Acson AWM Series User manual

TECHNICAL MANUAL

Chilled Water Fan Coil Units

AWM, ACK, ACM, ACC, ADB Series

AWM-JW ACK-EW ACK-CW

ACC-CW ADB-BW

TM-FCUW-AMA2

ACM-EW

ACC-FWDACC-GW

Table of Contents

Table of Contents

Nomenclature......................................................................................................................1

Product Line-Up.............................................................................................................7

Application Information .....................................................................................................9

Operating Limits ............................................................................................................9

Installation Guide.........................................................................................................12

Sound Data........................................................................................................................25

Sound Pressure Level .................................................................................................25

Sound Power Level .....................................................................................................31

NC Curve.....................................................................................................................37

Selection Process.............................................................................................................65

Fan Performance Curve ..............................................................................................67

Engineering & Physical Data.........................................................................................104

Outlines & Dimensions ..................................................................................................117

Wiring Diagrams .............................................................................................................135

Service & Maintenance ..................................................................................................143

Troubleshooting .............................................................................................................144

Table of Contents

ii

Nomenclature

1

Nomenclature

Remark:

* : Capacity value under Nomenclature is an indication.

Please refer to Engineering and Physical Data for exact capacity value

A WM 07 J W - A M E B A

Model

W : Chilled Water Fan Coil Unit

Brand

A : Acson

Product Series

B : B Series

C : C Series

E : E Series

J : J Series

Product Type

WM : Wall Mouted Type

Size*

07 : 7,000 btu/hr

10 : 10,000 btu/hr

15 : 15,000 btu/hr

20 : 20,000 btu/hr

Revision

A : Revision 1

Power Supply

A : 50Hz/1Ph/220-240v

Manufacturer

M : Malaysia

Motor/Control Module/Wired Controller

E : Handset : GS01 / 02EC

Control Module : 50WJW

Griller

B : Grille B (J Panel)

Nomenclature

2

Remark:

* : Capacity value under Nomenclature is an indication.

Please refer to Engineering and Physical Data for exact capacity value

ACK 06 AAEW - A C C

Specication

C: AC Motor Cooling and Heating

D: DC Motor Cooling and Heating

Revision

AA: Revision 1

AB: Revision 2

Market

C: Export with CE Mark

E: Export without CE Mark

Power Supply

A: 220-240V/1Ph/50Hz

F: 380-415V/3Ph/50Hz

Product Series

E: E series

Size

06: 6 kW*

08: 8 kW*

Fan Coil Unit Type

ACK: Ceiling Cassette (900x900)

Nomenclature

3

Remark:

* : Capacity value under Nomenclature is an indication.

Please refer to Engineering and Physical Data for exact capacity value

CC 10 C W - A C A A AA

Water Pipe Connection

A : Right Piping

B : Left Piping

Revision

A : Revision 1

B : Revision 2

Controller

A : With Controller

N : Without Controller

Power Supply

A : 220-240V/1Ph/50Hz

F : 380-415V/3Ph/50Hz

Product Series

C : C series

Size*

10 : 10,000 btu/hr

15 : 15,000 btu/hr

20 : 20,000 btu/hr

25 : 25,000 btu/hr

Fan Coil Unit Type

CC : Ceiling Concealed

Market

C : Export with CE Mark

E : Export without CE Mark

Model

W : Chilled Water Fan Coil Unit

Brand

A : Acson

Nomenclature

4

Remark:

* : Air Flow Rate value under Nomenclature is an indication.

Please refer to Engineering and Physical Data for exact capacity value

Note:

Please consult factory for customised enquiry.

CC 06 F D - 5 C R F A X A AWA

Product Type

CC : Ceiling Concealed

Size*

06 : 600 CFM

09 : 900 CFM

12 : 1200 CFM

15 : 1,500 CFM

Product Series

F : F series

Application

D : District Cooling

(High ∆T ≈ 9°C)

External Static Pressure

5 : 50Pa

8 : 75-80Pa

Coil & Water Pipe Connection

C : 3 Row, Right Piping

D : 3 Row, Left Piping

E : 4 Row, Right Piping

F : 4 Row, Left Piping

Return Air Plenum & Filter

Removal

R : Rear Return & Side/Bottom

Filter Removal

Filter

F : 8mm Saranet Filter

H : 1inch Aluminium Filter

Drain Pan Material & Length

A : Galvanised Steel

E : Stainless Steel & Standard

Length

Motor/Control Module/Wired

Controller

X : AC/Without Control Module/

Without Wired Controller

Revision

A : Revision 1

B : Revision 2

Insulation Material/Thickness

A : PE/Drain Pan

Standard;Return Air Plenum

Without Insulation

K : NBR/Drain Pan

Standard;Return Air Plenum

Without Insulation

Model

W : Chilled Water Fan Coil Unit

Brand

A : Acson

Nomenclature

5

Remark:

* : Air Flow Rate value under Nomenclature is an indication.

Please refer to Engineering and Physical Data for exact capacity value

Note:

Please consult factory for customised enquiry.

CC 03 G W - 5 C X X A X D AA

Product Type

CC : Ceiling Concealed

Size*

03 : 300 CFM

04 : 400 CFM

06 : 600 CFM

08 : 800 CFM

Product Series

G : G series

External Static Pressure

5 : 50Pa

8 : 75-80Pa

Coil & Water Pipe Connection

C : Right Piping

D : Left Piping

Return Air Plenum & Filter

Removal

X : Without Return Plenum &

Without Filter Removal

S : Rear Return & Side Filter

Removal

Filter

X : No Filter

H : 1’’ Aluminium Filter

F : 8mm Saranet Filter

A : 8mm Aluminium Filter

Drain Pan Material & Length

A : Galvanised Steel & Standard

Length

B : Galvanised Steel & Extended

100mm

E : Stainless Steel & Standard

Length

F : Stainless Steel & Extended

100mm

Motor/Control Module/Wired

Controller

X : AC/Without Control Module/

Without Wired Controller

Revision

A : Revision 1

B : Revision 2

Insulation Material/Thickness

D : PE (10mm)

G : PE (20mm)

K : NBR (10mm)

R : NBR (20mm)

Model

W : Chilled Water Fan Coil Unit

Brand

A : Acson

Nomenclature

6

DB 75 B W - F C N P AA

Water Pipe Connection

P : Right Piping

Q : Left Piping

Air Discharge Direction

A : Horizontal

B : Vertical

Controller

N : Without Controller

Power Supply

A : 220-240V/1Ph/50Hz

F : 380-415V/3Ph/50Hz

Product Series

B : B series

Size*

75 : 75,000 btu/hr

100 : 100,000 btu/hr

125 : 125,000 btu/hr

150 : 150,000 btu/hr

Product Type

DB : Ducted Blower

Market

C : Export with CE Mark

E : Export without CE Mark

Remark:

* : Capacity value under Nomenclature is an indication.

Please refer to Engineering and Physical Data for exact capacity value

Model

W : Chilled Water Fan Coil Unit

Brand

A : Acson

Nomenclature

7

Product Line-Up

Chilled Water Fan Coil Units

Model

Classication

PCB

Handset

Control

Connection

Air Return

Air Discharge

Filter

50WJWXX*

UCW_W2.0*

W3*

Without Controller

BRC52A

BRC51A

Auto Air Swing

Turbo

Quiet

1/2” BSP Female Thread Adaptor

3/4” BSP Female Thread Adaptor

1 1/4” BSP Female Thread Adaptor

3/4” BSPT Female Thread Adaptor

Horizontal Flow

Vertical Flow

Convertible

Horizontal Flow

Vertical Flow

Convertible

Saranet Filter

Viledon R29

AWM07JW X X X X X X X

AWM10JW X X X X X X X

AWM15JW X X X X X X X

AWM20JW X X X X X X X

AWM25JW X X X X X X X

ACK10CW X X X X

ACK15CW X X X X

ACK20CW X X X X

ACK20EW X X X X X X

ACK25EW X X X X X X

ACK30EW X X X X X X X

ACK40EW X X X X X X X

ACK50EW X X X X X X X

ACM15EW X X X X X X X

ACM20EW X X X X X X

ACM25EW X X X X X X

ACM30EW X X X X X X

ACM40EW X X X X X X

ACM50EW X X X X X X

Nomenclature

8

Model

Classication

PCB

Handset

Control

Connection

Air Return

Air

Discharge

Filter

50WJWXX*

UCW_W2.0*

W3*

W3DC*

Without Controller

BRC52A

BRC51A

Auto Air Swing

Turbo

Quiet

3/4” BSP Female Thread Adaptor

1 1/4” BSP Female Thread Adaptor

3/4” BSPT Female Thread Adaptor

1” BSPT Female Thread Adaptor

Horizontal Flow

Vertical Flow

Convertible

Rear Return

Bottom Return

Convertible

Saranet Filter

Viledon R29

ACC10CW X X X X X X

ACC15CW X X X X X X

ACC20CW X X X X X X

ACC25CW X X X X X X

ACC30CW X X X X X X

ACC38CW X X X X X X

ACC40CW X X X X X X

ACC50CW X X X X X X

ACC60CW X X X X X X

ACC06FWD X X X X X X

ACC09FWD X X X X X X

ACC12FWD X X X X X X

ACC15FWD X X X X X X

ACC18FWD X X X X X X

ACC24FWD X X X X X X

ACC30FWD X X X X X X

ACC02GW X X X X

ACC03GW X X X X

ACC04GW X X X X

ACC06GW X X X X

ACC08GW X X X X

ACC10GW X X X X

ACC12GW X X X X

ACC14GW X X X X

ACC16GW X X X X

ACC18GW X X X X

ACC20GW X X X X

ADB075BW X X X X X

ADB100BW X X X X X

ADB125BW X X X X X

ADB150BW X X X X X

* PCB naming

** Standard Model, optional items please refer to Nomenclature.

9

Application Information

Application Information

Model: AWM-JW

Operating Limits:

Thermal carrier : Water

Water temperature : 4°C ~ 10°C (Cooling), 35°C ~ 50°C (Heating)

Maximum water pressure : 16 bar

Air temperature : (as below)

Cooling Mode

Temperature Ts °C/°F Th °C/°F

Minimum indoor

temperature 19.0 / 66.2 14.0 / 57.2

Maximum indoor

temperature 32.0 / 89.6 23.0 / 73.4

Ts: Dry bulb temperature. Th: Wet bulb temperature.

.

Model: ACK-CW

Operating Limits:

Thermal carrier : Water

Water temperature : 4°C ~ 10°C (Cooling), 35°C ~ 50°C (2 Pipes) (Heating)

Maximum water pressure : 16 bar

Air temperature : (as below)

Cooling Mode

Temperature Ts °C/°F Th °C/°F

Minimum indoor

temperature 19.0 / 66.2 14.0 / 57.2

Maximum indoor

temperature 32.0 / 89.6 23.0 / 73.4

Ts: Dry bulb temperature. Th: Wet bulb temperature.

Model: ACK-EW (AC)

Operating Limits:

Thermal carrier : Water

Water temperature : 4°C ~ 10°C (Cooling), 35°C ~ 50°C (2 Pipes) (Heating)

Maximum water pressure : 16 bar

Air temperature : (as below)

Cooling Mode

Temperature Ts °C/°F Th °C/°F

Minimum indoor

temperature 16.0 / 60.8 11.0 / 51.8

Maximum indoor

temperature 32.0 / 89.6 23.0 / 73.4

Ts: Dry bulb temperature. Th: Wet bulb temperature.

.

10

Application Information

Model: ACM-EW

Operating Limits:

Thermal carrier : Water

Water temperature : 4°C ~ 10°C (Cooling), 35°C ~ 50°C

Maximum water pressure : 16 bar

Air temperature : (as below)

Cooling Mode

Temperature Ts °C/°F Th °C/°F

Minimum indoor

temperature 19.0 / 66.2 14.0 / 57.2

Maximum indoor

temperature 32.0 / 89.6 23.0 / 73.4

Ts: Dry bulb temperature. Th: Wet bulb temperature.

Model: ACC-CW

Operating Limits:

Thermal carrier : Water

Water temperature : 4 ~ 10°C (Cooling), 35°C ~ 50°C (Heating)

Maximum water pressure : 16 bar

Air temperature : (as below)

Cooling Mode

Temperature Ts °C/°F Th °C/°F

Minimum indoor

temperature 19.0 / 66.2 14.0 / 57.2

Maximum indoor

temperature 32.0 / 89.6 23.0 / 73.4

Ts: Dry bulb temperature. Th: Wet bulb temperature.

Model: ACC-FWD

Operating Limits:

Thermal carrier : Water

Water temperature : 4 ~ 10°C (Cooling)

Maximum water pressure : 16 bar

Air temperature : (as below)

Cooling Mode

Temperature Ts °C/°F Th °C/°F

Minimum indoor

temperature 19.0 / 66.2 14.0 / 57.2

Maximum indoor

temperature 32.0 / 89.6 23.0 / 73.4

Ts: Dry bulb temperature. Th: Wet bulb temperature.

11

Application Information

Model: ACC-GW (MSP , LSP)

Operating Limits:

Thermal carrier : Water

Water temperature : 4 ~ 10°C (Cooling)

Maximum water pressure : 16 bar

Air temperature : (as below)

Cooling Mode

Temperature Ts °C/°F Th °C/°F

Minimum indoor

temperature 19.0 / 66.2 14.0 / 57.2

Maximum indoor

temperature 32.0 / 89.6 23.0 / 73.4

Ts: Dry bulb temperature. Th: Wet bulb temperature.

Model: ADB-BW

Operating Limits:

Thermal carrier : Water

Water temperature : 4 ~ 10°C (Cooling), 35°C ~ 70°C (Heating)

Maximum water pressure : 16 bar

Air temperature : (as below)

Cooling Mode

Temperature Ts °C/°F Th °C/°F

Minimum indoor

temperature 19.0 / 66.2 14.0 / 57.2

Maximum indoor

temperature 32.0 / 89.6 23.0 / 73.4

Ts: Dry bulb temperature. Th: Wet bulb temperature.

12

Application Information

Installation Guide

System Conguration

The standard controller board comes with a VALVE jumper and a HEAT jumper. The system can be

congured as the jumper selection listed below:

HEAT Jumper VALVE Jumper

Heatpump Mode & Valve Application √ √

Heatpump Mode & Valveless Application √X

Cooling Mode & Valve Application X√

Cooling Mode & Valveless Application X X

√ Jumper Remained X Jumper Removed

Caution

Disconnect the power supply to the unit before attempting to connect the wiring

Valve, Heat and Fan Priority Setting

Model: AWM-JW

HEAT

VALVE

BLACK

N

CN_FAN

CN_PGRM CN_WIR CN_DSP

VALVE HEAT

VALVE

CN_STP

CN_ID COIL

CN_FAN FB

L

BLACK (LIVE)

RED (FAN CAP)

WHITE (NEUTRAL)

Valve Jumper

Heat Jumper

WHITE

BROWN

BLACK

BLUE

BLUE

RED

G/Y

NOTATION

FM : FAN MOTOR

AS : AIR SWING MOTOR

TH1 : INDOOR COIL THERMISTOR

TH2 : ROOM THERMISTOR

-WITH JUMPER FOR HEAT PUMP

-WITHOUT JUMPER FOR COOLING ONLY

-WITH JUMPER FOR VALVE APPLICATION

FIELD WIRING

-WITHOUT JUMPER FOR VALVELESS APPLICATION

2/3 WAY VALVE

LPOWER

SUPPLY

TH2

TH1

DISPLAY BOARD

WIRED

CONTROLLER

(OPTIONAL)

N

E

VALVE

N1 N L

AS

FM

13

Application Information

Model: ACK, ACM, ACC-CW

HTR

L

Heat Jumper Fan Priority Jumper

N2

LIVE

N1

HI

MED

LOW

CN_TW

CN_PGRM

CN_WIR

ROOM CN_STP

C_SENH_SEN

HEAT

VALVE

CN_DSP

SHED

M4

M3

M2

M1

TFULLA_FRZ W_OPEN UNOCP

SLIENT

CVLV

HVLV

WTP

AS

CN_DRY

Valve Jumper

CO_DRAFT

Jumper With Jumper (Default) Without Jumper

Fan Priority Jumper User set speed or lower fan if auto

mode is selected Fan Stop when thermostat cat off

Heat Jumper For Heat pump For Cooling only

Valve Jumper For valve control For valveless control

14

Application Information

Indoor Installation

Model: AWM-JW

The indoor unit must be installed in such a way so as to prevent short circuit of the cool discharged air with

the hot return air. Please follow the installation clearance shown in the gure. Do not place the indoor unit

where there could be direct sunlight shining on it. Also, this location must be suitable for piping and drainage,

and be away from doors or windows.

All dimensions are in mm

min. 50

(Space for

maintenance)

Air flow

(Indoor)

min. 50

(Space for

maintenance)

min. 75

(Space for

performance)

Required space

Air Purging

To prevent pump damage, the fan coil unit should not be energized until the coil and all water lines have

been purged of air.

The Air Vent located inside the casing. Removed the casing and connect hose to the air vent while doing

purging.

Ensure there is no water droplets go into the control box during purging process.

The water piping can be routed to the unit in a number of ways (left or right from the back of the unit), by

using the cut-out holes on the casing of the unit (see gure). Bend the pipes carefully to the required position

in order to align it with the holes. For the side and bottom, hold the bottom of the piping and then position it to

the required direction (see gure). The condensation drain hose can be taped to the pipes.

Right-side, right-back or right-bottom piping

Right-back piping

Right-bottom

piping

Right-side piping

Left-back piping

Left-side piping

Left-bottom piping

Left-side, left-back or left-bottom piping

Remove pipe port cover here

for left-bottom piping

Remove pipe port

cover here for

left-side piping

Remove pipe port cover here

for right-bottom piping

Bind coolant pipe

and drain hose

together with

insulating tape.

Remove pipe port cover here

for right-side piping

15

Application Information

Mounting Installation Plate

Ensure that the wall is strong enough to withstand the weight of the unit. Otherwise, it is necessary to

reinforce the wall with plates, beams or pillars.

Use the level gauge for horizontal mounting, and x it with 5 suitable screws for AWM07/10/15JW and 7

suitable screws for AWM20/25JW.

In case the rear piping draws out, drill a hole 65mm in diameter with a cone drill, slightly lower on the outside

wall (see gure).

Mounting plate

Mounting plate fixing screw

FWW05/06L

Mounting plate

Mounting plate fixing screw

FWW02/03/04L

Mounting plate

Mounting plate

fixing screw

(ALTERNATIVE INSTALLATION PLATE)FWW02/03/04L

Model: ACK/ACM/ACC-C

1. Preliminary Site Survey

Be sure to read this manual before installing the air-conditioner indoor unit.

• Voltage supply uctuation must not exceed +10% of rated voltage. Electricity supply lines must be

independent of welding transformers which can cause high supply uctuation.

• Ensure that the location is convenient for wiring, piping and drainage.

• Do not exert pressure on the resin parts when opening the unit or when moving it after opening.

• Do not move the unit from packaging while moving, until it reaches the installation site. Use safe material

or protection plates when unpacking it or lifting it to avoid damage or scratches to the unit.

eromrom5.0eromrom5.0eromrom5.0

3m or more

3m or more

1m or more

Floor

Obstacle

Beam

• Ensure a location where:

a) Drainage can be done easily.

b) Convenient for wiring and piping.

c) Which have enough space for installation and service work.

d) Where no risk of ammable gas leakage.

e) When free from any obstacles in path of cool air discharge and warm air return and must allow

spreading of air throughout the room (near the center of the room).

f) Must be provided clearance for indoor unit from the wall and obstacles as shown in gure below.

g) The installation place must be strong enough to support a load 4 times the indoor unit weight to avoid

amplifying noise and vibration.

h) The installation place (hanging ceiling surface) must be assuring levelness and the height in the ceiling

is 350mm or more.

i) The indoor unit must be away from heat and steam sources (avoid installing it near an entrance).

16

Application Information

Unit Installation

• Measure and mark the position for the hanging rod. Drill the hole for the angle nut on the ceiling and x the

hanging rod.

• The installation template is extended according to temperature and humidity. Check on dimensions in use.

• The dimensions of the installation template are the same as those of the ceiling opening dimensions.

• Before ceiling laminating work is completed, be sure to t the installation template to the indoor unit.

NOTE

Be sure to discuss the ceiling drilling work with the installers concerned.

ACK-EW (AC,DC) ACK-CW

Unit size 820mm

Piping Direction

Ceiling Opening Site = 890mm

Ceiling Opening Site = 890mm

Hanging Rod Site = 790mm

Unit size 820mm

Unit

Hanging Rod Site = 621mm

15.0 538.0

529.0 19.0

18.0

580.0 ~ 610.0mm (Ceiling Board Opening)

32.0

38.0

505.0

448.0

88.0

580.0 ~ 610.0mm (Ceiling Board Opening)

Unit Hanging

• Conrm the pitch of the hanging rod.

• Hold the unit and hang it on the hanging rod with the nut and washer.

• Adjust the unit height to 35.0mm between the indoor unit bottom surface and the ceiling surface.

• Conrm with a level gauge that the unit is installed horizontally and tighten the nut and bolt to prevent unit

failing and vibration.

• Open the ceiling board along the outer edge of the paper installation template.

Indoor Unit

Ceiling

Board

35.0 mm

35.0mm

Indoor Unit

Ceiling

Board

Drain Piping Work

• Drain pipe must be in downward gradient for smooth drainage.

• Avoid installing the drain pipe in up and down slope to prevent reversed water ow.

• During the drain pipe connection, be careful not to exert extra force on the drain connector at indoor unit.

• The outside diameter of the drain connection at the exible drain hose is 20mm.

• Be sure to execute heat insulation (polyethylene foam with thickness more than 8.0mm) on the drain

piping to avoid the condensed water dripping inside the room.

Pipe Clamp

Ceiling

700.0mm

or less

Panel

Flexible Hose

Indoor

Unit

This manual suits for next models

62

Table of contents

Other Acson Fan manuals

Popular Fan manuals by other brands

Banzai

Banzai COOL FANS SOUND VIBEZ instruction manual

ViM

ViM JBRB ECOWATT PR VCHV instruction manual

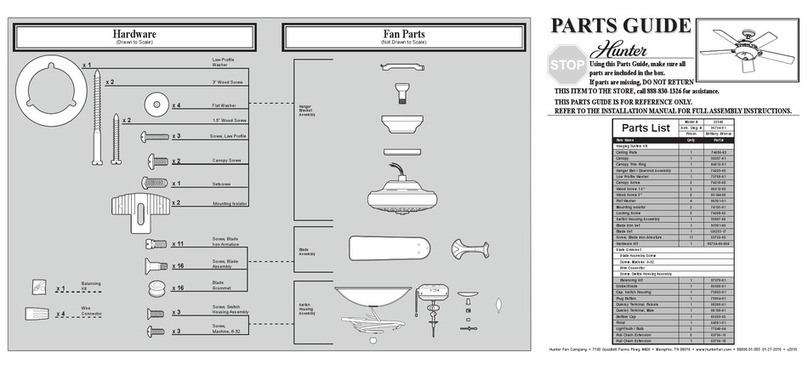

Hunter

Hunter Mill Valley 59309 installation manual

Monte Carlo Fan Company

Monte Carlo Fan Company 5WF52XXD Series owner's manual

Atlas

Atlas Kaye AC-MGM2W instruction manual

S&P

S&P TD-MIXVENT Series instruction manual