4/24 NT00000749-JBRB-ECOWATT-PR-VCHV-AN-211115

1.4 Warranty

The equipment is guaranteed for 24 months from the invoice date. The warranty is limited to the replacement

of parts or equipment whose operation is recognized as defective by VIM, excluding any compensation or

penalties. The costs of labor, removal and rest, travel related to the replacement are the responsibility of the

Customer. Excluded from our warranty are defects linked to abnormal use or not in accordance with the re-

commendations in our instructions, defects observed as a result of normal wear and tear, incidents caused

by negligence, lack of monitoring or maintenance, defects due to incorrect installation of devices or poor

storage conditions prior to assembly.

In any case, maker is not responsible for transformed material, even partially repaired.

2. PRODUCT PRESENTATION

2.1 Description

The PV re N° certies that the JBRB ECOWATT® PR VCHV range complies with the decree of March 22,

2004 of the Ministry of the Interior.

Approved 400°C ½ H C4 - PV Efectis N°: EFR-16-002341.

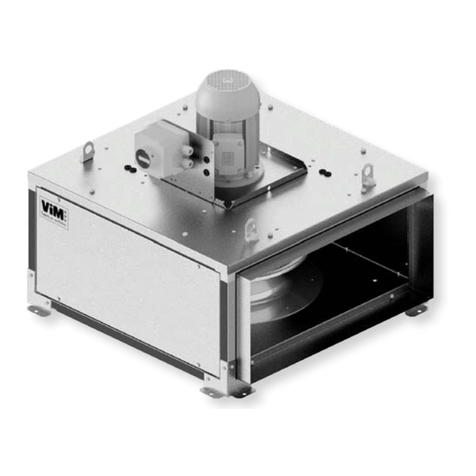

• Galvanized steel sheet casing equipped with 4 xing lugs (size 04 to 38) or 2 transverse omegas

(sizes 48 to 92).

• High performance reaction turbine in galvanized steel.

• INTZ: padlockable proximity switch mounted/wired.

• ECM direct current motor out of the air stream.

-04 to 22: IP44 class B single-phase 230V, 50Hz,

-30, 38, 48, 70, 82: IP54, class F, single-phase 230V, 50Hz,

-30, 38, 48, 70, 92: IP54, class F, three-phase 400V, 50 Hz.

• VCHV controller:

-Constant pressure operation COP.

-Control box, IP 54, factory assembled and

wired.

-4-digit display with setpoint adjustment keys.

Display of the measurement in clear text.

• Connection by circular spigot with class D seal. Vertical discharge version delivered without connec-

tion spigot (at spigot with PAPV seal to be mounted with self-drilling screws as an option).

• Standard or insulated version (acoustic insulation in 25 mm glass wool with M0 re rating).

• Lid equipped with handles, removable without tools.

• Horizontal or vertical discharge version.

• 3 congurations available: in line, double suction, modular: bent delivered with 1 cap or 2 suction at

90°.

Note:

JBRB ECOWATT® PR VCHV models are equipped with an electronically commutated motor.

This motor is protected by :

- an internal thermal protection on the motor winding,

- a thermistor in the electronics.

These safety devices integrated in the motors have been tested and validated during the re resistance

test, subject of a report of classication C4 400°C 1/2h.