DOCUMENT NUMBER: OPMM-007E-R0

3.3.2 Uncouple both fuel lines from the fuel tank cap and fill fuel tank with fuel.

ATTENTION

VERSI HEAT II NEEDS TO BE OPERATED WITH FRESH AND CLEAN FUEL. STALE AND/OR

CONTAMINATED FUEL IS THE MOST COMMON SOURCE OF PROBLEMS WITH WATER HEATERS.

VERSI HEAT II NEEDS TO BE OPERATED REGULARLY TO KEEP THE FUEL SUPPLY, FRESH AND

CLEAN. IF IDLE FOR MORE THAN A MONTH, CONTACT YOUR DISTRIBUTOR FOR ASSISTANCE.

3.3.3 Re-couple the fuel lines and strap fuel tank back onto water heater.

3.3.4 Loosen fuel cap 1/8 turn to open breather port on fuel cap neck (Very important).

3.3.5 Connect power supply cable to suitable power supply and press reset button on GFCI unit.

3.3.6 Connect a ¾” or larger supply hose to the inlet port on water heater.

3.3.7 Connect the delivery hose/s to the outlet ports on water heater.

3.3.8 Open the fresh water delivery valve/s and close solution valve/s.

3.3.9 Turn on water supply.

3.3.10 Allow water heater and connected equipment to flush out.

3.3.11 Make sure the heater is clear of all combustible materials and properly vented.

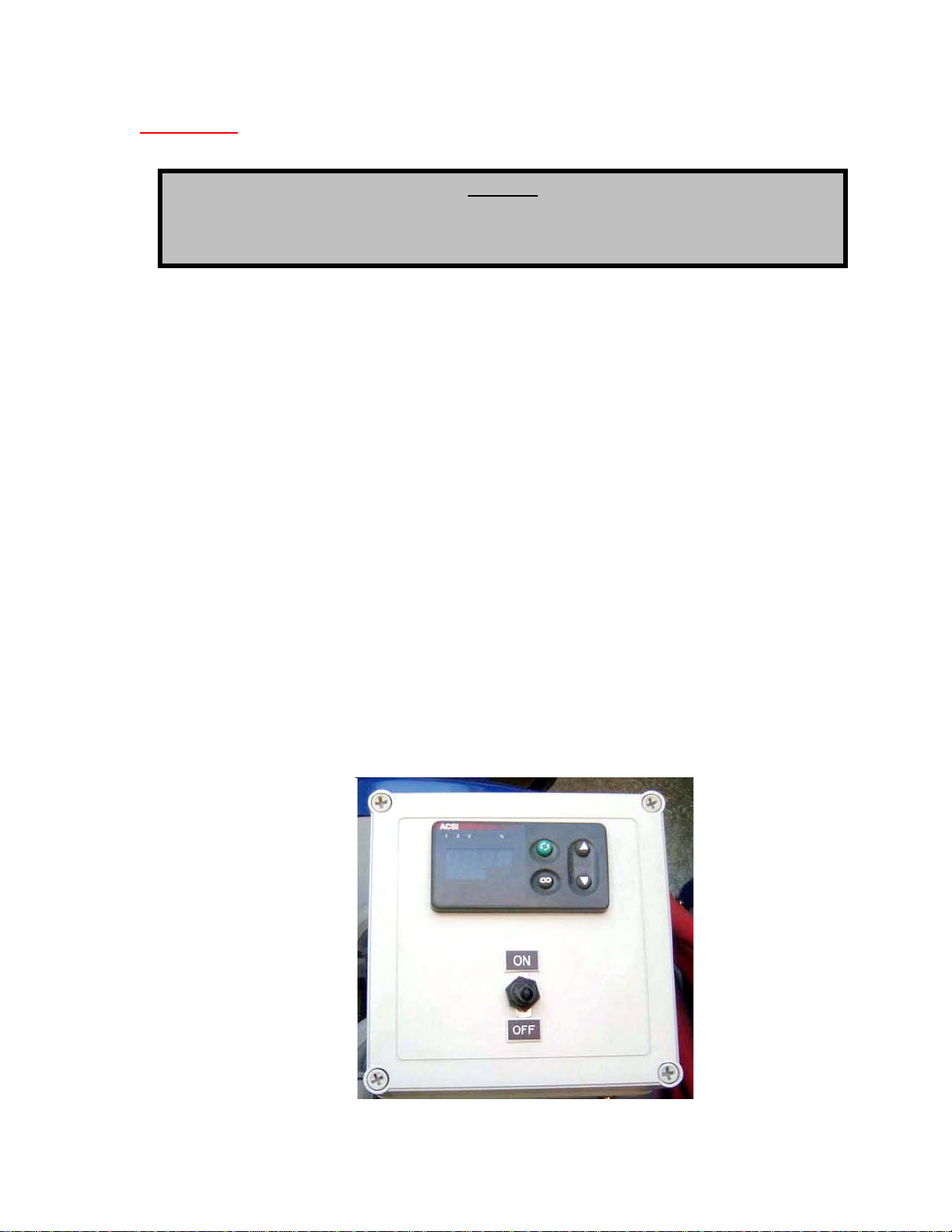

3.3.12 Set the switch on the control panel (Fig. 1) to the “on” position.

3.3.13 The temperature controller display will now show the incoming water temperature and the

burner will fire.

3.3.14 As the burner cycles, the water temperature will increase. The display on the digital

temperature controller will show the outgoing water temperature. When the heater reaches

the set temperature, the burner will begin to short cycle to maintain the set temperature.

3.3.15 The temperature controller is programmed from factory at 92°F / 33°C for optimal

temperature comfort.

3.3.16 If applicable, place the decontamination solution container in designated area close to Versi

Heat II unit and submerge the solution dosing pump pickup line fully into solution. Now set

the solution percentage to desired number by turning the handle adjacent to the pick up line

on dosing pump.

3.3.17 Turn solution valve/s on for solution delivery. A tapping sound can be heard when the

solution pump is activated.

3.3.18 To stop solution injection, simply turn the solution valve/s off.

3.4 Shut-Down Procedure:

3.4.1 Set the switch on the control panel (Fig. 1) to the “off” position.

3.4.2 Allow unit to cool down.

Proprietary Information: This document is the property of ADVANCED CONTAINMENT SYSTEMS, Inc. It shall not be copied

or duplicated and shall not be submitted to outside parties without the company consent.

Page 5 of 122/14/2005