2 3

SAFETY INFORMATION

• Always follow vehicle manufacturer recommendations for snowplowing.

• Always exercise safety, courtesy and common sense.

• Always know the terrain before plowing.

• Always wear your seat belt.

• Always look where you are going when backing up, don't rely on mirrors or back up

cameras.

• Always plow snow during low-trac hours.

• Always be cautious of pedestrians and vehicles.

• Always be aware of engine temperature, avoid overheating.

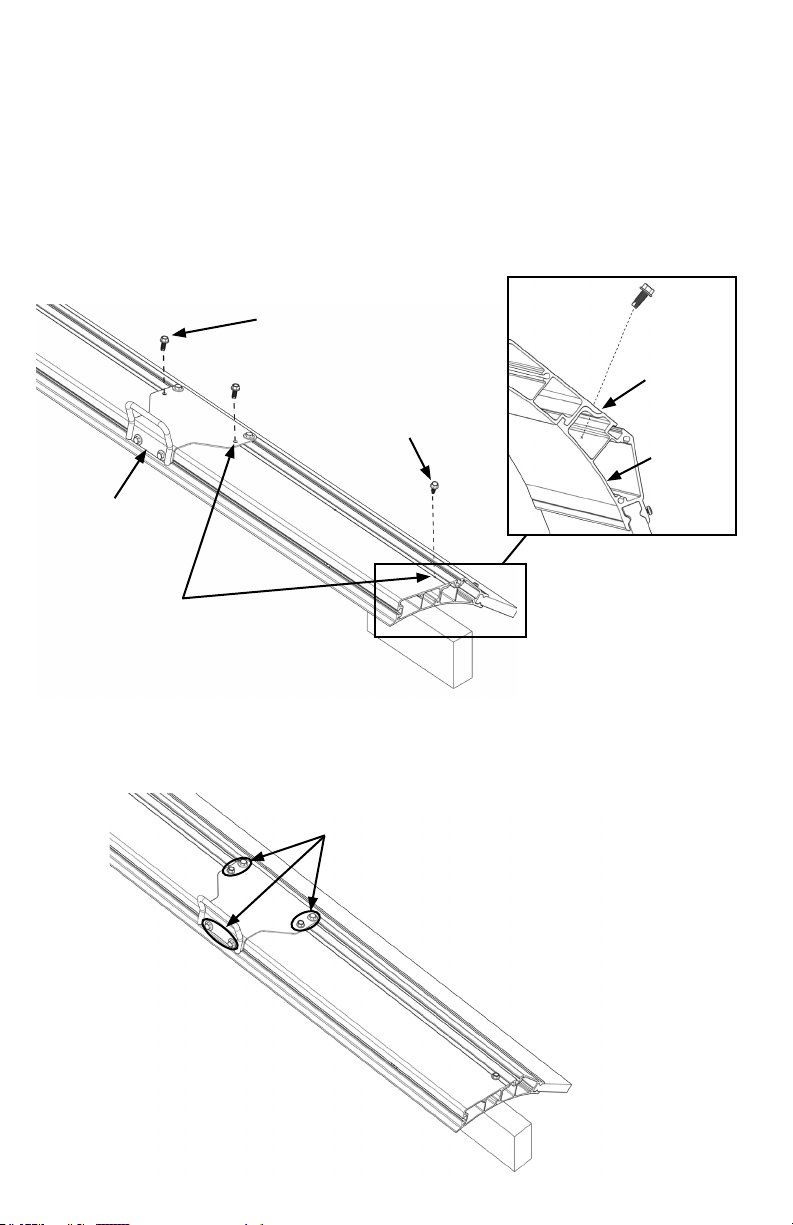

• Always transport blade in retainer grooves secured by quick pins.

• Always use lowest transmission gear, on 4WD select low range if equipped.

• Always drive straight with blade set to center postition when creating piles as angled

may cause damage to plow or vehicle.

• Never overload your plow or vehicle, snow depth and water content determines

amount of snow to be cleared per pass.

• Never plow snow with your head/body parts out of the window, an unexpected

sudden stop could result in personal injury.

• Never exceed 65 MPH when transporting plow.

• Never exceed 10 MPH when plowing.

• Never pile snow where it obstructs visibility of trac.

• Never pile snow near handicapped or parking areas.

• Never pile snow on someone else’s property, streets, sidewalks, mail boxes, water

drains, electrical boxes or by re hydrants.

• Periodically inspect hardware and components, perform maintenance as required.

SNOWPLOWING TIPS

• Check local regulations before plowing snow.

• Mark or remove any potential hazards in plowing area as they can be easily covered

by snow and forgotten.

• If blade is kept in warm storage, cooling outside prior to plowing prevents snow from

freezing to blade.

• For gravel surfaces, we recommend packing the snow by making several passes with

blade up to help prevent movement of loose rock when pushing snow.

• Start a pass by accelerating slowly to allow for tire traction and blade to accumulate

snow.

• Amount of snow to be cleared eciently per pass is determined by snow depth and

water content, adjust the width of each pass and plow more often during continuous

snowfalls.

• As you come to the end of a pass, reduce speed and apply brakes as needed.

• When creating piles, drive straight with the blade set to center position.

• To stack snow on hardened piles, start a new pile then push onto existing snow bank.

• Ensure to push snow far enough for future snowfall.

• Wet snow can compact and freeze which requires chipping to break loose before

attempting to move.