Acro Pro SR User manual

AcroProtm Instruction Manual, Page 1

ing at the photo is

all you’ll have to

do to figure out

what’s going on. If

there’s something

about a particular

step that’s critical

or unusual, we’ll

mark that step

with the exclama-

tion point symbol.

Anytime you see

it, please read the

text for that step.

We used

thin, fast setting,

CA glue in

assembling all of

the AcroPro

prototypes. If we

recommend a

different glue for a

particular step,

we’ll mention it in

the notes.

Just about

any radio system

can be used.We’ve

specifically set up

the AcroPro for the

very fast and powerful MPI MX50HP ball bearing

servos.These servos will work with any brand of radio

and we strongly recommend them. If you can’t find them

locally, we always keep them in stock at SR. In fact, we

stock everything for the AcroPro from the covering mate-

rials to the tools that will make it easier and quicker to

build your AcroPro.

It’s time to get going so grab your glue, turn the

page, and let’s get building!

AcroProtm Instruction Manual© 2002

You’re in for a

real treat. Like the

X250 and the Cutie

before it, the Acro-

Pro is fun to build

and it flies great.

With the suggested

power system it’s

fully aerobatic and

will even do vertical

and horizontal eights.

It’s just a blast to

hotdog around the

sky and with its fully

steerable tailwheel,

it’s just as much fun

on the ground. This

is an airplane that

you’re going to fly

for a long, long time.

No kidding!

Please read

this!

We know you’ve

been told a million

times to read the in-

structions, but this

time you really

should. The AcroPro

employs brand new

construction techniques that you probably haven’t run

into before. Nothing about building the AcroPro is diffi-

cult, but much of it will be new to you. If you do mess

up, give us a call. We promise not to holler at you. But,

why not do it right the first time and follow the instruc-

tions? You’ll save a lot of time if you do.

That having been said, we know the more experi-

enced builders are going to ignore us, so let’s make a

deal. Most of the time, reading the heading and look-

AcroProtm Instruction Manual, Page 2

Finding the parts...

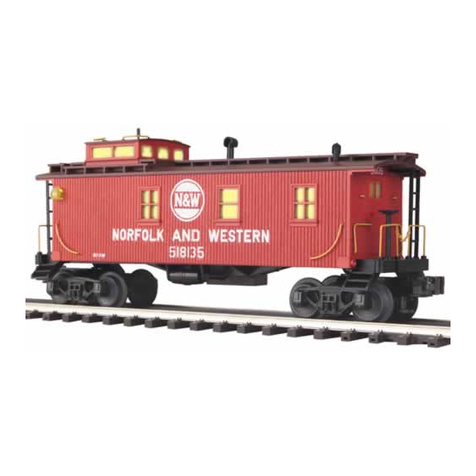

We’ve included master parts sheetsthat identifyeach part in the

AcroPro kit. They will make it a lot easier to find the parts. In these

instruction we’ll tell you on which sheet a particular part is located.

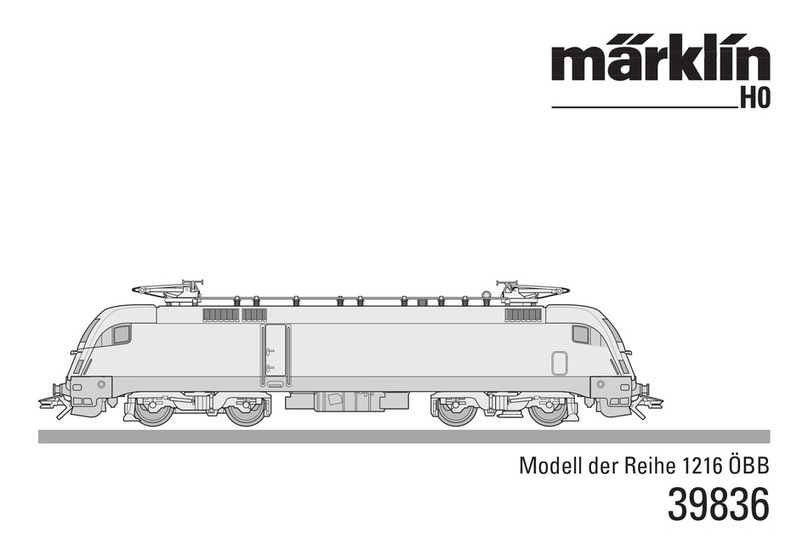

Power Systems...

Literally hundreds of hours of computer time were spent

optimizing the AcroPro design. We didn’t just design an aircraft, we

designed an entire system. Although you can experiment and come up

with your own system, we’re sure you’ll be more than happy with the

components we’ve included in the AcroPro’s optional Power System.

It consists of the Jeti Phasor 15/4 motor with the corresponding Jeti

JES 30-3P speed control, a Graupner CAM 9x6 prop, and an SR 1300

Max or 1500 Max 7 cell battery pack. We have a special package

price for AcroPro builders for a complete power system so check

with us if you have any questions.

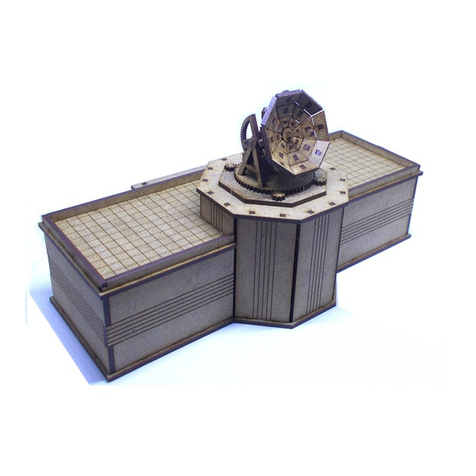

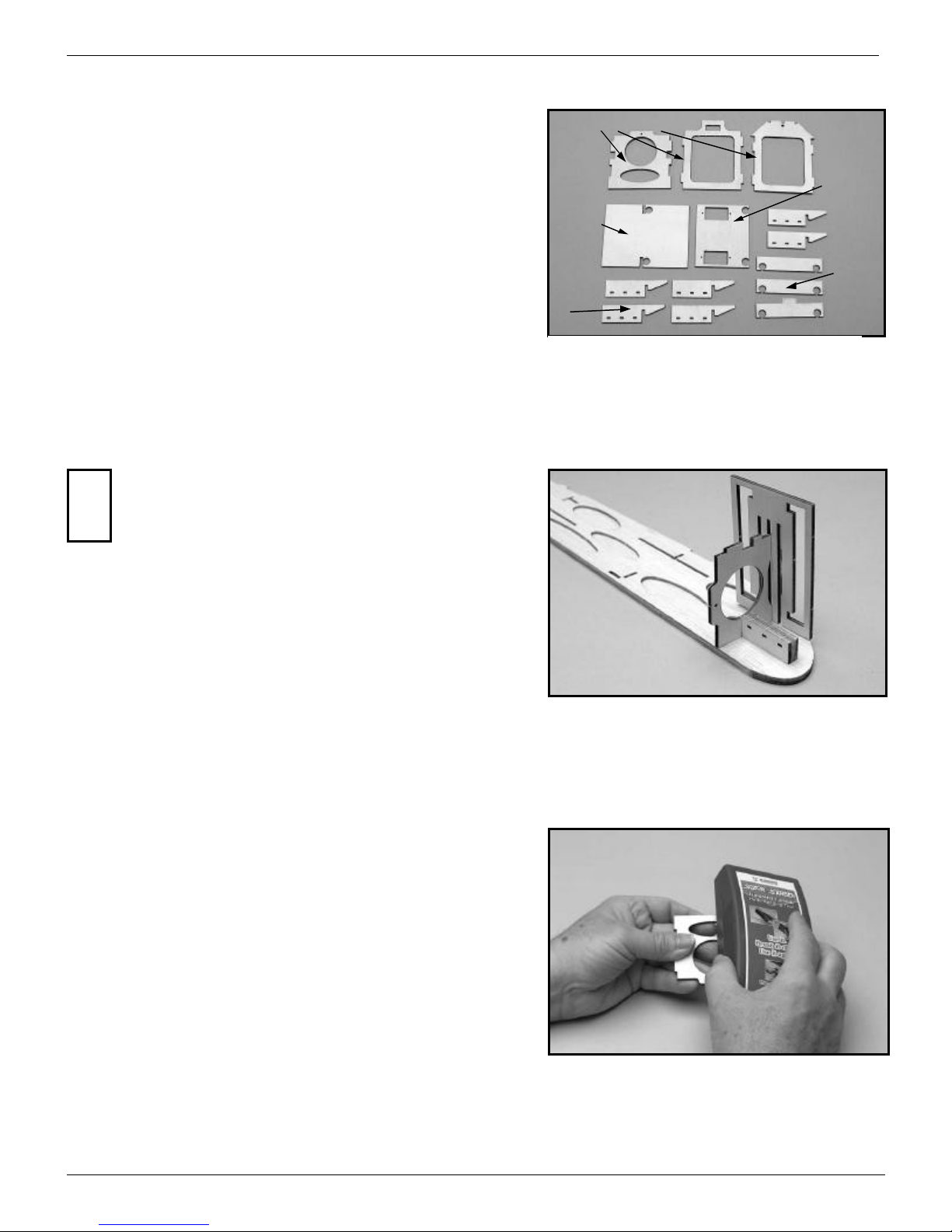

Cut parts free using a straight edge

Cutting the parts free...

We’ve deliberately left all of the MicroLaser Cut parts for the

AcroPro in their sheets to protect them. Use your modeler’s knife and

a straight edge to cut the small tabs that hold the parts in place. To

make it easier for you, just about all of the cuts will be with the grain

and you’ll notice that the tabs are usually in a line from top to bottom

across the 3” width of the sheet.

Although you can cut out all of the parts before you begin, we

suggest that you leave them in their sheets until you’re ready for

them. It’s up to you, but you’ll be less likely to lose a part or have

trouble identifying it if you leave it in its sheet until you’re ready for

it.Variations in the density of the wood will sometimes cause parts to

not quite be cut all the way through. If you find any of the parts aren’t

cut all the way, just complete the cut on the back of the sheet.

AcroProtm Instruction Manual, Page 3

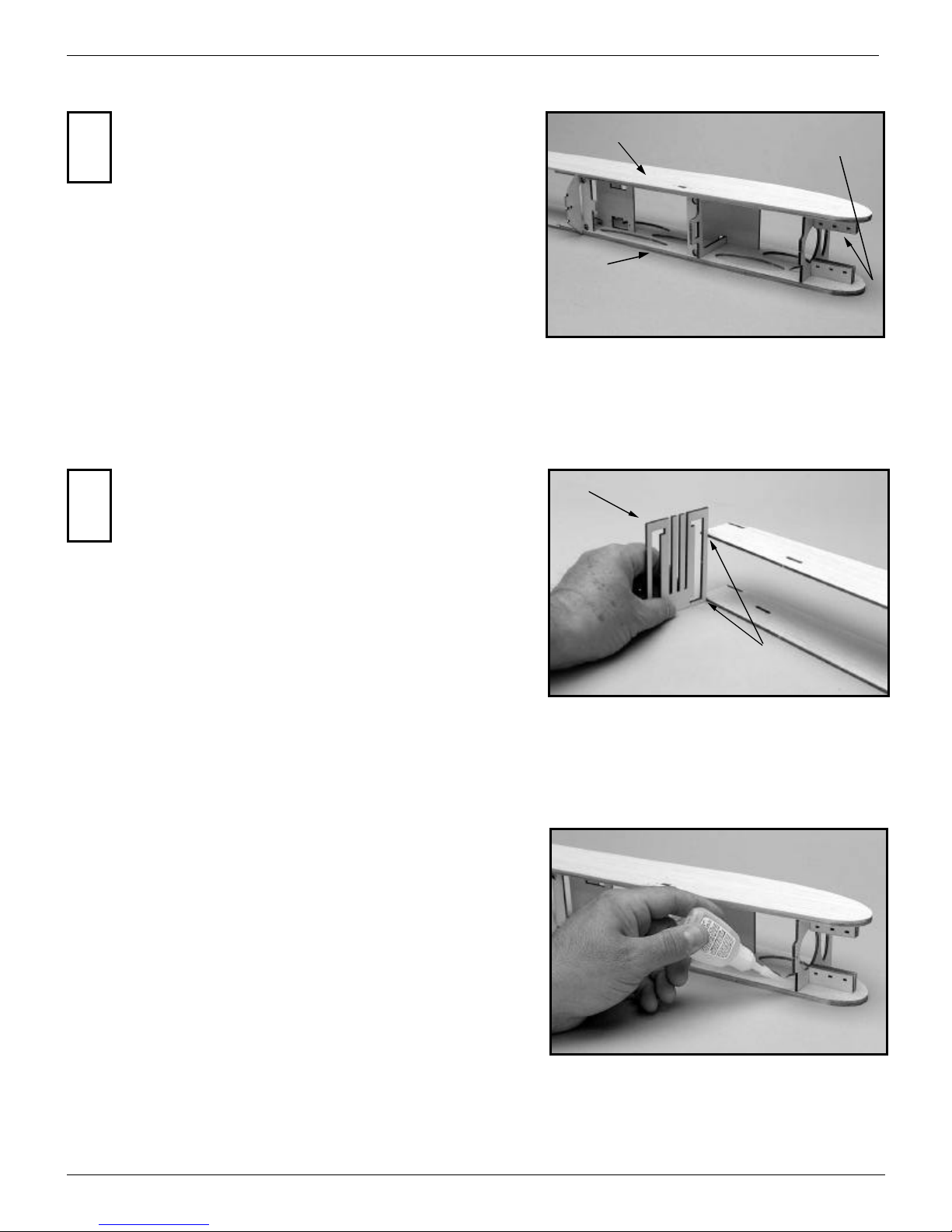

Note the cutouts in the left fuselage side and

doubler for the speed control’s switch.

Right side

Left side

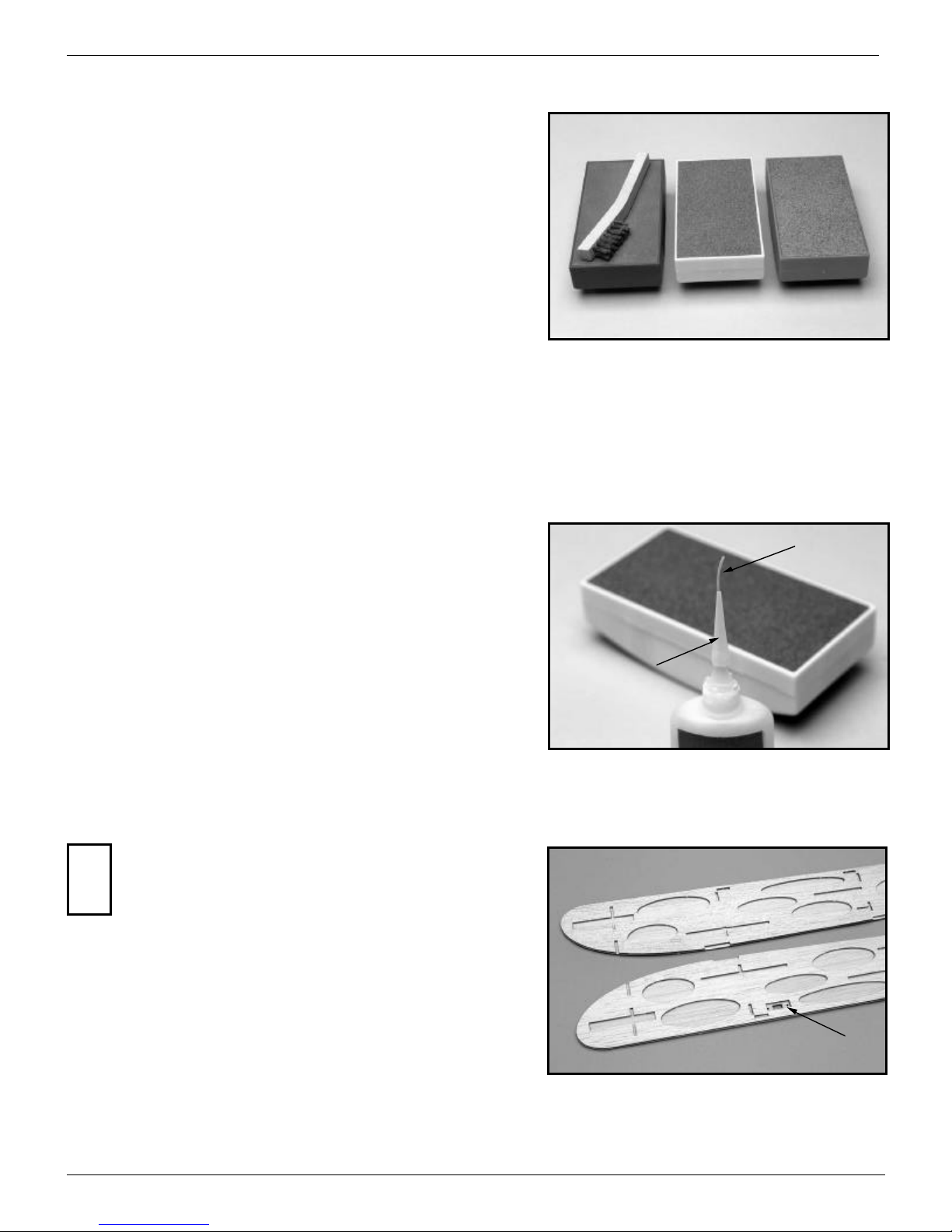

Midwest permanent tungsten carbide sanding blocks come

in fine, medium, and coarse and include a cleaning brush

Optional glue tip

Teflon tubing

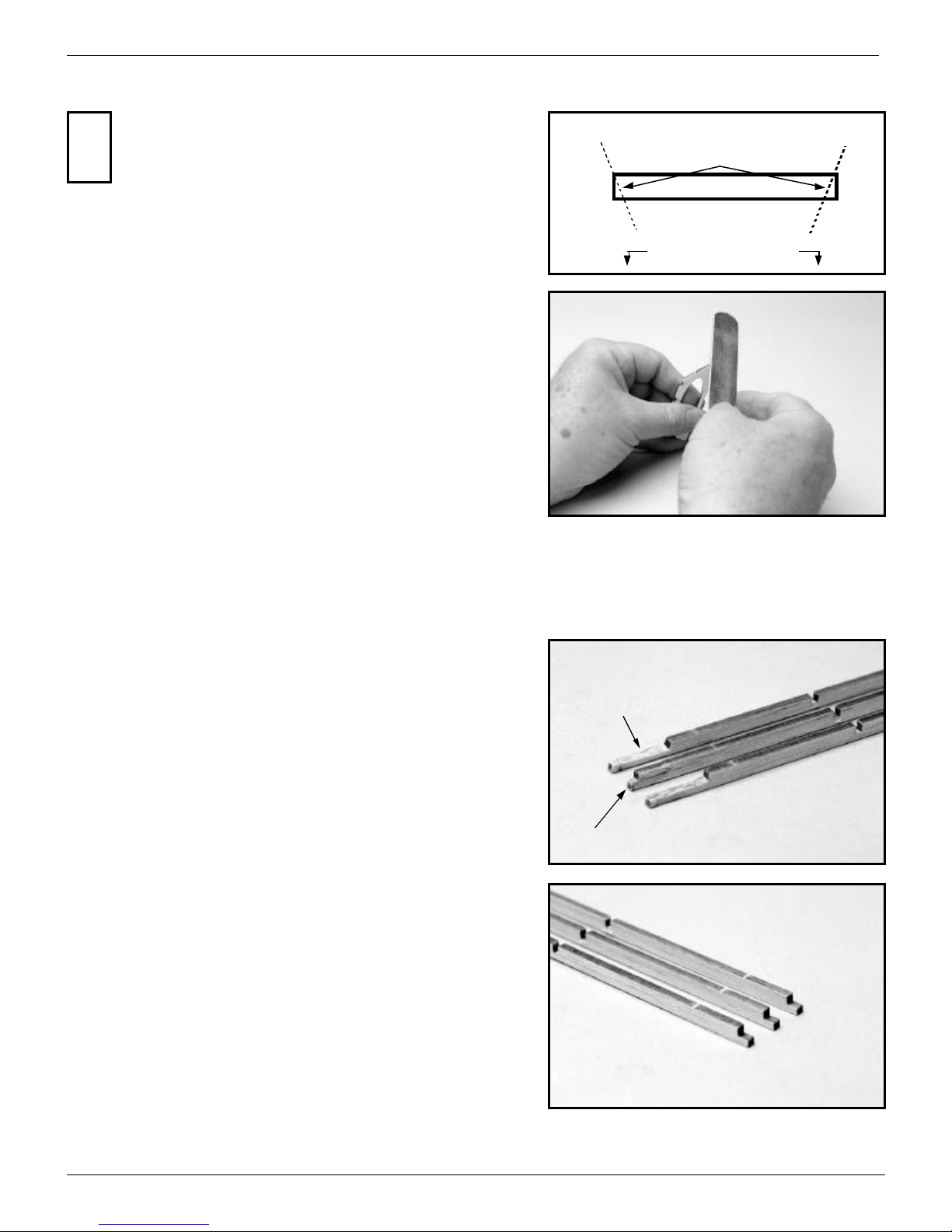

Sanding...

In most cases, the SR MicroLaser Cut process leaves the balsa

parts with a honey colored edge that needs no sanding.Unfortunately,

the glues used in making plywood tend to glaze the edges of the

plywood parts when they are laser cut. We use a special plywood that

is designed for laser cutting, but we recommend that all plywood

parts be lightly sanded along their edges before gluing the partsin

place. In addition, like spruce, plywood parts tend to have an oily film

on their surfaces which prevents CA glues from taking a good hold.

For this reason, we recommend that all plywood parts be given a light

sanding on all surfaces before you glue them in place. We strongly

recommend the Midwest permanent, tungsten carbide, sanding blocks

which come in fine, medium, and coarse grits and even include a

brass cleaning brush. We stock them at SR if your hobby shop doesn’t

have them. They’ll make building your AcroPro a lot easier and

faster.

Controlling thin CA glue...

As stated earlier, thin CA glue can be used for just about every

step in building your AcroPro kit. However, thin CA glue can be hard

to control straight out of the bottle. You’ll make life a lot easier if you

buy some of the glue tips that are available and then add a piece of

Teflon tubing to make it even easier to control the flow of the glue.

To keep from gluing the parts to your building board, remember

to use a piece of waxed paper under your work. To keep from gluing

the parts to your fingers... Well, I haven’t figured that one out yet.

Warning, Warning, Warning!!!

This is the single most important step in building your Acro-

Pro. The entire trueness of the fuselage depends on you

properly aligning the fuselage doublers to the sides of the

fuselage before you glue them to each other. Take your time

and don’t rush this step even though it may seem very simple. DON’T

MAKE TWO LEFT OR TWO RIGHT FUSELAGE SIDES!!! There

is an easy way to identify the lefts from the rights. The left fuselage

side and left doubler have cutoutsfor the speed control’s switch!

Don’t lose the four little triangles in the center of the doubler

sheet.

!

AcroProtm Instruction Manual, Page 4

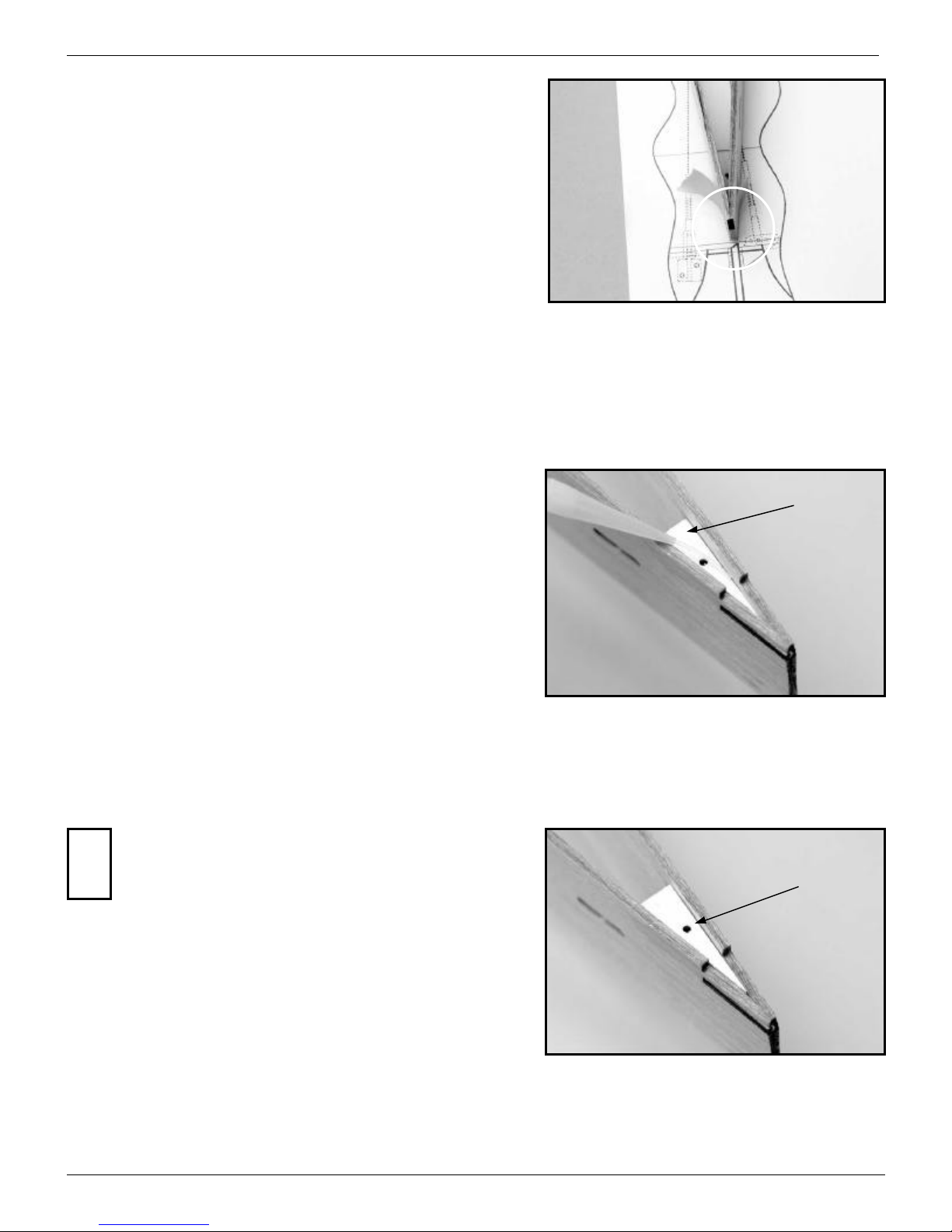

Align the fuselage side and doubler at the nose

When everything is perfectly aligned,

glue ovals first, then cutouts

Slide the jigs towards one another to

align the doubler with the fuselage

side from top to bottom

The fixture will hold the two

parts in perfect alignment

Last 1/2”

1/32” Down

Leftfuselageside

Gluing the fuselage doublers in place...

When you’re satisfied with the alignment of the fuselage side and

doubler, glue them together with thin CA glue. First, put a drop of

glue every 1/2” or so around the perimeter of the oval cutouts in the

doubler. Then, put a drop of glue every 1/2” or so around the rest of

the cutouts, but don’t get carried way with the glue. When you insert

the formers and other parts into these cutouts you’ll be gluing them

again so you don’t need to get crazy with the glue at this stage.

When you’re done, run a bead of glue around the edge of the

doubler where it meets the fuselage side. Do the same for the other

doubler and fuselage side andDON’T MAKE TWO LEFT SIDES!!!

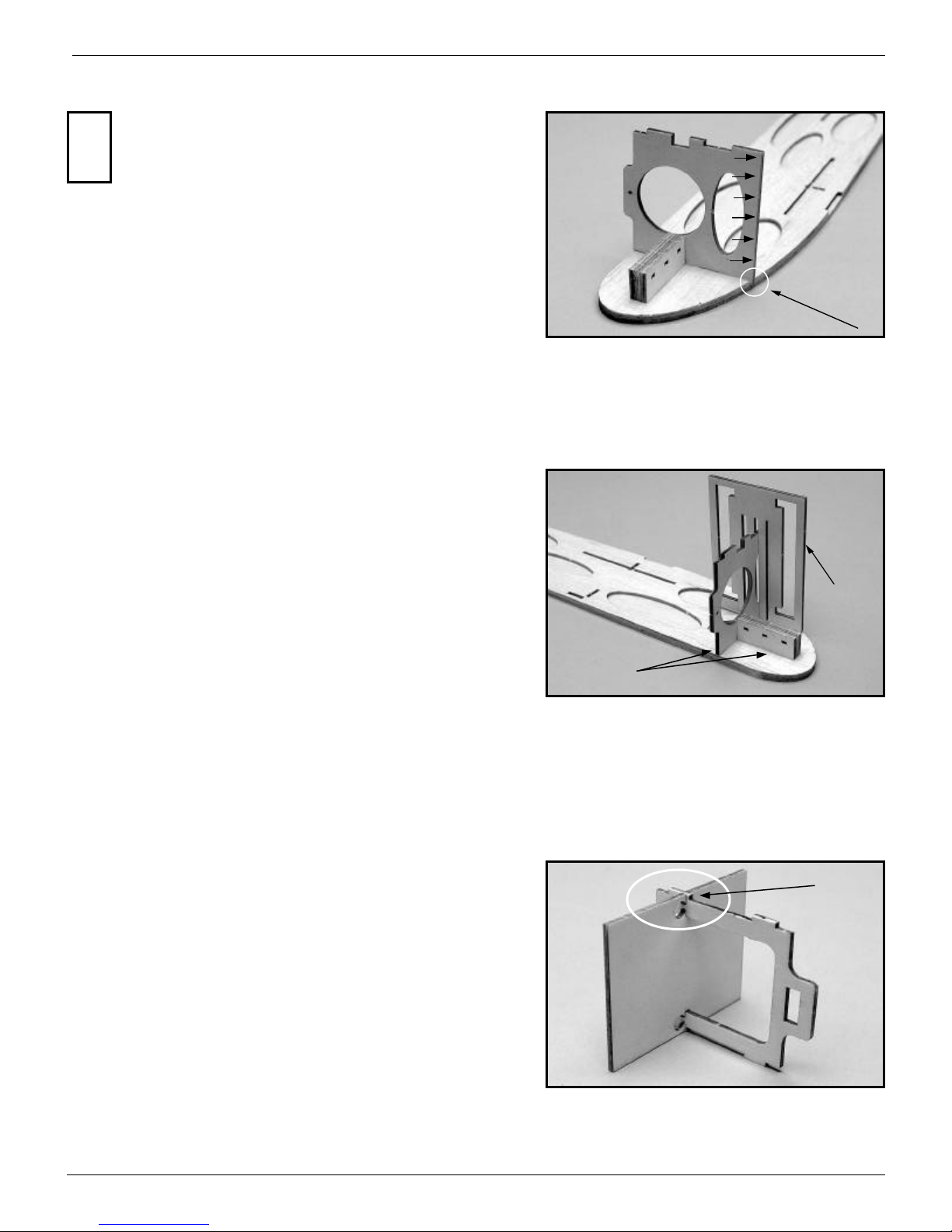

Aligning the fuselage doublers...

Now, for the fuselage doublers. Be careful, there’s a right and

a left! The left doubler has the cutout for the speed control’s

switch. To help you align the doubler with the fuselage side,

we’re included two “C” shaped plywood alignment fixtures.

First, use your eye and finger tips to align the two at the nose.

Then, slide on the front fixture from the nose and slide it rearward.

Then position the rear fixture and slide it forward. The fixtures will

only slide so far and then they will stop because the fuselage side and

doubler become larger in width than the cutout in the fixture. When

the fixtures can’t be slid any further towards one another, they will

have automatically put the doubler and fuselage side in perfect align-

ment with one another from top to bottom. The only thing you’ll have

to do is check to see that the two are still flush with one another at the

nose. If the two noses aren’t perfectly lined up with one another,

loosen the two fixtures, realign the two at their noses and then slide

the fixtures back on to realign the fuselage side and doubler from top

to bottom.

!

Chamfering the fuselage sides at the tail...

Before you start work on the doublers, you’ll have to chamfer

the rear inside edges of the fuselage sides so that when the fu-

selage sides are finally joined at the tail, the resulting fuselage

width will be 1/8”. To do this, you’ll only have to remove

1/32” of balsa in the last 1/2” of each fuselage side so that it ends up

being 1/16” thick. Make sure you’ve identified the right and left fu-

selage sides properly so that you’re sanding their inside edges and

not their outside edges!!! An easy way to make sure you don’t sand

past the 1/2” line is to lay a piece of masking tape along the line and

then sand up to the tape.

An easy way to know when you’re down to a thickness of 1/16”

is to use a scrap piece of 1/16” balsa as a feeler gauge. Keep compar-

ing the thickness of the aft edge of the fuselage with the 1/16” scrap.

When they are the same thickness, you’re done.

!

(See parts sheet #1)

AcroProtm Instruction Manual, Page 5

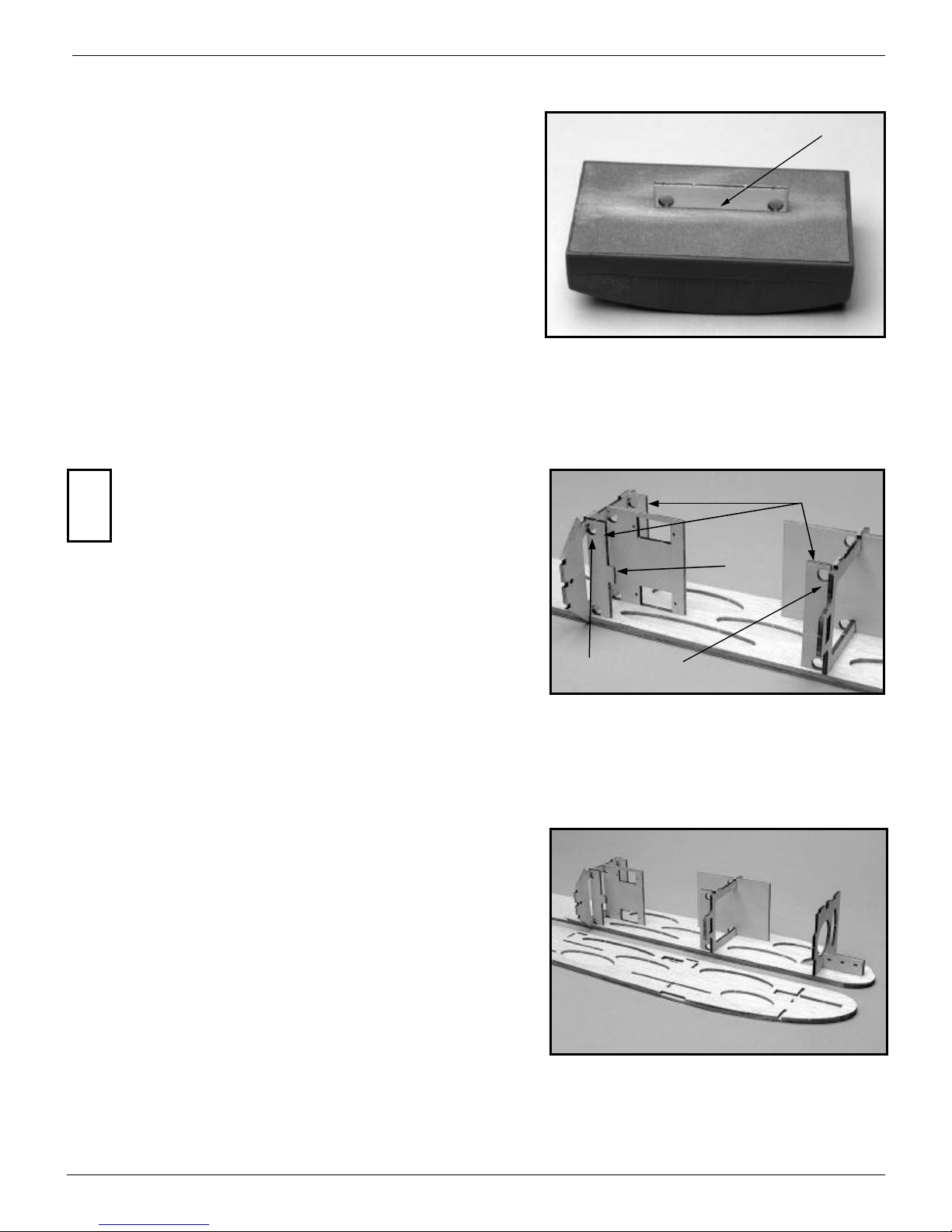

Find the parts...

The photo at the right illustrates the parts you’ll need for the next

steps so remove them from their sheets and give them a light sanding.

Trial fit your servos in the servo mounting tray and make any neces-

sary adjustments. The stock cutouts have been sized for MPI

MX50HP servos. Use a piece of wire to pop out any holes after first

cutting them free and trial fit the wing support tubes in the wing sup-

port mounting plates. If you do the same with the servo tray, you’ll

find that the holes are deliberately oversize so don’t panic.

Adjust the fit of the parts...

Use just a few gentle swipes of your sanding block at a very shal-

low angle on the edges of the parts where they are inserted into the

doubler to make them fit more easily. We are not talking about a lot

of sanding here. A few gentle swipes is all it will take. The parts

shouldn’t be loose, but they shouldn’t be tight either.

Don’t forget to do both edges because it will be more difficult to

sand these parts after one side has been glued in place.

Trial fit the right motor mount and firewall...

Each motor mount is made up of three pieces of plywood. The

top and bottom pieces should have the grain running the short

way across the motor mounting plate and the center piece

should have its grain running the long way down the plate.

Trial fit, but don’t glue, the three right motor mounting plates and

firewall into the right doubler. You’ll probably find that they are a

snug fit, but a little light sanding will fix that.

!

Formers F1, F2, and F3

Battery Pack

Tray

Servo Tray

Motor

Mounts

Wing

Support

Mounts

(See parts sheets #1, #2, and #3)

AcroProtm Instruction Manual, Page 6

Use the alignment jig...

We’ve given you a plywood alignmentfixture to keep everything

aligned properly. The fixture has three slots. The center slot is used

with plywood parts. The largest slot is for aligning the vertical

stabilizer after it’s covered and the narrowest slot is used with 3/32”

parts. The outer corners of the fixture are cut at exactly 90° which

will come in handy later.

With the firewall and motor mount firmly seated in their recesses

in the doubler, use the alignment fixture to make sure the firewall is

square with the doubler. Don’t glue anything! You’ll glue the fuse-

lage components together later after you’ve determined that every-

thing is in perfect alignment. We’ll tell you when to glue!

Alignment

Fixture

Tack glue

Battery pack mounting plate...

Before you install the second former, you’ll first insert the bat-

tery pack mounting plate through the hole in the center of the former

and rotate it into place. Slide the mounting plate down so that it’s po-

sitioned slightly below the top of the tab in the side of the former.

Trial fit it into the fuselage side to make sure the positioning of both

parts is perfect.

Chamfer the bottom forward edge of the firewall...

If you look closely, you’ll see that the forward, bottom edge of

the firewall needs to be sanded back at an angle because it

overlaps the fuselage side. Use your sanding block at an angle

and remove the small amount of overlapping material so that it

won’t interfere with the bottom sheeting when it’s glued in place.

!

AcroProtm Instruction Manual, Page 7

Third former...

Repeat the above step with the third former making sure it isn’t

snug or tight. Don’t glue anything!

Third former

Servo Mounting

Tray

Servo mounting tray...

Now is the time to trial fit your servos into the servo mounting

tray. We’ve already sized the plate forthe MPI MX50HP servo

that we highly recommend for the AcroPro, but it will be easy

for you to adjust the tray for other brands of servos. We’ve left

plenty of extra material in the plate so just open up the hole until it

fits the servos you’re going to use.

Dry fit and adjust the tray as necessary, but Don’t Glue It In

Place yet.

!

Second former...

Check the fit of the second former and battery mounting plate.

Again, use your sanding block to make sure you have a smooth fit

that isn’t snug or tight. Don’t glue anything!

Second former and battery

pack mounting plate

AcroProtm Instruction Manual, Page 8

The right side is done...

Here’s what the right fuselage side should look like at this point.

The right motor mount, firewall, battery pack mounting plate and

servo tray are in place.

Prepare the support plates...

The edge of the three wing support plates will probably have

some small protrusions where the tabs were left to keep the parts from

falling out of the plywood sheets. Take a few swipes with your sand-

ing block on the edge closest to the holes. Only move the piece in one

direction rather than back and forth as it will give you a straighter

edge. Don’t try to remove any material from this edge. You’ll only

trying to knock off any protrusions that would prevent the plates from

resting properly against the formers.

Don’t try to sand this edge. Only remove protrusions!

Right side

Leftside

Insert the support plates...

The three wing support plates should be dry fit and adjusted as

necessary. Notice that the upper rear support plate has a

“tab” protruding forward! Don’t glue them in place! Also,

notice that the holes are positioned closest to their respective

formers!

!Wing support plates

Holes close to formers!!!

Note Tab!

AcroProtm Instruction Manual, Page 9

Right angle jig

With one fuselage side flush up against

the right angle fixture, the other fuselage

side should be within 1/16” of thefixture.

If everything looks good, glue the

parts into the right fuselage side

Rightfuselageside

Leftfuselageside

Weight

Don’t Glue Anything Yet!!!

Don’t forget the Left motor mount!

Glue the parts into the right fuselage side...

OK, now you can use some glue! If the fuselage sides are close to

being square (within an 1/16” or so), go ahead and tack glue some of

the parts into the right fuselage side and then check the alignment

again.If the two are way off (1/8” or more), try to sand and adjust the

ends of the parts and the recesses in the doubler until you can align

the two fuselage sides with one another. If everything still looks good,

go ahead and glue the parts into the right fuselage side. This is an im-

portant step so make sure you get it right.

Check fuselage alignment...

Before gluing any parts together, use the right angle fixture to

check how closely the two fuselage sides line up at the tail. Put

the fixture flat on the building surface and see how close each

of the fuselage sides comes to the fixture.

If you were careful about lining up the doublers with the fuselage

sides and all of the formers were firmly seated in their recesses, the

fuselage sides should line up very closely with one another.

!

Trial fit the left fuselage side...

Following these instructions will assure a straight and true

fuselage without any twists.

Dry!!! fit the left fuselage side. Before you do, insert the

left motor mounting plates into the left fuselage side. Then,

starting at the nose, slip the firewall, battery pack support plate, sec-

ond former, wing support plates, servo tray, and third former into

their corresponding recesses in the left side doubler. Take your time.

Make sure that the parts are firmly seated in their recesses and that

nothing is preventing them from completely seating.

!

AcroProtm Instruction Manual, Page 10

Attach the left fuselage side...

Carefully turn the fuselage over. Make sure all of the parts are

still positioned properly and weight the fuselage down if necessary.

Check the alignment at the tail again with the right angle guide and if

everything looks good, go ahead and glue all of the parts into the left

fuselage side.

Float mounting plate Landing gear mounting plate

Gear mounting plates...

You’ll find that there are two recesses in the bottom of the fuse-

lage doublers for landing gear mounting plates. The forward set is

used for the landing gear and the rearward set is an attachment point

for floats if you ever choose to fly your AcroPro off of the water.

Even if you think you’ll never use floats, install the second mounting

plate anyway.

Assemble the landing gear mounting plates...

The first step in assembling the gear mounting plates is to

glue the two upper plates to the lower plate. You’ll find that

the upper plates are smaller.

To make it easier for you to align the three plates over one

another, we’ve cut a small notch in edge of each plate. If you line

these notches up with one another, you’ll find that the holes in the

plates are automatically lined up. The edge of the plates with the

notch should be flush with one another. When aligned properly, there

will be a recess formed on the other three sides of the assembled

mounting plate. Carefully align the upper and lower plates with one

another and glue them together.

!Upper plates

Lower plate

Notches

Align both plates along

this edge

Recessed

(See parts sheets #2 and #3)

AcroProtm Instruction Manual, Page 11

Dry fit before gluing the

mounting plate in place

Dry fit the gear plates...

The next step is probably best done with slow CA glue or ali-

phatic resin glue. But, before you glue anything, dry fit the two plates

in their recesses to see how they fit. They should just drop into place

snugly.

Glue the gear plates in place...

If you’re happy with the fit, run a bead of glue along the two

doubler recesses, the top of the former, and the face of the former.

Press the mounting gear plate firmly in place and let the glue dry. Do

this with both the front gear mounting plate and the rear float mount-

ing plate.

Final gluing...

When the glue is dry, use thin CA glue along any edges of the

two mounting plates that you can get at to make sure they are firmly

locked into place.

AcroProtm Instruction Manual, Page 12

Joining the fuselage sides at the tail...

If you’re lucky, the stiffness of your two fuselage sides will be

exactly the same and if you join them at the tail, they come together

centered. Forget about it. It isn’t going to happen. Wood is wood and

chances are the stiffness of the two sides will be different. No prob-

lem!

Before we start, I’m going to warn you that it’s very easy to

break loose the small piece of balsa that sticks out from each fuselage

side at the tail. Try to be careful and don’t bump this piece. If you do

and it cracks loose, don’t panic. Just line it back up and CA it back in

place. I know it’s easy to do because I’ve had to do it twice myself!

Insert a tail wheel mounting

plate into one lower slot in one

of the fuselage sides

Chances are that when you

bring the two fuselage sides

together, one will be longer

than the other because they

aren’t centered

Line up the two sides per-

fectly with each other and

the end of the tail wheel

mounting plate and tape

the sides together

Masking tape

Tail wheel mounting plates...

In the center of the third former located on the plywood parts

sheet #3, you’ll find three plywood pieces that look like arrow heads.

They are the mounting plates for your tail wheel assembly. Two look

like a barbed arrowhead and one looks like a regular point. The

barbed ones are the top and bottom tail wheel mounting plates. The

regular one fits between them. With your fuselage side turned upside

down, insert one of the barbed plates into the lower notch in the fuse-

lage side. Now, bring the two fuselage sides together at the tail and

see how they meet. Chances are they’ll look like the photograph

above and one will be longer than the other because they aren’t meet-

ing in the center.

Centering the tail...

In order to be centered, the two fuselage sides must be exactly

the same length and be flush with the end of the tail wheel mounting

plate. Have a friend hold the fuselage down or use some weights so

that it doesn’t move. Move the tail left or right until the two ends line

up with each other and the end of the mounting plate. When you think

you have it right,wrap a piece of masking tape around the tail to hold

everything in place.

(See parts sheet #3)

AcroProtm Instruction Manual, Page 13

Glue the fuselage sides together...

Now that the fuselage sides are centered and tack glued to each

other, run a bead of thin CA glue around the edges of the barbed tail

wheel mounting plate and down the joint where the two fuselage sides

meet.

Lower tail wheel mounting plate

Center tail wheel mounting plate.

Make sure the hole lines up with

the one below!

Double check the centering...

Now, turn the fuselage over, right side up, and lay it over the top

view of the fuselage on the plans. Take your time to line the front of

the fuselage up with the top view. Is your tail centered? It should lie

directly over the center line shown on the plans. If not, adjust it and

try again. Take your time as this is an important step. When you’re

happy with the result, tack glue the two fuselage sides together.

Insert the center tail wheel mounting plate...

Lay the center tail wheel mounting plate (the one without the

barb) on top of the first that you’ve already glued in place.

This second plate simply sits between the two fuselage sides.

Look down through the hole in the center plate and see if it

lines up with the first. Chances are that it won’t and you’ll have to

sand the two edges of the plate until it can slide back enough towards

the tail so that the two holes line up. When they do, glue the center

plate in place over the first plate.

!

Turn the fuselage

over and lay it over

the plans. The tail

should be centered.

If not, adjust it and

try again. When it’s

right, tack glue the

two sides together

AcroProtm Instruction Manual, Page 14

Glue the third plate in place...

You’re almost done. Lay the top barbed plate in place and if eve-

rything lines up, it should, glue it in place over the previous two tail

wheel mounting plates.

Finally, re-glue around the entire assembly including the joint at

which the two balsa fuselage sides meet.

The basic AcroPro fuselage assembly...

At this point you’ve completed the basic assembly of your Acro-

Pro’s fuselage. Most of the tough parts that will determine how well

your AcroPro will fly are behind you so pat yourself on your back and

let’s get the fuselage finished!

Bulkheads

Stringers Lower edge of bulkhead

Third tail wheel mounting plate

Assemble the top rear of the fuselage...

The top rear of the fuselage is constructed of three stringers and

four bulkheads. Two of the stringers are different from the third, but

we’ll get to that in a moment.

(See parts sheets #3, #4, and #11)

AcroProtm Instruction Manual, Page 15

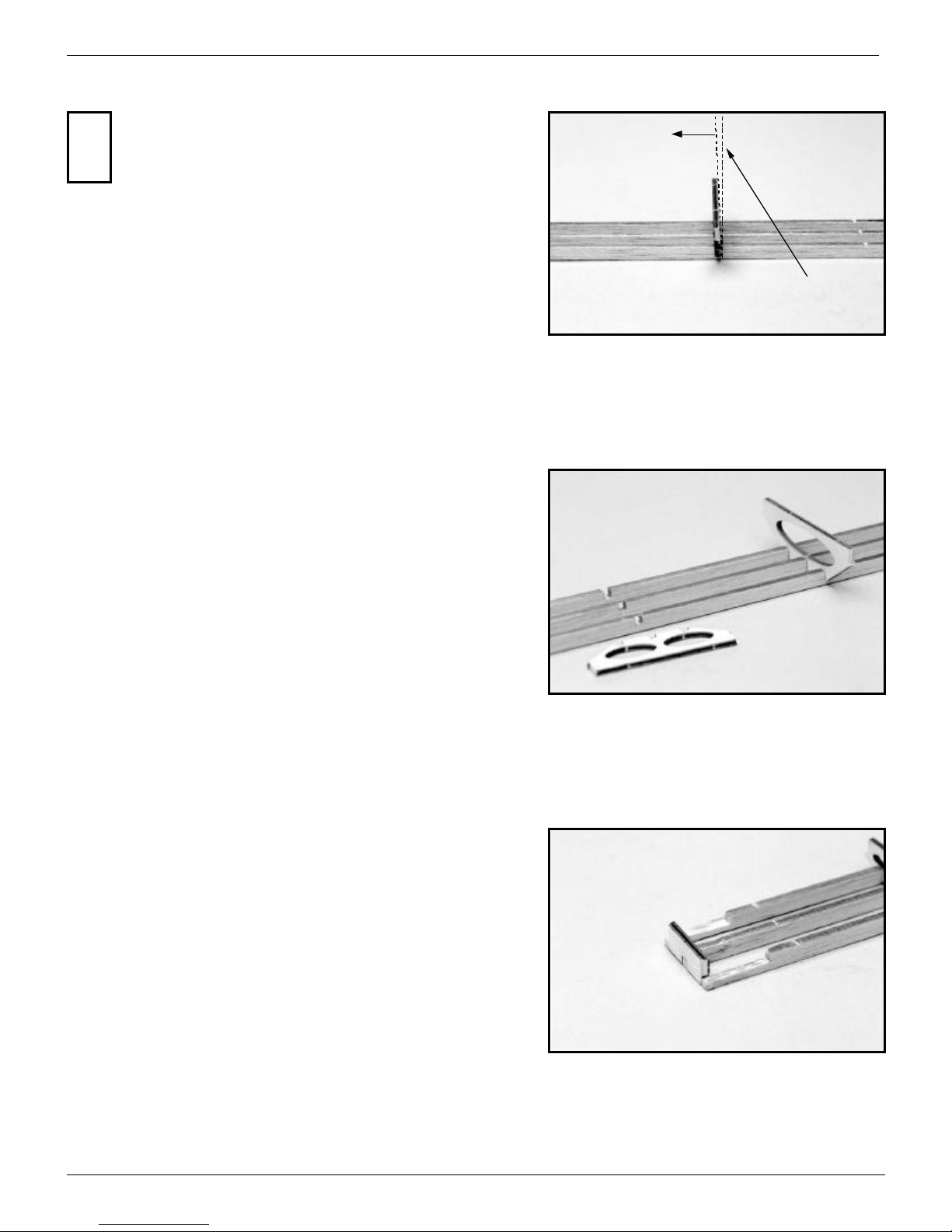

Forward ends of the stringers

Rearward ends of the stringers

Center stringer

Long cutout in outer

stringers

Emery boards are

great for delicate

sanding

We’ve exaggerated the angle

here to make the point

Trim lower rear edges of bulkheads

where they meet the fuselage sides

Towards the fuselage rear

Identify the center stringer...

It’s easy to pick out the center stringer. If you look at the ends of

the stringers, you’ll see that two of them have long cutouts in one end.

Those are the outside stringers and the remaining one, with a short

cutout at both of its ends, is the center stringer.

Taper the edges of the bulkheads...

Because the fuselage tapers towards the rear, the rear edges of

the bulkheads have to be trimmed slightly so that they make

better contact with the fuselage sides. An emery board or a

scrap of plywood with a piece of sandpaper glued to it is a

great tool for this kind of delicate sanding.

Make sure you trim both edges of the bulkhead in the correct

direction (Don’t ask me how I know!). Don’t make one going for-

ward and one going rearward. Once you’ve decided which is the front

and which is the rear of each bulkhead, put a pencil mark on the front

side so that it will be easier to identify later on.

!

AcroProtm Instruction Manual, Page 16

Identify the front and rear of the center stringer...

Trying to figure out which end of the center stringer goes to-

wards the front and which end goes towards the rear is a little

tougher. Lay the three stringers down so that they are flush with each

other at one end and the center stringer is in the middle. Take a look

at the first set of notches in the stringers. Are all three notches in line

with one another, or is the notch in the center string out of alignment

with the other two? If you have the three stingers oriented properly,

all three notches will be lined up with each other.

Don’t panic trying to get this right. In the next step, nothing will

line up if you have it wrong and you’ll know immediately that you

have the center stringer turned the wrong way.

If properly oriented, with all three

forward ends of the stringers

aligned, the first row of notches will

be aligned too.

The center notch is out of

alignment with the other two

so the center stringer has to

be turned around

Out of alignment

DON’T reach for the glue...

The next steps will be done dry, without glue, initially to make

sure everything fits right. You won’t glue everything together until

the end.

AcroProtm Instruction Manual, Page 17

This line is perpendicular

to the stringers

The bulkhead is

leaning rearward

Take your time and dry fit the bulkheads

into the stringers one at a time

The fourth bulkhead will be flush

with the ends of the stringers

Insert the bulkheads one at a time...

Gently insert the bulkhead into the notches in the stringers.

You’ll notice that the bulkhead won’t go all the way down to the sur-

face of your table. We don’t want the bulkhead to show through your

covering material so the bulkhead stops short of the surface of the

stringers. Use the marks you made on the forward sides of the bulk-

heads as a guide to make sure the corners of the bulkheads that you

trimmed away by sanding them back are all facing rearward.

Be gentle with the stingers and try not to crack them. No, this is

one mistake I haven’t made yet, but if you do crack one, just use

some CA glue to fix it.

The final bulkhead...

Take your time and work each of the four bulkheads into place.

The fourth bulkhead, towards the tail, will end up being flush with the

ends of the stringers.

The bulkheads aren’t square to the stringers...

Before you insert the first bulkhead into the stingers, notice

that it doesn’t fit into the stringers at a 90 degree angle. In-

stead, it’s angled back some. The bulkhead will end up being

perpendicular to the fuselage, but it’s not perpendicular to the

stringers.

!

AcroProtm Instruction Manual, Page 18

If everything looks right, glue the

bulkheads into place

Install the stringer assembly...

While holding the rear of the stringer assembly up a little, slide

the ends of the stringers into the notches in the top of the third fuse-

lage former. Now, lower the stringer assembly at the rear and spread

the fuselage sides a little as each bulkhead drops into place. Make

sure that the stringers stay firmly seated in the notches in former #3.

Insert the forward ends of the

stringers into the notches in former

#3 first

When bulkhead #4 is inserted be-

tween the fuselage sides, the outer

stringers will come to rest on top of

the fuselage sides

The outer stringers rest on top of the fuselage sides...

Work your way to the rear and finally insert the fourth bulkhead

between the fuselage sides. You’ll find that the outer stringers will

come to rest on top of the fuselage sides.

Take a good look at the assembly. Are all of the little stops at the

outer corners of the bulkheads sitting firmly on the top of the fuselage

sides? Are the stringers still fully seated in former #3? If so, you can

go ahead and glue everything into place.

Glue the bulkheads to the stringers...

Double check the fit between the bulkheads and the stringers.

Are the bulkheads fully inserted into the notches? Are all the

tapers you sanded into the edges of the bulkheads facing to-

wards the rear of the fuselage??? If they are and everything is

sitting nice and flat on your building board, use thin CA glue to glue

all of the bulkheads to the stringers. You did remember to use waxed

paper under your work so that it doesn’t stick to the building board

didn’t you???

!

This manual suits for next models

1