3

Marvair GAA A/C w/Gas Heat I&O Manual

06/2023 Rev.5

WARNING - SAFETY REQUIREMENTS

• If the information in these instructions are not followed exactly, a re, carbon monoxide poisoning or explosion may result causing

property damage, personal injury or loss of life.

• Read all instructions carefully prior to beginning the installation. Do not begin installation if you do not understand any of the

instructions.

• Improper installation, adjustment, alteration, service or maintenance can cause property damage, personal injury or loss of life.

• Installation and service must be performed by a qualied installer, service agency or the gas supplier in accordance with these

instructions and in compliance with all codes and requirements of authorities having jurisdiction.

• Follow all safety codes.

AVERTISSEMENT - EXIGENCES POUR LA SÉCURITÉ

• Si les informations contenues dans ces instructions ne sont pas suivies exactement, ipeut en résulter un empoisonnement au

monoxyde de carbone ou une explosion, causant dommages, blessure ou mort.

• Lisez soigneusement toutes les instructions avant de commencer l'installation. Ne la commencez pas si vous n'avez pas assimilé

toutes ces instructions.

• Une mauvaise exécution d'installation, réglage, altération, intervention ou entretien peut causer dégâts matériels et dommages

corporels ou même mort.

• Installation et interventions doivent être effectuées par un installateur ou une agence de dépannage qualiés, ou par le fournisseur

de gaz en conformité avec toutes les normes et exigences des autorités ayant juridiction en la matière.

• Respectez toutes les normes de sécurité.

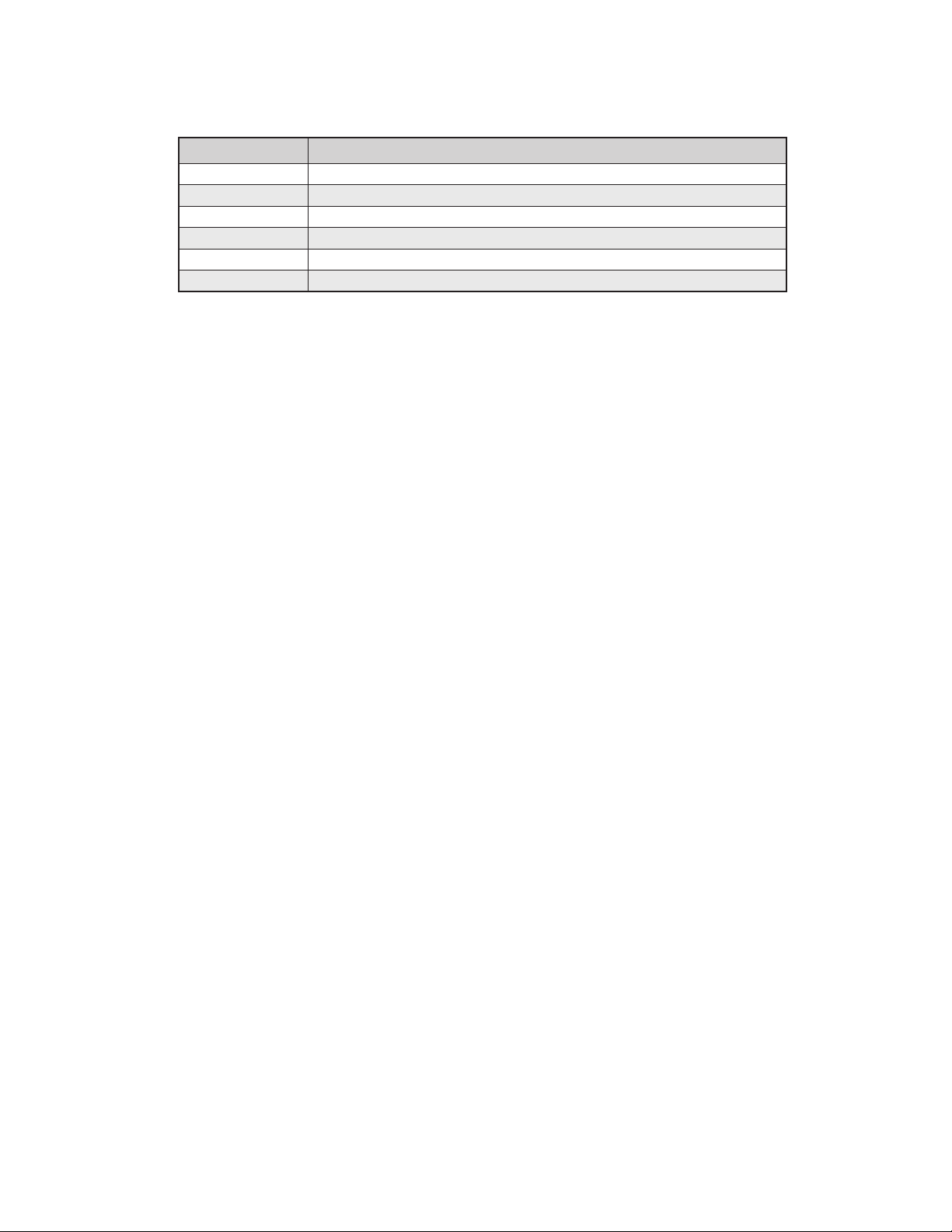

Table of Contents

Chapter 1 - Description & Specications

1.1 General Description ...............................................................................................................................5

1.2 Model Identication ..............................................................................................................................6

1.3 Serial Number Date Code ......................................................................................................................6

1.4 Cooling Mode ......................................................................................................................................6

1.5 Sequence of Operation - Heating Mode ...............................................................................................7

1.6 Ventilation Options ..............................................................................................................................8

1.7 Economizer Operation – Cooling Cycle (unit with economizer only) ................................................9

Chapter 2 Electronic Control Board

2.1 Introduction............................................................................................................................................10

2.2 Installation and Replacement .................................................................................................................11

2.3 PCB Details and Information.................................................................................................................11

2.4 Operation................................................................................................................................................15

2.5 Sequence of Operation ...........................................................................................................................15

Chapter 3 – Safe Installation Requirements

3.1 Safety Rules .......................................................................................................................................28

Chapter 4 – Installation

4.1 Location and Clearances ....................................................................................................................30

4.2 Installation Requirements ..................................................................................................................31

4.3 Dimensional Data ...............................................................................................................................33

4.4 Equipment Inspection ........................................................................................................................36

4.5 Clearances ..........................................................................................................................................36

4.6 Installation Materials .........................................................................................................................37

4.7 Porting and Duct Work ......................................................................................................................38

4.8 General Information ...........................................................................................................................38

4.9 Wall Openings ....................................................................................................................................38

4.10 Minimum Airow Requirements .......................................................................................................38

4.11 Ducting ...............................................................................................................................................39

4.12 Hanging the Unit on the Wall ............................................................................................................39

4.13 Gas Supply and Piping .......................................................................................................................40

4.14 Gas Supply Requirements ..................................................................................................................40

4.15 Gas Piping Requirements ...................................................................................................................40

4.16 Electrical Connections .........................................................................................................................43

4.17 Venting of the Furnace .......................................................................................................................47

4.18 Installation of the Vent Hood. ............................................................................................................47