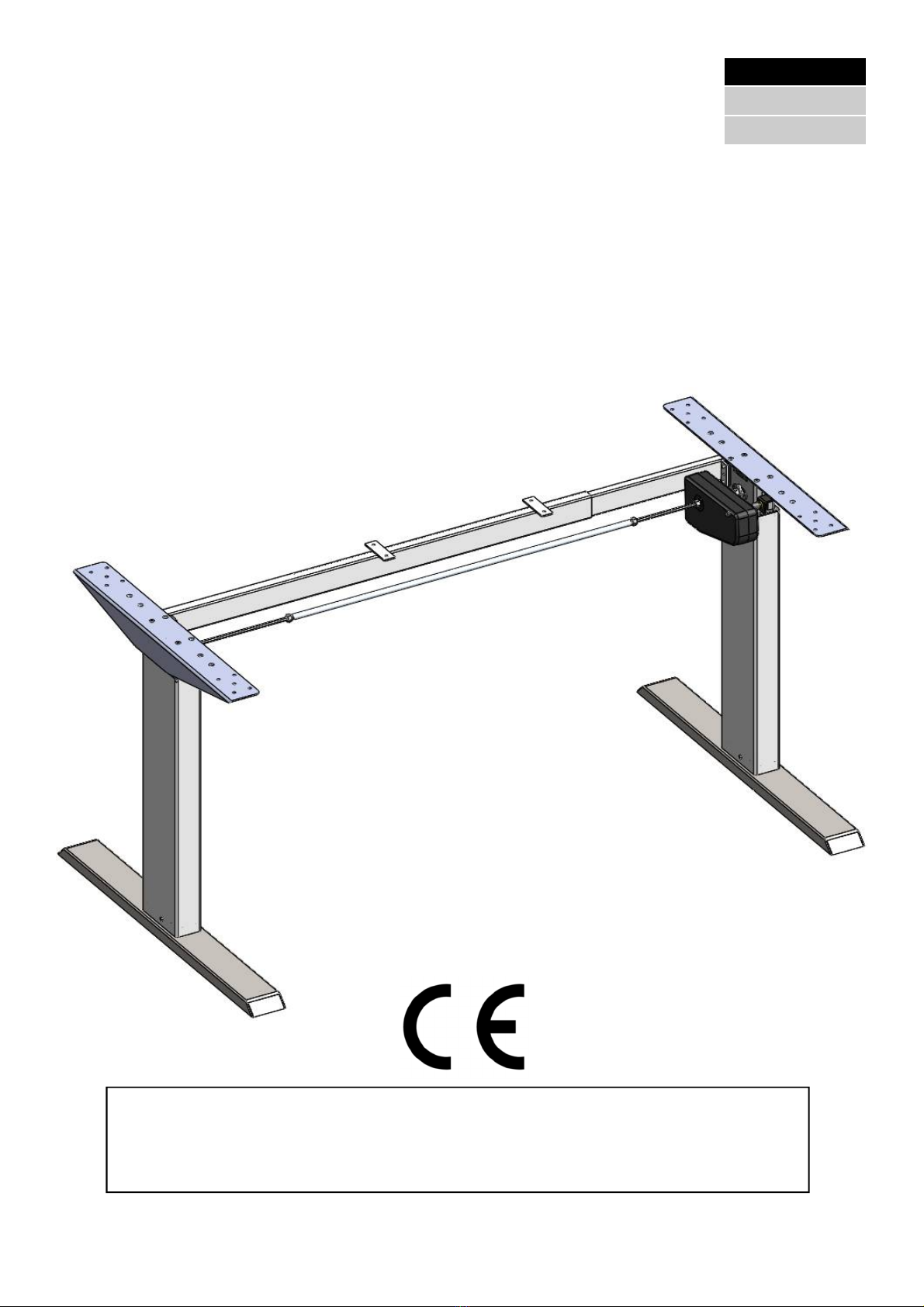

Actiforce Aluforce Pro 140 M User manual

Frame for an electro-motorized workstation

Aluforce Pro 140 M

Read this manual thoroughly and store in a safe place!

Assembly Manual

P19300-1EN-DE-NL

English

Deutsch

Nederlands

2

Content

1 GENERAL ....................................................................................................................................................... 3

1.1 Local value of the assembly/operating manual ...................................................................................... 3

1.2 Intended use ........................................................................................................................................... 3

1.3 Improper use .......................................................................................................................................... 3

1.4 Content box ............................................................................................................................................ 4

2 SAFETY INFORMATION .............................................................................................................................. 5

2.1 Symbols/warnings .................................................................................................................................. 5

2.2 Symbols used on the workstation frame ................................................................................................. 5

2.3 Organizational measures ........................................................................................................................ 5

2.4 Informal safety measures ....................................................................................................................... 5

2.5 Note for those assembling the workstation ............................................................................................. 5

2.6 Transport and assembly ......................................................................................................................... 5

2.7 Safety/protective measures ..................................................................................................................... 5

2.8 Use of the workstation frame ................................................................................................................. 6

2.9 Specific dangers ...................................................................................................................................... 6

2.10 In an emergency ..................................................................................................................................... 6

2.11 Maintenance and upkeep ....................................................................................................................... 6

2.12 Cleaning ................................................................................................................................................. 6

2.13 Persistent risks ....................................................................................................................................... 6

3 ASSEMBLY ..................................................................................................................................................... 7

3.1 Checking the items supplied ................................................................................................................... 7

3.2 Packaging ............................................................................................................................................... 7

3.3 Tightening torques for screws used ........................................................................................................ 7

3.4 Assembly of the workstation .................................................................................................................. 7

3.4.1 Pre-assembly of the Crossbar ............................................................................................................... 7

3.4.2 Mounting the Crossbar ........................................................................................................................ 8

3.4.3 Mounting the Feet .............................................................................................................................. 10

3.4.4 Mounting the Hexagon Shaft ............................................................................................................. 12

3.4.5 Mounting the Top Supports ................................................................................................................ 14

3.4.6 Mounting the Drive Unit .................................................................................................................... 15

3.4.7 Adjustment of the frame width ............................................................................................................ 16

3.4.8 Connecting the Cables Drive Unit ....................................................................................................... 17

3.4.9 Frame test without tablet op ................................................................................................................ 18

3.4.10 Note: Mounting the table top .............................................................................................................. 18

3.4.11 Note: Mounting the power supply underneath the table top......................................................................18

3.4.12 Identification sticker...................................................................................................................................18

4 TECHNICAL SPECIFICATIONS ................................................................................................................. 19

5 OPERATION AND INDICATORS ................................................................................................................ 21

5.1 Indicators .............................................................................................................................................. 21

6 CUSTOMER SERVICE ................................................................................................................................ 22

7 MANUFACTURER ........................................................................................................................................ 22

8 RECYCLING .................................................................................................................................................. 22

8.1 Taking the workstation out of active duty ............................................................................................. 22

8.2 Taking the workstation apart ................................................................................................................ 22

8.3 Recycling ............................................................................................................................................... 22

3

1 General

1.1 Local value of the assembly/operating manual

The guiding principle for safe use and trouble-free operation of this workstation frame is knowledge

of basic safety information and regulations. This assembly/operating manual contains the most im-

portant information needed for assembling and operating the workstation frame safely. This assem-

bly/operating manual, in particular the safety information contained herein, must be observed by any

person building the frame and working on the finished surface. More importantly, the rules and regu-

lations applying to accident prevention in the locality in which the workstation frame is to be used

must be observed at all times.

1.2 Intended use

The workstation frame must be used only as an electrically height-adjustable workstation for sitting/

standing use in offices or other enclosed areas. The frame must be used for this purpose only. The

workstation frame may be set up and operated solely in office environments. Do not use the work-

station frame in the home. Please observe the provisions of Section 2, Safety Information. Children

may be unaware of the dangers presented by the workstation frame if unsupervised. Any other use

than the above shall be deemed improper. The manufacturer can in no way be held liable for damage

arising from improper use.

Intended use shall also include:

Observation of all information from the assembly/operating manual and

Prohibition of any sort of addition to/conversion of the workstation.

1.3 Improper use

Never use the workstation frame to lift people or loads.

Do not exceed the maximum load of the workstation frame (see Section 4, Technical Data).

Do not use the workstation frame in the home; alternatively, use it only in offices.

WARNING Any changes or modifications not expressly approved by the manufacturer

could void the user’s authority to operate the equipment.

4

12

04

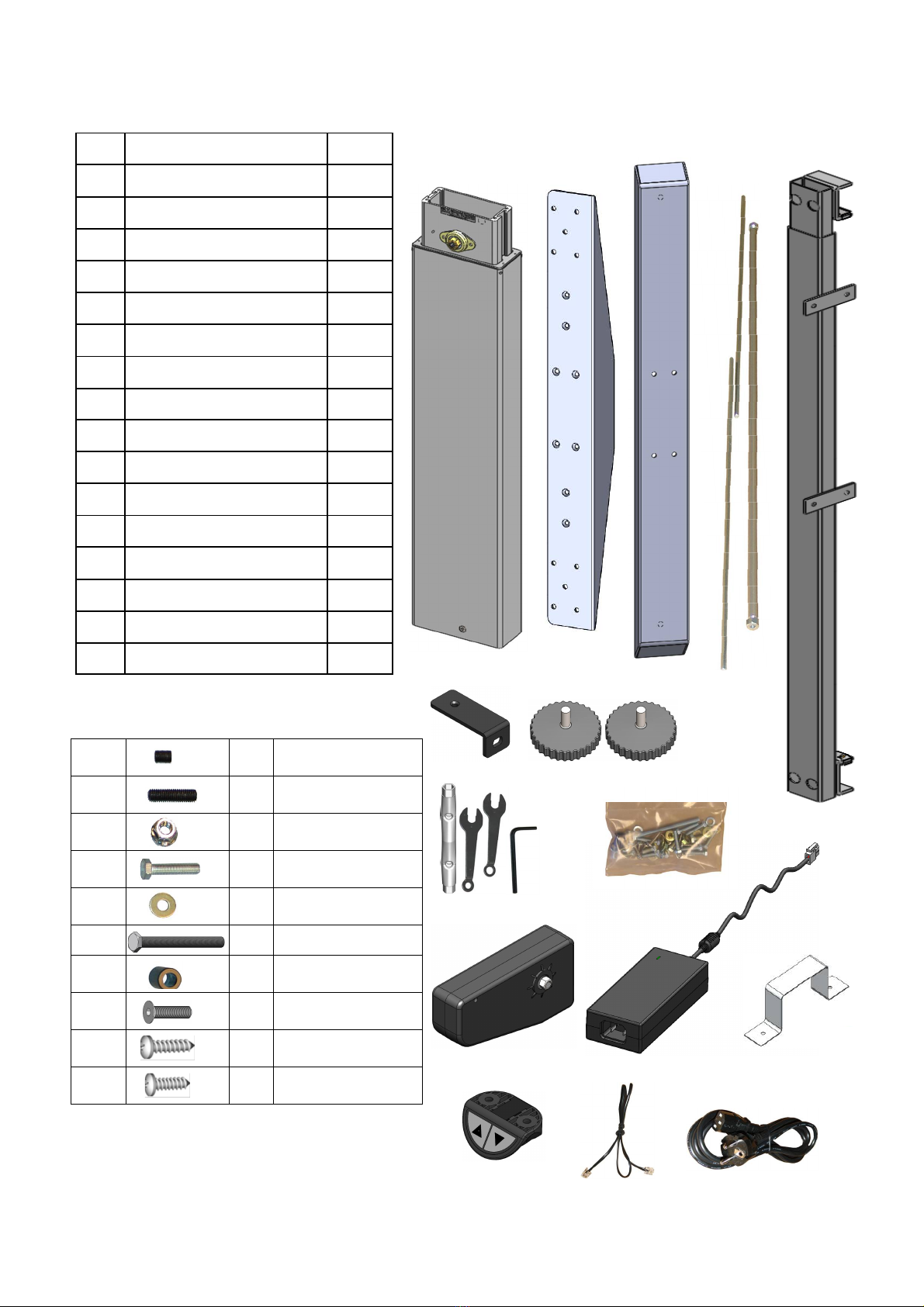

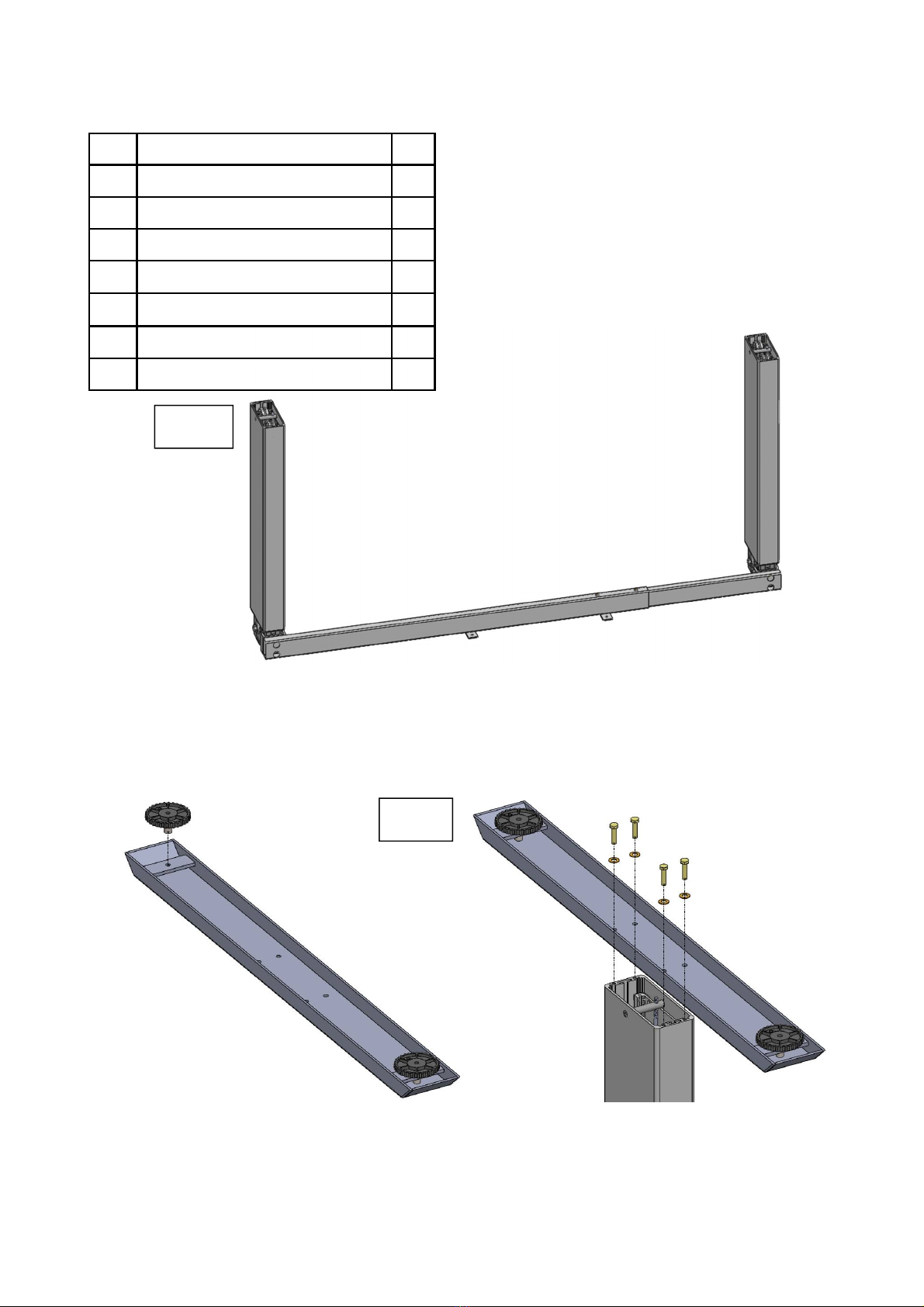

1.4 Content box

05

03

01

06

02

10

09

11

07

13

15

# Part name Qty

01 Leg 2

02 Top support 2

03 Foot 2

04 Hexagon shaft 2

05 Axle Drive 1

06 Crossbar 1

07 L-Bracket 1

08 Foot adjusters 4

09 Tools 1

10 Mounting hardware kit 1

11 Drive unit 1

12 Power supply 1

13 Holder 1

14 Up/down switch 1

15 Cable up/down switch 1

16 Power Cord 1

08

14 16

10.1 2x Set Screw M6x6

10.2 4x Set Screw M6x20

10.3 6x Flange Nut M6

10.4 8x Hex Bolt M6x25

10.5 9x Washer M6

10.6 1x Hex Bolt M6x80

10.7 1x Spacer

10.8 9x CSK M5x25

10.9 2x Chipboard 4.5x20

10.10 26x Chipboard 4.5x16

5

2 Safety Information

2.1 Symbols/warnings

The assembly/operating manual uses the following terms and signs to indicate dangers:

2.2 Symbols used on the workstation frame

2.3 Organizational measures

The workstation frame can best be assembled by two people. Turning the frame, once the

work surface has been fitted, is a task in particular which requires two people!

2.4 Informal safety measures

Keep the assembly/operating manual in the place where the workstation frame is used at all

times.

Make sure that all safety information on the table (see Section 2.2, Symbols used on the

workstation frame, page 5) is legible, replacing the same if necessary.

2.5 Note for those assembling the workstation

The workstation must be assembled/worked on by persons over the age of 16.

The persons referred to above must have read and understood the assembly/operating manu-

al.

2.6 Transport and assembly

The workstation frame must be moved by two persons only, and in such cases must be re-

tracted.

Do not drag or pull the workstation frame over the floor.

Assemble the workstation frame with the supplied tools only. They are the only tools which

ensure that the screws can be tightened to the correct torque.

2.7 Safety/protective measures

Replace the drives if the circuit breaker in the drives fails. Faulty circuit breakers will not

switch off the drive in the top/bottom setting. In such cases, the workstation frame has been

taken to the mechanical stop and can no longer be raised/lowered.

This symbol indicates an immediate threatening situation for any person’s life

or health. Failure to adhere to such information may have serious consequences

for health, or could even result in life-threatening injury or death.

This symbol indicates important information. Failure to adhere to such infor-

mation could lead to damage to the workstation.

Do not place objects or parts of the body under the workstation frame or be-

tween the cross members. This could cause serious injury.

Do not exceed the maximum permitted load on the workstation frame. Over-

loading could lead to breakage and serious injury as a consequence.

6

2.8 Use of the workstation frame

Do not allow children to use the workstation frame unsupervised. Children may be unaware

of the dangers presented by the workstation frame. They would be in serious danger of injur-

ing themselves, possibly even with fatal consequences. Further adjustment must then be im-

possible as a safeguard against use by children.

The workstation frame must only be used in appropriate areas (see Section 4 Technical Da-

ta).

Do not use the workstation frame on an uneven surface. In such conditions it will not be

steady.

Never exceed the maximum load on the workstation frame (see Section 4 Technical Data).

2.9 Specific dangers

When adjusting the height of the frame there is danger of injury. Make sure that there is no-

one else in the immediate surroundings of the frame.

When assembling the workstation frame, make sure there is ample space to avoid collisions

(i.e. inclination of roof, fixed objects, filing cabinets, waste-paper bins etc.) in all imaginable

directions.

Make sure there is ample space to avoid collisions if there are objects on the work surface

such as computers or computer peripherals.

Make sure there is clearance of at least 25 mm from all other furniture, all around the work-

station frame.

2.10 In an emergency

Stop using the workstation frame at once if you notice anything unusual (strange sounds

etc.).

Have the workstation frame repaired by specialists. Refrain from using the workstation

frame until it has been successfully repaired.

2.11 Maintenance and upkeep

The workstation frame and its components are low-maintenance items and need no special

regular maintenance.

Do not perform any repairs on the work surface or other components yourself.

Do not alter the construction of the work surface or its frame.

Any faulty components removed must be replaced with new, original components from the

manufacturer. Use only original replacement parts made by the manufacturer. Have any such

work carried out by a specialist, making reference to this Assembly/operating manual.

2.12 Cleaning

Dust the workstation frame once a week with a dry cloth.

Clean the workstation frame with a damp cloth and a weak solution of cleaner once a fort-

night.

2.13 Persistent risks

This workstation frame has been built to the state of the art and to recognized safety regulations.

Nonetheless, its use may constitute a risk to the health and safety of users or third parties, damage

to the workstation frame or to other items. The workstation frame must be used only:

for the purpose for which it was intended.

if it is completely safe to do so.

7

3 Assembly

3.1 Checking the items supplied

Carefully open the cardboard packaging.

In doing so, do not use any long knife blades. They may damage the components inside.

Check the parts supplied against the list in Section 1.4 Items supplied.

Check the contents for visible transit damage, paying particular attention to the electrical wiring.

In the event of any damage or incorrect components, contact customer services (see Section 7).

Do not attempt to assemble the workstation frame if there is any damage or if there are any in-

correct components.

3.2 Packaging

Remove the packaging. Treat as household waste/paper.

Observe national legislation.

3.3 Tightening torques for screws used

Assemble the workstation frame with the tools supplied only.

3.4 Assembly of the workstation

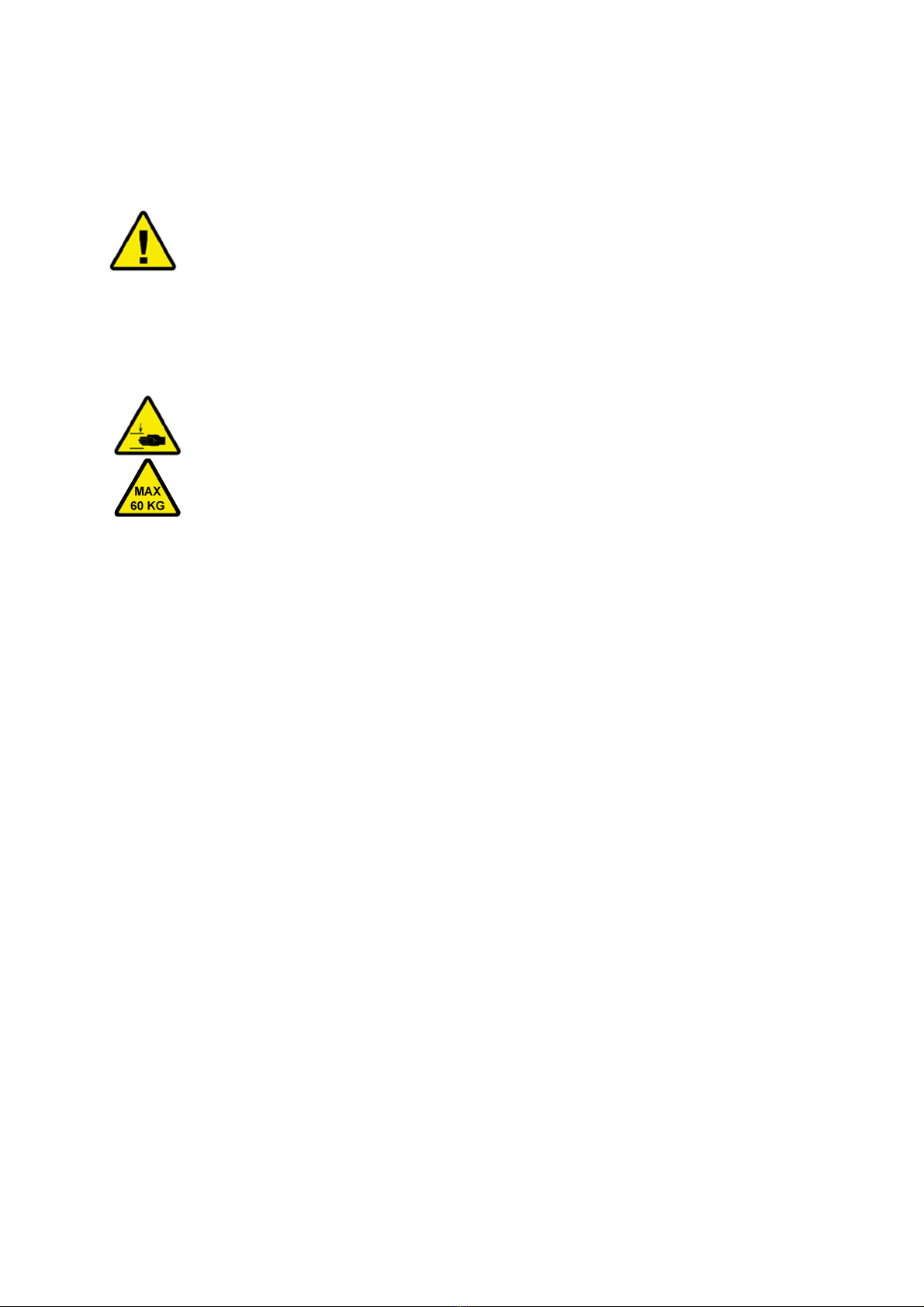

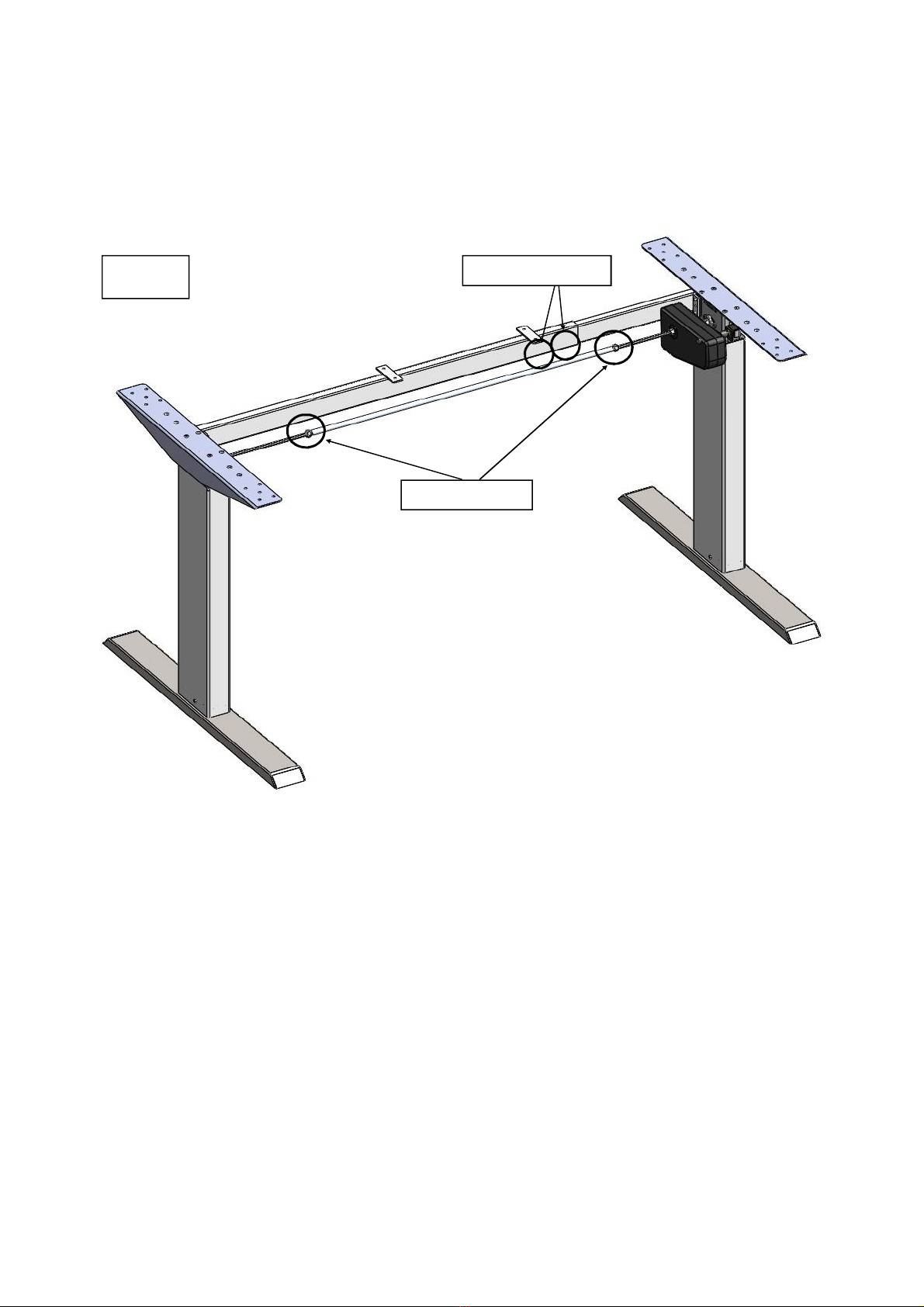

3.4.1 Pre-assembly of the Crossbar

Assemble the following components:

Before attempting assembly, read the safety information in Section 2.

Assemble the 2 set screws in the tapped holes.

Do not yet tighten the socket screws!

Tighten the socket screws only after assembling the components in step 3.4.7 Adjustment

of the frame width, page 16.

Indicative:

Frame set-up Wide/size tabletop

1,1 m 120 cm

1,3 m 140 cm

1,5 m 160 cm

1,7 m 180 cm

# Part name Qty

06 Crossbar 1

09 Allen key M3 1

10.1 Set Screw M6x6 2

Set screw M6x6

8

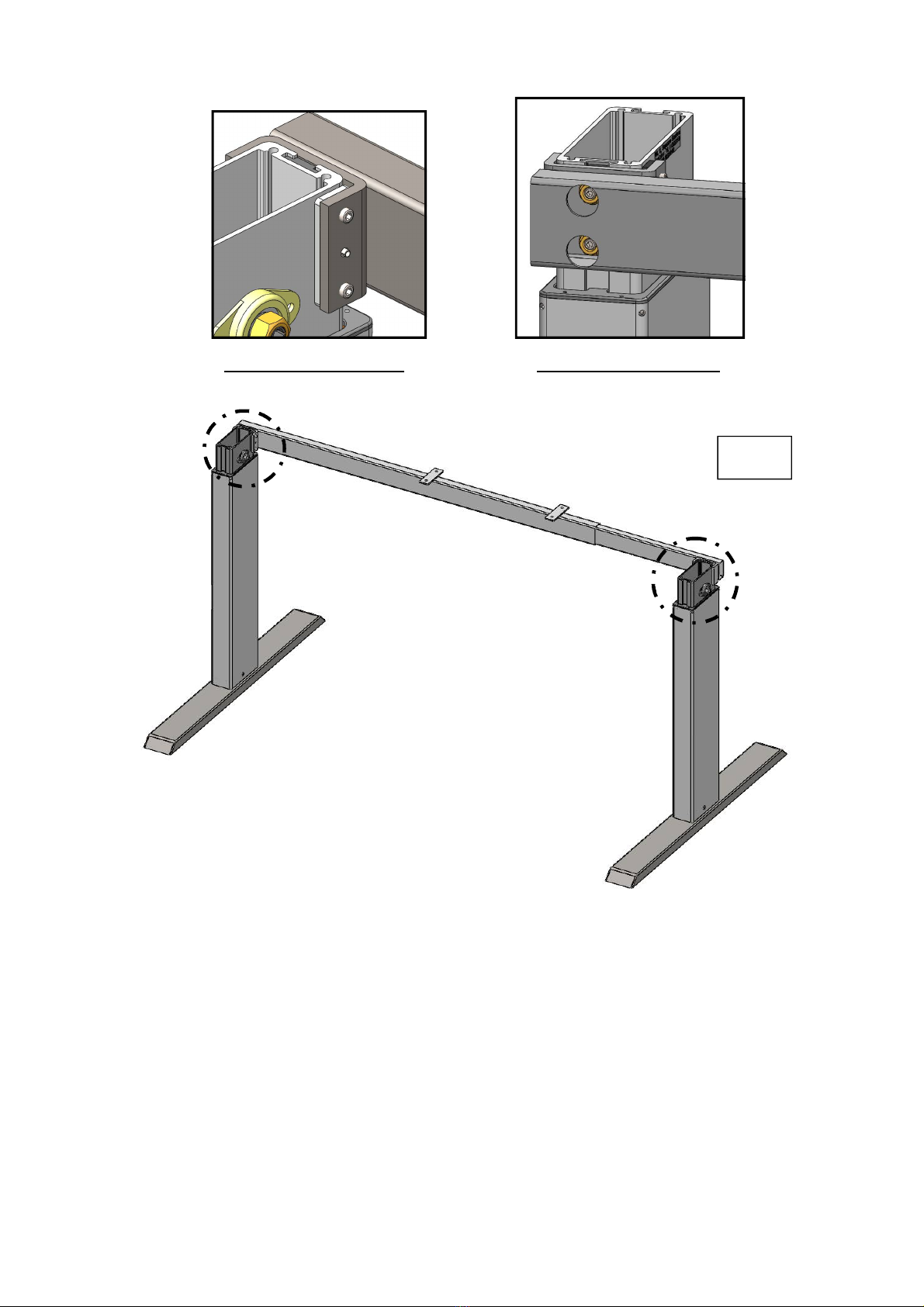

3.4.2 Mounting the Crossbar

Assemble the following components:

# Part name Qty

01 Leg 2

06 Pre-assembled Crossbar 1

09 Pipe Key M10 1

09 Allen key M3 1

10.2 Set Screw M6x20 4

10.3 Flange Nut M6 4

2

Photo 2

Place both legs flat on the floor, parallel to each other.

Be aware that both slide nuts point upwards.

Twist in 2 set screws into the slide nut of each leg.

Gently tighten the set screws with the Allen key M3.

Photo 1

Remove the transparent cellulose tape on the crossbar bracket before mount to the

leg unit.

1

Cellulose

Tape

9

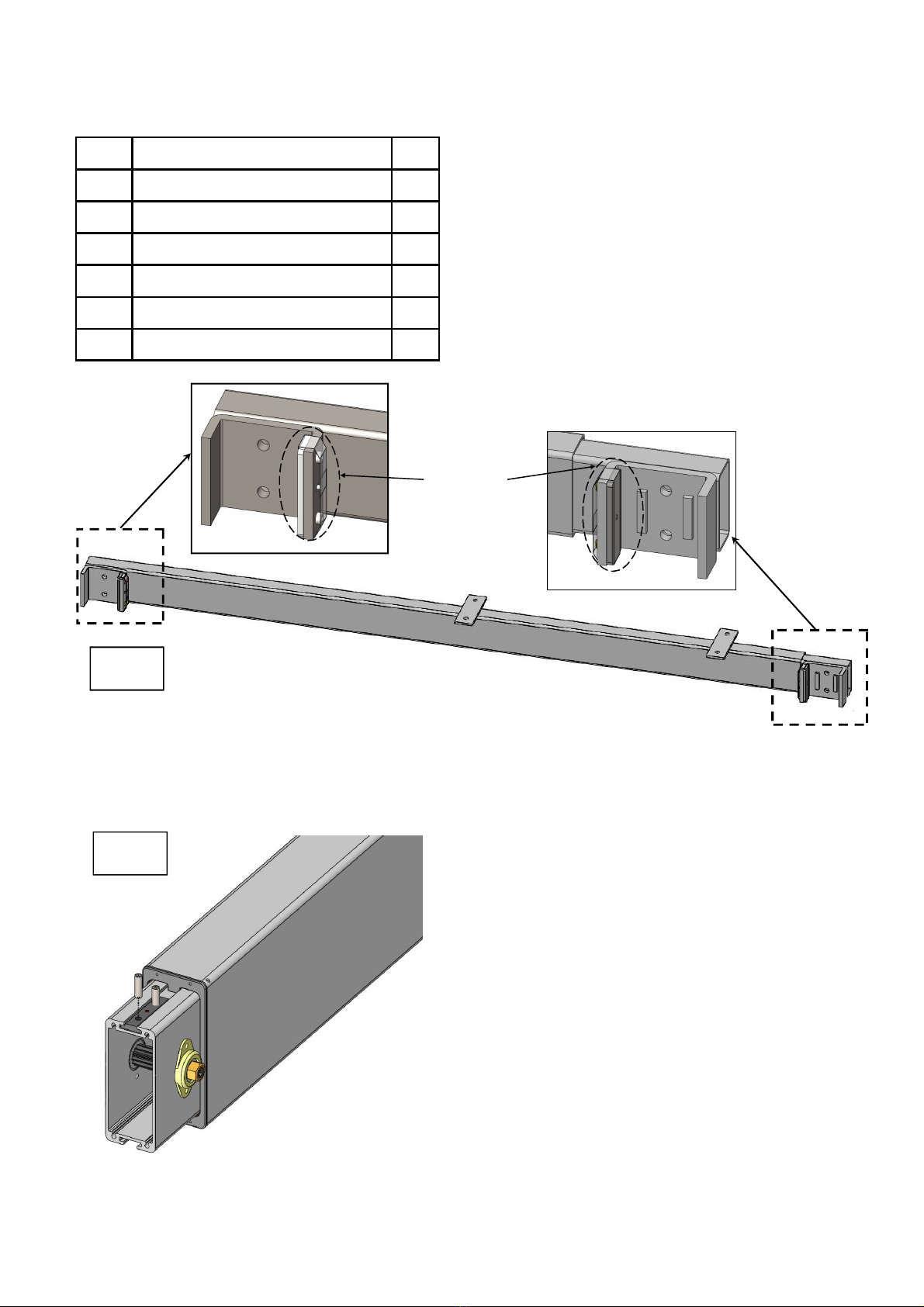

3

4

Photo 3

Place the pre-assembled crossbar over the set screws.

Place the 4 flange nuts on the set screws.

Hand tighten the 4 flange nuts with the Pipe Key M10.

Important !!!

Do not fully tighten the flange nut.

Prevent the plate in crossbar bracket

from falling off!

10

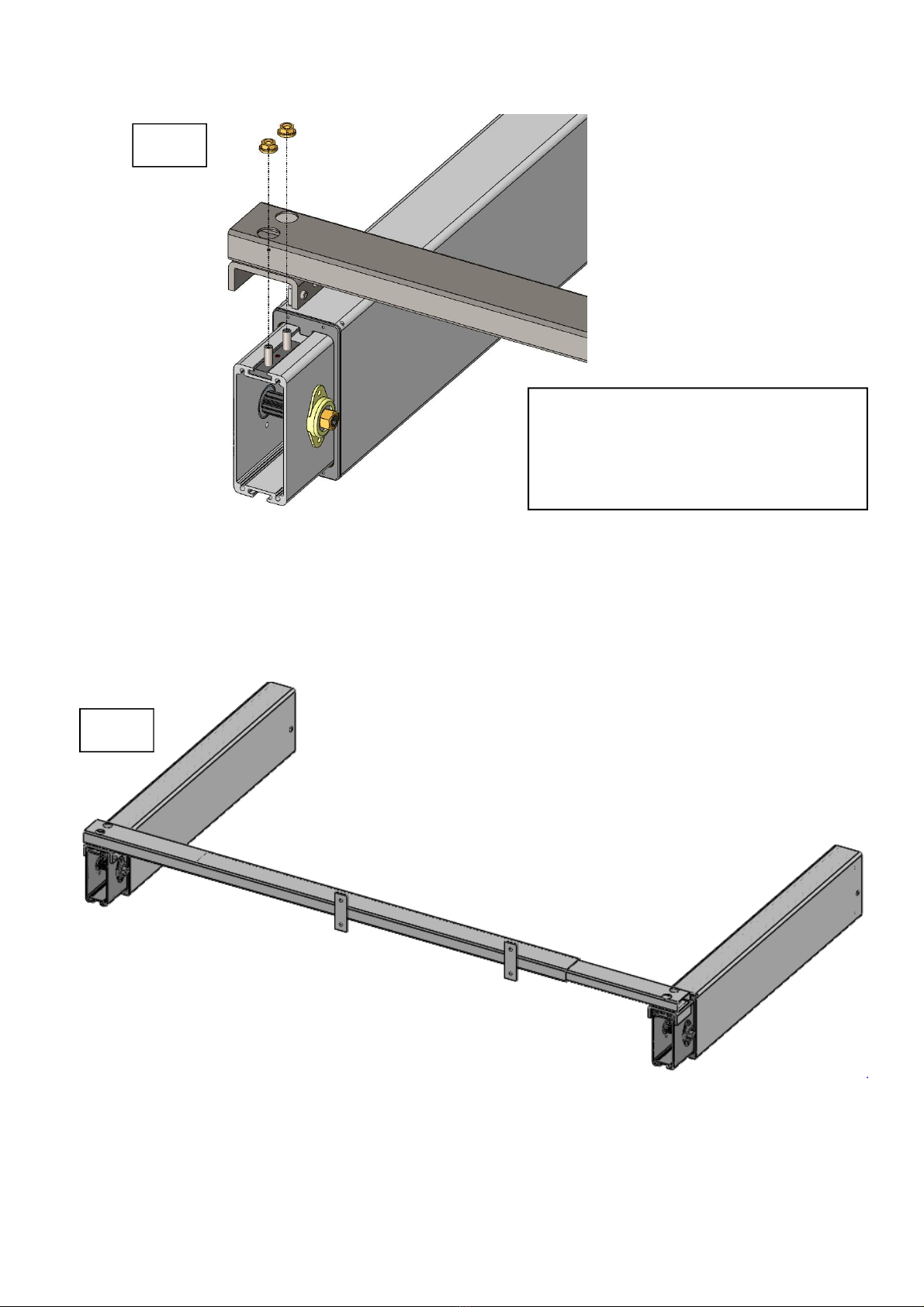

3.4.3 Mounting the Feet

Assemble the following components:

# Part name Qty

03 Foot 2

08 Foot adjusters 4

09 Spanner M10 / Pipe Key M10 1

10.4 Hex Bolt M6x25 8

10.5 Washer M6 8

09 Allen Key M3 1

09 Pipe Key M10 1

5

Photo 6

Place 2 foot adjusters on the bottom of each foot.

Position the foot, like photo 6, in relation to the crossbar.

Connect each foot to a leg with 4 bolts and 4 washers.

Tighten the 8 bolts with the Spanner M10/ Pipe Key M10.

6

Photo 5

Turn the pre-assembled legs and crossbars up-side-down (with 2 persons).

The crossbars are now closest to the floor.

Secure the pre-assembled legs against falling over.

11

Photo 7

Turn the frame back on its foot (with 2 persons).

Now only :-

- FIRMLY tighten the 4 set screws on the crossbar bracket with Allen Key M3.

- FIRMLY tighten the 4 flange nuts on the crossbar with Pipe key M10.

7

Tighten the set screws. Tighten the flange nuts

12

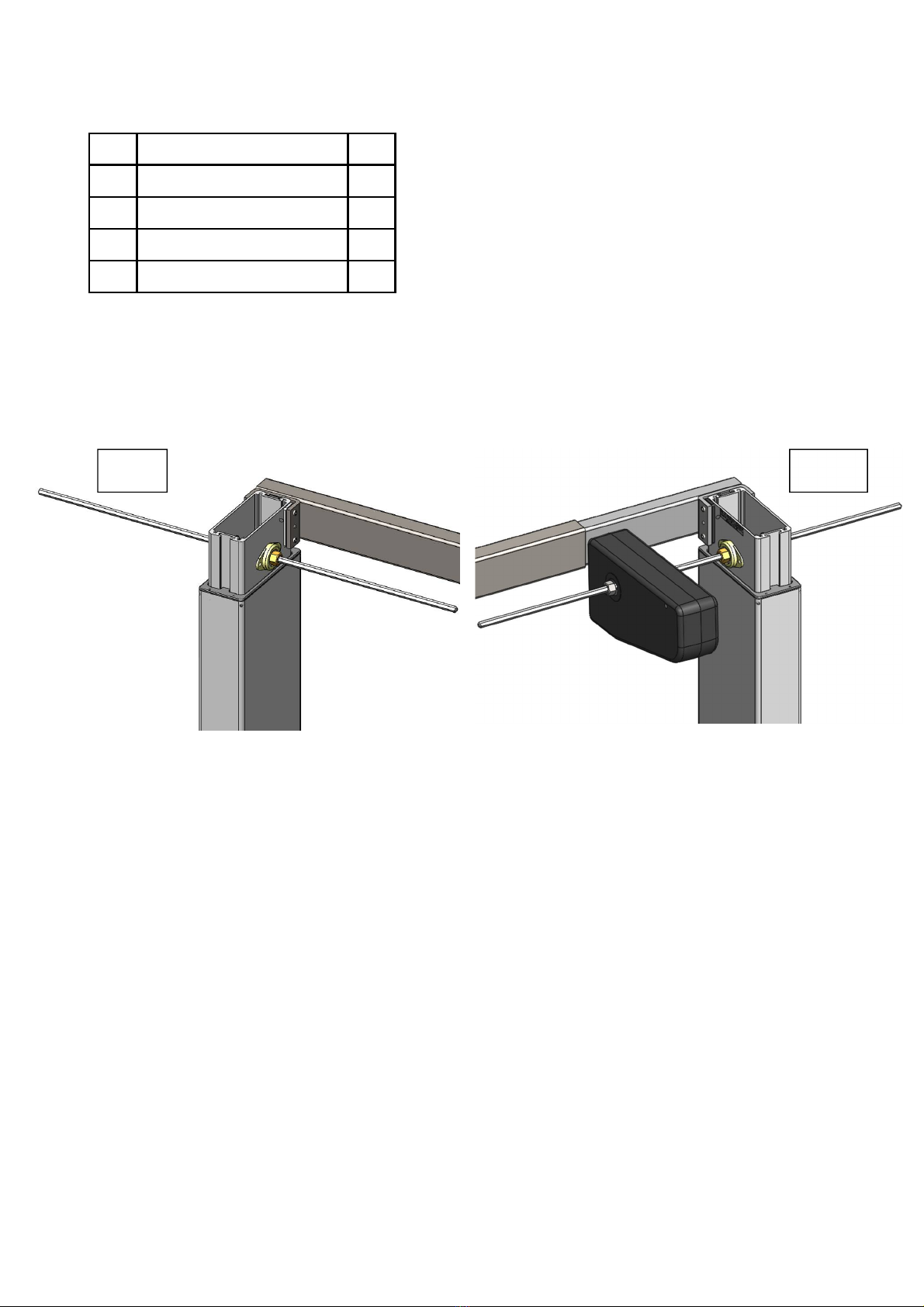

3.4.4 Mounting the Hexagon Shaft

Assemble the following components:

9 8

Photo 8

Slide the 1st hexagon shaft through the hexagon holes in the left legs until it stick ±15 cm

inside the frame.

Photo 9

Slide the 2nd hexagon shaft through the hexagon holes in the right legs until it stick ±15 cm

inside the frame.

Slide the drive unit over the hexagon shaft, at the side where the up-down switch needs to be

placed.

Be aware that both legs are completely in the lowest position.

Be aware that the drive units have not been connected to a power source before the complete

assembly has been done .

Be aware that all components are originally packed.

# Part name Qty

04 Hexagon shaft 2

05 Axle Drive 1

09 Spanner M10 1

11 Drive unit 1

13

Photo 10

Slide the axle drive over both hexagon shafts.

10

Photo 11

Slide both hexagon shafts inward, until they are flush with the outside surface of the leg.

11

14

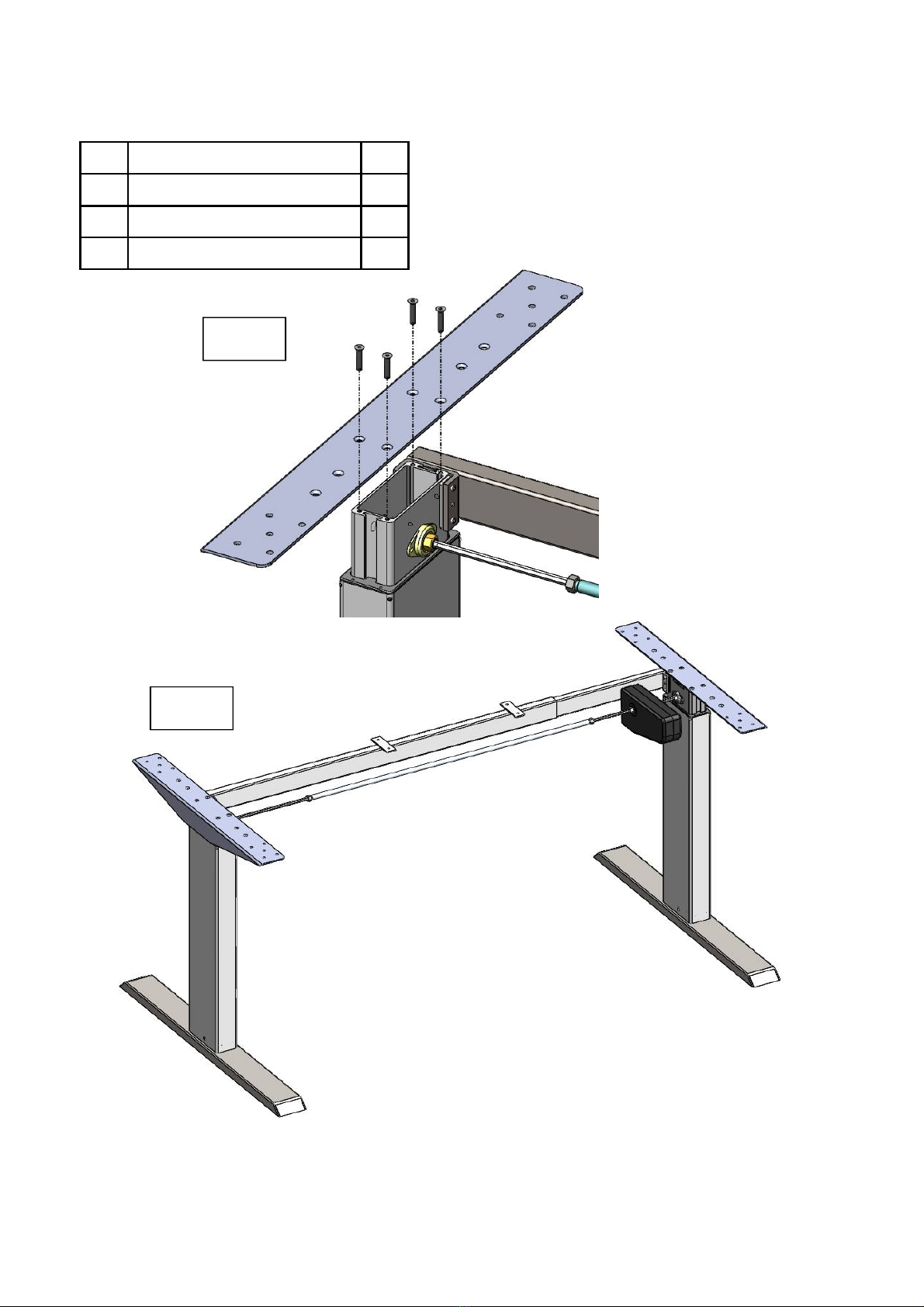

3.4.5 Mounting the Top Support

Assemble the following components:

# Part name Qty

02 Top support 2

09 Allen Key M3 1

10.8 CSK M5x25 8

Photo 12 & 13

Position the top support, like photo 12, in relation to the crossbars

Connect each top support to a leg with 4 CSK screws

Tighten the 8 screws with the Allen Key M3.

12

13

15

14 15

17

16

Parallel !!!

3.4.6 Mounting the Drive Unit

Assemble the following components:

Photo 14

Slide the long bolt (M6x80mm) with a washer through the specific hole in the drive unit.

Slide the plastic spacer and flange nut over the already placed bolt.

Photo 15

Slide the L-bracket over the already placed bolt (between the drive unit and the top support).

Screw another flange nut, as showed on the photo, over the bolt.

Photo 16

Adjust the drive unit towards the top support until L-Bracket’s hole align with hole on top support.

Screw the L-Bracket with CSK screw M5x25mm.

Photo 17

Be aware of that the drive unit is parallel in relation to the top support.

# Part name Qty

09 Spanner M10 1

10.6 Bolt M6x80 1

10.5 Washer M6 1

10.3 Flange nut M6 2

10.7 Plastic spacer 1

07 L-Bracket 1

10.8 CSK M5x25 1

09 Allen Key M3 1

16

3.4.7 Adjustment of the frame width

Pull the frame outward to the required wide (see chapter 3.4.1 Pre-assembly of the Crossbar)

Tighten the set screws in the bottom crossbar and pinching nuts on the axle drive with the

Spanner M10 only now.

18 Tighten set screw

Tighten the nut

17

Jumper

Keypad Cable

Powersupply

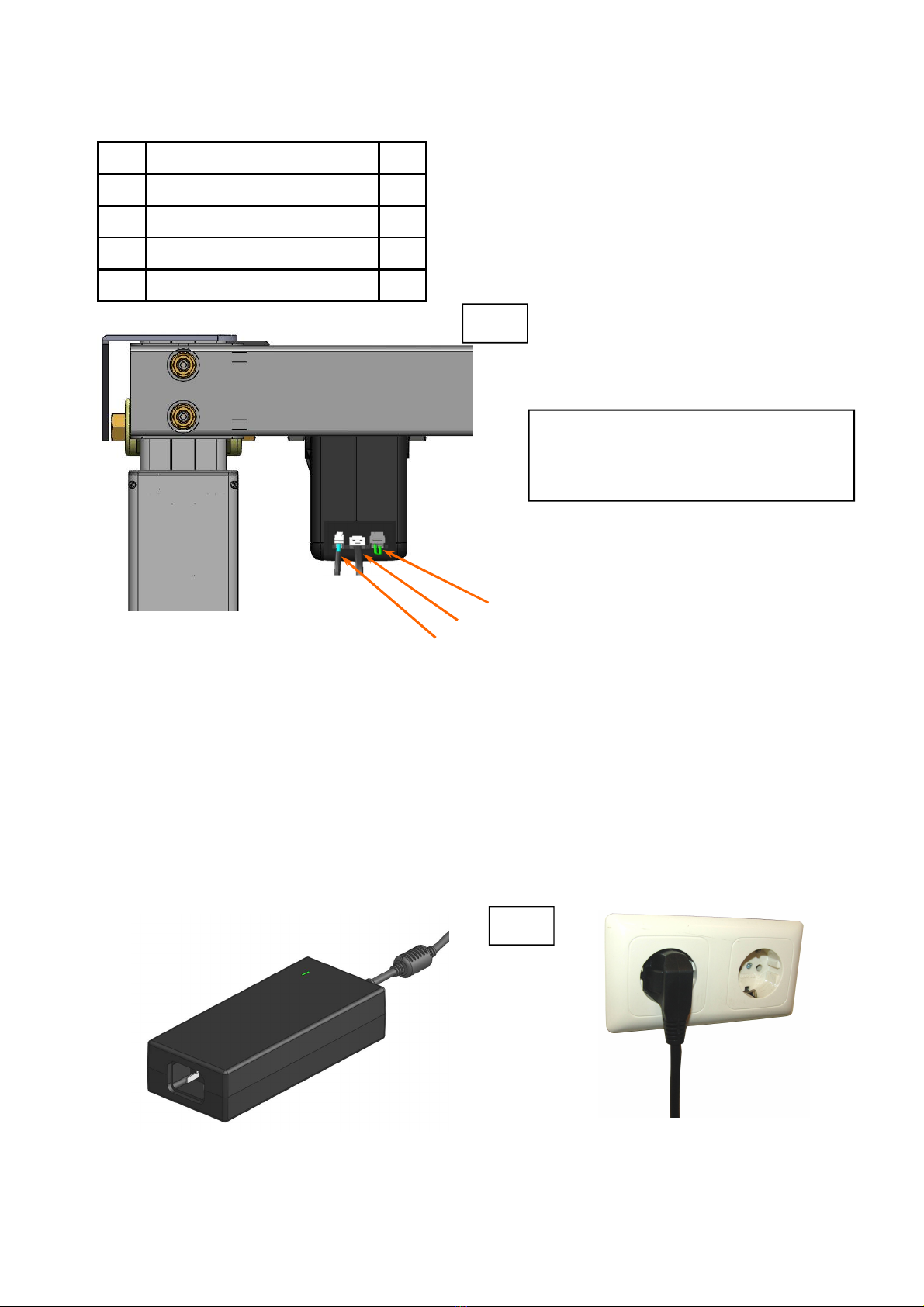

3.4.8 Connecting the Cables Drive Unit

Assemble the following components:

# Part name Qty

12 Power supply 1

14 Up/down switch 1

15 Cable up/down switch 1

16 Power Cord 1

19

Photo 19

Connect the cable up/down switch to the up/down switch and the correct connector of the

drive unit.

Connect the Power supply to the correct connector of the drive unit.

Make sure that the course of the cables is always unobstructed! Tighten the cables to the top

crossbar or top support with tape or cable binders (not included).

Photo 20

Connect the power cord to the power supply and stick the plug in to the electricity socket (100

-240 V~, 50-60Hz).

20

Keep the Jumper in the Drive Unit.

Without this plug the Drive Unit

will not work.

18

3.4.9 Frame test without tabletop

Photo 21

Press “UP” button, the frame goes up.

Release the button, the frame stops.

Press “DOWN” button, the frame goes down.

Release the button, the frame stops.

UP DOWN

21

Make sure that the workstation frame can move correctly and freely

at all times.

When there is a need to plug or unplug the wires from the motor or

the display/handset, always disconnect the controller from the main

power source.

3.4.10 Note: Mounting the table top

Refer to the separate manual of the table top.

3.4.11 Note: Mounting the power supply underneath the table top

Refer to the separate manual of the table top.

3.4.12 Identification sticker

19

4 Technical Specifications

Frame for Electro Motorised Workstation

Assembly Manual version P19300-1EN-DE-NL

Year of construction 2016

Production country Malaysia

System 1-step, external drive

Material Aluminium, steel and plastic

Stroke (max.) 46 cm

Frame load (max.) 60 kg

Frame weight ± 22 kg

Speed 0 kg frame load ± 21 mm/s

Speed 60 kg frame load ± 17 mm/s

Input power 100 - 240 V~, 2A, 50/60 Hz

Duty cycle 10 % (1 Minute on / 9 Minutes off)

Life span 10.000 Cycles (average use)

Noise level < 50 dB(A)

Environmental temperature Use 15 - 30°C

Environmental temperature Storing 10 - 50°C

Humidity Use <85%

Humidity Storing <50%

Maximum Storing time -

Indoor use only!!!

20

Minimum frame height 70 cm

Maximum frame height 116 cm

Maximum stroke 46 cm

Frame Width 110 - 170 cm

Frame Depth 75 cm

Minimum Tabletop Depth 60 cm

Maximum load 60 kg

4 Technical Specifications

110 - 170 cm 60 cm

75 cm

116 cm

Stroke 46 cm 70 cm

(* General Tolerance = ± 1 cm)

Other manuals for Aluforce Pro 140 M

2

Table of contents

Popular Desktop manuals by other brands

Compaq

Compaq BL10e - HP ProLiant - 512 MB RAM Technology overview

Shuttle

Shuttle DH410S Series user manual

Addonics Technologies

Addonics Technologies Storage Tower III user guide

Mitsubishi Electric

Mitsubishi Electric APRICOT 340 Owner's handbook

Epson

Epson EL 486UC+ Product information guide

Asus

Asus M32AAS user manual