AD Klima Fan Coil Unit Specification sheet

Fan Coil Unit

Operation and Installation Manual

One-Way Cassette Fan Coil

2 Pipe System FC02, 03, 04, 05

*Please read this manual before using the fan coil.

*Please keep this manual for future use

Fan Coil Unit One-Way Cassette Type

1

Table of Contents

1.Safety and User Information………………………………02

2.Product Introduction………………………………………05

3.Controller operation………………………………………...10

4.Dimensions, Weight and Wiring diagram……………….12

5.Installation………………………………………………….14

6.Commissioning……………………………………………22

7.Maintenance and Troubleshooting…………………….24

Note:

All illustrations and contents in this manual are provided for information only. We will continuously

improve the products in aspects of product dimensions, performances, materials and structures

without prior notification.

FanCoilUnitOne-WayCassetteType

2

1. Safety and User Information

1.1 Safety instructions

The One-Way Cassette fan coil units are developed and manufactured in accordance with the

state-of-the-art technological standards and established technical safety norms and regulations.

The One-Way Cassette fan coil units comply with the Machinery Safety Directive.

The One-Way Cassette fan coil units are reliable and satisfy high quality standards. This product

range combines advanced technology with a high level of user friendliness and ease of

maintenance.

However, all fan coil units inevitably pose residual risks of injury to the user or third parties or

material damage to the unit or other objects. For this reason, you should take into account and

follow all safety instructions. Ignoring these safety instructions is connected with risks to your health

and safety, can lead to the environmental damage and/or extensive material damage.

Observing the safety instructions in the operation manual will help you to avoid risks, ensure

economical operation of the unit and enjoy full benefits of the product.

The safety aspects covered by this chapter are valid for the entire operation manual. To ensure

your own safety consider the following safety instructions.

THE SAFETY INSTRUCTIONS AFTER LABLE

‘’ IS CONSIDERED AS WARNING WHICH

MEANS INCORRECT OPERATION MAY RESULT

IN SEVERE CONSEQUENCES OF DEALTH OR

SERIOUS INJURIES!

ELECTRICAL HAZARD!

Before carrying out any work on the unit, power the unit down to avoid injury from electrical current.

Check that the unit is isolated and ensure that the appropriate point of the unit for the on-site

power supply is secured against being switched back on.

DANGER OF SCALDING!

Before performing work on the valves or the inlet or outlet pipes, seal off the heating or cooling

water inlet to prevent scalding. Do not commence work before the heating water has cooled down.

DANGER OF ROTATING UNIT PARTS!

Rotating fan wheels can cause injury! Before performing any work on the unit, ensure that it is

powered down. Ensure that the appropriate point of the unit for the on-site power supply is

secured against being switched back on.

FanCoilUnitOne-WayCassetteType

3

DANGER OF OVERHEAD LOADS!

Wear a helmet and safety boots to prevent injury from falling components, especially when fitting

the unit to the ceiling. Ceiling installations should always be performed by two people.

PERSONAL INJURY!

Always wear protective gloves when moving or fitting the unit to avoid injury from sharp edges.

1.2 Important notes

The fan coil units are end units of chilled/hot water air conditioning system featuring high

profession and high technological requirement, therefore, the unit shall be installed, operated and

maintained only by qualified, specially trained and authorized staff.

1.2.1 Proper use

One-Way Cassette fan coil units are exclusively designed for heating, filtering and cooling

purposes. Chilled water/Hot water may be used as the medium. The following limit values

apply to the chilled/hot water for operating Cu/Al heat exchangers:

Unit Value

pH value (at 20 °C) 7,5 – 9

Conductivity (at 20 °C) μS/cm < 700

Oxygen content O2mg/l < 0,1

Total hardness °dH 1 – 15

Dissolved sulphur Snot detectable

Sodium Na+mg/l < 100

Iron Fe2+, Fe3+ mg/l < 0,1

Manganese Mn2+ mg/l < 0,05

Ammonium content NH4+mg/l < 0,1

Chloride Cl-mg/l < 100

Sulphate SO42- mg/l < 50

Nitrite NO2-mg/l < 50

Nitrate NO3-mg/l < 50

DAMAGE TO THE UNIT!

On open systems (e.g. when using well water observe the limit values stated in above table), the

used water should additionally be cleansed of suspended matter using a filter which should be

located at the inlet. Otherwise there is a risk of erosion by suspended matter.

You also have to ensure that the unit is protected from dust and other substances that can cause

acidic or alkaline reaction when combined with water (aluminum corrosion).

–The One-Way Cassette fan coil units may only be used indoors.

–The One-Way Cassette fan coil units can also be fitted into an intermediate ceiling.

The unit is considered to be used in a proper manner if it is applied for other purposes or a

purpose that is not covered by the scope of the given operation manual. The manufacturer or

FanCoilUnitOne-WayCassetteType

4

supplier is not liable for any resulting damage: the user alone bears the full risk.

The user is responsible for proper use. Proper use also stipulates the observance of the operation

manual and the inspection and maintenance conditions defined by the manufactures.

1.2.2 Improper use

The One-Way Cassette fan coil may not be operated:

- For treatment of outside air,

- In locations where there is a risk of explosion

- In wet areas or

- In locations with high dust levels or aggressive air.

PERSONAL INJURY & MATERIAL DAMAGE!

Improper use can cause personal injury and material damage.

FanCoilUnitOne-WayCassetteType

5

2. Product Introduction

2.1 Features and benefits

Space saving

One-Way Cassette fan coil maximize utilization of room space with recessed ceiling installation.

Compact design as unit height only 235mm, easy for installtion.

Stylish design

Newly stylish and elegant design is in harmony with top interior decoration requirement.

High efficiency

Round and optimized engineering designed coils enables the most effective energy exchanging.

Healthy Fresh Air

Much more fresh air by utilizing high efficiency synthetic fiber washable filter. (optional)

Effectiveness

One-Way Cassette fan coil units guarantee cosy and comfortable room atmosphere.

One-Way air blowing and wide angle flapping guarantees average energy diffusion.

Quietness

Newly designed pressure-stable centrifugal fan ensures the lowest operation noise.

Cost effectiveness

One-Way Cassette fan coil units have become the effective standard solution in many and various

industrial segments for comfortable economical air conditioning.

Profitability

One-Way Cassette fan coil units operate with low maintenance and follow-up costs.

2.2 Nomenclature

2.3 Operating limits

Unit and heat exchanger Values

Max. operating pressure 1.4 MPa (14 bar)

Max./Min. water temperature 75 °C / 2°C

Operating voltage 220~230V AC (50Hz or 60Hz) **[Refer to nameplate]

Power consumption/protectionclass *[Refer to nameplate]

Product Type:

CAS: Cassette One-Way

CAD: Cassette Two-Way

CAQ: Cassette Four-Way

CAX: Cassette Six-Way

Coil Layout:

2: 2 Pipes (or omitted)

Power Supply

1=220~230V/50Hz/1 Ph

2=220~230V/60Hz/1 Ph

5=115V/60Hz/1 Ph

Air Flow:

×100 CFM

Fan Coil

FC 02 CAS 2 / 1

FanCoilUnitOne-WayCassetteType

6

DAMAGE TO THE UNIT!

Please refer to unit name plate to know the right power supply! Wrong power supply may

damage the motor and unit permanently!

2.4 Unit Components

1.Cover

2.Drain pan

3.Coil left hook

4.Coil right hook

5.Drain pump

6.pumpfixtrue

7.Coil

8.Inlet water pipe assembly

9.Water purge

10.Outlet water pipe assembly

11.Coil join plate

12.Mounting brackers

13.Left side plate

14.Fan motor hook

15.Control box cover

16.Control board

17.Transformer

18.Terminal blocks

19.Capacitor

20.Control box

21.Right side plate

22.Capacitor

23.Fan blower

24.Volute

25.Casing

26.Cover panel assemb

2.5 Specification

Specification Cassette 1-Way Fan Coil Unit - 2 Pipe System (CAS)

Specification FC02 FC03 FC04 FC05

CFM 200 300 400 471

m3/h 340 510 680 800

CFM 159 235 306 382

m3/h 270 400 520 650

CFM 112 176 235 294

m3/h 190 300 400 500

1.90 2.70 3.60 4.00

1.50 2.10 2.80 3.30

1.00 1.60 2.10 2.60

1.30 1.90 2.50 2.80

1.10 1.60 2.10 2.30

0.80 1.30 1.70 1.80

2.70 4.10 5.40 6.40

2.20 3.20 4.10 5.20

1.50 2.40 3.20 4.00

Power Input 45 54 62 70

Running Current 0.2 0.24 0.28 0.31

Noise Level 39/36/30 39/36/30 40/37/31 42/39/37

330 480 625 690

0.092 0.133 0.174 0.192

Water Resistance 10 15 18 20

20 20 25 35

2 3

1095*535*310

23

850*400*235

1045*465*30

Centrifugal Fan

Split Permanent Capacitor Motor

Class B

220~230V/1Ph/50 or 60Hz

Seamless copper mechanically expanded into aluminum fins

1.4 MPa

3/4" FPT

Φ25

Gross Weight

kg

Unit

Panel

Note:

1. Nominal Testing condition:

Cooling: entering air temp 27°C DB/19.5°C WB; entering water temp 7°C, leaving water temp 12°C;

Heating: entering air temp 21°C; entering water temp 60°C, the same water flow as in cooling;

2.Sound pressure level are measured in acoustic room, position of the measure point is 1.5m below the vertical center line of the unit

25.5

Packing Dimension

W/D/H mm

Unit

Panel

Net Weight

kg

Unit

Panel

Inlet/Outlet Water Pipe

Condensate Water Pipe

Net Dimension

W/D/H mm

Unit

Panel

Coil

Type

Rows

Max. Working Pressure

kPa

Fan Type

Motor

Type

Insulation Class

Power Supply (V/Ph/Hz)

Power Consumption (W)

W

A

dB(A)-H/M/L

Water Flow kg/h

l/s

Heating Capacity

kW

H

M

L

Sensible Cooling

Capacity

kW

H

M

L

Total Cooling Capacity

kW

H

M

L

Model

Air Flow

H

M

L

FanCoilUnitOne-WayCassetteType

8

2.6 Decorative panel

DANGER OF ROTATING UNIT PARTS!

Don't put fingers or any other things into the inlet/outlet and swing louver while the conditioner is in

operation, because the high speed fan is very dangerous and may cause injuries.

NOTE!

- The unit cannot be cleaned with water otherwise it may have short circuit or be destroyed.

- Remember to close the air inlet grill properly after cleaning air filter.

- Operate the unit according to instructions strictly for effective efforts. Otherwise it may cause

leakage or work abnormally.

- Please adjust indoor temperature properly, especially when there are old people, children,

and patient and so on in the house.

- Lightning and electromagnetic radiation may influence this machine. If the machine is

influenced, please cut off electric power then turn on it again.

- It is forbidden to block or cover the air outlet and inlet.

2.6.1 Panel overview

1. Remote control receiver

2. Body of panel

3. Blade

4. Air inlet grille

2.6.2 Remote receiver and LED display

a) Remote receiver:

It receives operational orders sent out by infrared remote controller. To ensure the quick and

effective operation of the unit, please operate the controller aims at remote receiver on the panel.

b) Buzzer:

It would sound ‘Bi…’ when you do any one of the following actions:

- Turn on the unit

FanCoilUnitOne-WayCassetteType

9

- Operation of remote controller and infrared signal from remote controller is correctly received.

c) LED display

When the air conditioner has malfunction, the self-diagnostic system will identify malfunction

automatically and display malfunction code. Please refer to section "Malfunction and

troubleshooting".

2.6.3 LED display sketch

LED Display:

- Green: Cooling;

- Yellow: Timer;

- Red: Heating;

- Reset: Emergency Switch.When the unit is switched off, press the reset button then the unit

will enter into cooling mode automatically; if press again the reset button then the unit will

enter into heating mode; if press again the reset button then the system will be switched off.

- Receiver: Remote receiver

FanCoilUnitOne-WayCassetteType

10

3.Controller operation

3.1 Infrared controller

On/Off

Clock

Temp

oolCyDr nFa atHe langSi

Louver

Clock

Sleep

Swing

Fan Speed

Set Temp

Operation instruction:

1. ‘On/Off’ Button

- Press On/Off button to turn on/turn off the unit.

2. TEMP 'Up' 'Down' Button

- Press 'Up' or 'Down' button to increase or decrease the temperature desired.

3. 'MODE' Button

- Select unit operation mode: Cool->Dry->Fan->Heat->Auto (both cool and heat symbol light

up)

4. 'FAN' Button

- Press 'Fan' button to select fan speed: Auto->Low->Medium->High.

5. 'FAN' Button

- Press 'Fan' button to select fan speed: Auto->Low->Medium->High.

- In Fan mode, only low, medium, high speed is available.

- In Dry mode, fan speed will not be displayed.

6. 'TIMER ON' Button

- Press the ‘TIMER ON’ button once, the previous timer setting will display on the LCD.

Slide Down

FanCoilUnitOne-WayCassetteType

11

- Press the ‘TIMER ON’ button continuously, the timer will be changed in one minute intervals

- You can hold on the ‘TIMER ON’ button to speed up the time adjusting until reaches the

desired time.

7. 'TIMER CANCEL' Button

- Press ‘TIMER CANCEL’ to cancel all the timer setting.

8. 'TIMER OFF' Button

- Press the ‘TIMER OFF’ button once, the previous timer setting will display on the LCD.

- Press the ‘TIMER OFF’ button continuously, the timer will be changed in one minute intervals

- You can hold on the ‘TIMER ON’ button to speed up the time adjusting until reaches the

desired time.

9. ‘SLIDE DOWN’ Button

- Slide down the cover in order to put in or replace the battery (1.5V).

10. ‘SWING’ Button

- Press ‘SWING’ button to turn on/turn off swing function.

11. ‘CLOCK UP’ Button

- Press ‘CLOCK UP’ button continuously for 2 seconds, then the current set time will increase 1

minute at each press.

- You can hold on the ‘CLOCK UP’ button to speed up the time adjusting until reaches the

desired time.

12. ‘CLOCK DOWN’ Button

- Press ‘CLOCK DOWN’ button continuously for 2 seconds, then the current set time will

decrease 1 minute at each press.

- You can hold on the ‘CLOCK DOWN’ button to speed up the time adjusting until reaches the

desired time.

13. ‘LOUVER’ Button

- Press ‘LOUVER’ button to select the louver position 1,2,3,4 auto, or stop.

14. ‘SLEEP’ Button

- Press ‘SLEEP’ button to activate the energy saving sleep function which will automatically

control the unit working according to the room temperature.

3.2 Controller Installation

Install the remote controller holder to the wall and put the battery (1.5V*2) as shown below.

FanCoilUnitOne-WayCassetteType

12

4. Dimensions, Weight and Wiring diagram

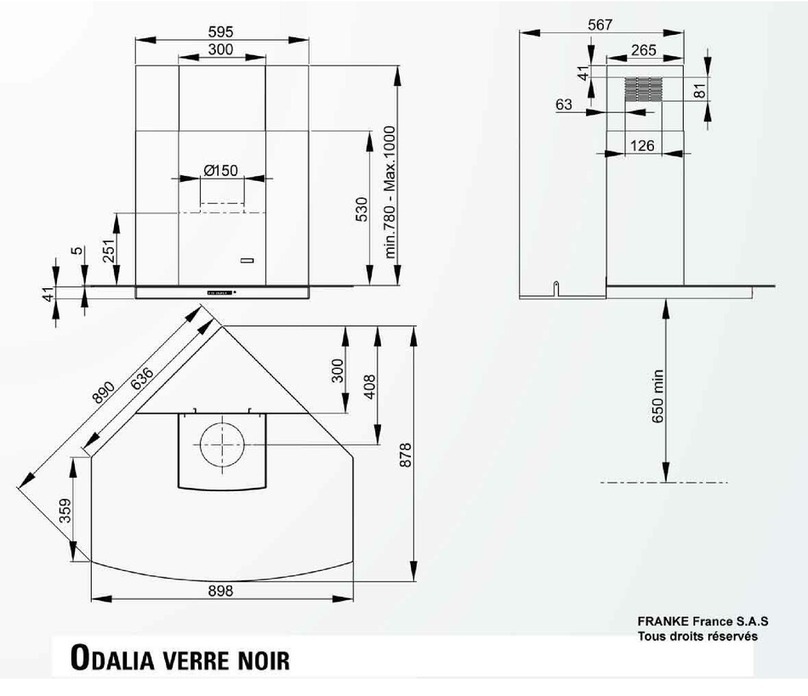

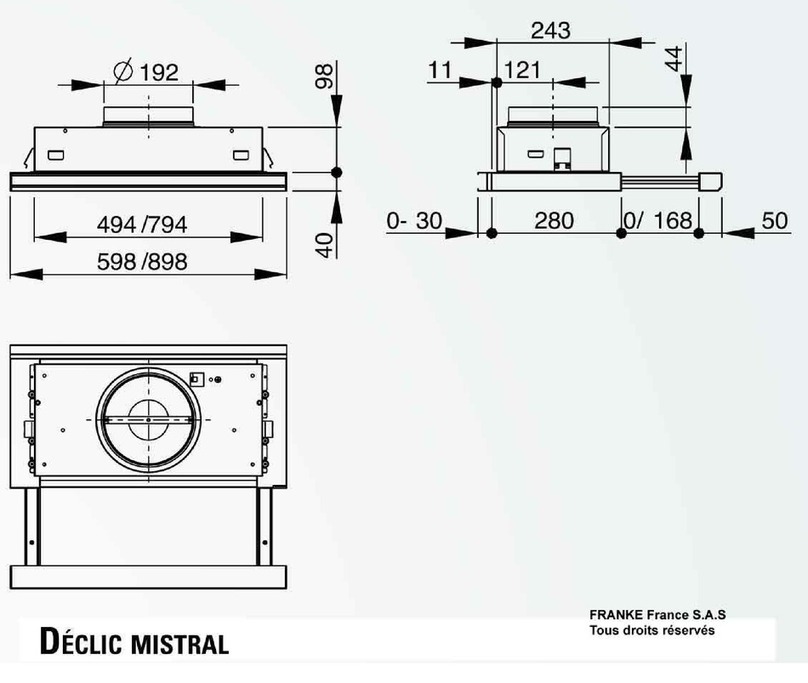

4.1 Dimensions - Model FC02/FC03/FC04/FC05

Frequently used installation data

- Unit external dimension (W*D*H): 848*394*235mm

- Panel external dimension: 1043*468*30mm

- Hanging hook position dimension: 760mm*434mm

- Ceiling open dimension: (938~993)*(414~448)mm

Other dimensions are marked in above fig.

4.2 Weight

Please refer to product nameplate or product specification sheet to know the weight of the unit.

FanCoilUnitOne-WayCassetteType

13

4.3 Wiring diagram

- Installation with motorized valve: Short-Connect connection port S6;

- Installation without motorized valve: Cut off connection port S6;

FanCoilUnitOne-WayCassetteType

14

5.Installation

5.1 Checking and acceptance

Each fan coil is packaged in corrugated cartons to avoid damages during transportation, handling

and site placement. To make sure no damages occurred due to transportation, please follow below

steps to check upon receiving the equipment:

a) Before acceptance, please check if each unit shows any abnormal facts, if carton edges and

corners are in good conditions and if there are obvious carton damages;

b) For any obvious carton damages, please immediately unpack to inspect the unit itself. If the

unit is indeed damaged, please indicate on the receipt and refuse to accept. Please also

check accessories;

c) Check hidden damages of the unit;

d) If any hidden damage is found, do not move the unit on the site. The receiver has the

obligation to evidence such damage does not occur after delivery. Meanwhile, please stop

unloading and take photos for reference;

e) If damages are found, please notify the carrier, and request the carrier and the receiver to

conduct a joint inspection;

f) Do not repair it yourself before inspection and confirmation by the carrier representative has

been made;

g) After confirmation of damages, please contact related persons for replacement.

5.2 Transport

DAMAGE TO UNIT AND PERSONAL INJURY!

- Use protective gloves to avoid injury due to sharp edges.

- Ensure that at least two people carry the fan coil to avoid injury.

- In case of deliveries on pallets, use only lifting and transport vehicles with sufficient carrying

capacity.

- Secure the load during transit to prevent it from tipping or falling.

Grasp and transport the Cassette Fan Coil using the outer casing only. Refer to below fig.

FanCoilUnitOne-WayCassetteType

15

5.3 Temporary storage

When storing the unit for a temporary period, the following points must be considered:

- Store the fan coil unit in its original packaging.

- The storage location must be weatherproof, dry and free of dust. Humidity must be between

50 and 85% r.h.

- The storage temperature must stay in the range from -10 to +50°C.

5.4 Prepare for Installation

DANGER FROM ELECTRICAL CURRENT!

- Ensure that the intended drilling area is free from electrical cables or pipes before drilling.

PERSONAL INJURY!

- Injury may be caused by falling parts and sharp edges!

- Wear a helmet, safety boots and protective gloves when installing the unit. Ceiling installations

should always be performed by two people.

NOTE!

- You must ensure that no mechanical deformations or twisting occurs during

installation of all models in all installation locations.

5.4.1 Installation location

The type, condition and ambient temperature of the installation location must be suitable for the

appropriate fan coil unit. Observe the following instructions:

- Ceiling or mounting systems must be capable of bearing the weight of the unit, including all

accessories.

- Install the unit only indoors.

5.4.2 Installation requirement

Please respect to below installation space requirement as well as ceiling requirement

a) Installation space requirement (H=235mm)

FanCoilUnitOne-WayCassetteType

16

b) Ceiling requirement

- The intermediate ceiling is installed and a corresponding opening is available for the unit.

- There may not be any openings to the outside in the area of the intermediate ceiling.

- The entire intermediate ceiling area must be dry and sufficiently protected against humidity

and moist air.

- The internal opening dimension must be within the minimum and maximum dimensions listed

in section 4.1 as ceiling opening dimension.

- The electrical wiring is prepared and is available for connection in the intermediate ceiling.

5.4.3 Recommended service opening

In order to carry out all necessary service and maintenance work on the basic unit it is

recommended that a service opening with Min. 400*400mm or larger is reserved in the false

ceiling.

5.5 Unit installation

5.5.1 Precautions

To ensure good installation and operation, do check the following items before installation of the

unit:

a) Adequate space shall be provided for installation and maintenance of the unit. Please refer to

Unit Dimensions in section 4.1. Removable ceiling panels or accesses shall be provided for

daily maintenance;

b) Determine locations of pipelines and electric wires before installation; and adequate fitting

space should be reserved.

c) Make sure hanging structure adequate to support the unit weight;

d) All units shall be leveled to ensure smooth water drain and proper operation;

e) Thermal insulation of chilled water valves and pipelines shall be made by the installer.

5.5.2 Unit mounting

a) Install a suspending bolt (M10 bolt)

To support the unit weight, anchor bolt shall be used in the case of already exists ceiling. For new

ceiling, use built-in type bolt or parts prepared in the field.

Before going on installing adjust space between ceilings.

*All above parts should be prepared in field.

b) Unit mounting

The unit is installed under the building ceiling with threaded rods to be provided by the customer.

- Determine the position of the drilled mounting holes according to the hanging hook dimension

FanCoilUnitOne-WayCassetteType

17

in section 4.1

- Provide the fixing for the threaded rods with suitable tools.

- Fasten the threaded rods to the building ceiling. The length dimensions depend on the

distance to the intermediate ceiling.

- Push the unit, with the terminal box facing front, into the intermediate ceiling at an angle, until

the unit is fully placed into the intermediate ceiling.

- Place the unit straight over the opening. Provisional fast installation is possible using the

hooks on the suspension lugs. After final positioning fix the straps to the unit wall using

tapping screws.

- Screw the unit firmly onto the threaded rods. Make sure that the unit is exactly horizontal.

5.5.3 Panel installation

NOTE!

- Check whether indoor unit is horizontal with leveler or polythene pipe filled with water,

and check that the dimension of the ceiling opening is correct. Take off the lever gauge

before install the panel.

The design panel with an air filter is not delivered pre-assembled. The required mounting material

(setscrews) is packed separately in a plastic bag.

- Loosen the air intake grille by turning each of the 2 locks.

- Remove the air intake grille. (Refer to below indication fig)

Install the panel board in the right direction, you can follow below steps.

FanCoilUnitOne-WayCassetteType

18

a) Make sure the right direction of panel in order that the installation holes on the panel is

corresponding to the unit, put two bolt in diagonal position ST4×10 and screw it but not tightly.

b) Connect wiring cable of stepping motor, display board to the elec. box and tidy up the wiring

cables.

c) Put the other two bolt in diagonal position ST4×10 and screw it to the main unit but not tightly.

d) Adjust the location and direction of panel to make air outlet frame and the drain pan wind way

acdordant.

e) Screw up the bolts tigthly and make sure the well match between unit and panel.

f) Install the air inlet grille opposite to the sequence when disamount the grille.

NOTE!

- The incorrect direction will result in water leakage, meanwhile swing and signal

receiving are displayed that cannot be connected.

- Please refer to section 5.7 before connect the cables.

- If screws are not tightening, problems in below Fig. might occur. Tighten screws

properly.

- If there is still space after tightening of screws, please readjust the height of indoor

unit.

5.6 Pipe connection

DANGER OF SCALDING BY ESCAPING

HEATING MEDIUM!

Before the on-site piping and the fan coil hydraulic connection is set up, the heating/cooling water

should be isolated and secured against being opened unintentionally.

NOTE!

- At the beginning of the fitting procedure, remove the caps on the water inlet and outlet

pipes.

- All on-site pipes by others for the cooling water must be insulated against condensate

formation.

- When all connections have been completed, all screw connections should be tightened

and checked that they are free of mechanical stress.

5.6.2 Valve connection

The units are supplied without valves, In case of installation with valves by others, the installation

FanCoilUnitOne-WayCassetteType

19

of the water inlet and outlet depends on the location of the water connection and/or the used

valves.

Below showed Fig. indicate the connection of a 2-way valve and 3-way valve to the units.

2-Wayvalve 3-Wayvalve

NOTE!

- In case of installation with motorized valve, it is necessary to short-connect the

connection port S6 on unit PCB; (If no motorized valve, then S6 should be open/cut off)

5.6.3 Water inlet/outlet pipe connection

- Connect the chilled water pipe to coil pipe by using 3/4" external thread connecter.

- Distinguish the inlet/outlet water according to the sign on the unit.

- Heat preservation must be used for the chilled water pipe, and pay attention to the end side

management of insulate material.

*Indicativefigof2pipesystem

5.6.4 Condensate water pipe connection

- Condensate pipe diameter shall be equal or larger than that of the fitxting of the unit. (Size:

20mm)

- Drain pipe should be short, with a downward slope at least 1/100 to prevent air bag from

happening.

- If downward slope can't be made, take other measures to lift it up.

- Keep a distance of 1-1.5m between suspending brackets, to make water hose straight.

Table of contents