ACORN AQUA A112408B/S-VR-UBL Manual

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

Vandal Resistant Refrigerated Universal Bi-Level AquaAccess

Barrier Free, Wall Mounted Water Cooler

A112408B/S-VR-UBL

1.800.591.9360

Technical Assistance Fax: 1.626.855.4894

TECHNICAL ASSISTANCE TOLL FREE TELEPHONE NUMBER:

ACORN AQUA

P.O. Box 3527

City of Industry, CA 91744-0527

United States of America

www.acornaqua.com

Page 1 of 8

NOTES TO INSTALLER:

1. Please leave this documentation with the owner of the fixture when finished.

2. Please read this entire booklet before beginning the installation.

3. Check your installation for compliance with plumbing, electrical and other applicable

codes.

LIMITED WARRANTY - UNITED STATES & CANADA

Acorn Aqua warrants that its products are free from defects in material or workmanship under normal use and

service for a period of one year from date of original shipment or for 18 months after the date of shipment from the

factory, whichever comes first. The compressor, condenser and refrigeration tubing is warranted for five years.

Acorn’s liability under this warranty shall be discharged solely by replacement or repair of defective material,

provided Acorn is notified in writing within one year from date of shipment, F.O.B. Industry, California.

This warranty does not cover installation or labor charges and does not apply to materials, which have been

damaged by other causes such as mishandling or improper care or abnormal use. The repair or replacement of the

defective materials shall constitute the sole remedy of the Buyer and the sole remedy of Acorn under this warranty.

Acorn shall not be liable under any circumstances for incidental, consequential or direct charges caused by defects

in the materials, or any delay in the repair or replacement thereof. This warranty is in lieu of all other warranties

expressed or implied. Product maintenance instructions are issued with each unit and disregard or non-compliance

with these instructions will constitute an abnormal use condition and void the warranty. Stainless steel must be

protected on jobsite during construction and must be properly maintained after the water has been introduced

into the water cooler or drinking fountain, or Acorn’s limited warranty is void.

LIMITED EXPORT WARRANTY - One year on parts only.

L1001134 Revised: 09/07/11

OR

Standard ConfigurationAlternate Configuration

Page 2 of 8

IMPORTANT

This fixture is intended to dispense water that has been lowered in temperature, but otherwise remains

unchanged by the materials in the water cooler. It is common for electrical equipment to be grounded to

water lines either within a structure or away from it. Every attempt should be made to prevent this kind

of grounding from generating electrical feedback into the water cooler creating electrolysis. Electrolysis

will cause a metallic taste or cause water metal content to increase.

NOTICE

A dielectric coupling must be used to connect the water cooler to the water supply. A nonmetallic

coupler is furnished with this water cooler to meet this requirement.

ROUGHING-IN AND DIMENSIONAL DRAWING

Prior to roughing consult with local, state, and federal codes for proper mounting height.

NOTES:

1. Dimensions shown for ADA compliant installation. For Child ADA 2010 compliant parallel approach

installation, decrease height of * dimensions by 2-3/4".

2. Provide clear floor space as required. Adjust vertical dimensions as required to comply with federal,

state, and local codes.

See next page for alternative mounting of units, roughing-in and dimensional drawing.

A112408S/B-VR VANDAL RESISTANT REFRIGERATED UNIVERSAL BI-LEVEL AQUAACCESS

(Standard Configuration Left Unit High with Right Unit Low)

AIR FLOW

GENERAL NOTES:

ALL DIMENSIONS ARE IN INCHES [MM]

ALLOW 4 INCHES [102 MM] MINIMUM CLEARANCE PER SIDE FOR VENTILATION

DIMENSIONS SHOWN ARE FOR RECOMMENDED ADULT HEIGHT. ADJUST VERTICAL

DIMENSIONS AS NECESSARY TO COMPLY WITH FEDERAL, STATE, & LOCAL CODES.

STOP VALVE, TRAP, & ELECTRICAL OUTLET NOT SUPPLIED.

IMPORTANT: COOLERS MUST BE ATTACHED TO WALL WITH ANCHOR SCREWS.

1.

2.

*3.

4.

5.

Ø3/8" [10] O.D. COPPER TUBE SUPPLY

ELECTRICAL OUTLET

Ø1-1/4" [32] O.D. P-TRAP (NOT FURNISHED)

A

B

C

181

2"

[470]

*375

8"

[956]

RIM

HEIGHT

*315

8"

[803]

RIM

HEIGHT

*383

4"

[984]

ORIFICE

*323

4"

[832]

ORIFICE *207

8"

[530]

TAILPIECE

65

8"

[168]

65

8"

[168]

181

2"

[470]

185

8"

[473]

41

4"

[108]

77

8"

[200]

77

8"

[200]

*155

8"

[397]

*291

8"

[740]

*351

8"

[892]

*215

8"

[549] *163

8"

[416]

*217

8"

[555]

51

4"

[133]

61

2" [165]

C

A

B

Ø1

4" [6]

4 ANCHOR

HOLES

Ø3

8" [10]

3 HOLES

EACH

BRACKET

Page 3 of 8

A112408S/B-VR VANDAL RESISTANT REFRIGERATED UNIVERSAL BI-LEVEL AQUAACCESS

(Alernate Configuration Left Unit Low with Right Unit High)

AIR FLOW

181

2"

[470]

*375

8"

[956]

RIM

HEIGHT

*315

8"

[803]

RIM

HEIGHT

*383

4"

[984]

ORIFICE

HEIGHT

*323

4"

[832]

ORIFICE

HEIGHT

65

8"

[168]

65

8"

[168]

181

2"

[470]

185

8"

[473]

41

4"

[108]

77

8"

[200]

77

8"

[200]

*155

8"

[397]

*291

8"

[740]

*207

8"

[530]

TAILPIECE

*351

8"

[892]

*215

8"

[549]

51

4"

[133]

61

2"

[165]

*223

8"

[568]

*277

8"

[708]

GENERAL NOTES:

ALL DIMENSIONS ARE IN INCHES [MM]

ALLOW 4 INCHES [102 MM] MINIMUM CLEARANCE PER SIDE FOR VENTILATION

DIMENSIONS SHOWN ARE FOR RECOMMENDED ADULT HEIGHT. ADJUST VERTICAL

DIMENSIONS AS NECESSARY TO COMPLY WITH FEDERAL, STATE, & LOCAL CODES.

STOP VALVE, TRAP, & ELECTRICAL OUTLET NOT SUPPLIED.

IMPORTANT: COOLERS MUST BE ATTACHED TO WALL WITH ANCHOR SCREWS.

1.

2.

*3.

4.

5.

C

B

A

Ø3/8" [10] O.D. COPPER TUBE SUPPLY

ELECTRICAL OUTLET

Ø1-1/4" [32] O.D. P-TRAP (NOT FURNISHED)

A

B

C

Ø3

8" [10]

3 HOLES

EACH

BRACKET

Ø1

4" [6]

4 ANCHOR

HOLES

IMPORTANT:

1. Waste P-Trap, Water Supply Service Angle Stop Valve and 2” x 4” Electrical Plug-In Receptacle

to be supplied by others in accordance with local codes. A metallic p-trap (by others) must be

used for the drain connection.

2. Provide 4” minimum clear space on fixture sides to allow for proper ventilation through cabinet

louvers.

3. Water supply is 3/8” Outside Diameter copper tube. Waste is 1-1/4” Outside Diameter.

4. Completely flush supply lines of all foreign debris before connecting to fixture. Water cooler

designed to not affect taste, odor, color, or sediment. Optional water filter (Wf1) is available should

any of these problems arise from the water supply.

5. Do NOT solder copper tube when inserted into the coupler as damage to the o-ring will result.

6. All burrs must be removed from outside of cut tubes before inserting into coupler or other

components.

7. Power supply must be identical in voltage, cycle and phase to that specified on the cooler data

plate. Electrical outlet and furnished power cord with plug must be used to supply power to

fixture. Do NOT wire compressor directly to the power supply.

8. This unit must be grounded per the requirements of applicable electrical codes.

9. WARNING: Warranty is voided if installation is not made following current Acorn Aqua

installation instructions and if components are assembled to the fixture that is not approved by

Acorn Aqua.

10. Fixture operates within water pressure range of 20 to 105 psig. Acorn Aqua will not warranty

fixtures damaged when connected to supply lines with flow pressure lower than 20 psig or

higher than 105 psig. A pressure regulator must be furnished by others on supply line if inlet

pressure is greater than 105 psig.

11. Due to cold waste water, Acorn Aqua recommends that p-trap supplied by installer be insulated

to prevent excessive condensation.

12. Per UPC 609.10- All building water supply systems in which quick acting valves are installed

shall be provided with devices to absorb the hammer caused by high pressure resulting from the

quick closing of the valve. These pressure-absorbing devices shall be approved mechanical

devices. Water pressure-absorbing devices will be installed as close as possible to the quick

closing valve.

INSTALLATION:

Choose configuration; Remove and reinstall filler plate, item 30 , reverse drain assembly

if required for alternate mounting configuration.

1. Mount hanger bracket to wall horizontally level as shown in Roughing-In and Dimensional Drawing.

Note: Adjust height of bracket if bubbler outlet height is required to vary from that shown.

WARNING: Hanger Bracket MUST be securely anchored to wall with fasteners sufficient to support

3 times the weight of cooler. If wall can not provide adequate support, order and install optional

fixture support carrier.

2. Remove the bottom cover from the water cooler and set aside in a safe place. Save the screws

in a secure location for re-use in later stages of installation.

3.

START UP:

1. Before connecting power supply and assembling bottom cover to water cooler, but after thoroughly

flushing the supply line and connecting it to the fixture, turn on building water supply and check all

connections for leaks.

2. Air within the water cooler system or the structure supply piping will cause an irregular bubbler

outlet stream until purged out by incoming water. Covering the bubbler with a clean cup (or

similar object) is recommended when first activating water cooler to prevent excessive splashing.

Depress the pushbutton until steady water stream is achieved.

3. If water flow requires adjustment, insert a slotted narrow blade screwdriver through the hole

centered on the pushbutton to the flow regulator. Turning clockwise will increase flow and turning

counterclockwise will decrease flow.

4. Recheck all water and drain connections with water flowing through system.

5. With power still NOT connected, carefully manually rotate cooling fan to insure proper clearance

and free fan action.

6. Plug water cooler in to electrical outlet and make sure unit begins to function.

7. Assemble bottom cover to water cooler with screws furnished.

Hang the water coolers on the hanger brackets ensuring the bracket tabs engage AND seat in the

slots in the back of the water coolers. Note: Hanging of refrigerated unit first is recommended since

it is the heavier of the two. Verify water coolers are level, left to right AND front to back from bottom

of unit.

Caution: The bubbler stream may be adversely affected if units are not square and level. Bottom of

units and louvers should be used as reference to verify unit is square and plumb.

4. Anchor the water coolers to the wall at the lower mounting points in each back panel. Shim lower

mounting points to level unit if necessary.

5. Outlet tube from evaporator has an in-line tee with a tube going to refrigerated unit's valve and the

"TEE" not connected. Connect the loose supply tube from refrigerated unit to the "TEE".

6. Thoroughly flush the 3/8” O.D. supply line and then connect water cooler to water supply angle

stop valve (by others) with supplied 3/8” O.D. copper tube.

7. Use supplied flexible hose and clamps to connect waste tailpiece from upper unit to waste tailpiece

of lower unit and then make up 1-1/4” O.D. p-trap waste connection. Waste p-trap by others.

Page 4 of 8

STANDARD WASTE CONFIGURATION ALTERNATE WASTE CONFIGURATION

ITEM 30

FILLER PLATE

ITEM 30

FILLER PLATE

Page 5 of 8

TROUBLE SHOOTING:

IMPORTANT: BEFORE MAKING ANY OF THE REPAIRS LISTED, MAKE SURE THE WATER

COOLER IS DISCONNECTED FROM THE ELECTRICAL SUPPLY AND THE WATER SUPPLY

VALVE IS SHUT OFF.

1. Adjustments

a. Cartridge – The water flow can be adjusted through the pushbutton using a straight blade

screwdriver and turning clockwise to increase flow and counterclockwise to decrease flow.

b. Cold Water Thermostat – The water temperature can be adjusted using a slotted screwdriver and

turning clockwise to make colder and counterclockwise to make

warmer.

c. Bubbler Stream – Bubbler can be rotated slightly to direct the stream backwards or forwards. Adjust

the stream to minimize splashing. Splashing may occur from bubbler stream if the unit is not level.

Shim lower mounting points, if necessary, to level cooler.

2. Compressor Does Not Run

a. Check the electrical receptacle for power and correct voltage. The incoming voltage must be within

10% of the rated voltage on the serial nameplate.

b. The cold thermostat is accessible by removing the bottom access cover. If the cold thermostat

capillary bulb loses its charge or becomes kinked it will fail in the open position causing a disruption

of power to the compressor. Unplug the water cooler and using and ohm meter check for continuity

across the two electrical terminals on the

thermostat. Install a new thermostat if there is no continuity.

c. Check for loose wires within the compressor box. The incoming power leads must be connected to

the overload and relay.

d. If all components check positive for continuity then test the wiring harness plug for continuity to see

if there is a broken wire within the wiring harness insulation.

3. Compressor Runs – Water Is Warm

a. The most common cause for a water cooler to run without producing cold water is a loss of

refrigerant. The water cooler must be taken to a certified refrigerant technician for repairs.

b. Make sure the condenser fan motor is operative. The fan blade must turn freely to help remove the

heat of compression.

c. An incorrect refrigerant charge, restriction or defective compressor (not pumping) will also cause

the compressor to run without producing cold water. All these signs indicate a problem within the

refrigeration system and the water cooler must be checked by an authorized service company.

4. Compressor Cycling On Overload Protector

a. A dirty condenser or a blocked fan will cause a high head pressure and frequent cycling of the

overload protector.

b. Check the incoming voltage to make sure it is within 10% of the serial nameplate rating.

c. A restriction or moisture in the system will also cause intermittent cycling. A certified refrigeration

mechanic should be contacted in this situation.

d. Change the overload or relay if defective.

5. Noisy Operation

a. Check to make sure the fan blade is rotating freely.

b. Make sure the water cooler is correctly mounted to the wall. Absence of the two lower mounting

bolts may cause excess noise and vibration.

c. Check the compressor mounting to make sure the pins and clips are not rattling. If the compressor

appears to be noisy internally, it must be replaced.

6. Restricted Or No Water Flow

a. Ensure water supply service stop valve is fully open.

b. Verify minimum 20 psig supply line flow pressure.

c. Check for twists or kinks in bubbler tubing.

d. Check the water inlet strainer. Sediment from the main supply can get trapped in the screen along

with installation materials such as pipe dope and flux. The screen should be cleaned and checked

on a regular basis and replace if needed.

e. The cartridge valve located in the water control assembly or bubbler can also become clogged with

foreign material. The cartridge valve can only be replaced and not repaired.

f. The water cooler may also develop a freezing condition in which the water will become frozen

inside the evaporator coil. This indicates a refrigeration problem or thermostat failure in which case

the water cooler needs to be checked by a qualified technician.

Page 6 of 8

CLEANING & MAINTENANCE GUIDE:

1. Motors have lifetime lubrication and do not require scheduled maintenance.

2. Excess dirt or poor ventilation will cause the compressor overload protector to turn the

compressor off and it will cycle on and off with no cold water coming out of bubbler. Periodically

clean with vacuum cleaner, air hose or brush the condenser fins and cabinet ventilation louvers.

In environments where dirt and dust is more prevalent, clean more frequently.

3. Periodically remove access panels and clean out in-line strainer.

4. Do NOT use harsh chemicals, abrasive or petroleum based cleaners. Use of these will void the

Acorn Aqua warranty.

5. Exterior panels can be cleaned using mild household detergents or warm, soapy water. Extra

care must be used cleaning chrome plated items and mirror finished stainless steel. They can

scratch easily and should only be cleaned using a clean, soft cloth and mild soap with water or

a mild glass cleaner.

CARTRIDGE VALVE PARTS BREAKDOWN

Repairs must be made with Acorn Aqua parts only. Please order through your local representative or

distributor. The phone number to locate your local representative is 1.800.591.9360.

ITEM # PART NUMBER DESCRIPTION

1 7000-050-001 Valve Cartridge Assembly

2 7000-060-000

Valve Cartridge

3 7000-053-199 Jam Nut

Page 7of 8

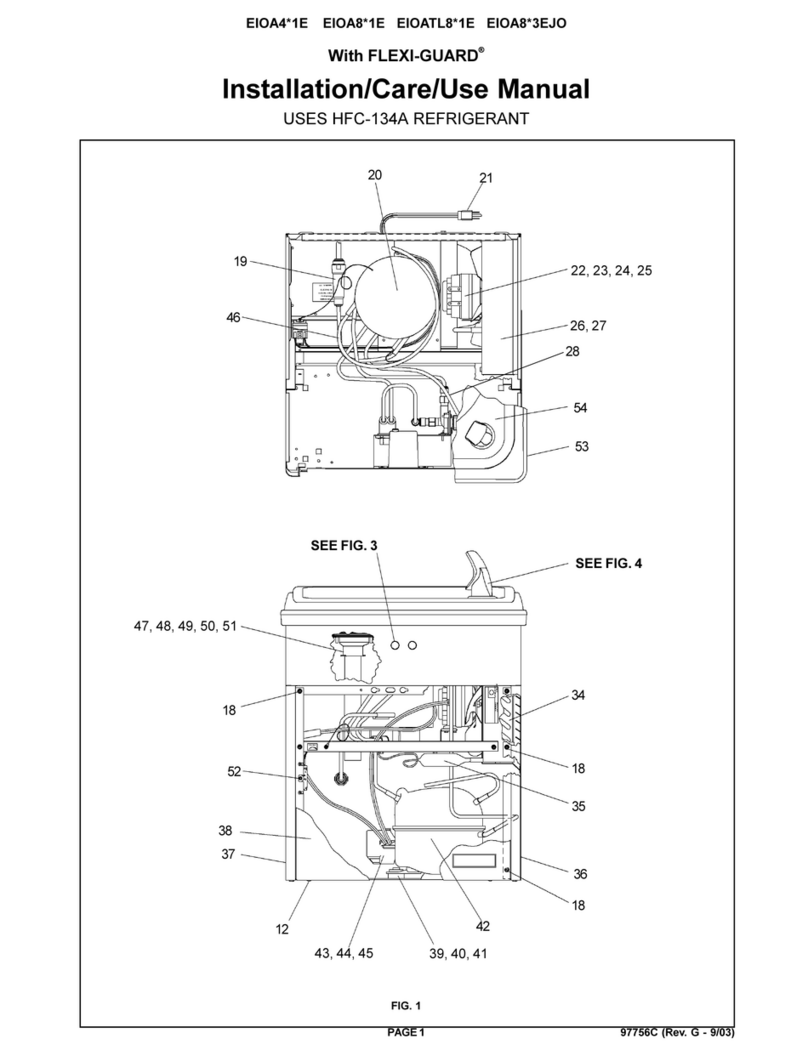

COOLER PARTS BREAKDOWN DRAWING

Standard A112408S/B-VR-UBL Refrigerated AquaAccess shown.

All 1/4" O.D. Plastic tubing 28 must be insulated with 29 foam insulation.

NOTE: See next page for table of part numbers corresponding to drawing above.

17

18

13

12

16

1415

3

1

32

25

23

20

19

11

10

24

2

27

21

22

26

28 29

3"

28

29

20"

29

2824"

31

9

28 29

3"

28

29

15"

28

29 8"

29 28

20"

4

8

4

5

7

6

6

30

29 28

20"

29 28

20"

31

31

22

32

WATERFLOW

WATERFLOW

33

NOTE: See previous page for fixture drawing corresponding to table of part numbers below.

Repairs must be made with Acorn Aqua parts only. Please order through your local representative or

distributor. The phone number to locate your local representative is 1.800.591.9360.

Page 8 of 8

COOLER PARTS BREAKDOWN TABLE

ITEM PART NUMBER DESCRIPTION

7003-001-199

7000-002-001

0124-032-000

7000-006-000

7003-182-000

7003-184-000

7003-181-000

7003-183-199

1895-710-000

7003-007-199

7003-250-000

7003-823-001

7000-065-001

7000-069-001

7003-016-001

7003-201-000

7003-350-000

7003-302-000

7012-062-001

7012-050-000

7003-014-199

7003-003-199

7012-001-001

BASIN TOP

CHROME PLATED BRASS BUBBLER ASSEMBLY

CONDENSER

#8 x 3/4" LG PHIL FLAT HD SELF TAPPING SCREW

FAN BLADE

FLAT DRAIN GASKET

FAN MOTOR

DRAIN ADAPTER

FAN MOTOR - 220V

7/8" SPRING HOSE CLAMP

Ø1-1/4" DRAIN TUBE

FILTER / DRYER

DRAIN HOSE

1/4" "T" PUSH-IN FITTING

FILLER PLATE - STAINLESS STEEL

SUPPORT STRUT

HANGER BRACKET

COLD CONTROL

BACK PANEL

COMPRESSOR

LEFT COVER - STAINLESS STEEL

COMPRESSOR - 220V

START RELAY

RECESSED PUSHBUTTON VALVE ASSEMBLY

START CAPACITOR

VALVE CARTRIDGE WITH FOAM WASHER

START CAPACITOR - 220

VR STAINLESS STEEL APRON ASSEMBLY

1

17

2

18

3

19

4

20

5

6

21

7

22

8

23

9

10

24

11

25

12

26

13

27

14

28

15

16

2169-000-000 1/4" O.D. TUBING

29 7012-055-000 TUBE INSULATION

30

31

STAINLESS STEEL BUBBLER ASSEMBLY7000-012-001

RIGHT COVER - STAINLESS STEEL

7003-100-001 EVAPORATOR ASSEMBLY

7000-022-000 "Y" STRAINER

7012-031-000

7012-002-000

7003-032-000

7012-002-000

7012-030-001

START RELAY - 220

1895-708-000 1/4" ELBOW PUSH-IN CONNECTOR

32 0110-005-000 #8 x 3/8" LG CENTER REJECT PAN HEAD SCREW

7003-824-001

7003-825-199

33 0124-050-000 #8 x 3/8" LG PHILLIPS PAN HEAD SCREW

Table of contents

Other ACORN AQUA Water Dispenser manuals

Popular Water Dispenser manuals by other brands

Zojirushi

Zojirushi CD-LCC40 operating instructions

GE

GE GXSF35E Owner's Manual & Installation Instructions

Watts

Watts PWSRTA Series Installation, operation and maintenance manual

Elkay

Elkay EIOA8 1E Series Installation, care & use manual

WaterGroup

WaterGroup 185HEDP owner's manual

vitapur

vitapur VWD1185BLS Use & care guide

Coway

Coway CP-07BLO user manual

Trixie

Trixie Duo Stream instruction manual

Midea

Midea YL1131AS user manual

GE

GE GXSF30H Owner's Manual & Installation Instructions

US Water Systems

US Water Systems Matrixx inFusion 081-IF Series owner's manual

Hellenbrand

Hellenbrand Economical Water Conditioning System Series... Specifications