Adimec Q-12 CoaXPress Series User manual

OPERATING AND USER MANUAL

________________________________________________________________________________________________________________

Operating and user manual

Q-12 CoaXPress series

rev2.1

OPERATING AND USER MANUAL Q-12 CoaXPress series

________________________________________________________________________________________________________________

_________________________________________________________________________________________

Adimec 2

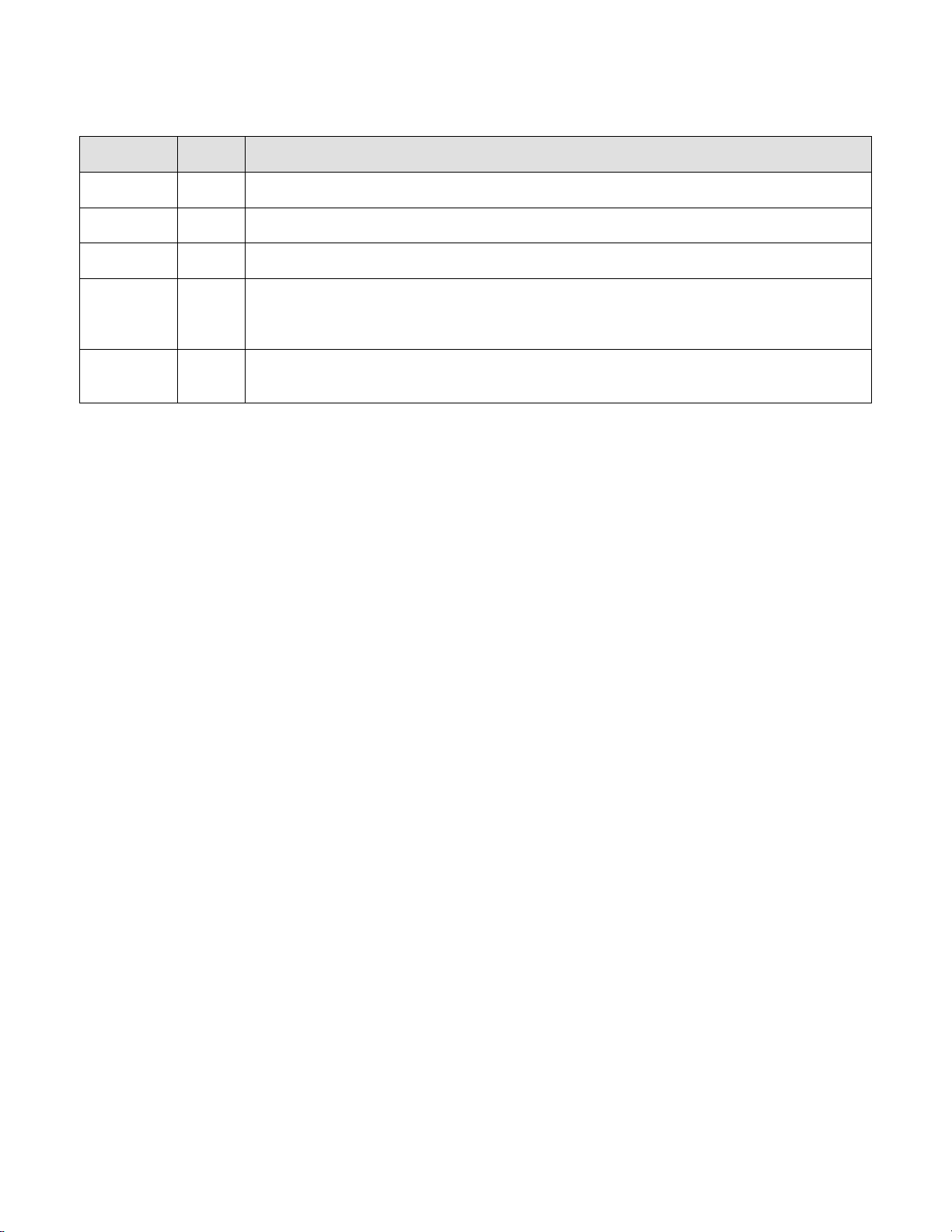

REVISION HISTORY

Revision

Page

Description of revision

2.0

-

Complete revision from the 1.x revision to include the Q-12A180 CXP issue 2.0 camera.

2.1

2

Revision history added.

28

Added remark about defect pixels and max frame rate in binned mode.

58/59

Added section 7.17.23 How to transfer a low frequency flat field calibration set from one

camera to another one. Sections 7.17.24 to 7.17.27 have been updated to describe the

functionality better.

68

Added APPENDIX B: C++ Example, transfer an LF FF calibration set.

OPERATING AND USER MANUAL Q-12 CoaXPress series

________________________________________________________________________________________________________________

_________________________________________________________________________________________

Adimec 3

ABOUT ADIMEC

Adimec designs, manufactures, and markets high performance industrial cameras for equipment manufacturers

in:

•Machine Vision

•Healthcare

•Global Security

Our high resolution cameras offer a unique combination of excellence in image quality, speed, and reliability.

With optimized functionality for the needs of specific applications, Adimec cameras exceed general purpose.

Adimec is a reliable partner with a focus on establishing long term relationships through a worldwide network of

highly qualified engineers.

Adimec aligns its roadmap in close cooperation with industry leaders and monitors the market for the latest

technology to continuously provide innovative cameras that enhance our customers' competitiveness. With our

capabilities, modular designs, process control and commitment to partnership, we can tailor to the exact solution

required in a short time to market and with low risk.

Adimec Advanced Image Systems B.V.

PO Box 7909

5605 SH Eindhoven

The Netherlands

Phone: +31 (0)40 235 3900

E-mail: SalesEU@adimec.com

Adimec Japan

2-10-3-103, Narimasu, Itabashi-Ku

175-0094 Tokyo, Japan

Phone: +81 (3) 5968 8377

Fax: +81 (3) 5968 8388

E-mail: SalesJP@adimec.com

Adimec USA

130 New Boston Street, Suite 204

Woburn, MA 01801, USA

Phone: +1 (781) 279 0770

Fax: +1 (781) 279 0571

E-mail: SalesUS@adimec.com

Adimec Asia/Pacific

60 Paya Lebar Road

#08-07 Paya Lebar Square

Singapore 409051

Phone: +65 6334 1236

Fax: +65 6334 1436

E-mail: SalesAP@adimec.com

OPERATING AND USER MANUAL Q-12 CoaXPress series

________________________________________________________________________________________________________________

_________________________________________________________________________________________

Adimec 4

TABLE OF CONTENTS

REVISION HISTORY.............................................................................................................................................. 2

ABOUT ADIMEC.................................................................................................................................................... 3

TABLE OF CONTENTS......................................................................................................................................... 4

1INTRODUCTION.............................................................................................................................................. 5

1.1 PRODUCT HIGHLIGHTS........................................................................................................................ 5

1.2 ABOUT THIS MANUAL .......................................................................................................................... 5

1.3 LIST OF FREQUENTLY USED ABBREVIATIONS ........................................................................................ 6

1.4 WASTE ELECTRICAL AND ELECTRONIC EQUIPMENT.............................................................................. 6

1.5 LIABILITY............................................................................................................................................ 7

2SAFETY PRECAUTIONS................................................................................................................................ 8

2.1 CLEANING OF THE CMOS SENSOR...................................................................................................... 8

2.2CAMERA HOUSING.............................................................................................................................. 8

3QUICK START GUIDE .................................................................................................................................. 10

4INTERFACES ................................................................................................................................................ 11

4.1 CONNECTOR OVERVIEW.................................................................................................................... 11

4.2 ELECTRICAL INTERFACES.................................................................................................................. 12

5CONTROL OF THE CAMERA ...................................................................................................................... 16

6FUNCTIONAL DESCRIPTION...................................................................................................................... 18

6.1 BLOCK DIAGRAM............................................................................................................................... 18

7FEATURE REFERENCE............................................................................................................................... 20

7.1 FEATURE DESCRIPTION STRUCTURE.................................................................................................. 20

7.2 REQUIREMENTS FOR CHANGING SETTINGS......................................................................................... 21

7.3 BOOTSTRAP COAXPRESS ................................................................................................................ 22

7.4 DEVICE CONTROL............................................................................................................................. 24

7.5 IMAGE FORMAT CONTROL................................................................................................................. 26

7.6 ACQUISITION CONTROL..................................................................................................................... 32

7.7 COUNTER AND TIMER CONTROL......................................................................................................... 38

7.8 HIGH DYNAMIC RANGE MODE........................................................................................................... 39

7.9 ANALOG CONTROL............................................................................................................................ 41

7.10 SENSOR .......................................................................................................................................... 43

7.11 FACTORY......................................................................................................................................... 44

7.12 LUT CONTROL................................................................................................................................. 44

7.13 TRANSPORT LAYER CONTROL........................................................................................................... 46

7.14 DEFECT PIXEL.................................................................................................................................. 46

7.15 DARK FIELD...................................................................................................................................... 50

7.16 BRIGHT FIELD................................................................................................................................... 51

7.17 LF FF CALIBRATION......................................................................................................................... 53

7.18 USER SET CONTROL ......................................................................................................................... 60

7.19 BAND............................................................................................................................................... 63

APPENDIX A: CMOS SENSOR CLEANING INSTRUCTIONS .......................................................................... 66

APPENDIX B: C++ EXAMPLE, TRANSFER AN LF FF CALIBRATION SET ................................................... 68

OPERATING AND USER MANUAL Q-12 CoaXPress series

________________________________________________________________________________________________________________

_________________________________________________________________________________________

Adimec 5

1 INTRODUCTION

The Quartz CMOS camera described in this manual provides 12 Mpx resolution through a CoaXPress interface.

The sensor has a global shutter architecture, combined with CCD like image quality and reliability. Unlike

competitors who are offering general purpose cameras, our products are developed with the specific needs of

OEMs and their applications in mind.

1.1 Product highlights

•12 Megapixel up to 187 fps

•True Global Shutter CMOS

•Column based DSNU and PRNU corrections

•Low frequency flat field correction (issue 2 only)

•Configurable 1,2 or 4 lane CXP3 - 6 interface

•M12 I/O connector

•CoaXPress V1.1.1 compliant

•CoaXPress V1.0 compatible

1.2 About this manual

This manual describes the Q-12 CoaXPress camera series:

Product name

Issue

Part number

Q-12A180-Fm/CXP-6-1.0

1.0

188160

Q-12A180-Fc/CXP-6-1.0

1.0

188170

Q-12A180-Fm/CXP-6-2.0

2.0

197360

Q-12A180-Fc/CXP-6-2.0

2.0

197370

Camera or issue specific functionality or specifications will be clearly indicated. Especially between issue 1.0 and

issue 2.0 there are significant differences in available functionality.

Practical tips or notes are indicated by the “NOTE:” sign.

OPERATING AND USER MANUAL Q-12 CoaXPress series

________________________________________________________________________________________________________________

_________________________________________________________________________________________

Adimec 6

1.3 List of frequently used abbreviations

Abbreviation

Full expression

ASP

Adimec Service Port

CMOS

Complementary Metal Oxide Semiconductor

CRC

Cyclic Redundancy Check

CXP

CoaXPress

DIN

Deutsches Institut für Normung

DPC

Defect Pixel Correction

DSNU

Dark Signal Non-Uniformities

EC

European Commission

EEC

European Economic Community

ESD

Electro-Static Discharge

GenAPI

GenICam Application Programming Interface

GenICam

Generic Interface for Cameras

GUI

Graphical User Interface

HDR

High Dynamic Range

I/O

Input/Output

JIIA

Japan Industrial Imaging Association

LED

Light Emitting Diode

LF FFC

Low Frequency Flat Field Correction

LUT

Look-up Table

PoCXP

Power over CoaXPress

PRNU

Pixel Response Non-Uniformities

RO

Read Only

ROI

Region of Interest

RW

Read and Write

SFNC

Standard Features Naming Convention

USB

Universal Serial Bus

WEEE

Waste Electrical and Electronic Equipment

WO

Write Only

XML

Extensible Markup Language

1.4 Waste Electrical and Electronic Equipment

With regard to waste electrical and electronic equipment (WEEE), Adimec wishes to follow the Directive

2002/96/EC of the European Parliament and of the Council. The purpose of this Directive is, as a first priority,

the prevention of waste electrical and electronic equipment (WEEE), and in addition, the reuse, recycling and

other forms of recovery of such wastes so as to reduce the disposal of waste. It also seeks to improve the

environmental performance of all operators involved in the life cycle of electrical and electronic equipment, e.g.

producers, distributors and consumers and in particular those operators directly involved in the treatment of

waste electrical and electronic equipment.

Separate collection for electronic equipment in your area is recommended in order to minimize the disposal of

WEEE as unsorted municipal waste and to achieve a high level of separate collection of WEEE.

OPERATING AND USER MANUAL Q-12 CoaXPress series

________________________________________________________________________________________________________________

_________________________________________________________________________________________

Adimec 7

1.5 Liability

Adimec prepares this manual with the greatest care. Please inform Adimec of any inaccuracies or omissions.

Adimec Advanced Image Systems B.V. cannot be held responsible for any technical or typographical errors and

reserves the right to make changes to the product and manuals without prior notice. Adimec Advanced Image

Systems B.V. makes no warranty of any kind with regard to the material contained within this document,

including, but not limited to, the implied warranties of merchantability and fitness for a particular purpose. Adimec

Advanced Image Systems B.V. shall not be liable or responsible for incidental or consequential damages in

connection with the furnishing, performance or use of this material.

All rights reserved. No part of this document may be reproduced, stored in a database or retrieval system, or

published in any other form or way, electronically, mechanically, by print, photo print, microfilm or any other

means without prior written permission from the publisher.

Layout, composing and editorial staff: Adimec Advanced Image Systems B.V.

Illustrations: Adimec Advanced Image Systems B.V.

All correspondence regarding copyrights and translations should be directed to:

Adimec Advanced Image Systems B.V.

PO Box 7909

5605 SH Eindhoven

The Netherlands

Tel: +31 (0)40 235 3900

E-mail: Support@adimec.com

URL: www.adimec.com

© Copyright 2017 Adimec Advanced Image Systems B.V. Eindhoven, The Netherlands.

OPERATING AND USER MANUAL Q-12 CoaXPress series

________________________________________________________________________________________________________________

_________________________________________________________________________________________

Adimec 8

2 SAFETY PRECAUTIONS

NOTE: A CMOS sensor camera is a sensitive device. Please read the following precautions carefully before

continuing unpacking or operating the camera.

NOTE: It is advised to unpack and handle the camera in a clean ESD protected working area.

NOTE: It is advised to read the whole manual before using the camera.

NOTE: Always keep the sensor cap in place as long as no lens is attached.

NOTE: Remove the lens cap just before the lens is screwed on the camera. It is advised to perform this

operation in a clean room or clean bench.

NOTE: Never touch the CMOS sensor surface. The cover glass is easily damaged and the CMOS sensor can

be damaged by ESD.

NOTE: In case the camera is used as a subsystem, it is advised to include the text of this chapter in the

assembly documents of the main system.

2.1 Cleaning of the CMOS sensor

The cleaning of a CMOS sensor is a difficult task with a high risk on permanent damage to the camera.

NOTE: It is advised to prevent cleaning the CMOS sensor as much as possible.

NOTE: Damage of the CMOS sensor due to scratches on the cover glass or ESD is not covered by warranty!

All cameras are checked for cleanliness in our factory before shipment.

Proper handling instructions during system assembly can prevent the CMOS sensor from getting contaminated.

Should cleaning of the CMOS sensor be necessary, please refer to Appendix A: CMOS Sensor cleaning

instructions.

2.2 Camera housing

Thermal interfacing

The actual housing temperature achieved depends on the thermal configuration of the camera and the system in

the end-user application. Provisions as to guarantee maximum housing temperature are therefore a

responsibility of the end-user.

NOTE: The housing temperature should not exceed +50° Celcius.

NOTE: Mount the camera on a substantial (preferably metal) body that can act as a heat sink.

NOTE: Create airflow over the camera e.g. by using a fan.

Cleaning of the camera housing

The camera housing should NEVER be immersed in water or any other fluid. For cleaning, only use a light moist

tissue.

OPERATING AND USER MANUAL Q-12 CoaXPress series

________________________________________________________________________________________________________________

_________________________________________________________________________________________

Adimec 9

Connectors

Take care of the connectors during handling of the camera. Connectors should not be damaged. Prevent the

entry of foreign objects or dirt into the connectors, as this will result in unreliable operation or damage.

Mounting screws

M4 screws should be used with a maximum screw depth of 5 mm. The recommended tightening torque is

188 cNm. Take notice of the maximum length of the screws that may be used for mounting the camera. Using

screws too long can cause damage to the camera.

2.3 Camera repair and Warranty

Repair, modification and replacement of parts shall be done only by Adimec to maintain compliance with the

directive 89/336/EEC electromagnetic compatibility, directive 72/23/EEC low voltage directive and the

international standards.

For repair and warranty claims contact your local dealer or the business offices in your region. The minimum

information we need to know for a repair request or warranty claim are the camera serial number and a detailed

failure description.

In case the camera needs to be returned to investigate the repair options or grant your warranty claim you will

receive a Return Material Authorization (RMA) number. Please use this RMA-number to ship the camera to

Adimec. Cameras without RMA number will be rejected.

Once the camera is arrived at Adimec the camera will be investigated to proof possible repair or grant your

warranty claim. In case of repair the repair costs will be quoted. After your approval of the repair cost camera will

be repaired and returned.

OPERATING AND USER MANUAL Q-12 CoaXPress series

________________________________________________________________________________________________________________

_________________________________________________________________________________________

Adimec 10

3 QUICK START GUIDE

The procedure to obtain the first images from the camera depends to some extend on the frame grabber brand

or type you use.

A general quick start guide is therefore difficult to provide.

NOTE: The Adimec support department has a couple of frame grabbers available. Inform at

support@adimec.com which frame grabber specific quick install guides are available

or can be created.

The general steps to collect your first images are:

1. Mount a lens on the camera.

2. Connect the CXP cables to the camera.

3. Connect the CXP cables to the frame grabber.

4. Start the PC.

5. Go through the frame grabber specific procedure to configure your frame grabber. Some frame grabbers

will automatically identify the camera while for others the right configuration file has to be loaded.

6. Use the capture software supplied by your frame grabber manufacturer to start acquiring images.

For a correct configuration in step 5, the factory default settings might be required. The relevant parameters are

listed in Table 3-1.

Table 3-1: Factory default settings for the Q-12 CoaXPress camera series.

Parameter

Value

Revision

1.1.1

ConnectionConfig

CXP3_X1

ConnectionConfigDefault

CXP6_X4

PixelFormat (mono)

Mono10

PixelFormat (bayer)

BayerGB10

AcquisitionMode

Continuous

ExposureMode

Timed

NOTE: Discovery always occurs on CXP3_X1. Most frame grabbers will change the ConnectionConfig feature

automatically to the ConnectionConfigDefault value after discovery.

OPERATING AND USER MANUAL Q-12 CoaXPress series

________________________________________________________________________________________________________________

_________________________________________________________________________________________

Adimec 11

4 INTERFACES

In this chapter the electrical interfaces as well as the optical interface are described.

4.1 Connector overview

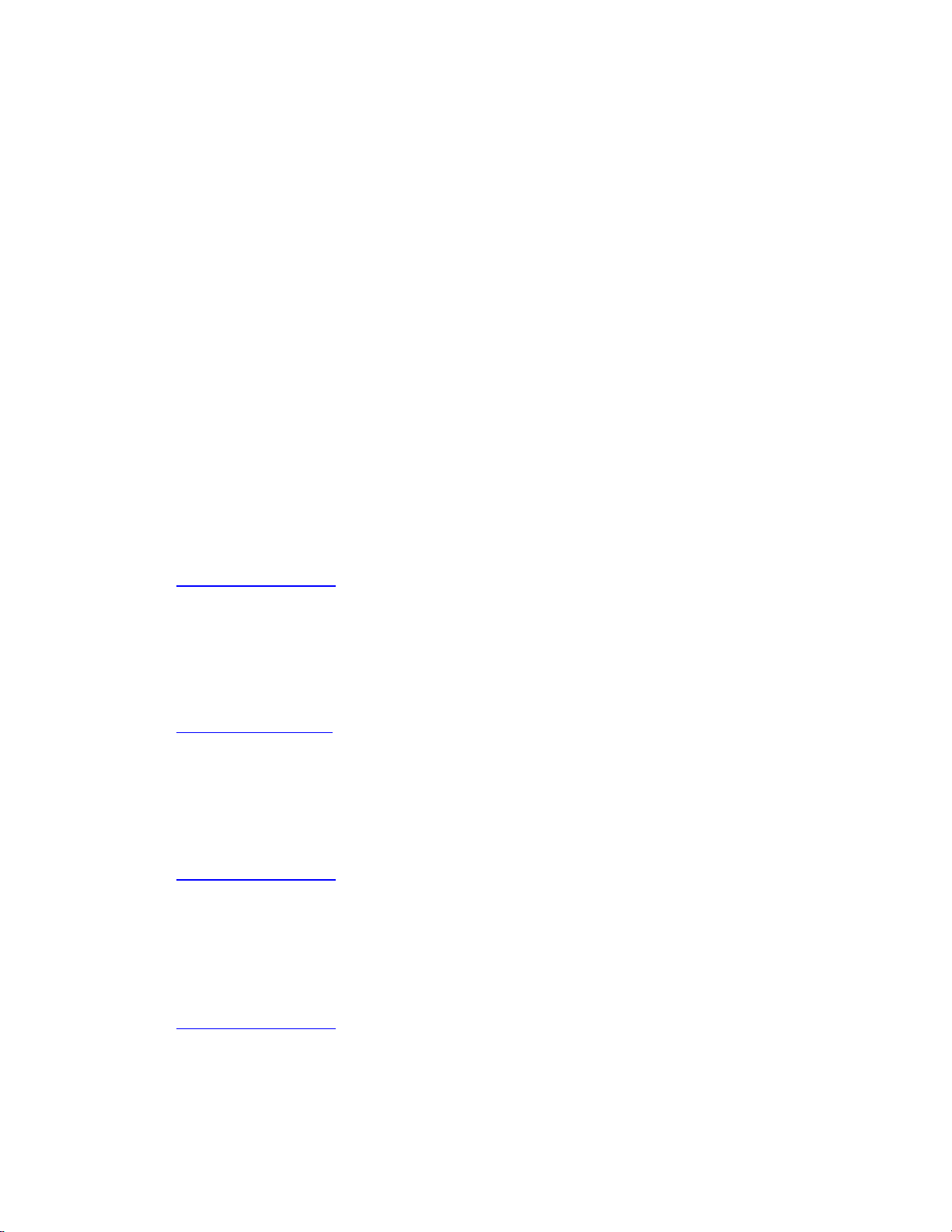

Figure 4-1: Camera back overview.

Table 4-1: Camera connections.

Connector

number

Connector type

Description

Mating connector

1

DIN 1.0/2.3

CXP connection 0 (Master connection)

Video, power, control, triggering

DIN 1.0/2.31

2

DIN 1.0/2.3

CXP connection 1 (Extension, Dual)2

Video

DIN 1.0/2.31

3

DIN 1.0/2.3

CXP connection 2 (Extension, Quad)3

Video

DIN 1.0/2.31

4

DIN 1.0/2.3

CXP connection 3 (Extension, Quad)3

Video

DIN 1.0/2.31

5

Binder M12 type

09-3432-216-04

I/O connector

Binder M12 type

79-3529-13-04

6

Micro USB, type B (Socket)

Adimec Service Port

Micro USB, type B (Plug)

Note:

1Single DIN cables and multi DIN cables supported.

2 Dual: CXP connection 0, 1 are used.

3Quad: CXP connection 0, 1, 2, 3 are used.

OPERATING AND USER MANUAL Q-12 CoaXPress series

________________________________________________________________________________________________________________

_________________________________________________________________________________________

Adimec 12

4.2 Electrical interfaces

4.2.1 Power and CoaXPress connectors

The CoaXPress interface supports communication in two directions. Power, control data and trigger signals are

transferred from the frame grabber to the camera and video data is transferred from the camera to the frame

grabber. The function of each connector is listed in Table 4-1. The CXP configurations that are supported by the

camera are listed in Table 4-2.

Table 4-2: The supported CXP configurations.

Compliance Labeling

Max Bit Rate

per Coax

Nr. connected

Cables

Maximum cable length

(Belden 1694A)

CXP-3 DIN 1

3.125 Gb/s

1

105 m

CXP-3 DIN 2

3.125 Gb/s

2

105 m

CXP-3 DIN 4

3.125 Gb/s

4

105 m

CXP-6 DIN 1

6.250 Gb/s

1

45 m

CXP-6 DIN 2

6.250 Gb/s

2

45 m

CXP-6 DIN 4

6.250 Gb/s

4

45 m

NOTE: Always connect CXP connector 0 as it supplies the camera with power according to the Power over

CoaXPress standard (PoCXP, max 13W).

NOTE: CXP connector 0 is identified by the triangular arrow symbol on the camera housing.

For a complete description of the CoaXPress interface standard please refer to the CoaXPress specification that

can be downloaded from http://jiia.org/en.

OPERATING AND USER MANUAL Q-12 CoaXPress series

________________________________________________________________________________________________________________

_________________________________________________________________________________________

Adimec 13

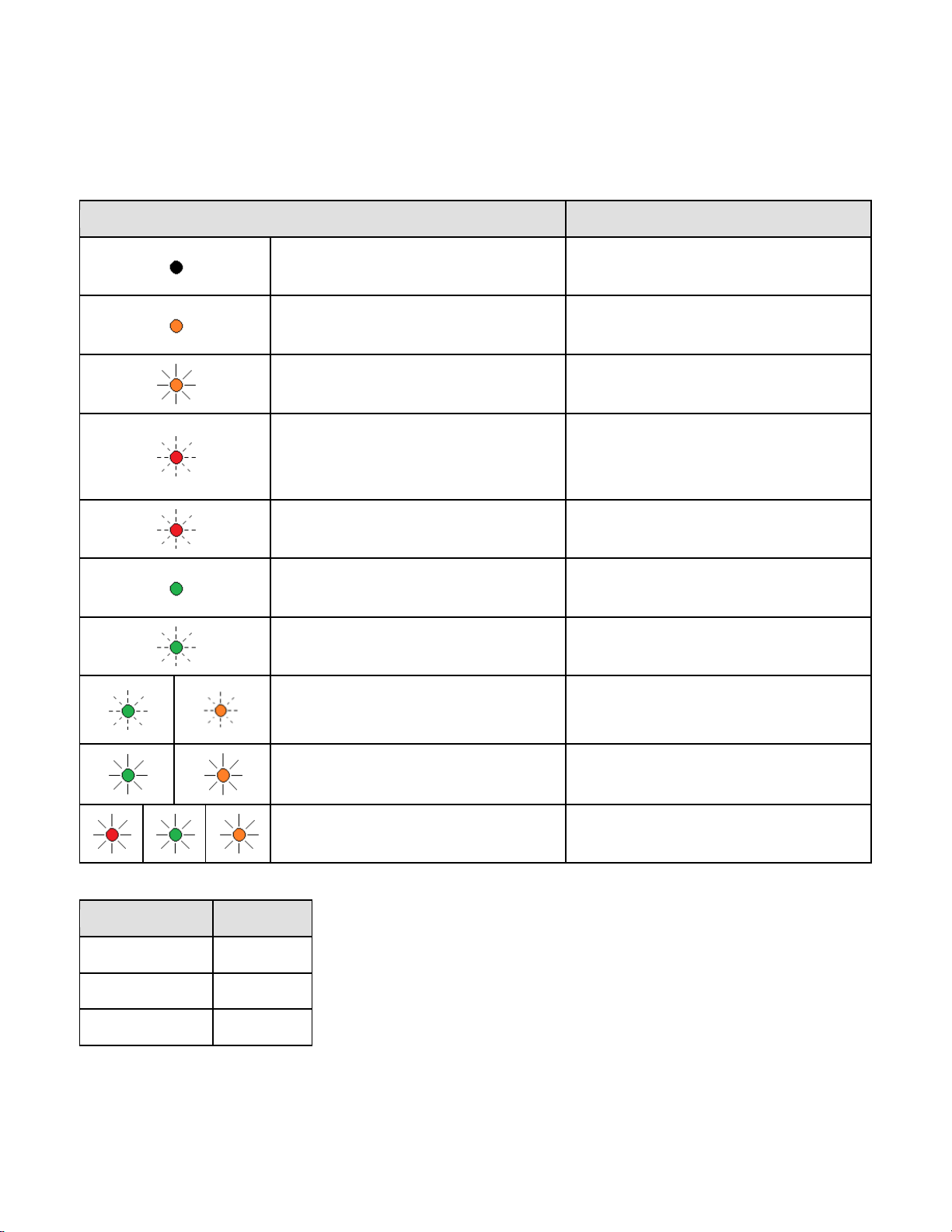

4.2.2 CoaXPress status LEDs

Next to the CoaXPress connector a multi-color LED status indicator is present. The meaning for each LED

indication is shown in Table 4-3, while Table 4-4 lists the frequencies of the fast and slow flashes.

Table 4-3: The meaning of the LED status indicator explained.

LED indication

Camera / interface status

Off No power

Solid orange System booting

Slow pulse orange Device / Host connected, waiting for event

(e.g. trigger, exposure pulse)

500 ms red pulse. In case of multiple

errors, there shall be at least two green

fast flash pulses before the next error is

indicated.

Error during data transfer (e.g. CRC error,

single bit error detected)

Fast flash red System error (e.g. internal error)

Solid green Device / Host connected, but no data

being transferred

Fast flash green Device / Host connected, data being

transferred

Fast flash alternate green / orange.

Shown for a minimum of 1 s even if the

connection detection is faster

Connection detection in progress, PoCXP

active

Slow flash alternate green / orange Connection test packets being sent

Slow flash alternate red / green / orange Compliance test mode enabled

Table 4-4: LED indicator flash frequency

Flash indication

Frequency

Fast flash

12.5 Hz

Slow flash

0.5 Hz

Slow pulse

1 Hz

OPERATING AND USER MANUAL Q-12 CoaXPress series

________________________________________________________________________________________________________________

_________________________________________________________________________________________

Adimec 14

4.2.3 Adimec Service Port

The Adimec Service Port (ASP) interface is available for firmware uploads to the camera.

USB driver XR21x141x is required to support communication via the ASP port.

The USB connection will be available as a virtual COM port.

4.2.4 I/O Connector

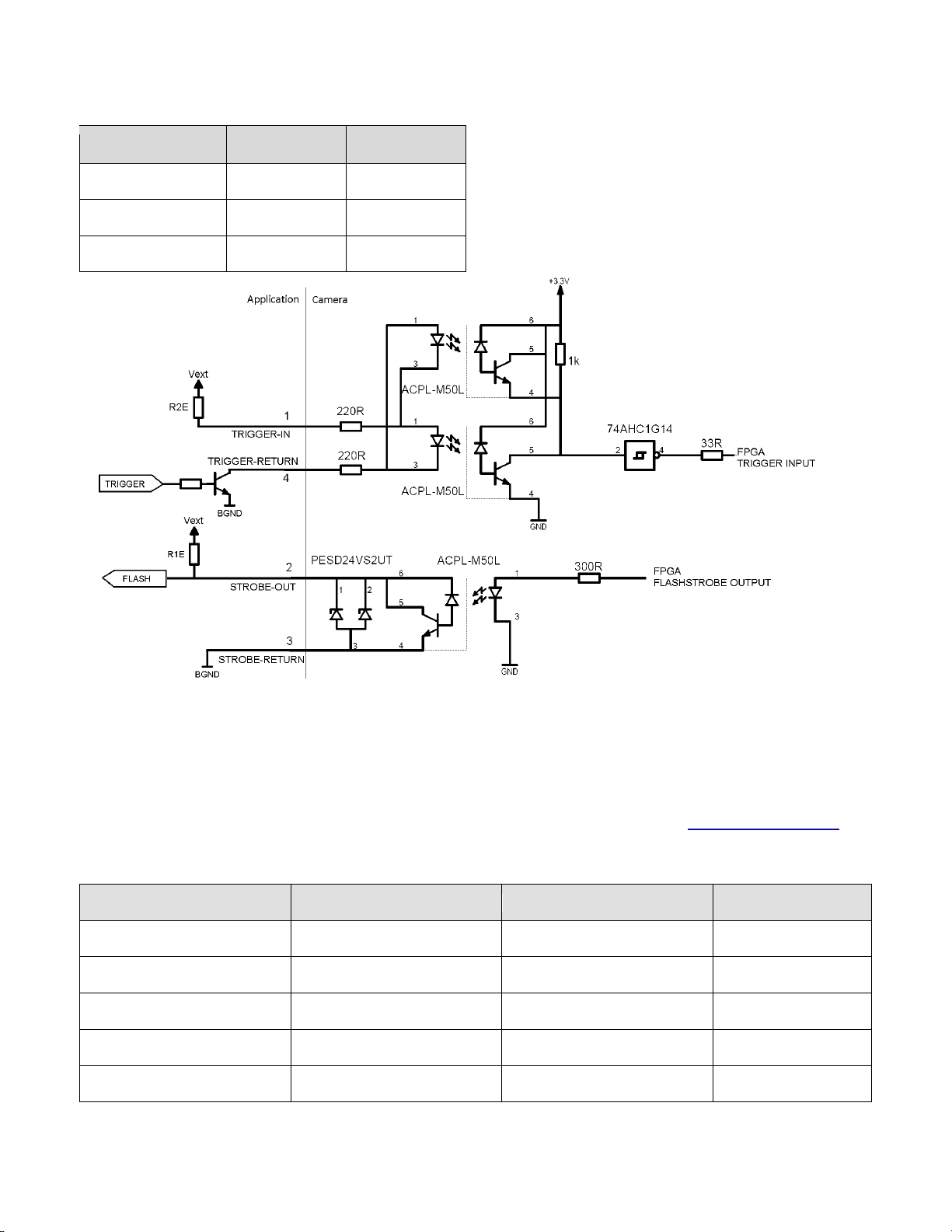

A trigger input and flash strobe output are available at the I/O connector. The input and output are galvanic

isolated from the internal camera electronics by means of an optocoupler (Avago ACPL-M50L).

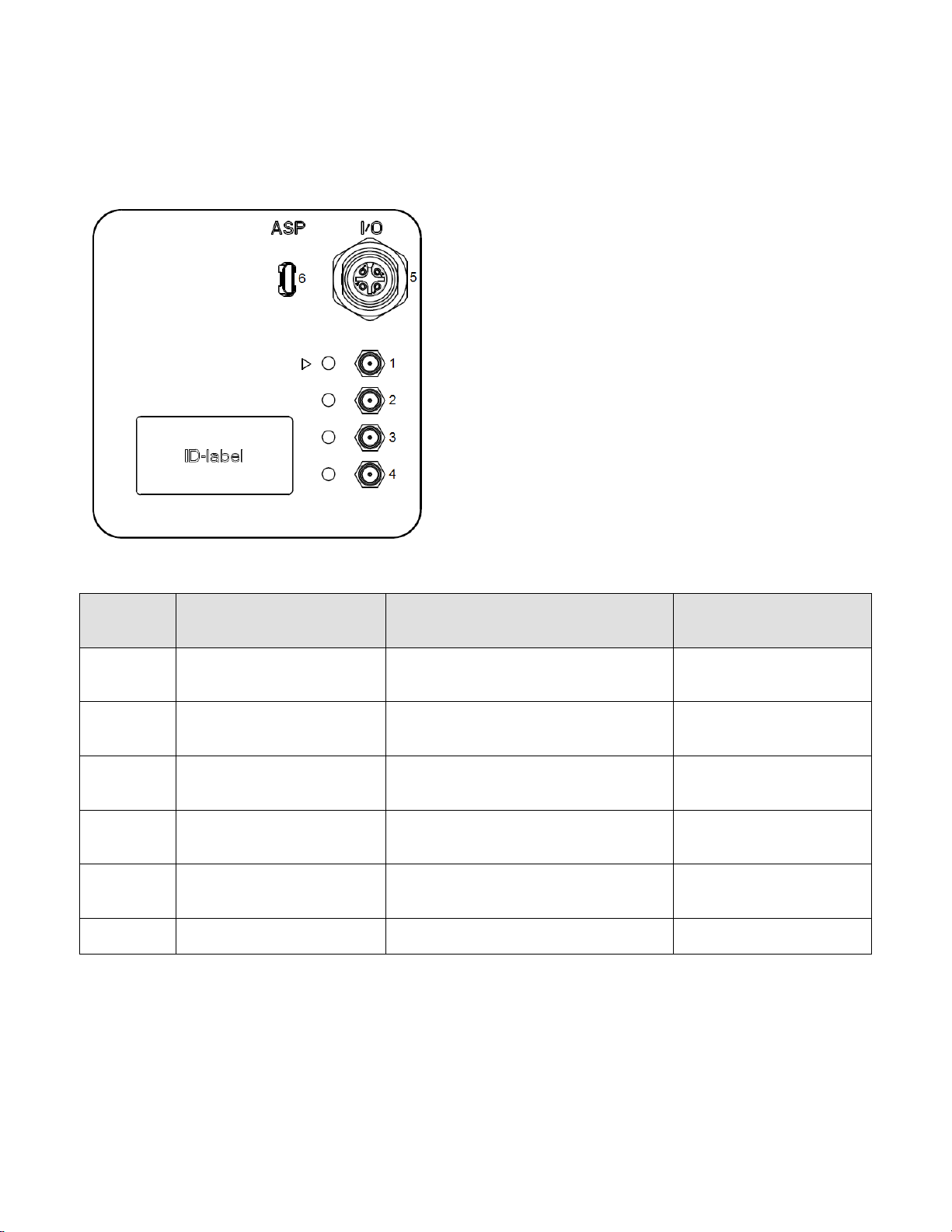

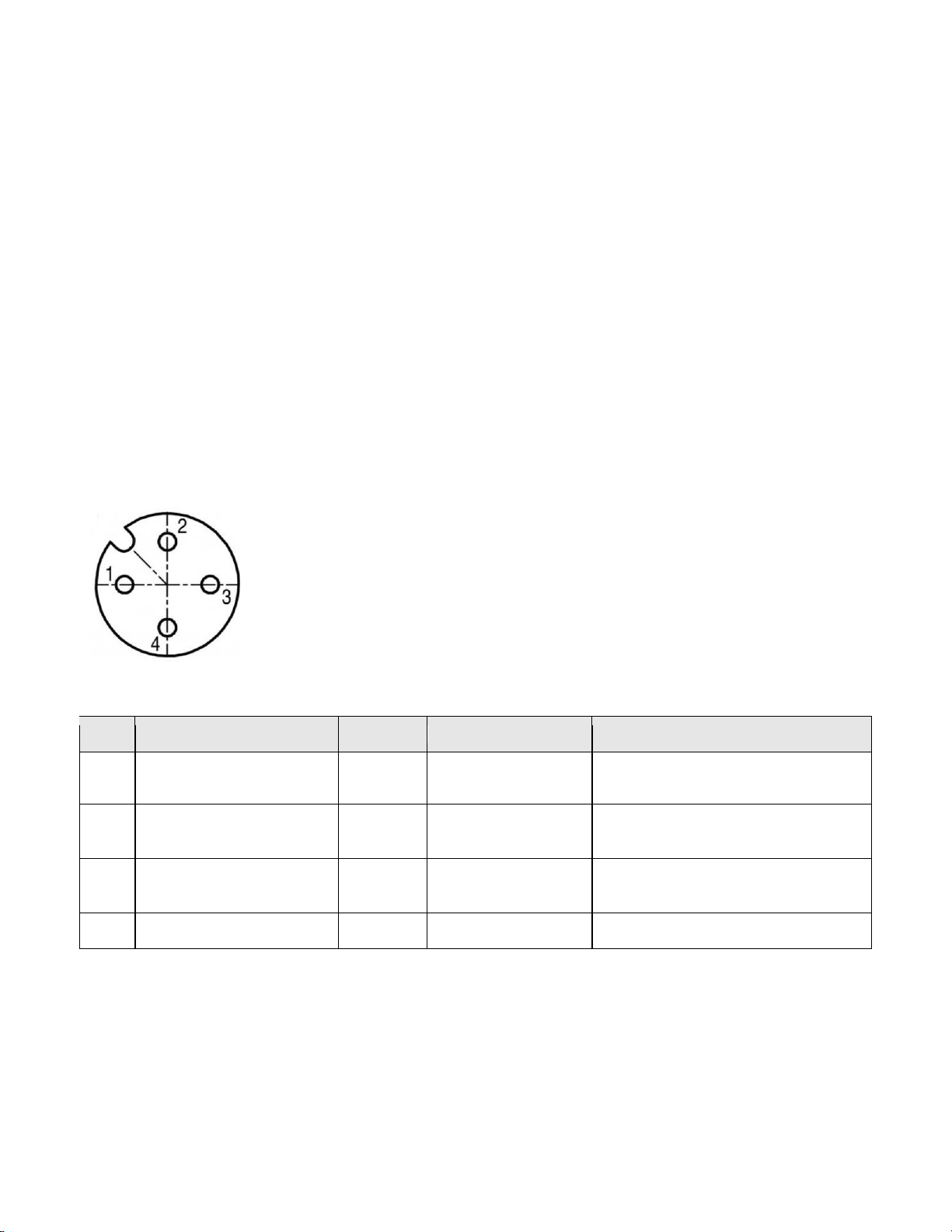

The connector layout is shown in Figure 4-2 with the pin description in Table 4-5.

Table 4-6 lists the recommended resistor values to be used in the termination circuitry to achieve the

recommended currents. In Figure 4-3 the recommended termination circuitry is shown.

NOTE: Opto-couplers require a certain response time to turn on or to turn off, i.e. to switch from the non-

conductive state to the conductive state or the other way around. This response time depends on the used

electronic circuit. For the “trigger in” it can be as short as < 0.5 µs. For the “flash strobe out” it can be as short as

< 2 µs. In practice this response time means that when a trigger is applied there will be a delay between the

rising edge of the trigger and the reaction of the camera.

Figure 4-2: Female I/O connector layout viewed from the backside of the camera

Table 4-5: Connector pinning

Pin

Signal name

Type

Level

Description

1

Trigger in

Input

10..20 mA (10 mA

recommended)

Anode of opto-coupler

*

2

Flash strobe out

Output

2.5 mA

Recommended

Open collector of opto-coupler photo

transistor.

3

Flash strobe return

Output

Isolated gnd

Emitter of opto-coupler photo

transistor.

4

Trigger return

Input

Isolated gnd

Cathode of opto-coupler

*serial resistors 2x 220 Ω inside camera.

OPERATING AND USER MANUAL Q-12 CoaXPress series

________________________________________________________________________________________________________________

_________________________________________________________________________________________

Adimec 15

Table 4-6: Recommended resistor values

Vext [V]

R1E ext [Ω]

R2E ext [Ω]

3.3

1000

Do not apply

5.0

2000

0

12

4700

470

Figure 4-3: Recommended terminations strobe output and trigger input

4.2.5 Lensmount overview

The Q-12 camera series can be supplied with various optical interfaces. The available interfaces are listed in

Table 4-7. Other interfaces might be possible as well by using converters. Inform at support@adimec.com for

the possibilities if your interface is not listed in Table 4-7.

Table 4-7: Lensmount overview

Interface

Adjustable

Product name

Product code

M42

No

LENSMOUNT-M42-60

191540

T2

Yes

LENSMOUNT-T2-60

189080

Fn

No

LENSMOUNT-Fn-60

187490

TFLII

Yes

LENSMOUNT-TFLII-60

189590

TFLII

No

LENSMOUNT-TFLII-60

188230

OPERATING AND USER MANUAL Q-12 CoaXPress series

________________________________________________________________________________________________________________

_________________________________________________________________________________________

Adimec 16

5 CONTROL OF THE CAMERA

Access to camera functions and data is provided through the CoaXPress (CXP) protocol. The CoaXPress

interface is GenICam compliant.

GenICam compliant means that an XML is stored in the camera that is used to translate the camera internal

register addresses to the user friendly feature nomenclature as defined by the Standard Features Naming

Convention, SFNC. Basically GenICam is designed to bridge the camera specific register addresses with a

camera and manufacturer independent user interface. The SFNC feature names should be used to operate the

camera.

How to address the SFNC feature names depends on your frame grabber. With CoaXPress frame grabbers a

GenICam Application Programming Interface (GenAPI) is provided. This is a software layer that reads the XML

from the camera and builds a graphical user interface (GUI) to control the camera. The GUI is often refered to as

the GenICam (feature) Browser.

Next to the GUI often a scripting language will be available in which you can use the SFNC naming to program

the camera and frame grabber according to your desired settings.

To illustrate the workflow of CoaXPress we will describe below what will happen if you set the pixel format to 10

bit in a monochrome camera.

When using the GUI:

1. Start the GenICam Browser, The browser will automatically load the XML from the camera and basically

builds a user interface.

2. In the GenICam browser search for the feature called PixelFormat.

3. Change this feature to “Mono10”. Often this can be done by selecting “Mono10” from a drop down list.

When using a scripting language

1. Look up the syntax and language used by your frame grabber.

2. By using the frame grabber syntax and language set the feature PixelFormat to Mono10.

3. Execute the script.

In both cases, for the GUI and for the scripting language, on the background the GenAPI uses the XML to link

the feature name PixelFormat to the camera register address 0x8144. Furthermore it links the feature value

name “Mono10” to a value of 0x1100003. Using the CoaXPress interface, the API will then write a value of

0x1100003 to the camera register 0x8144.

Note: The above mentioned register addresses and values are only for illustrational purposes. The exact

addresses in your camera might be different.

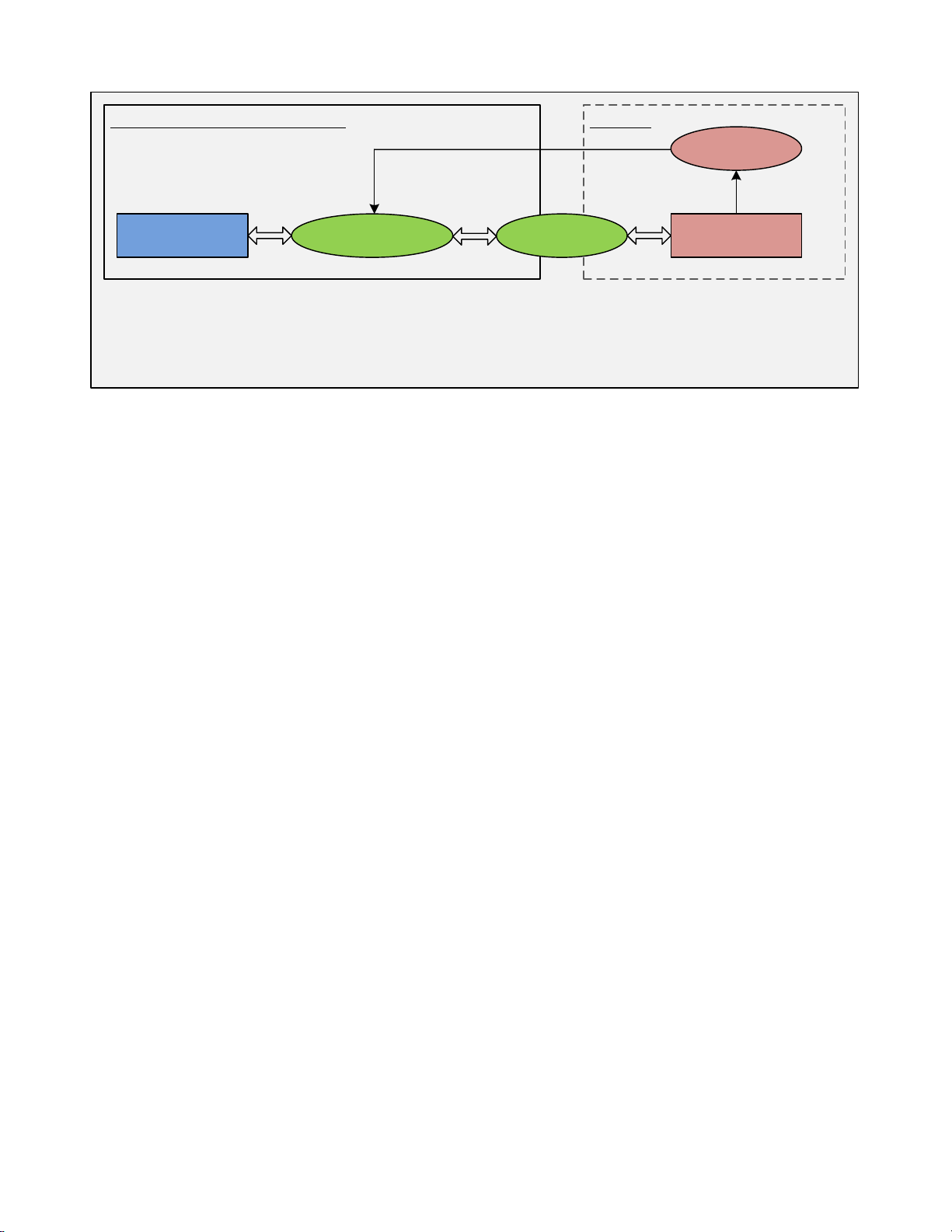

The above described communication protocol is schematically shown in Figure 5-1.

OPERATING AND USER MANUAL Q-12 CoaXPress series

________________________________________________________________________________________________________________

_________________________________________________________________________________________

Adimec 17

Application CameraGenAPI

Description XML

CoaXPress

Frame grabber manufacturer Adimec

Set PixelFormat to

Mono10

Translate SFNC syntax to

camera specific register

address by using the XML file

Transmit register address

and value according to

CXP protocol

Change setting:

Write value to

register

Command syntax

according to SFNC

PixelFormat = 0x00008144

Mono10 = 0x01100003 Write 0x01100003

to 0x00008144 0x00008144 = 0x01100003

Figure 5-1: Schematic view of the CoaXPress communication protocol.

OPERATING AND USER MANUAL Q-12 CoaXPress series

________________________________________________________________________________________________________________

_________________________________________________________________________________________

Adimec 18

6 FUNCTIONAL DESCRIPTION

This chapter contains a functional description of the Q-12A180 camera. It briefly describes the main functions

and features of the camera using a simplified block diagram. More in-depth explanations on these functions as

well as descriptions on how to control them can be found in the next chapters of this manual.

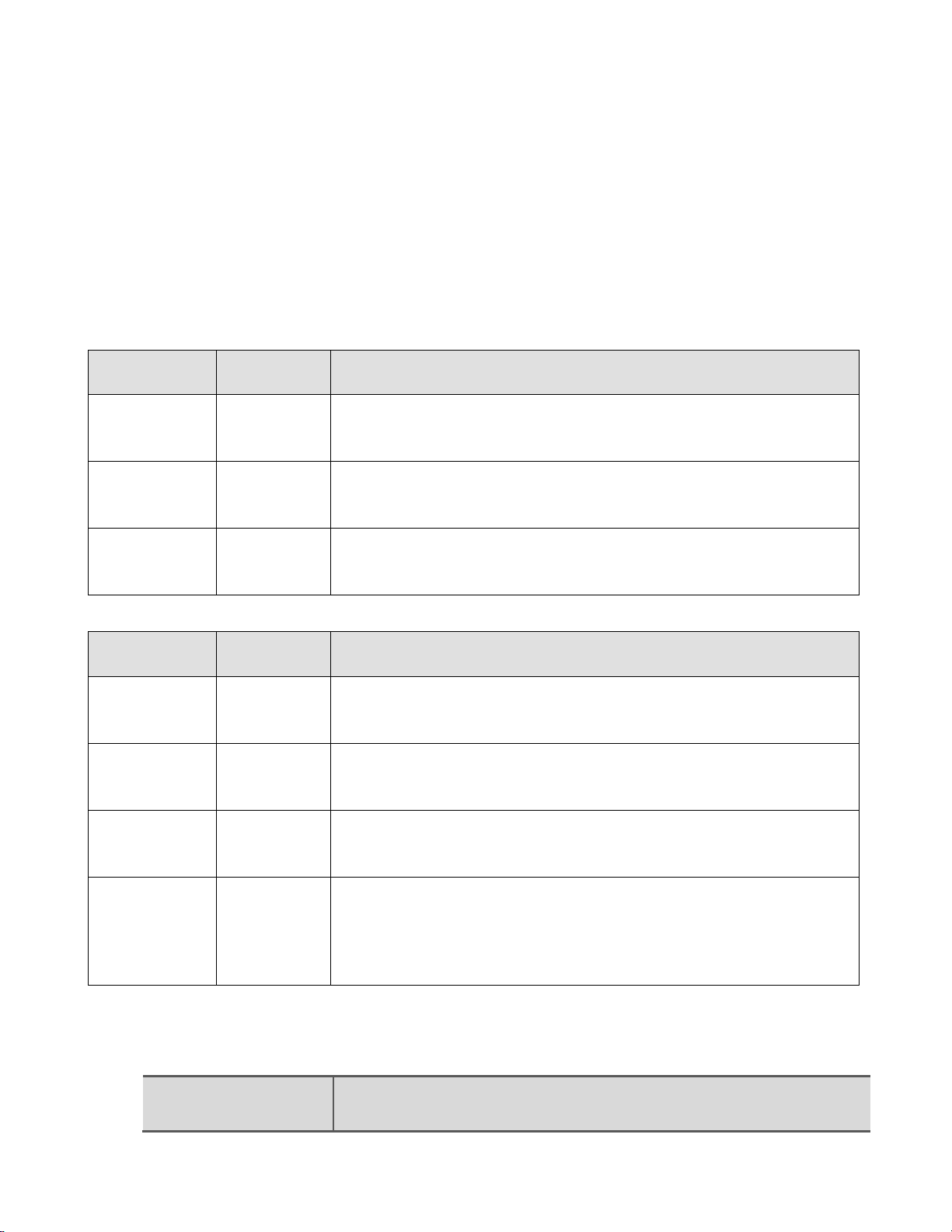

6.1 Block diagram

The diagram below shows the main functional blocks of the Q-12A180 camera.

Image

Sensor BLC

1Col.

FPNC

Test

Pat.

I/O Trigger-IN

I/O Stobe-OUT

LUT CXP

IF

CXP(0)

CXP(1)

CXP(2)

CXP(3)

Device trigger

Hor.

Mirror Insert

Crossh

Hor.

Crop

Trigger &

Sensor

control

White

Bal. DPC

mono

Gain &

Offset

LF FFC

Proc

LF FFC

Meas

Band

Vert.

Crop

Vert.

Mirror

Binning

234

6 7 8 9 10

11

12

7

2 13 3 14 15 16

17

HDR

5

Figure 6-1: Block diagram of the camera. The dashed blocks are sensor functions. The solid blocks are camera

functions. The functionality in the red blocks is only available in Issue 2 cameras.

1. An AMS CMV12000 sensor is used in this camera.

2. The output image can be mirrored horizontally and vertically.

3. A Region of Interest (ROI) can be defined by using the vertical and horizontal crop functionality. The

camera will only output video information from a programmable rectangular sub frame. This reduces the

amount of data and can increase the frame rate.

Issue 2 only – The increment in width has been reduced from 32 to 16. The increment in OffsetX has

been reduced from 16 to 8. This adjustment allows to enable the black clamp and at the same time

leave them outside the output image with the largest resolution possible.

4. Issue 2 only - The Band function generates a rectangular image from a set of configurable bands.

5. HDR - High Dynamic Range - With this function an optical high dynamic range can be realized by using

the multi slope feature of the sensor.

6. BLC - Black Level Clamp - The Black Level Clamp function clamps the black level per line using the dark

reference columns if this function is enabled.

OPERATING AND USER MANUAL Q-12 CoaXPress series

________________________________________________________________________________________________________________

_________________________________________________________________________________________

Adimec 19

7. Issue 2 only - LF FFC – Low Frequency Flat Field Correction – This functionality can correct for a global

(low frequency) non-uniformity. Such a non-uniformity can be present due to a lighting/lens profile or due

to the micro lenses on the sensor.

8. FPNC - Fixed Pattern Noise Correction - Dark field and bright field column based corrections allows for

correction of column based (high frequency) fixed pattern noise (PRNU and DSNU). Calibration of these

functions can be performed in the field.

9. Color only - White balance: a one push and manual white balance is available to set an individual gain

for the RGB channels.

10. This processing block contains the basic processing steps like digital fine gain and black level offset.

11. For functional testing of the camera and frame grabber chain, a test pattern generator is available. The

test pattern generator can be enabled and disabled on demand.

Issue 2 only – A running diagonal test pattern has been added.

12. DPC – Defect Pixel Correction - The defect pixel correction can be enabled and disabled on demand.

From factory a list is available with the major defect pixels. Defect pixels can be added to or removed

from the list by the user.

13. Issue 2 only - Binning – The camera supports up to 2x2 binning. Horizontal and vertical binning can be

enabled independent from each other.

14. An output look-up table (LUT) is available; this table allows real-time conversion of the video levels from

the processing chain according to a user programmable curve

Issue 2 only - a Gamma curve is available in the camera. Instead of the LUT this Gamma curve can be

used.

15. A crosshair overlay can be enabled. This function can be used for the optical alignment of the optics.

16. CXP IF – CoaXPress Interface - The video data is packed into the CXP format for sending data

according to the CXP protocol. The output resolution can be set to 8 bit or 10 bit by user command. The

output format can be set by user command. Both CXP 1.0 and 1.1.1 formats are supported and can be

configured. Standard the camera is configured for CXP 1.1.1. Contact Adimec if the camera needs to be

configured for CXP 1.0.

17. The acquisition rate and exposure time can be controlled externally via a selectable trigger input or the

camera can operate in Timed mode where the camera generates the timing.

The camera is equipped with a flash strobe output signal on the I/O connector. The active state of the

flash strobe output can be inverted to adapt to the application requirements. The flash strobe output can

be operated in two different modes, which are set through a user command.

•The automatic mode: The flash strobe will become active after the sensor is reset and a configurable

delay time is expired. The strobe will deactivate when the acquisition is completed.

•The programmed mode: Both delay time after a sensor reset as well as the duration of the active

state can be programmed.

The delay time between the sensor reset operation in the active state of the flash strobe, as well as the

duration of the flash strobe if the camera is in programmed strobe timing mode, can be user

programmed.

OPERATING AND USER MANUAL Q-12 CoaXPress series

________________________________________________________________________________________________________________

_________________________________________________________________________________________

Adimec 20

7 FEATURE REFERENCE

7.1 Feature description structure

To clearly explain the camera features the structure as described below is used throughout this chapter.

Section headings indicate the group to which the features belong.

Subsection headings indicate the feature name in bold and the accessibility and visibility in normal font.

For example: 7.5.2 Width | RW | B |

The possible accessibility and visibility values are given in respectively Table 7-1 and Table 7-2.

Table 7-1: Possible values for the accessibility level of a feature.

Accessibility

level Abbreviation Description

Read Only RO Features that only present values to the user

Write Only WO Features that can only be written and do not give any feedback to the user

Read and Write RW Features that both, provide information as well as that they can be used to

control the camera.

Table 7-2: Possible values for the visibility level of a feature.

Visibility level Abbreviation Description

Beginner B Features that should be visible for all users via the GUI and API. The

number of features with “beginner” visibility is limited to all basic features

of the devices so the GUI display is well-arranged and is easy to use.

Expert E Features that require a more in-depth knowledge of the camera

functionality. This is the visibility level for all advanced features in the

cameras.

Guru G Advanced features that might bring the cameras into a state where it will

not work properly anymore if it is set incorrectly for the cameras current

mode of operation. The guru parameters mainly have use in debugging.

Invisible I

This is a special visibility level. It is applied to features that are required for

proper operation of the camera or for specific factory settings. Not all

frame grabbers make these features really invisible to the user. However

Adimec advises to not use these features. For this reason they are not

explained in this manual. The features set to invisible are listed at the end

of this Chapter.

The features will mostly be described in a two column table in which the left column gives the possible

input/output values and the right column a short description of the feature or specific feature value. This general

presentation structure is visualized in below table.

Feature input/output

value

Feature or feature value description

This manual suits for next models

8

Table of contents

Other Adimec Digital Camera manuals