Actavo BoSS SOLO 700 User manual

www.actavo.com

BoSS

SOLO700

One Man Aluminium Tower

3T - Through the Trapdoor Method

www.actavo.com

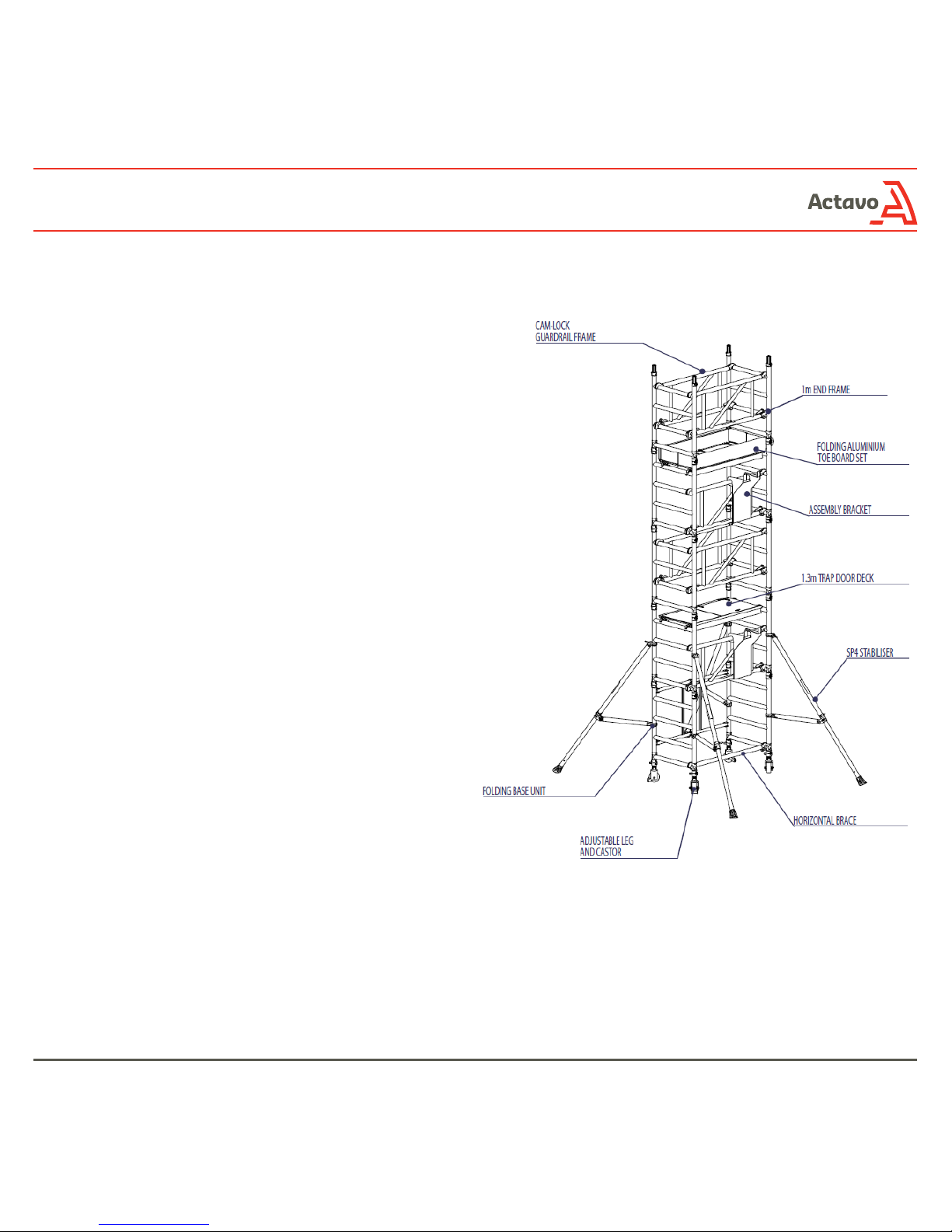

BoSS SOLO700 USER GUIDE

Safety First

Mobile Towers - 3T Method

INTRODUCTION

Please read this Userguide carefully. Please note that diagrams

are for illustrative purposes only. User guides are also available

to download - please contact us for details.

BoSS aluminium towers are light-weight scaffold towers used

throughout the building and construction industry for both

indoor and outdoor access solutions where a stable and secure

platform is required. Ideal for maintenance and installation work

or short term access, the highly versatile towers provide a strong

working platform at a variety of heights.

The law requires that personnel erecting towers must be

competent. Any person erecting, dismantling or altering a BoSS

Zone 1 mobile tower must have a copy of this guide.

For further information on the use of mobile access and working

towers consult the PASMA code of practice. If you need further

information, design advice, additional guides or any other help

with this product, please contact Actavo on 0800 214 005 or

email quoteme@actavo.com

COMPLIANCES

The BoSS Clima aluminiumsystemhas been tested and certified

to EN 1004: 2004 Class 3

Instruction Manual EN 1298-IM-EN

PREPARATION AND INSPECTION

Inspect the equipment before use to ensure that it is not

damaged and that it functions properly. Damaged or incorrect

components should not be used.

Safety First

SAFE USE

•Check that all components are on site, undamaged and that

they are functioning correctly - (refer to Checklist and

Quantity Schedules). Damaged or incorrect components

should not be used.

•Check if the ground on which the mobile access tower is to be

erected and moved is capable of supporting the tower.

•The safe working load is 275 kgs (606lbs) per platformlevel,

uniformly distributed up to amaximumof 950kgs (2100lbs),

per tower (including self weight).

•Towers must always be climbed fromthe inside using the

built-in ladder during assembly and use.

•It is recommended that towers should be tied to asolid

structure when le unattended.

•Adjustable legs should only be used for levelling.

LIFTING OF EQUIPMENT

•Tower components should be lied using areliable liing

material (e.g. strong rope), employing areliable knot (e.g.

clove hitch), to ensure safe fastening and always li within the

footprint of the tower.

•Assembled mobile towers

FREEPHONE: 0800 214 005

www.actavo.com

BoSS SOLO700 USER GUIDE

Safety First

STABILISERS/BALLAST

•Stabilisers or outriggers and ballast weights should always be

fitted when specified.

•The Quantity Schedules showthe recommended stabilisation.

In circumstances where there is restricted ground clearance for

stabilisers/outriggers, contact your supplier for advice. Ballast

must be made up of solid materials (i.e. not water or loose

sand) and should not be positioned to overload individual legs.

Ballast should be secured against accidental removal where

practicable, and be supported on the lowest rung of the

bottomframe.

MOVEMENT

•The tower should only be moved by manual eort, and only

fromthe base.

•Beware of live electrical apparatus when moving the tower

(particularly overhead), plus wires or moving parts of

machinery.

•No person or materials should be on the tower during

movement.

•Caution should be exercised when wheeling atower over rough,

uneven or sloping ground, taking care to unlock and lock

castors. If stabilisers are fitted, they should only be lied a

maximumof 25mm above the ground to clear ground

obstructions.

•The overall height of the tower when being moved should not

exceed 2.5 times the minimumbase dimensions, or 4 metres

overall height.

•Before use, check that the tower is still correct and complete.

•Aer every movement of the tower, use aspirit level to check

that it is vertical and level and set the adjustable legs as

required.

•Do not move the tower in wind speeds over 7.7 metres per

second (17mph).

Safety First

DURING USE

•Beware of high winds in exposed, gusty or mediumbreeze

conditions. We recommend that in wind speeds over 7.7

metres per second (17 mph), cease working on the tower and

do not attempt to move it. If the wind becomes astrong breeze

(expected to reach 11.3 metres per second - 25 mph) tie the

tower to arigid structure. If the wind is likely to reach gale

force (over 18 metres per second - 40 mph), the tower should

be dismantled.

•Beware of open ended buildings, which can cause afunnelling

effect.

•Do not abuse equipment. Damaged or incorrect components

should not be used.

•Raising and lowering components, tools, and/or materials by

rope should be conducted within the lower base. Ensure that

the safe working load of the supporting decks and the tower

structure is not exceeded.

•The assembled tower is aworking platformand should not be

used as ameans of access or egress to other structures.

•Beware of horizontal forces (e.g. power tools) which could

generate instability. Maximumhorizontal force 20kg.

•Mobile towers are not designed to be suspended - please refer

to your supplier for advice.

•Do not use boxes or stepladders or other objects on the

platformto gain extraheight.

FREEPHONE: 0800 214 005

WIND BEAUFORT BEAUFORT SPEED IN SPEED IN

DESCRIPTION SCALE NO. MPH M/SEC

Medium

Breeze

Strong Breeze

Gale Force

Raises dust and

loose paper, twigs

snap o

Large branches in

motion, telegraph

wires whistle

Walking is dicult

4

6

8

8-12

25-31

39-46

4-6

11-14

17-21

www.actavo.com

BoSS SOLO700 USER GUIDE

Safety First

TIES

•Ties should be used when the tower goes beyond its safe

height, beyond the limits of the stabilisers/outriggers or if

there is adanger of instability. They should be rigid, two way

ties fastened to both uprights of the frame with load-bearing

right angled or swivel couplers. Only couplers suitable for the

50.8mm diameter tube of the tower should be used. Ideally,

ties should be secured to both faces of asolid structure by

means of anchorages.

•The tie frequency may vary depending on the application, but

they should (at aminimum) be every 4 metres in height.

•For further information on tying-in atower please contact your

supplier or BoSS.

MAINTENANCE - STORAGE -

TRANSPORT

•All components and their parts should be regularly inspected

to identify damage; particularly to joints. Lost or broken parts

should be replaced, and any tubing with indentation greater

than 5mm should not be used and put to one side for

manufacture repair. Adjustable leg threads should be cleaned

and lightly lubricated to keep themfree running.

•Brace claws, frame interlock clips, trapdoor latches and

platformwindlocks should be regularly checked to ensure they

lock correctly.

•Components should be stored with due care to prevent

damage.

•Ensure components are not damaged by excessive strapping

forces when transported.

Safety First

FREEPHONE: 0800 214 005

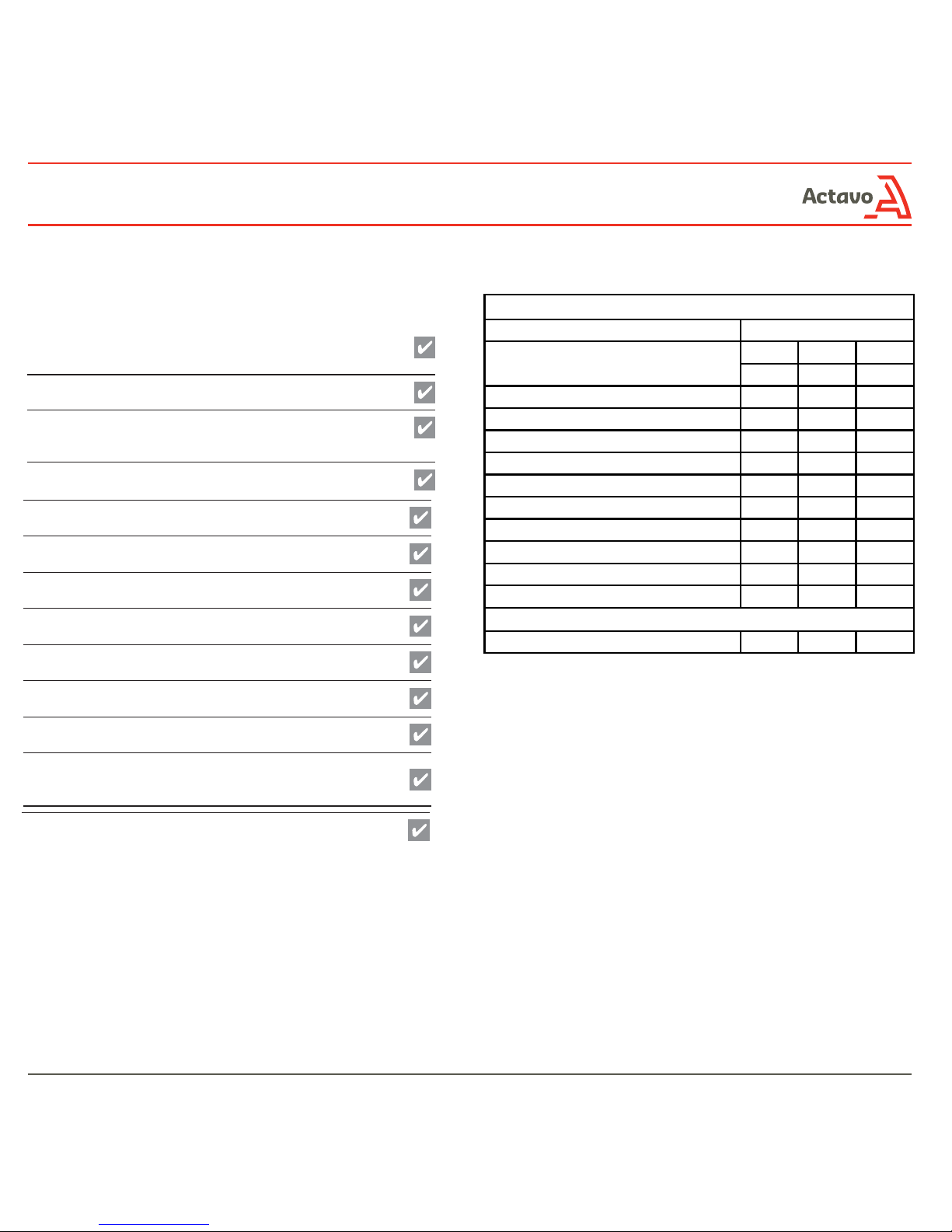

Safety Checklist

Mobile Towers - 3T Method

CHECKLIST

Ensure all components are present (see quantity

schedule on page 9)

Inspect components prior to erection

Inspect tower prior to use

Tower upright and level

Castors locked and legs correctly adjusted

Diagonal braces fitted

Stabilisers/outriggers fitted as specified

Platforms located and windlocks on

Toeboards located

Check guardrails are fitted correctly. See

illustration below.

www.actavo.com

BoSS SOLO700 USER GUIDE

FREEPHONE: 0800 214 005

Ensure all brace claws, cam-locks and adjustable

legs operate correctly

Ensure castors rotate freely and brakes lock

Re-inspect the tower every seven days or less

Quantity Schedule

BoSS Solo 700 - 1.3m x 0.7m

3T Method Internal or external use

Component

Working Height (m)

Platform Height (m)

4.2 5.2 6.2

2.2 3.2 4.2

Castor 444

Adjustable Leg 444

4 Rung End Frame (1.0m high x 0.7m wide) 468

Folding Base Unit 111

1.3m CamLock Guardrail Frame 356

1.3m Trap Door Deck 122

1.3m Horizontal Brace 111

Aluminium Folding Toe Board 111

Assembly Bracket 222

SP4 Telescopic Stabiliser 444

Total Self Weight of Tower (Kg) 93 121 134

Table of contents