Addison DC Series User manual

1

WARNING: READ SAFE OPERATION RULES AND MANUAL CAREFULLY

INSTALLATION OPERATION and MAINTENANCE MANUAL

High Efficiency Packaged Models DC Series B, Air Conditioning

Systems, Model Sizes 036 Thru 420

No Heat Recovery Cabinet

Extended Heat Recovery Cabinet

TABLE OF CONTENTS

Safety Labeling and Signal Words...........2

General Description ..................................3

Unpacking, Inspection ........................3

Design Certification..............................3

Codes & Ordinances ............................3

Installation..............................................3- 6

Unit Location, Clearances ...................3

Curb Installation ...................................3

Rigging...................................................4

Electrical................................................4

Ductwork ...............................................5

Condensate Piping...............................5

Gas Piping and Venting ...................5- 6

Cooling System Options.......................6- 8

Hot Gas Bypass ....................................6

Head Pressure Control.........................6

Variable Speed Control........................6

Adjustable High and Low Pressure....7

Hot Water Heat Recovery.................7, 8

Mechanical Adjustments ....................9, 10

Evaporator Blower Fan ..................9, 10

Electrical System Options......................10

Air Flow Switch...................................10

Clogged Filter Indicator..........................10

Convenience Outlet............................10

Exhaust Fan Interlock ........................10

Power Through the Curb ...................10

Firestat.................................................10

Sure-TripTM ..........................................10

DDC controls.......................................10

Sequence of Operation...........................11

Heating, Steam/Hydronic...................11

Gas Heat..............................................11

Electric Heat........................................11

Energy Conservation Wheel..............12

Trouble Shooting Guides...................13-18

General Refrigeration Circuit .......13-16

Varispeed™ Condenser Control.......15

Hot Gas Bypass Regulator................16

Gas Furnace........................................17

!

R410A

Insert for all ADDISON®product manuals

Instructions:

In accordance with California Proposition 65 requirements, place enclosed label(s) in a highly visible location on outside of

equipment to be repaired (i.e., near equipment’s serial plate). See label placement drawing in equipment’s Installation, Op-

eration and Service manual for label location (when available). Avoid placing label on areas with extreme heat, cold, corro-

sive chemicals or other elements. Extra labels are also included where repair of multiple units is involved. To order additional

labels, please call +1.407.292.4400.

To obtain a copy of the manual or for more information, visit the applicable website(s) below:

Incluya en todos los Manuales de productos de ADDISON®

Instrucciones:

De conformidad con los requerimientos de la Propuesta 65 de California, ubique la(s) etiqueta(s) adjunta(s) en un lugar bien

visible en el exterior del equipo a ser reparado (es decir, cerca de la placa serial). Ver dibujo de instalación de la etiqueta en

el Manual de Operaciones y Mantenimiento (si esta disponible). Evite colocar la etiqueta en áreas con calor, frío, productos

químicos corrosivos u otros elementos. Se incluyen etiquetas adicionales para el caso de reparación de varias unidades.

Para ordenar etiquetas adicionales, por favor llamar al +1.407.292.4400.

Para obtener una copia del manual o para obtener mas información visite los sitios Web correspondientes a continuación.

www.addison-hvac.com

Código de Instalación e Inspecciones Anuales: Todas las instalaciones y mantenimientos de productos

ADDISON

®

deben ser realizados sólo por personal cualificado en la instalación y mantenimiento de los equipos

vendidos y suministrados por Addison y/o por sus distribuidores y deben cumplir con todos los requisitos

dispuestos en los manuales de ADDISON

®

y con todos los estándares locales aplicables a la instalación,

mantenimiento, funcionamiento y etiquetado del equipo. Para conseguir un funcionamiento óptimo y seguro,

Addison recomienda que un técnico cualificado revise anualmente sus equipos y realice el mantenimiento

siempre que sea necesario, usando exclusivamente piezas de repuesto de ADDISON

®

.

Información adicional: A través de los distribuidores de Addison está disponible la información sobre

aplicaciones, guías detalladas sobre diseño de sistemas e instalación y funcionamiento de los productos. Por

favor contacte con nosotros si necesita más información o si requiere un manual de instalación,

funcionamiento y mantenimiento.

Este producto no es para uso residencial.

La intención de este documento es la de ayudar a los profesionales autorizados en el libre ejercicio de su

profesión.

Installation Code and Annual Inspections: All installation and service of ADDISON

®

equipment must be performed by a contractor qualified in the

installation and service of equipment sold and supplied by Addison and conform to all requirements set forth in the ADDISON

®

manuals and all applicable

governmental authorities pertaining to the installation, service, operation and labeling of the equipment. To help facilitate optimum performance and

safety, Addison recommends that a qualified contractor conduct, at a minimum, annual inspections of your ADDISON

®

equipment and perform service

where necessary, using only replacement parts sold and supplied by Addison.

Further Information: Applications, engineering and detailed guidance on systems design, installation and equipment performance is available through

ADDISON

®

representatives. Please contact us for any further information you may require, including the Installation, Operation and Service Manual.

This product is not for residential use.

This document is intended to assist licensed professionals in the exercise of their professional judgment.

www.addison-hvac.com Printed in U.S.A. P/N 91070020 Rev B 03/12

Page 1 of 1

© 2012 Addison All rights reserved. No part of this work covered by the copyrights herein may be reproduced or copied in any form or by any means –

graphic, electronic, or mechanical, including photocopying, recording, taping, or information storage and retrieval systems – without

written permission of Addison.

Addison

7050 Overland Road

Orlando, FL 32810 U.S.A.

Telephone: +1.407.292.4400

Fax: +1.407.290.1329

www.addison-hvac.com

2

Form #527I-1053 (0703)

SAFETY LABELING AND SIGNAL WORDS

Danger, Warning and Caution

The signal words DANGER, WARNING and

CAUTION are used to identify levels of hazard

seriousness. The signal word DANGER is only

used on product labels to signify an immediate

hazard. The signal words WARNING and

CAUTION will be used on product labels and

throughout this manual and other manuals that

may apply to the product.

Signal Words

DANGER – Immediate hazards which WILL

result in severe personal injury or death.

WARNING – Hazards or unsafe practices

which COULD result in severe personal injury

or death.

CAUTION – Hazards or unsafe practices which

COULD result in minor personal injury or

product or property damage.

Signal Words in Manuals

The signal word WARNING is used throughout

this manual in the following manner:

The signal word CAUTION is used throughout this

manual in the following manner:

CAUTION

Product Labeling

Signal words are used in combination with colors and/or

pictures on product labels. Following are examples of

product labels with explanations of the colors used.

WARNING

Electric Shock Hazard.

Turn Off All Power

Before Servicing.

DANGER

!

Fire Hazard.

Use copper wire only.

Failure to observe could

result in property

damage, bodily injury or

death.

WARNING

!

Cuts and Abrasion Hazard.

Wear gloves and handle

with care.

Failure to observe could

result in bodily injury.

CAUTION

!

WARNING

Danger Label

White lettering on a black background except the word

DANGER which is white with a red background.

Warning Label

White lettering on a black background except the word

WARNING which is white with an oran

g

e back

g

round.

Caution Label

White lettering on a black background except the word

CAUTION which is white with a yellow background.

!

This unit contains chlorodifluoromethane (HFC-22), a substance that harms public health and environment by

destroying ozone in the upper atmosphere.

DO NOT VENT HCFC-22 to the atmosphere. The U. S. Clean Air Act requires the recovery of any residual

refrigerant.

!

3

GENERAL DESCRIPTION

The model DC Series B packaged cooling and heating

unit is designed to cool a conditioned space with

mechanical refrigeration, chilled water, energy

conservation wheel or a combination of these systems.

During the heating mode supply air may be heated by

indirect fired gas, electric strip, steam or hot water. The

cabinet design provides space for a number of options,

including 100% outside air applications and the use of

desiccant wheels. Most of these options will be covered in

this manual; for those of a more custom nature, consult the

ADDISON Application Engineering Department.

Models DC units are designed for rooftop curb, slab

mounted or installed on post and rail applications with field

convertible vertical or left and right horizontal return and

supply air duct connections.

Unpacking, Inspection

When received, the unit should be checked for damage

that might have occurred in transit. If damage is found, it

should be noted on the carrier’s Freight Bill. Request for

inspection by carrier’s agent should be made in writing at

once.

Design Certification

All units are certified by Electrical Testing Laboratories

(E.T.L.) under ANSI/UL 1995. The gas furnace designs are

certified by E.T.L. under ANSI Z83.9 (latest edition) for use

with natural or propane (L.P.) gas as specified when

ordering unit.

Codes and Ordinances

These units must be installed in accordance with the

standard of the National Fire Protection Association or the

National Fuel Gas Code ANSI Z83.9 (latest edition). The

National Fuel Gas Code is available from the American

Gas Association, 1515 Wilson Boulevard, Arlington, VA

22209. NFPA Publications are available from the National

Fire Protection Association, Batterymarch Park, Quincy,

MA 02269. Local authorities having jurisdiction should be

consulted before installations are made to verify local

codes and installation procedures.

All field wiring to the unit must be done in accordance with

these instructions, the National Electric Code (ANSI/NFPA

70-1981) in the United States and all local codes and

ordinances.

Clearances from the heater and vent to construction or

material in storage must conform with the National Fuel

Gas Code ANSI Z83.9 (latest edition), pertaining to gas-

burning devices, and such material must not attain a

temperature over 160°F by continued operation of the

heater.

Installation should be done by a qualified agency in

accordance with the instructions in this manual and in

compliance with all codes and requirements of authorities

having jurisdiction.

INSTALLATION

Unit Location, Clearances

An intake louver protects the service end and clearance at

this point should be maintained. A 36" clearance must be

allowed for access to the compressor and electrical panel.

A 24" clearance must be maintained for the air inlet to the

condenser coil(s). Do not locate the unit under an

overhang that will short circuit hot air to the coil intakes.

When installed at ground level, the unit should be mounted

on a level concrete slab which should extend at least 2"

beyond the unit on all sides. The top of the slab should be

2" above the ground level.

The depth of the slab below the ground level and its

structural design is governed by the type of soil and

climatic conditions. The slab must not be in contact with

any part of the building wall or foundation. The space

between the slab and building wall prevents the possibility

of transmitting vibration to the building.

The dimensions of the slab or roof mount should be

checked and verified before the equipment arrives. Unit

supports, roof opening, roof curb flashing, drain

requirements, and electric locations are important to a

good installation.

When installing the equipment on top of a building, the

following should be considered:

Structural members supporting the unit must be sufficiently

strong for the weight of the unit and mounting rails.

Transmission of sound into the building is sometimes a

problem when the structure is not strong enough.

Locate the unit as near as possible to the center of the

area to be environmentally controlled. Sufficient clearance

must be available for service, edge of roof, other units, or

hazards.

The condenser air inlet and discharge air must be

unobstructed by overhang, walls, or other equipment.

Avoid locations next to exhaust fans or flues.

Select a location where external water drainage cannot

collect around the unit.

Locate the unit so roof runoff water does not pour directly

on the unit. Provide gutter or other shielding at roof level.

Where snowfall is anticipated, mount the unit above the

maximum snow depth for the area.

Curb Installation, Protrusions

Proper installation for the DC series requires that the roof

mounting, field assembled curb be firmly and permanently

attached to the roof structure. Check for adequate

fastening method prior to setting rooftop unit on curb.

Inspect curb to insure that none of the utility services

(electric, gas, drain lines) routed through the curb protrude

above the curb. Duct connections will normally be made

after unit is set on curb. If duct is prefabricated and

installed within the curb prior to setting unit, insure that

ductwork does not protrude above curb.

CAUTION: DO NOT ATTEMPT TO SET UNIT ON CURB

IF PROTRUSIONS EXIST.

CAUTION: Units may look identical but have significant

internal differences.

Check specific unit location carefully (referring to plans if

necessary) prior to setting unit.

4

INSTALLATION CONTINUED

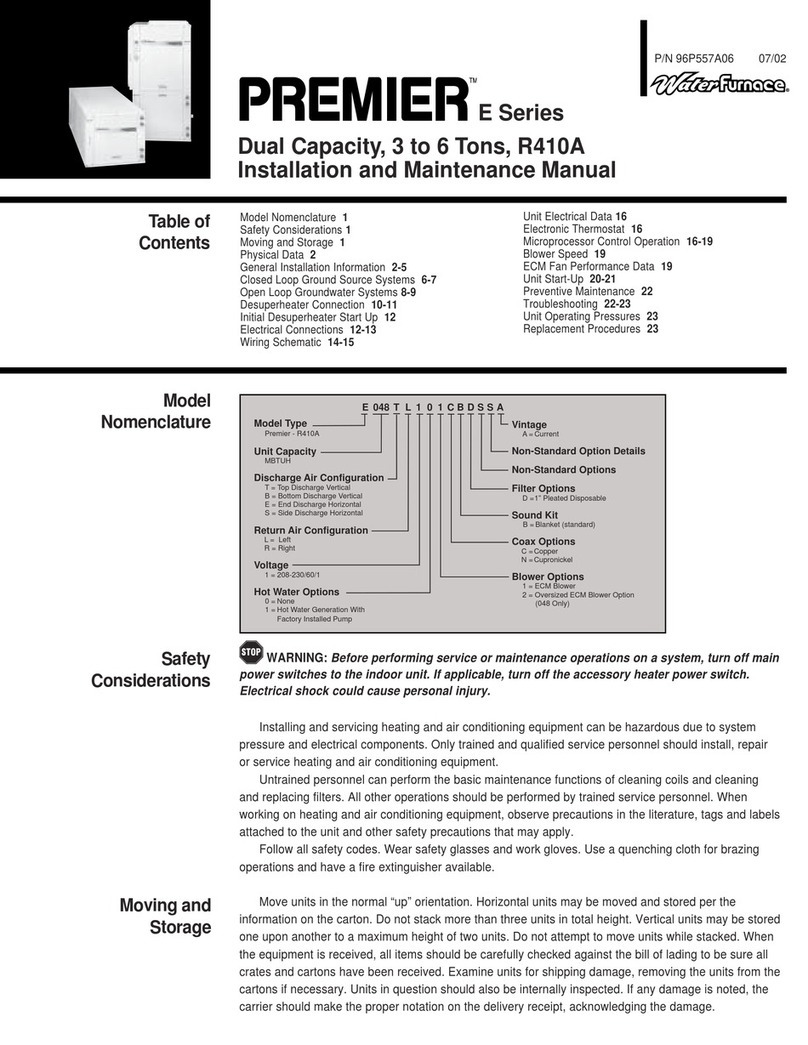

Rigging

WARNING: Be sure that the crane and lift material (bars,

cable, chain), (or other lifting device) capacity is adequate

for the unit weight. See Addison specification literature for

weights. The total unit weight calculated must include all

appropriate options for your unit. Certain options can add

significant weight to a unit.

Refer to labeling on unit for the required use of spreader

bars. Spreader bars keep the lift cables from damaging the

cabinet once the unit has been lifted. Larger units will

require a third or fourth support in the middle of the unit.

Keep the tension equal improper lift tension can damage

wiring, refrigeration lines and the water tight integrity of the

cabinet as well as sheet metal damage to the unit cabinet.

FRONT OF UNIT CENTER OF UNIT REAR OF UNIT

UNIT FRAME RIGGING CONNECTION POINTS

INSERT LIFT BAR

HERE (BOTH RAILS) HERE (BOTH RAILS)

INSERT LIFT BAR

DC SERIES B UNIT

STEEL BASE FRAME

FULL PARIMETER STRUCTURAL

USE A TEE LOOP OR

DO NOT USE A BAR!

HOOK TYPE LIFT

RIGGING MUST BE SUCH THAT EQUAL TENSION IS EXSERTED ON

ALL FRAME LIFT POINTS OR SEVERE UNIT DAMAGE WILL RESULT!

WARNING:

YOUR UNIT MAY VARY

FROM WHAT IS SHOWN

Figure 1

Lower unit carefully onto roof mounting curb or mounting

rails or ground level slab. While rigging unit, center of

gravity will cause condenser end to be lower than

supply/return air end. Bring condenser end of unit into

alignment with curb. With condenser end of unit resting on

curb member and using curb as fulcrum, lower front end of

unit until entire unit is seated on curb.

Rigging Removal

Remove spreader bars, lifting cables and other rigging

equipment. Use caution not to dent scratch or otherwise

damage cabinet or intake and exhaust hoods.

CAUTION: Do not allow crane hooks and spreader bars

to rest on roof of the unit.

ELECTRICAL

Wiring Connections

Power wiring should be connected to the main power

terminal block located within the unit main control section.

Power wiring connections on units with factory disconnects

should be made at the line side of the disconnect switch.

Low voltage wiring connections are made to the remote

mounted controller or time clock.

DO NOT TAMPER WITH FACTORY WIRING

Contact your local representative or the factory if

assistance is required. The internal power and control

wiring of these units is factory installed and each unit is

thoroughly tested prior to shipment.

Independent Power Source

It is recommended that an independent 115-volt power

source be brought to the vicinity of the rooftop unit for

portable lights and tools used by the service mechanic.

Main Power Wiring

The units are factory wired for the voltage shown on the

nameplate.

Main power wiring should be sized for the minimum wire

ampacity shown on the nameplate.

An external weather-tight disconnect switch properly sized

for the unit total load is required for each unit. Disconnect

must be installed in accordance with Local and/or National

Electric Codes.

Power wiring may enter the Rooftop Unit through the side

on all models or through the unit base and roof curbs on

models with the Power Through Curb option. Install

conduit connectors at the entrance locations. External

connectors must be weatherproof.

Grounding

All units must be properly grounded. The ground lug is

provided for this purpose. DO NOT use the ground lug for

connecting a neutral conductor. The unit must be

electrically grounded in accordance with local codes, or in

the absence of local codes, with the NEC ANSI/NFPA 70

1981.

Once it is established that supply voltage is within the

utilization range, check and calculate if an unbalanced

condition exists between phases. Calculate percent

voltage unbalance as follows:

Contact power company if phase unbalance exceeds 2%.

Control System Wiring: For commercial equipment the

following table lists the minimum size of 24 volt class 2

wire to be used.

5

Note: Wiring - Consult the wiring diagram furnished with

the unit. These units are custom designed for each application. The unit wiring diagram is located inside the

control panel of each unit.

INSTALLATION CONTINUED

Ductwork

Properly sized and installed ductwork is critical to reliable

performance of the unit and system. The DC Series B is

field convertible for down flow or left and right horizontal

supply and return duct connections. The DC Series B is

shipped from the factory with all duct connections capped

off. Simply remove the duct caps required for duct

installation. Unit connection sizes are in the engineering

specification literature. All ductwork must be installed

according to local codes, practices and requirements.

Industry manuals should be used as a guide to sizing and

designing the duct system.

Ducts passing through unconditioned spaces must be well

insulated with vapor barrier to prevent condensation.

Condensate Piping

A condensate trap must be provided by customer.

Drainage of condensate directly onto the roof is acceptable

if permitted by local codes. It is recommended that a small

drip pad of either stone, or tar, wood or metal be provided

to prevent any possible damage to the roof. If condensate

is to be piped into the building drainage system, the drain

line must penetrate the roof external to the unit. Refer to

local codes for additional requirements.

CAUTION: Units with high internal and external static

pressure drops will require a deeper trap. Use the

graph and table in Figure 2.

GAS PIPING AND VENTING

For DC units with gas furnace options locate the gas

furnace instruction manual located inside each gas

furnace vestibule. This manual will provide you with

specific installation requirements and important safety

and warning information that must be reviewed prior

to installation of the gas heating equipment.

Gas-fired appliances are not designed for use in

hazardous atmospheres containing flammable vapors

or combustible dust, in atmospheres containing

chlorinated or halogenated hydrocarbons, or in

applications with airborne silicone substances.

Improper installation, adjustment alteration, service, or

maintenance can cause property damage, injury, or

death. Read the installation, operation, and

maintenance instructions thoroughly before installing

or servicing this equipment.

FOR YOUR SAFETY

The use and storage of gasoline or other flammable

vapors and liquids in open containers in the vicinity of

this appliance is hazardous.

WARNING

Figure 2

WARNING

6

INSTALLATION CONTINUED

Clearances

Adequate clearance around the unit must be kept for

safety, accessibility, service, and maintenance. 48 inches

clearance is required on the rear (furnace and electrical)

end of the unit. This clearance must be maintained for

compressor removal and in the case of a furnace unit, for

removal of the furnace and to insure proper flue gas flow.

All combustible materials must be kept out of the area. A

48 inch clearance is also required on the front (outside air)

end of the unit for blower removal and for adequate

outside air accessibility. The clearance of 96 inches on the

filter access side of the unit is required for blower shaft

removal and 36 inches is required on the condenser side

for an adequate supply of condenser air.

Combustion Air Clearances (See Model DF Instruction Manual For Additional Information)

REQUIRED CLEARANCES

Sides* Bottom

Model Top Control Opposite To

Combustibles To Non-

Combustibles

DF

Series 36"

Width

Of

Furnace

Plus 6" 0" 24" 0"

*Provide clearance as shown for safety, for combustion, and for service.

COOLING SYSTEM OPTIONS

Hot Gas Bypass

Hot gas bypass is a means of capacity control during lower

ambient temperature conditions.

The Hot Gas Bypass valve is an adjustable valve and

should be set to open when the refrigerant suction

pressure drops to 110-112 psig. It varies unit capacity by

introducing discharge refrigerant into the evaporator circuit

where it creates a false evaporator load. The hot gas is

cooled prior to its return to the compressor as it passes

through the evaporator.

The Hot Gas Bypass Solenoid Valve is energized through

the thermostat and routes discharge gas to the hot gas

bypass valve. It is de-energized during the pump down

cycle.

Head Pressure Control

Low ambient control. Cycling the condenser fan or fans in

response to compressor discharge pressure will permit

stable operation in ambients down to 32F. The operating

pressure switch is adjustable to match customer needs; it

is factory set to re-energize the fans when discharge

pressure drops to 295 psig and energize them when

pressure increases to 430 psig.

Variable Speed Control

The VARISPEED Fan Control System controls the

compressor discharge pressure. The speed control

module responds to discharge pressure; it speeds the

condenser fan up as pressure rises and slows the fan

down as pressure falls due to load conditions or as

outdoor ambient temperature falls.

Head pressure control is accomplished with one or two

variable speed condenser fan drives, factory set to begin

fan rotation at 380 psig and be at full fan speed at 430

psig.

Dual compressor dual fan units have one variable speed

motor and control on each circuit.

Single compressor four fan units have one variable speed

motor and control and three 3 phase constant speed

motors. Two adjustable pressure controls are used on the

3 fans, the first operating one fan between 440 psig and

355 psig, the second operating two fans between 460 psig

and 375 psig.

CAUTION: Pressure settings on the constant speed fans

must NOT be set so as to permit operation below 355 psig

or the variable speed motor may stall and overheat.

Single compressor, single fan units will have one variable

speed motor and control.

Dual compressor, single fan units will have one variable

speed motor and control with a sensor in each refrigerant

circuit. The control reacts to the higher of the two operating

pressures.

Single compressor dual fan units are equipped with one

variable speed motor and control and one constant speed

three-phase motor.

At low ambient, the variable speed fan operates,

increasing in speed until maximum RPM is achieved at or

around 45°F ambient. An adjustable pressure switch

operates the constant speed three-phase fan set to

energize the motor at 440 psig and de-energize at 355

psig. In the ambient temperature span of approximately

7

50°F to 53°F, the variable speed fan will ramp between

maximum and minimum speed while the constant speed fan cycles. The start-stop cycle varies from 45 seconds to

2½ minutes during this period.

COOLING SYSTEMS OPTIONS

At 53°F, both fans are operating; the variable speed at

minimum RPM and the constant speed at full RPM. As

the ambient continues to rise, the variable speed motor

increases to full speed and remains there.

If the application calls for a closer setting between

maximum and minimum pressure settings on the

constant speed fan, for example 440 psig on, 390 psig

off, the effect will be to lengthen the temperature span

during which the cycling takes place, for example 50°F

to 57°F.

Adjustable High and Low Pressure Switches

Standard cooling units are equipped adjustable pressure

switches. The low pressure switch is adjustable between

0psig – 150 psig and is factory set to open at 60 psig

and close at 35psig. The high pressure switch is

adjustable between 200 psig. And 610psig and factory

set to open at 600psig and to close at 550 psig

MECHANICAL ADJUSTMENTS

SET FAN RPM.

All evaporator motor sheaves are set when tested and

shipped from the factory. Actual rpm must be set and

verified with a tachometer. Refer to the following Blower

Performance Chart for basic unit fan rpm.

With disconnect switch open, place a jumper wire across

Terminals R and G at TS1 Terminal Block. Close

disconnect switch; evaporator fan motor will operate so

rpm can be checked.

FAN ROTATION CHECK

Check that fan rotates clockwise when viewed from the

drive side of unit and in accordance with rotation arrow

shown on blower housing. If it does not, reverse two

incoming power cables at TB Terminal Block.

Do not attempt to change load side wiring. Internal wiring

assures all motors will rotate in correct direction once

evaporator fan motor rotation check has been made.

FORWARD CURVE

Figure 4

Blower Rotation

8

DRIVE BELT TENSION AND ALIGNMENT

Fan belt alignment and tension should be checked.

Tension should be 3/4" depression per foot of belt span

between pulleys.

Personal injury hazard.

Use extreme care during the following procedures and

obey Safety Information.

Failure to do so may result in personal Injury.

The following safety rules MUST always be followed when

working near belt drive.

Always Turn The Power Off

1. Turn the power to the unit OFF before you begin

working on it.

Always Wear Protective Clothing

2. NEVER wear loose or bulky clothes, such as

neckties, exposed shirttails, loose sleeves, or lab

coats around belt drives. Wear gloves while

inspecting sheaves to avoid nicks, burrs, or sharply

worn pulley edges.

The blower speed is changed by adjusting the

variable speed pulley mounted on the blower motor.

If the blower speed needed is different than the

speed of the blower as shipped, follow the steps

below to change the blower speed. Before changing

the blower speed, read the above safety rules first.

3. Turn electric power OFF.

4. Remove the side blower access panel.

Loosen the four motor mount bolts.

6. Turn the motor adjustment bolt counterclockwise until

the belt is slack enough to come off easily.

7. Remove the belt. Do NOT pry off belt.

8. Loosen set screw(s) on the outer half of the

adjustable pulley.

9. The unit has one of two different types of adjustable

pulleys.

10. Remove key if unit has a keyway type pulley.

11. To set the blower for a desired CFM (L/s), first turn

the outer half of the adjustable pulley clockwise until it

meets the inner half of the pulley.

12. Turn the outer half of the adjustable pulley counter

clockwise the correct number of turns to obtain the

desired CFM (L/s).

NOTE: To increase the blower speed, turn the outer

half of the adjustable pulley clockwise. To decrease

the blower speed, turn the outer half of the adjustable

pulley counter clockwise.

13. Replace key if unit has keyway type pulley.

14. Tighten set screw(s).

15. Put on belt.

16. Turn motor adjustment bolt clockwise until the belt

has enough tension at the proper deflection. Use one

of the commercially available belt tension gauges to

set the correct tension at the proper deflection.

17. Use a straight edge (angle iron, straight piece of

board or anything with a straight surface or edge) to

check the alignment of the blower pulley with blower

motor pulley.

MECHANICAL ADJUSTMENTS CONTINUED

18. It may be necessary to back the tension off the belt

temporarily and tighten one of the motor mount

bolts before it is possible to adjust the angle of the

blower motor.

19. Tighten all four blower motor mount bolts.

9

ELECTRICAL SYSTEM OPTIONS

Airflow Switch. Designed to prevent system operation

unless there is proof of blower operation. A differential

pressure switch measures the air pressures at the suction

and discharge of the blower.

Clogged Filter Indicator. Dirty or clogged filters are

indicated when the preset pressure differential across the

filters is reached. The indicator is factory installed and is

manually reset. It includes contacts for remote indication.

Convenience Outlet. A 115V GFCI receptacle mounted in

a 2"x4" enclosure may be furnished with either a 15 amp

circuit breaker or fuse block or 15 amp fuses. Separate

115-volt power source and ground is required.

Exhaust Fan Interlock. A relay installed in the unit control

panel is energized when the blower is to interlock the unit

with building exhaust fan(s).

Power Through the Curb. On curb mounted downflow

units, a sleeve can be installed in the compressor section

to bring power wiring inside the curb, preventing a

separate roof penetration. The sleeve must be sealed after

wiring is

completed with a suitable mastic to prevent water from

entering the space.

Firestat. This control, mounted in the return air section,

de-energizes the unit when return air reaches 135°F. It is a

manual reset control.

Sure-Trip™. This control automatically stops the unit

whenever a phase is lost, when phases are out of

sequence, or when supply voltage drops too low. Restart

is automatic with a 5-minute delay after proper power

supply conditions are restored.

DDC Controls. A multi-function direct digital controller in

which temperature, pressure, and/or humidity sensors may

be interfaced to provide a complete operating and

monitoring system. Additional control information is

provided with the unit such as controller instructions and

unit wiring diagrams. Information can also be obtained thru

the application department at Addison, See last page for

contact information.

Figure 5

Preliminary Check

Figure 6

10

SEQUENCE OF OPERATION

Heating, Hydronic or Steam

Both hydronic and steam heat require a one or two row

coil generally located downstream of the evaporator coil.

Controls for hydronic heat will involve a 3 way motorized

mixing or blending valve, driven by a signal from a leaving

air temperature thermostat.

Controls for low-pressure steam heat contain a motorized

throttling valve driven by a signal from a leaving air

temperature thermostat

Gas Heat

See the gas furnace instruction manual for wiring and

performance data. Additional information can be found on

the furnace access door such as the rating and serial

label, wiring and lighting instruction label.

1. Blower operation is confirmed by line voltage from the

load side of the blower contactor to the gas furnace

power supply terminals.

2. The furnace section is energized from the control

terminal across the normally closed contacts of the

combustion pressure switch, energizing pilot ignition

time delay relay heater. After delay of approximately

30-50 seconds the time delay relay’s switch closes

energizing the furnace venter motor. As the venter

operates, it causes the combustion pressure switch to

open. The ignition control energizes the pilot valve

solenoid in the combination gas valve. A high voltage

electric spark lights the pilot flame.

3. The flame sensor proves the presence of the pilot

flame generating a DC current of 0.2 microamp (or

greater) to the ignition control. The ignition control’s

internal switch action then de-energizes the spark

transformer and makes a circuit to the high fire

solenoid of the combination gas valve.

4. When there is a call for gas furnace operation the

discharge air temperature causes a change in the

resistance of a discharge air sensor thermistor. The

Electronic solid state control center measures the

sensor’s change in resistance and sends a varying DC

current to the Modulator-Regulator valve to adjust the

gas input as required.

5. The flame sensor proves the presence of the pilot

flame generating a DC current of 0.2 microamp (or

greater) to the ignition control. The ignition control’s

internal switch action then de-energizes the spark

transformer and makes a circuit to the high fire

solenoid of the combination gas valve.

Electric Heat

1. DC units that use the down flow discharge. The

installer MUST use an “L” shaped discharge duct

that does not have an outlet directly below the

units discharge opening, per UL1995. To guard

against the very rare occurrence of a piece of an

electric heating element breaking away. A straight

duct or outlet grill directly below the unit discharge

may allow a hot fragment to land in a conditioned

space and start a fire.

2. Blower operation is generally confined by an air

pressure differential switch as part of the heater

assembly.

3. A thermostat or thermostats in the entering outside

air energize the strip heat as required. Unit leaving

air temperature will vary depending on kW, the

number of stages, and the entering air

temperature. Calculate the temperature rise using

the following formula:

°F Rise = kW x 3413

1.08 CFM

Where °F rise is the air temperature increase, kW is the

heater capacity in kilowatts and CFM is the total airflow of

the unit.

Subtract the °F rise from the desired leaving air

temperature and set the thermostat at that value. For

multiple stages, calculate the °F rise for each stage and

set thermostats subtracting each rise from the previous

entering air temperature.

For example:

CFM 2000

kW 22.5, 3 stage, 7.5 kW each

Leaving air desired 65°F

°F Rise = 7.5 x 3413 = 11.7°F

1.1 x 2000

Set 1st stage thermostat to energize at 65-11.7 = 53.3° F

Set 2nd stage to energize at 53.3 -11.7 = 41.6°F

Set 3rd stage to energize at 41.6-11.7 = 29.9°F

11

ENERGY CONSERVATION WHEEL

Before starting up the unit, check the following:

1. Does the rotor rotate freely by hand?

If not, recheck the seal to determine whether or not it is

binding and if so adjust seals following the instructions

below.

2. Is the motor rotation correct?

This can be checked by detaching the belts from the drive

sheave and bumping the motor. The sheave should be

rotating in the direction such that the belt will result in

rotation per the exterior markings. If not, rewire the motor.

3.Does the air flow orientation match up to design?

See the identification markings on the cassette and/or

refer to the general arrangement drawing to check the four

duct connections to the unit.

4. Are the belts on correctly and sufficiently tight?

Belt length is set by the manufacturer. Consult NovelAire if

the belt appears too loose.

5. Is the VFD programmed to control the unit and to

prevent frost formation?

If not, follow the instructions in the manual accompanying

the VFD and/or consult NovelAire.

Seal checks

The ECW is provided with a neoprene bulb seal which

provides not only an effective seal in both the peripheral

and side-to-side sealing directions but also one which is

easily adjusted to compensate for seal run-in, shipping

misalignment, etc. The neoprene bulb is

attached to a metal reinforced U-shaped neoprene grip.

The metal/neoprene grip allows for an expandable grip

range which can be moved closer or further from the

sealing face as needed. The peripheral bulb seals against

the wheel outer band and the inner bulb seals against the

wheel face. With the wheel stopped, move seals as close

to the sealing surface as possible but without exceeding

grip range of bulb seal and without pressing the bulb

down against the seal face. Bump the motor. If the motor

will not turn, the seal is too close and should be nudged

back where needed. The seal will seek its equilibrium

position based on the closest part of the sealing face.

Because the seal is meant to be a non-contact seal, small

gaps may be seen between seal and sealing surface once

the equilibrium position is reached. Seal leakage is meant

to be less than 5% at 1 inch of differential between supply

and exhaust. Some seal run-in is to be expected, so don't

be alarmed by small amounts of wear in the neoprene.

Variable speed drive (VFD)

Check the power supply for proper rating. Make sure that

the proper jumper orientation is used for the specific

control input. Make sure that the unit is programmed for

proper input voltage and output voltage.

Maintenance

Bearings

Small ECW’s, (smaller than ECW666) are provided with no

maintenance inboard bearings. These bearings should

require no maintenance during the life of the equipment.

Larger ECW’s come equipped with an external flanged

bearing which should be greased annually. Use a

petroleum based lubricant.

Drive Motor

The drive motors should require no maintenance.

Replacement motors may be purchased from normal

motor distributors such as Grainger, or directly from

NovelAire if preferred.

Drive Belts

NovelAire ECW belts are multilink belts with individual

links constructed of a high performance polyurethane

elastomer reinforced with multiple plies of polyester fabric.

This belt provides a strong, yet flexible, belting. The

multilink feature provides quick, easy servicing or

replacement. See the Appendix for belt repair/replacement

instructions.

Seals

The seals are designed to be durable and require no

maintenance other than adjustment, but if seals become

worn or damaged they may easily be replaced. The seals

are made to clip on the cassette or post metal easily. Call

NovelAire for servicing information.

Wheel

The wheel is designed to last the life of the equipment. It

should be protected by an ASHRAE 30% filter to keep dust

and dirt from the heat transfer surface. The wheel is

somewhat self cleaning through its normal action of

rotating in and out of countercurrent air flow streams. If the

wheel becomes dirty, it may be cleaned by blowing out the

unit with compressed air (20 psig maximum). In cases of

severe filthiness, the wheel may be removed from the

cassette and washed with water following wheel

removable procedures outlined below:

1. Remove air handler plenum sections so that the front or

back of the cassette may be easily accessed and cleared.

2. Support the wheel from the bottom.

3. If the unit is equipped with an external flanged bearing,

loosen the Allen screws in the bearing housing that keeps

the shaft affixed in the horizontal plane of both bearing,

front and back. Remove the shaft clips at the face of the

hub from both sides of the shaft. Unbolt one post

completely and remove post with bearing completely out.

Remove the shaft. Roll the wheel carefully out.

4. If the unit is equipped with an internal bearing, unbolt

the shaft screw on both sides of the shaft. Unbolt one post

completely and remove post. Remove the shaft clips at the

face of the hub from both sides of the shaft. Remove the

shaft. Roll the wheel out carefully

5. With the wheel out, wash the media carefully with water.

Once clean, allow the media to dry out for several hours or

days if necessary.

6. Reinstall using the reverse procedure. Run the unit. It

may take several hours for the desiccant to dry out and for

the wheel to perform normally.

12

TROUBLE SHOOTING GUIDES

General Refrigeration Circuit

SYMPTOM POSSIBLE CAUSE

1. Power off, loose electrical connections or fuse open.

2. Compressor contactor not closing.

3. Internal compressor thermal overload open.

4. Compressor defective.

5. High or low pressure switch open or defective.

6. Oil pressure control open or defective.

1. Low refrigerant charge

2. Airflow restricted.

3. Restriction in liquid line.

4. Defective low pressure switch.

1. Refrigerant overcharge.

2. Condenser fan control has incorrect setting.

3. Fan motor defective.

4. Condenser coil inlet obstructed or dirty.

5. Air or non-condensables in system.

6. Defective high pressure switch.

7. Restriction in discharge or liquid line.

1. Low voltage.

2. Sustained high discharge pressure.

3. High suction and discharge pressures.

4. Defective compressor overload.

5. Defective run capacitor.

6. Improper refrigerant charge.

7. Bearings or pistons too tight.

8. Allow time for compressor to cool.

1. Low oil level.

2. Defective oil pump.

3. Defective control.

4. Liquid refrigerant is entering crankcase.

1. Scroll compressors are rotation sensitive.

2. Refrigerant overcharge.

3. Excessive or insufficient oil in compressor 3. Check oil level in hermetic compressors. Check total

e

crankcase.

4. Liquid floodback.

5. Tubing rattle.

6. Compressor defective.

4. Com

p

ressor will be wet. Check crankcase heater or cause for li

q

uid feedback.

6. Check internal parts (semi-herm.)

1. Reverse wiring at disconnect switch, recheck for correct evaporator blower rotation.

2. Check pressures and subcooling.

4. Check TXV setting. Check for refrigerant overcharge. oil as recommended.

5. Dampen tubing vibration by taping or clamping. Bend tubing away from contact where possible.

8. Check dome tem

p

erature of the com

p

ressor.

1. Check crankcase sightglass - add oil to bring level to midway in sightglass.

2. Check oil pump.

3. Check oil failure control for calibration.

4. Allow compressor to cool for two hours if compressor is hot. Recheck for open circuit.

5. Check run capacitor for compressor and fan motor.

6. Check subcooling.

7. Check for low oil level.

7. Check dischar

g

e and li

q

uid line

p

ressures

,

check TXV.

1. Check voltage.

2. Check running amperage and conditions described under “high discharge pressure.”

3. Check TXV setting, check for air in system.

3. Check fan motor.

4. Check coil and inlet clearances and for possible air recirculation.

5. Check high side equalized pressure reading with equivalent outdoor temperature.

6. Check calibration of switch.

5. Check calibration of high or low pressure switch, re-calibrate or replace.

4. Check calibration of switch.

1. Check pressures, charge by sub cooling.

2. Check calibration of low ambient control.

1. Check sightglass and check pressures.

2. Check for dirty evaporator coil, dirty filters, dampers closed, iced evaporator, proper belt

adjustment, proper motor amps, duct design

3. Check head pressure, check and adjust TXV if not functioning properly, check pressure drop

across filter drier.

6. Check oil failure control. See oil failure control below.

1. Check disconnect switch, fuses and wiring. Replace parts or repair as necessary.

REMEDY

3. If compressor is hot, allow 2 hours to cool. See thermal overload below.

4. Check compressor for electrical failure. Compressor may be seized, check for L.R.A.

2. Check voltage to contactor coil, transformer, slave relay, system. Replace parts as necessary.

E. Compressor cuts out on oil failure

control (semi-herm.)

F. Noisy compressor.

A.Compressor will not start

B.Compressor starts but cuts out on

low pressure switch.

C. Compressor starts but cuts out on

high pressure switch.

D. Compressor cuts out on thermal

overload.

13

TROUBLE SHOOTING GUIDES CONTINUED

General Refrigeration Circuit

Continued

SYMPTOM POSSIBLE CAUSE REMEDY

1.Blower rotational noise. 1. Check blower, motor and drive for faulty adjustment or noisy bearings, loose parts, blower out of

balance.

2.Air noise. 2. Check ductwork. Air velocity too high.

3.Chattering contactor. 3. Check for adequate control voltage, check for shorts or breaks, check thermostat, check contact

points.

4.Tubing rattle. 4. Dampen by taping or clamping, bend tubing away from contact when possible.

1.Excessive load on evaporator coil. 1. Check for high entering wet bulb temperature. Check for excessive airflow.

2.Broken compressor valves (Scroll compressors do not

have valves.) 2. Remove head (semi-herm.) inspect reeds. Scroll compressors should not be pumped down below 5

psig.

3.Compressor is unloaded. 3. Check head pressure, check and adjust TXV if not functioning properly, check pressure drop across

filter drier. Re-calibrate unloader pressure switch.

4.Leaking check valve. 4. Check temperature across check valve.

5.Expansion valve not secured to suction line or TXV

defective. 5. Check the TXV, ensure bulb is insulated.

1.TXV setting. 1. Check TXV setting and calibrate superheat.

2.Air inlet to condenser dirty or obstructed. 2. Check for proper clearances and possible air recirculating.

3.Condenser fan motor defective. 3. Check condenser fan motor and run capacitor.

4.Condenser fan control has incorrect setting. 4. Check calibration of low ambient head pressure control.

1.Refrigerant undercharge. 1. Check pressures and subcooling.

2.Blower running backward. 2. Interchange any two wires from 3 phase disconnect.

3.Loose blower, pulley or belts. 3. Check drive pulley alignment, belt tension.

4.Defective or improperly adjusted expansion valve. 4. Check superheat and adjust TXV.

5.Dirty filter. 5. Check filter and evaporator coil.

6.Too little air flow or low entering air temperature. 6. Check airflow and entering air wet bulb conditions.

7.Restriction in suction or liquid line. 7. Check refrigerant circuit for restriction

1.Insufficient refrigerant charge. 1. Check subcooling, check for leak.

2.Defective or improperly adjusted expansion valve. 2. Check sub cooling and adjust TXV.

3.Low suction pressure. 3. See “suction pressure too low” above.

4.Condenser fan control setting. 4. Check calibration of low ambient control.

5.Defective compressor. 5. See “high suction pressure” above.

1.Thermostat location or malfunction. 1. Check thermostat, check heat anticipator setting.

2.Improper refrigerant charge. 2. Check subcooling, verify superheat.

3.Defective high or low pressure control. 3. Check high or low pressure switch.

4.Liquid floodback. 4. Possible tight bearings.

5.Defective expansion valve. 5. Check TXV and superheat.

6.Poor air distribution. 6. Check ductwork for recirculating.

7.High discharge pressure. 7. See “high discharge pressure” above.

8.Leaking discharge valves in compressor. 8. See “high suction pressure” above.

1.Refrigeration undercharged. 1. Check subcooling.

2.Dirty filter or evaporator coil. 2. Check filter, coil and airflow.

3Dirty or clogged condenser coil. 3. Check coil and airflow.

4.Air or other non-condensables in system. 4. Check equalized high side pressure with equivalent outdoor temperature.

5.Defective compressor. 5. Check compressor for proper operation.

6.Restriction in suction and liquid line. 6. Check for restrictions in refrigerant circuit.

7.Control contacts stuck. 7. Check thermostat, shorts in wiring, slave relay compressor contactor

M.Running cycle too long or unit

operates continuously.

G.Noisy unit operation.

H.High suction pressure.

L.Compressor short cycles.

K.Head pressure too low.

J.Suction pressure too low.

I.High discharge pressure.

14

TROUBLE SHOOTING GUIDES CONTINUED

General Refrigeration Circuit Continued

SYMPTOM POSSIBLE CAUSE REMEDY

1. Refrigerant undercharge or leak in system. 1. Check subcooling and check for leaks.

2. Evaporator plugged with dirt or ice. 2. Check evaporator, airflow and filter.

3. Improperly adjusted or defective expansion valve. 3. Check superheat and adjust TXV, check bulb.

4. Defective compressor. 4. Check compressor for proper operation.

5. High discharge pressure. 5. See “high discharge pressure” above.

6. Airflow is too high. 6. Check external static pressure.

1. Airflow is too low. 1. Check evaporator coil, filter, check for closed dampers, grills, drive for loose parts, belts,

misalignment, check external static pressure.

2. Return air temperature too low. 2. Check entering air wet bulb conditions.

1. Refrigerant undercharge. 1. Adjust the charge by subcooling.

2. High discharge pressure. 2. See “high discharge pressure” above.

Q. Liquid line frosted or wet. 1. Restriction in liquid line. 1. Restriction upstream of point of frosting.

1. Insufficient evaporator air flow. 1. Check airflow, check drive for loose parts, belts, closed dampers.

2. Restriction in suction or liquid line. 2. Restriction upstream of point of frosting.

3. Malfunctioning or defective expansion valve. 3. Check bulb of TXV.

1. Improper wiring. 1. Check wiring diagrams.

2. Defective motor. 2. Check motor and controller.

3. Defective thermostat or control circuit. 3. Check control circuit.

4. Motor off on overload protector. 4. Allow motor to cool, check amperage.

S. Blower motor not running.

N. Supply air temperature too high.

O. Supply air temperature

P. Liquid line too hot.

R. Suction line frosting.

Varispeed™ Condenser Head Pressure Control

SYMPTOM POSSIBLE CAUSE REMEDY

1. Input pressure is below operating range. 1. No problem, normal operation.

2. No 24 volt control voltage 2. Check for 24 V AC at control.

3. No input pressure to control. 3. Check alignment of capillary fitting. Schrader valve depressor must depress Schrader valve enough to allow

pressure into capillary.

4. Bad fan motor. 4. Disconnect power. Place a jumper from L1 to M1 and connect power. If fan does not start, motor is bad and

should be replaced.

5. Pressure transducer problem. 5. Disconnect 6 pin connector from right side of control. Place a jumper wire between third pin from the top and

bottom pin on the control (not the cable). If fan goes to full speed, check for input pressure. If it has been

determined there is adequate pressure, the transducer is bad and the control must be replaced.

B. Fan stops when pressure reaches

the high end of the operating range. 1. Control is not wired correctly. 1. See wiring diagrams.

C

.

N

o

f

an mo

d

u

l

a

ti

on

(O

n-

Off

Operation) 1. Control is not wired correctly. 1. See wiring diagrams.

D. Fan starts at full speed. 1. Control is not wired correctly. 1. See wiring diagrams.

1. Control is not wired correctly. 1. Check to see if control voltage (24 V AC) is on same phase as motor.

2. Dirty or blocked condenser coil. 2. Clean condenser coil.

F. Fan motor is cycling on thermal over 1. Dirty or blocked condenser coil. 1. Clean condenser coil.

2. Wrong motor for fan speed control application. 2. Replace with motor approved for fan speed control application.

A. No fan operation.

E. Erratic fan operation.

15

TROUBLE SHOOTING GUIDES CONTINUED

Hot Gas Bypass Regulator

SYMPTOM POSSIBLE CAUSE

1. Defective regulator.

2. Dirt causing regulator to bind.

3. Power source to hot gas solenoid or

operation of the solenoid is intermittent.

1. Dirt in regulator causing seat to remain open.

2. Worn or eroded seating surface on regulator.

1. Regulator is oversized.

2. Regulator and liquid injection Thermo Valve

have control interaction.

3. Regulator and cylinder unloaders have

1. Regulator seat is restricted.

2. Pressure adjusting stem is set at a point so

high that suction pressure never reaches the set

point.

3. Strainer clogged at the regulator inlet.

4. MOPD exceeded across the solenoid or loss

of source voltage.

5. Solenoid coil burned out.

6. Wrong type distributor for hot gas bypass to

the evaporator.

1. Dirt under seat of the regulator.

2. Diaphragm failure (leakage around the

adjusting stem)

3. Pressure adjusting stem is set at a point so

high that suction never reaches the set point.

4. Blocked external equalizer passage.

5. Worn or eroded regulator seat.

A. Erratic pressure control.

E. Regulator fails to close.

D. Regulator will not provide

pressure control.

C. Regulator hunting

(chattering) large fluctuations

in controlled pressures.

B. Regulator leakage.

4. Locate and remove stoppage. Install strainer.

5. Replace defective part.

2. Increase superheat setting. Dampen bulb response by repositioning.

2. Readjust the regulator.

4. Replace solenoid or troubleshoot the electrical problem.

6. Install proper Venturi - Flo type distributor for low pressure drop.

2. Replace defective parts.

3. Readjust the regulator.

1. Locate and remove stoppage. Install strainer or drier filter.

3. Locate and remove stoppage.

5. Replace coil.

3. Differential should be increased between the controls by lowering the

regulator’s set point.

1. Locate and remove stoppage. Install strainer.

1. Clean the regulator. Install strainer.

2. Replace defective part.

1. Contact Addison manufacturer for correctly sized regulator.

REMEDY

1. Replace defective part.

2. Disassemble regulator and clean internal parts. Install strainer.

3. Determine if problem is caused by supply voltage, solenoid, or excessive

MOPD. Make changes necessary to correct problem.

16

TROUBLE SHOOTING GUIDES CONTINUED

General Gas Furnace

See gas furnace Instruction Manual Included with gas furnace(s) for trouble shooting details.

TROUBLE SHOOTING GUIDES CONTINUED

Electronic-Regulator

SYMPTOM POSSIBLE CAUSE FIELD TEST REMEDY

1. Faulty automatic control valve. 1. Remove wire from valve, if valve doesn’t close —valve is faulty. 1. Replace automatic control valve.

2. Installation wiring error. 2. Remove wire from amplifier terminal 10 and 11. If valve remains open

check for miswiring. 2. Correct wiring.

3. Amplifier is faulty. 3. If AC voltage will not drop to zero at terminals 8 and 11 when DC voltage at

terminals 1 and 2 is above 20 V DC, amplifier is faulty. 3. Replace amplifier.

1. Faulty automatic control valve. 1. Read voltage across valve terminals. If 24 V AC, valve is faulty. 1. Replace automatic control valve.

2. Open wire to automatic valve. 2. Read voltage across terminals 8 and 11 on amplifier. If 24V AC, check for

open circuit to automatic valve. If space temperature is less than 60° or

greater than 85°F.

2. Correct wiring.

3. Amplifier is faulty. 3. If AC voltage reading remains zero when DC voltage at terminals 1 and 2 is

below 14V DC, amplifier is faulty. If space temperature is less than 60° or

greater than 85°F.

3. Replace amplifier.

1. Faulty power supply. 1. Read voltage at amplifier terminals 8 and 14 (24 V AC). 1. Power supply must be 24V AC.

2. MR valve installed backward. 2. Arrow on MR valve should point in direction of gas flow. 2. Install properly.

1. Room Override Thermostat, if used,

calls for heat. 1. Remove T115 wires from amplifier terminals 3 and 14. 1. If proper operation is obtained, check thermostat

wiring for shorts. Rotate thermostat dial above and

below room temperature to prove thermostat

function.

2. Open circuit in sensing and setting

circuit. 2. Disconnect and measure across wires connected to amplifier between

terminals 3 and 4 (A1010). Should read between 8,000 and 12,000 ohms. 2. If above 12,000 ohms check circuit for open or

loose wires.

1. Open circuit in wiring to MR valve. 1. Check wiring for defects. 1. Replace wiring if necessary.

2. Plunger jammed or installed upside

down. 2. Plunger should be smooth and clean and operate freely in solenoid sleeve. 2. Clean or replace plunger.

3. Faulty MR valve. 3. Measure voltage across MR valve.

F. Furnace won’t activate due

to constant high modulating

voltage (above 17 VDC).

1. Short circuit in sensing and setting

circuit 1. Disconnect and measure across wires connected to amplifier terminals 3

and 4 (A1010). Should read between 8,000 and 12,000 ohms. 1. If below 8,000 ohms check circuit for shorts or

miswiring.

A. Automatic control valve will

not close despite full range of

modulating voltage at terminals

1 and 2.

B. Automatic control valve will

not open despite full range of

modulating voltage at terminals

1 and 2.

C. No gas flow.

E. Continuous high fire but

automatic valve cycles.

D. Continuous high fire.

17

TROUBLE SHOOTING GUIDES CONTINUED

Electronic-Regulator Continued

SYMPTOM POSSIBLE CAUSE FIELD TEST REMEDY

1. Heat load requires low fire only. 1. Increase temperature setting 10 degrees. 1. If heater goes to high fire, system is working

correctly.

2. Plunger and/or maximum spring

missing. 2. Check for parts. 2. Install correct parts.

3. Jammed plunger. 3. Examine. Plunger should be clean, smooth, and operate freely in solenoid

sleeve. 3. Clean, or replace plunger if necessary.

4. Other valves faults. 4. Remove wire from MR valve. 4. If MR valve remains on low fire, valve may be

faulty.

5. Inadequate supply pressure. 5. Remove max. adjustment spring from MR valve, push down on plunger.

Insufficient manifold pressure with furnace operating indicates supply is too

low.

5. Check for obstruction in gas pipe ahead of

controls. Increase gas pressure if possible.

H. Incorrect discharge air

temperature. 1. Calibration. 1. Check seal on calibration potentiometer. 1. Recalibrate per “Temperature Calibration”

procedure.

1. Dirty or sticking plunger. 1. Examine. Plunger should be clean, smooth, and operate freely in solenoid

sleeve. 1. Clean or replace plunger if necessary.

2. Loose or broken wiring. 2. Inspect wiring. 2. Correct wiring.

3. Erratic voltage. 3. Observe DC voltage across amplifier terminals 1 and 2. 3. If erratic or pulsating DC voltage is observed and

wiring shows no defects, replace amplifier. If erratic

or pulsating voltage continues, contact Addison.

G. Continuous low or medium

fire, but automatic valve cycles

correctly.

I. Erratic or severely pulsating

flame.

*Control circuits external to the Electronic-Regulator and Amplifier can cause burner malfunction. Always check gas valve to be certain it is turned on, and check limit controls for normal operation.

19

This manual suits for next models

2

Table of contents

Other Addison Air Conditioner manuals

Popular Air Conditioner manuals by other brands

LG

LG MultiV Series installation manual

Daikin

Daikin Split Sensira R32 Service manual

Mitsubishi Electric

Mitsubishi Electric MSZ-DM25VA operating instructions

Friedrich

Friedrich WallMaster WS10 Installation and operation manual

Honeywell

Honeywell CL20AE user manual

Toshiba

Toshiba RAV-RM561KRTP-E installation manual