37

Figure 5-8 STS Voltage Mask......................................................................................................................38

Figure 5-9 STATUS Menu ...........................................................................................................................40

Figure 5-10 INFO Menu ..............................................................................................................................41

Figure B-1 Manual Bypass Scematic...........................................................................................................44

Figure C-1 Grounding of Neutral for Inverters with Transfer Switch .........................................................46

Figure C-1 SERVICE sub-menu structure ...................................................................................................47

Figure F-1 SLI to ACX Translator Connectors............................................................................................51

Figure F-2 Typical System Schematic .........................................................................................................53

TABLES

Table 4-1 Signal Description .......................................................................................................................15

Table 5-1 Front Panel LED Status Indications ............................................................................................28

Table A-1 Input Requirements .....................................................................................................................43

Table A-2 Input Wire Size............................................................................................................................43

Table C-1 Grounding Restrictions ...............................................................................................................46

Table E-1 Factory Settings...........................................................................................................................49

Table F-1 SLI to ACX Translator Signal Connections ................................................................................51

Table F-2 SLI to ACX Translator Power Connections ................................................................................52