Adjust-a-Sink E140 Series User manual

Adjust-A-Sink® System by Accessible Systems Inc. | Minneapolis, MN | 612-238-4600 | www.adjustasink.com

1 of 25

3/2023

There are three keys to a successful installation:

1. Locate the drain rough-in along the centerline of the installed sink system. Hair interceptors

need to be aligned straight back to not interfere with the moving shroud when fully assembled.

If the rough-in is not on center and you are installing on a cabinet – correct the offset within the

cabinet bulkhead space.

2. This unit requires both supply lines installed on the left of the drain connection.

3. Secure the telescoping drain and verify the full range of vertical motion of the sink FIRST,

then connect the trap between the drain and rough-in. You may need to construct a trap from

components to get the elevations to align.

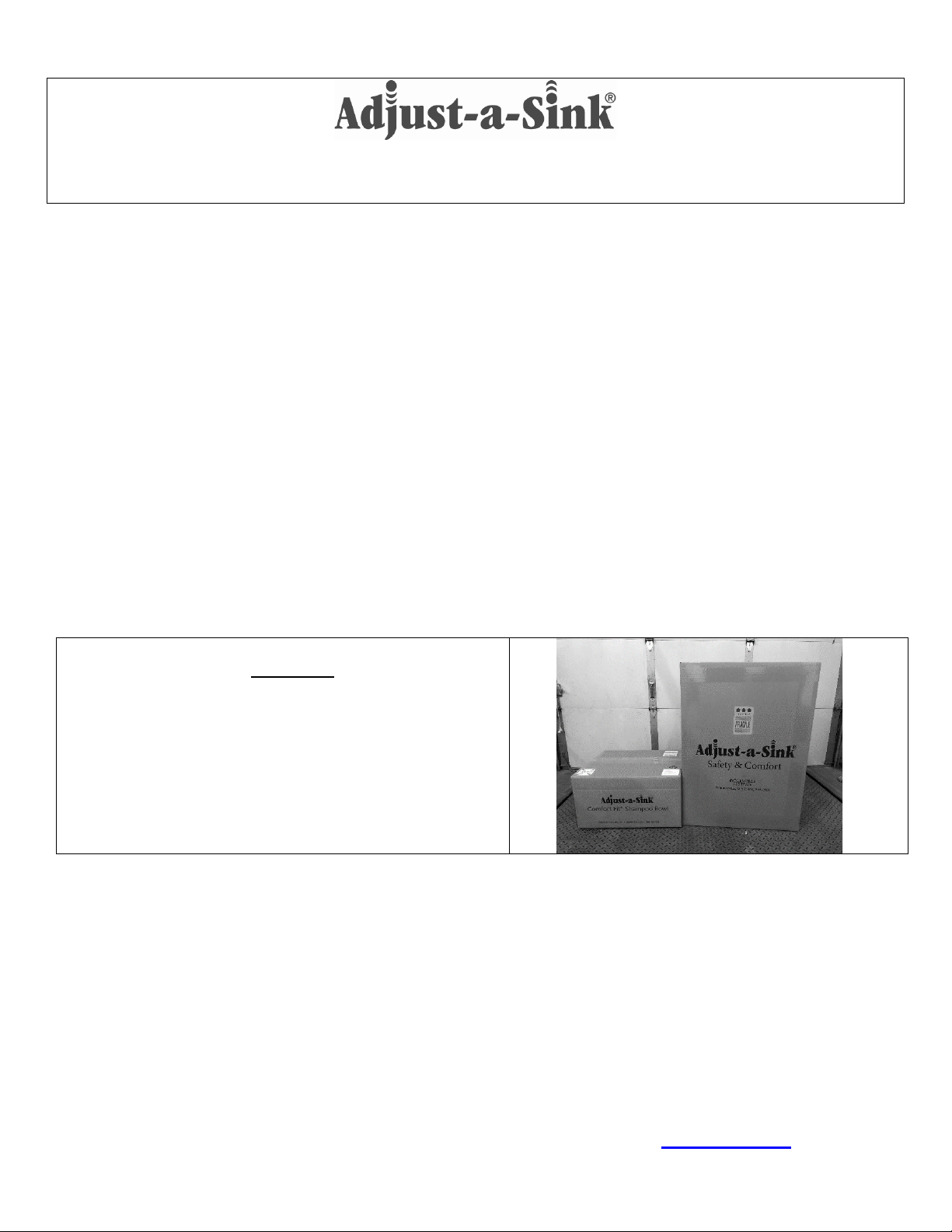

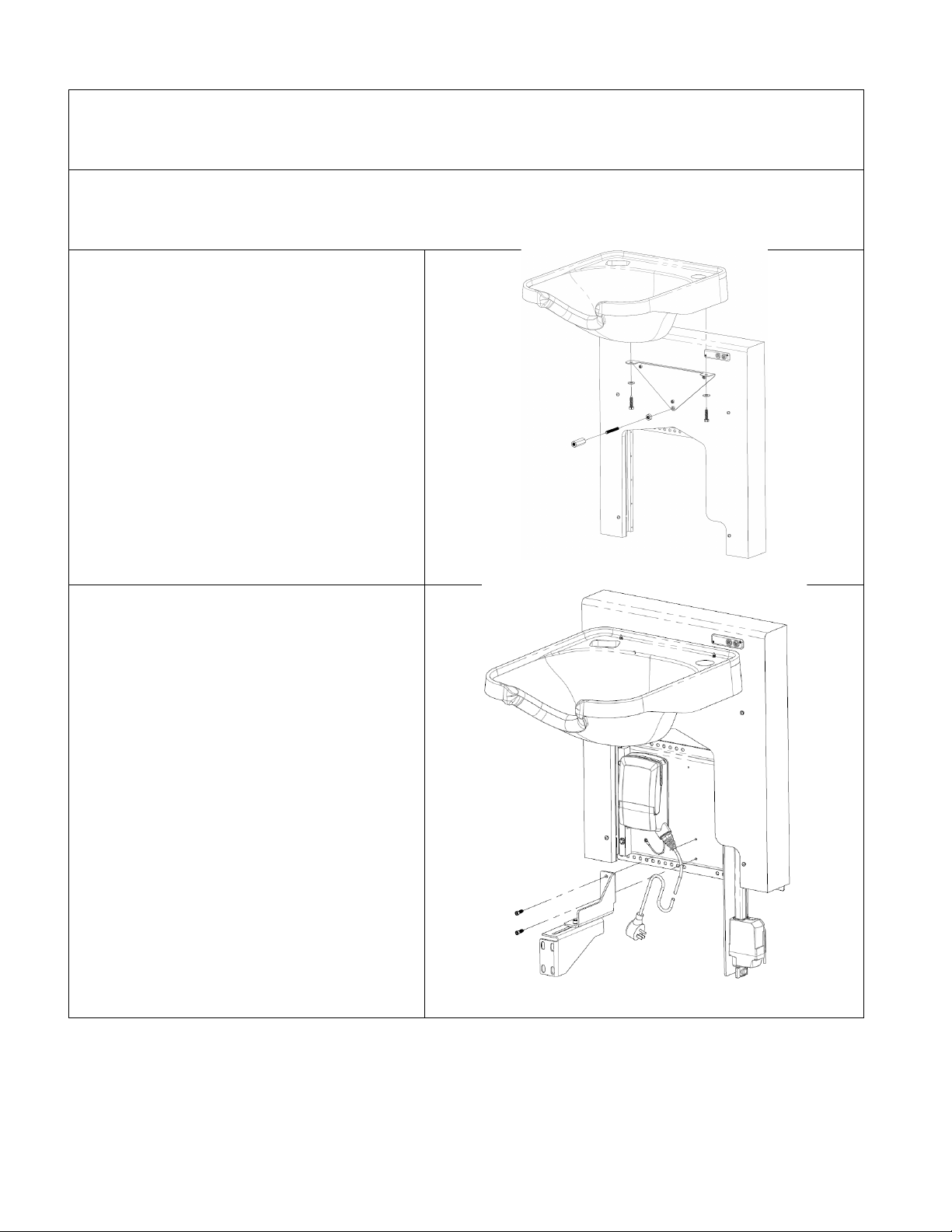

Your system comes in two boxes, what is

included:

Shampoo Bowl box (left in photo):24”x26”x15”, 36

lbs. Contains the 3050 bowl, bowl, fixtures, spray hose,

and vacuum breaker or backflow preventer.

E140 box: 14” x 28” x 39”, 95 lbs. Contains the main

unit lift system, panels and shrouds.

Required Hardware/Supplies Not Included: 1 ½” UPC Listed P-Trap, 90 Degree Supply line shut-off valves,

Lag Bolts and/or 5/16” Bolts-Washers-Nuts (if mounting to cabinet), Plumbing Supplies such as Plumbers Putty,

Sealant, Silicone Caulk, etc.

For replacement part orders or further information please contact Customer Service at: (612) 238-4600

Local Building Codes May Apply. Adjust-a-Sink® is a registered trademark of Accessible Systems, Inc.

E140 SERIES

**INSTALLATION INSTRUCTIONS**

Adjust-A-Sink® E140 System by Accessible Systems Inc. | Minneapolis, MN | 612-238-4600 | www.adjustasink.com

2 of 25

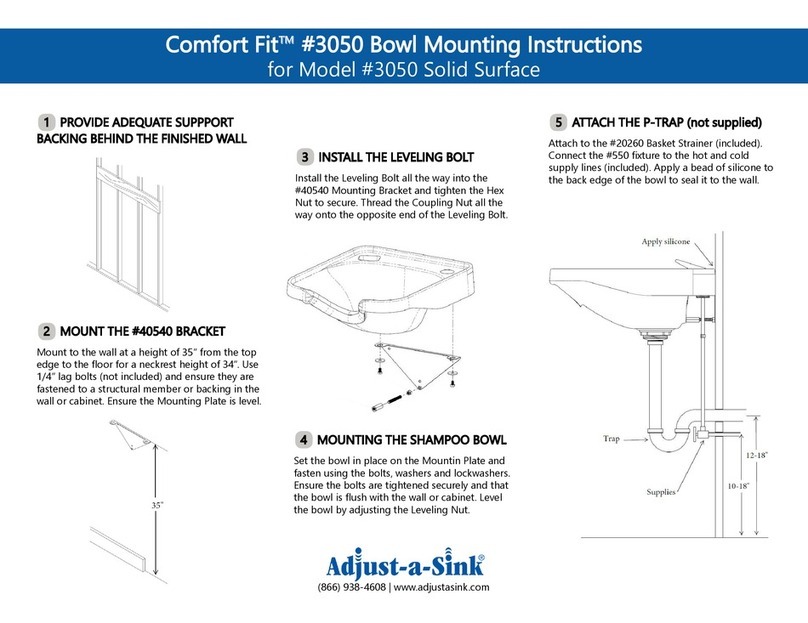

STEP 1: SITE EVALUATION, PLUMBING ROUGH IN, & MOUNTING PANEL PREPARATION

The Adjust-a-Sink® System is designed to be mounted directly to the face of a finished interior

wall, with the proper rough-in plumbing already installed. The System can also be cabinet or

station mounted by a qualified installer.

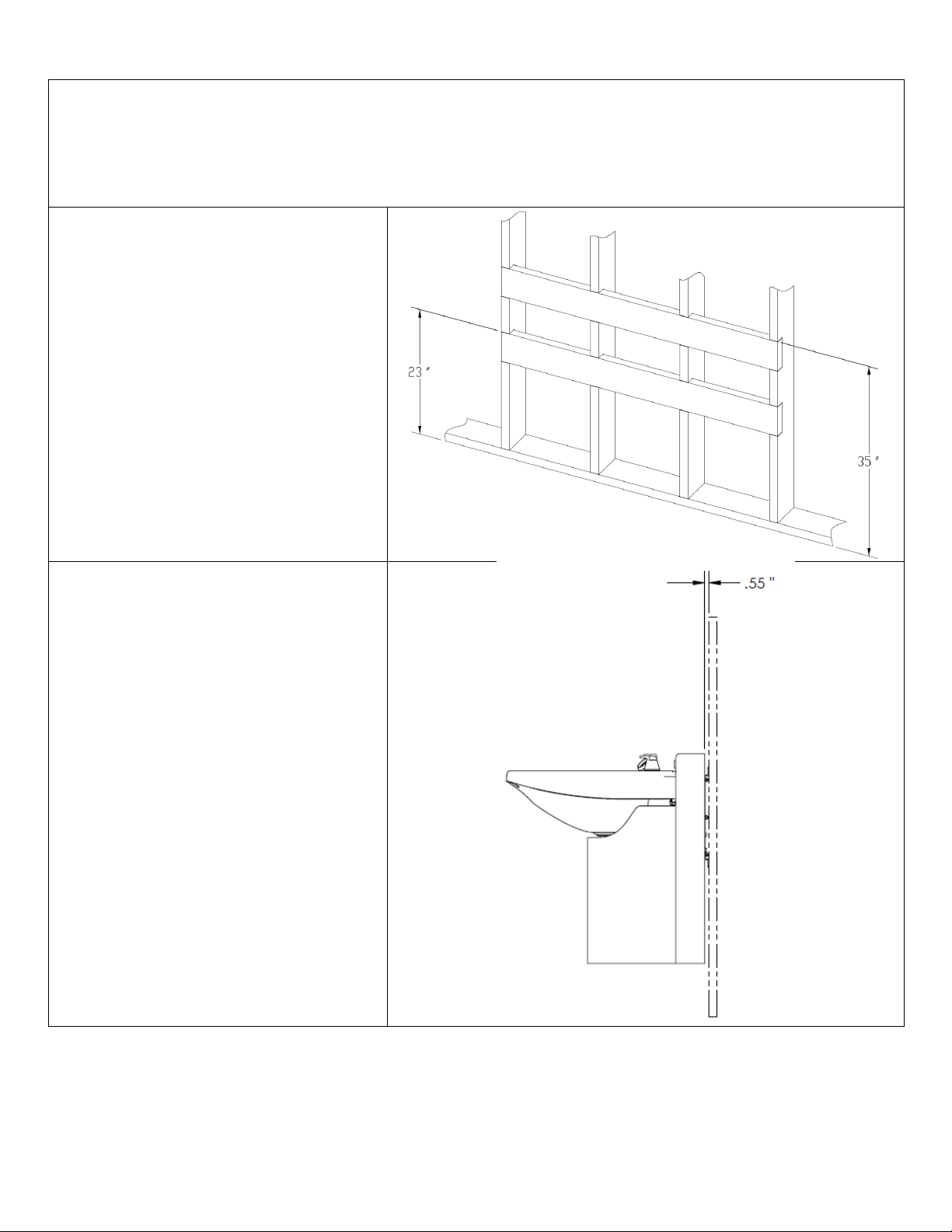

For installation directly on a wall, place

blocking behind finished wall as shown

here:

If mounting to a cabinet, have the

bulkhead section constructed of ¾”

plywood and mounted securely to framing

members.

The adjustable backsplash requires

adequate clearance to lift. The

clearance to the back wall surface is ½

inch. Add spacer blocks or panels

behind the unit if trim work or counter

tops will interfere.

Adjust-A-Sink® E140 System by Accessible Systems Inc. | Minneapolis, MN | 612-238-4600 | www.adjustasink.com

3 of 25

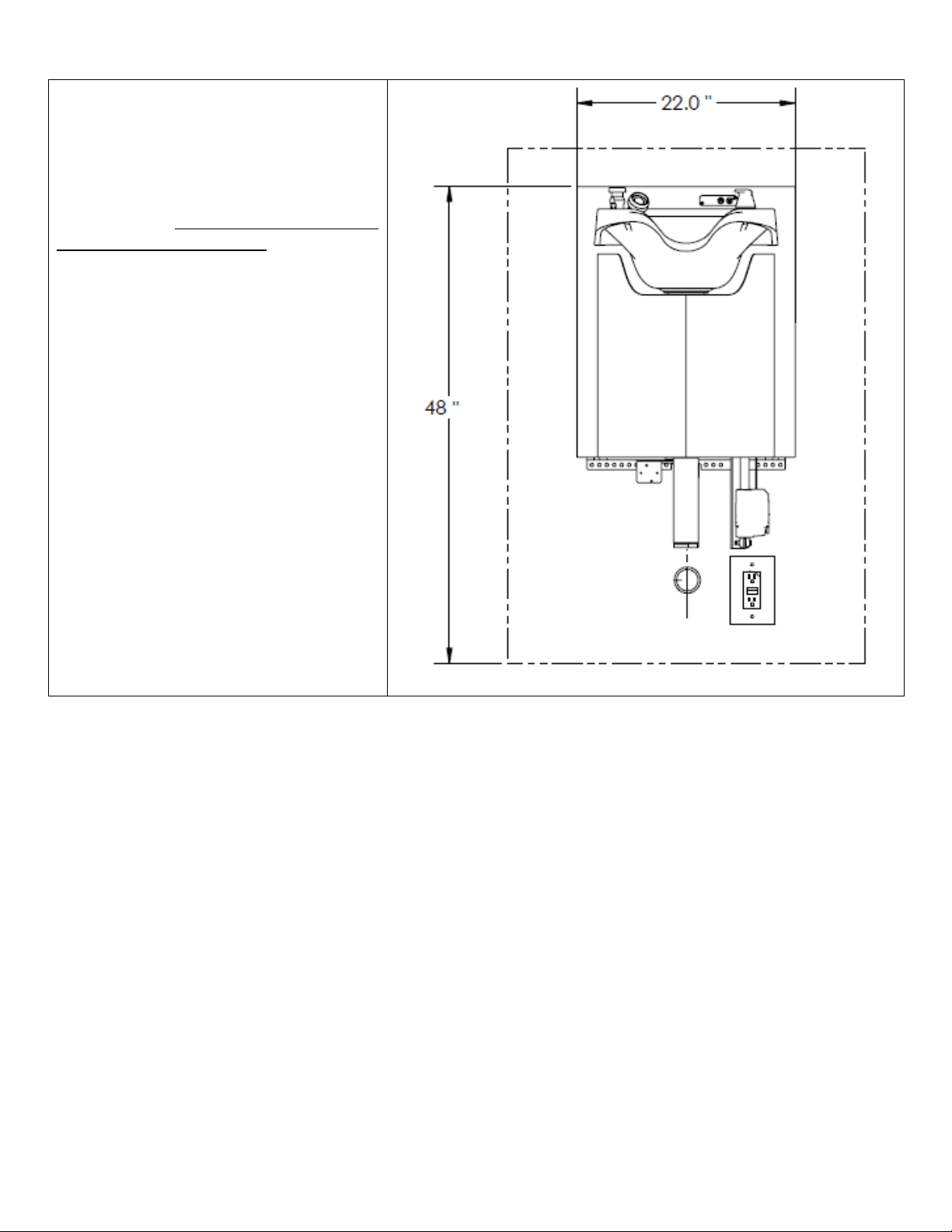

1A. The Adjust-a-Sink is 22” wide and

34” high, the sink and backsplash will

elevate to 48”.

The drain waste rough in should be

centered beneath the sink, the center

of the drain is 10” from the left edge of

the metal mounting panel. Keeping

this in mind will simplify the process.

The supplies should both be located

on the left side of the drain.

A GFCI receptacle should be installed

to the right of the drain. Alternately,

salon workstations typically have

receptacles in a cabinet on the right

side of the sinks, holes can be drilled

and the power cord can be passed

through to these connections. The

E140 comes with a 10’ 3-prong power

cord.

Installed Unit – in UP Position

Please see page 19 of these instructions for the E140 Plumbing Rough-In Drawing

The following Step-by-Step Instructions reference the following Accessible Systems drawings:

E140 Overall Assembly, Sheets 1 through 3

E140 Plumbing Rough-in Drawing (sheet 4)

Adjust-A-Sink® E140 System by Accessible Systems Inc. | Minneapolis, MN | 612-238-4600 | www.adjustasink.com

4 of 25

STEP 2: MOUNTING THE LIFT UNIT

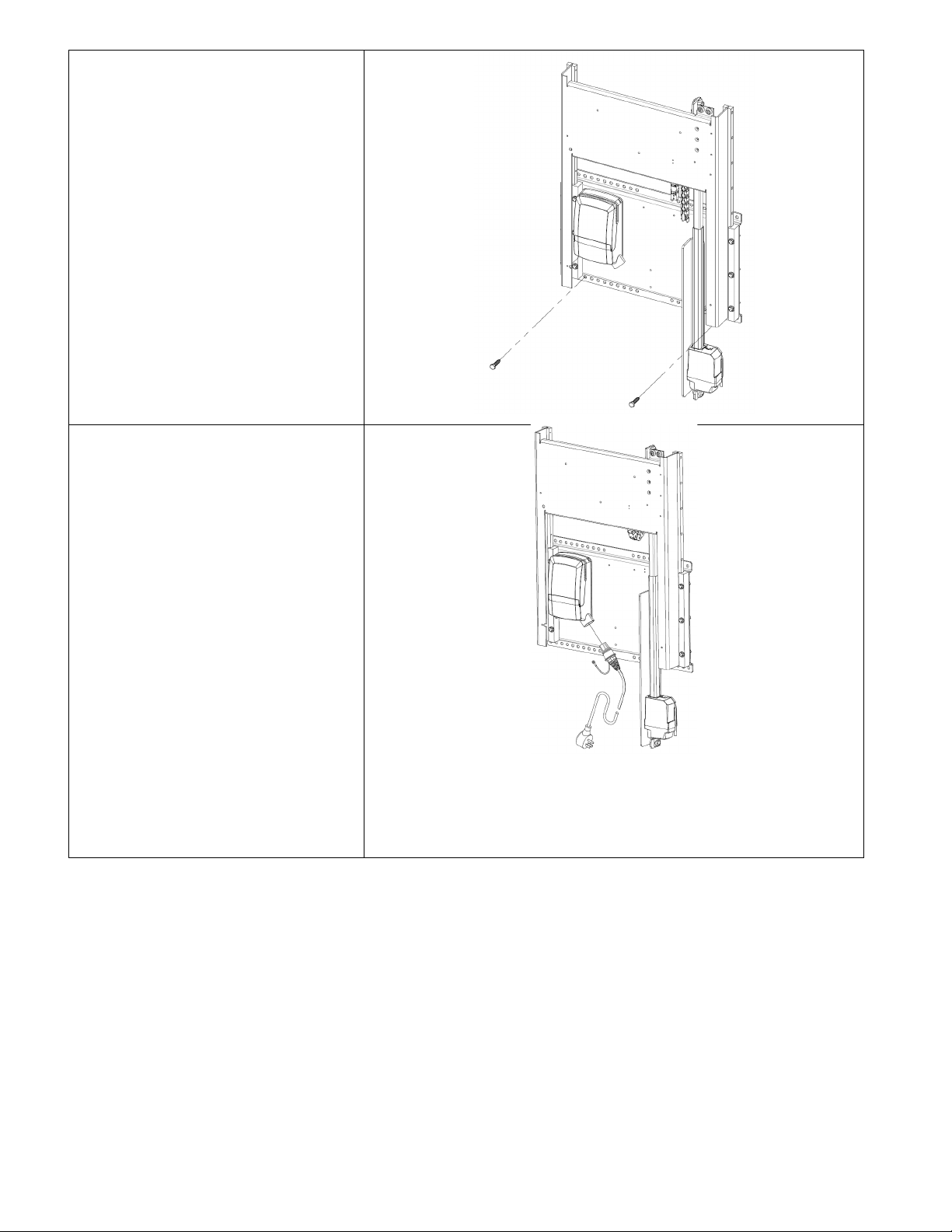

2A. Carefully unpack the balance

of the Adjust-a-Sink® System and

verify all components are included

and undamaged. The Adjust-a-

Sink® System comes with most of

its components already assembled.

For installation on a wall, place

blocking behind finished wall as

shown here. If mounting to a

cabinet, have the bulkhead section

constructed of ¾” plywood and

mounted securely to framing

members.

2B. Install the Lift Unit to the

cabinet or wall using a minimum of

four 5/16” fasteners of appropriate

type and length. Mount the top edge

of the lift unit 32.5” above the floor

for the recommended final bowl

height adjustment range.

Start by securing the unit with a

minimum of two fasteners through

the top row of mounting holes.

2C. Remove the cable tie which

secures the slide section to the wall

mounting panel section.

Temporarily plug in the unit in and

use the buttons to raise the front

panel to its maximum height, an

extension cord may be needed.

Cable Tie

Adjust-A-Sink® E140 System by Accessible Systems Inc. | Minneapolis, MN | 612-238-4600 | www.adjustasink.com

5 of 25

2D. Install two 5/16” fasteners of

appropriate type and length through

the bottom row of mounting holes.

2E. Unwrap the AC power cord as

needed and plug in to the intended

receptacle.

Press the switches on the upper

right of the lift unit and verify the

vertical travel and movement of the

slide section before continuing with

the installation.

Secure any excess supply cord so it

will not interfere with the slide

sections when in use.

TROUBLESHOOTING:

1. The linear actuator has built-it limit switches, so if it is at the end of travel, it will not move or make

any noise, try the reverse direction switch.

2. The linear actuator has a safety mechanism, so it only pushes the lift up, gravity pulls the lift down.

The slides on a new lift may be tight until break in, and the lift may not drop at this step of the

installation. The unit will drop with the full weight of the assembly and sink installed. You can

push down on the lift to get it back to the bottom position.

Adjust-A-Sink® E140 System by Accessible Systems Inc. | Minneapolis, MN | 612-238-4600 | www.adjustasink.com

6 of 25

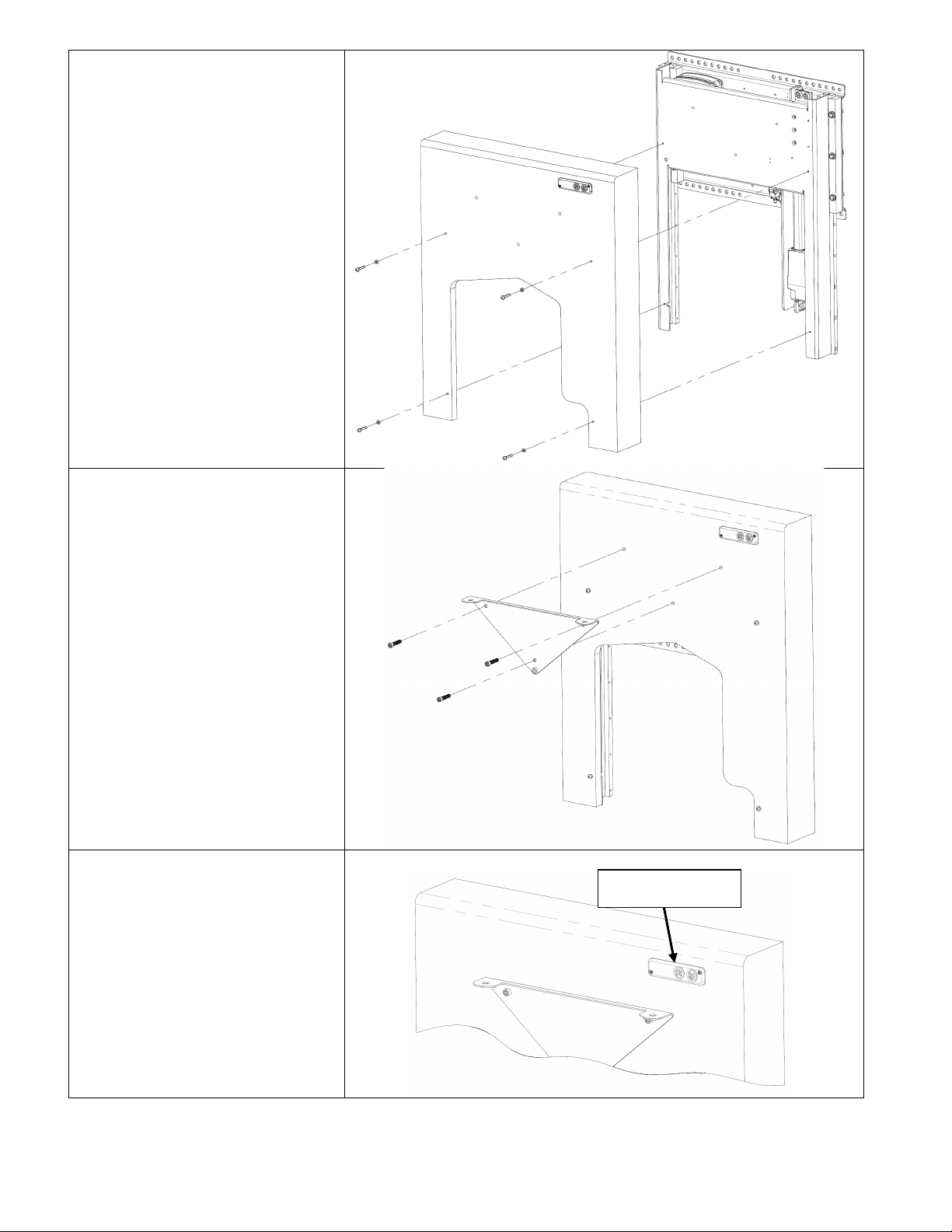

2F. Mount the laminated or solid

surface front panel to the slide

section using four #10-32

screws with plastic spacers.

2G. IF your shampoo bowl uses

a bracket, attach it now to the

front panel using ¼-20 x 1-1/4”

bolts.

NOTE: Comfort Fit bowls have

the mounting bracket molded

into the bowl itself, if this is the

bowl you have, skip this step,

there is not separate bracket to

mount.

2H. Test the operation of the

height adjustment buttons on the

front panel. The buttons are

pre-adjusted at the factory to

properly engage the switches on

the lift unit, but can be field

adjusted if needed.

Height buttons

Adjust-A-Sink® E140 System by Accessible Systems Inc. | Minneapolis, MN | 612-238-4600 | www.adjustasink.com

7 of 25

STEP 3: FINISH PLUMBING

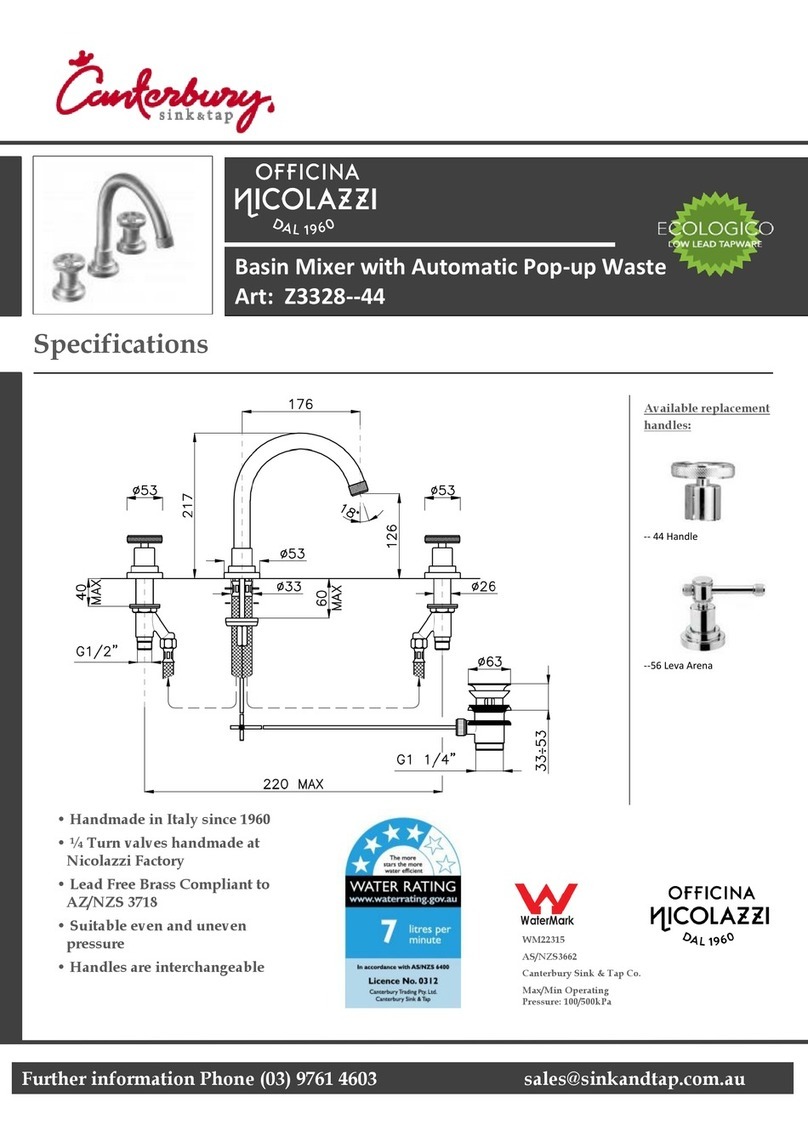

3A.Finish the supply water line installation. For both the Hot and Cold, use 1/2” x 3/8” (copper tube

OD x ID) 90-degree Angle Compression Water Supply Shutoffs and Trim Bezels. (Not Supplied)

3B. Shampoo Bowl: Install the faucet, hose and all related pieces to the shampoo bowl per the

instructions provided from the manufacturer.

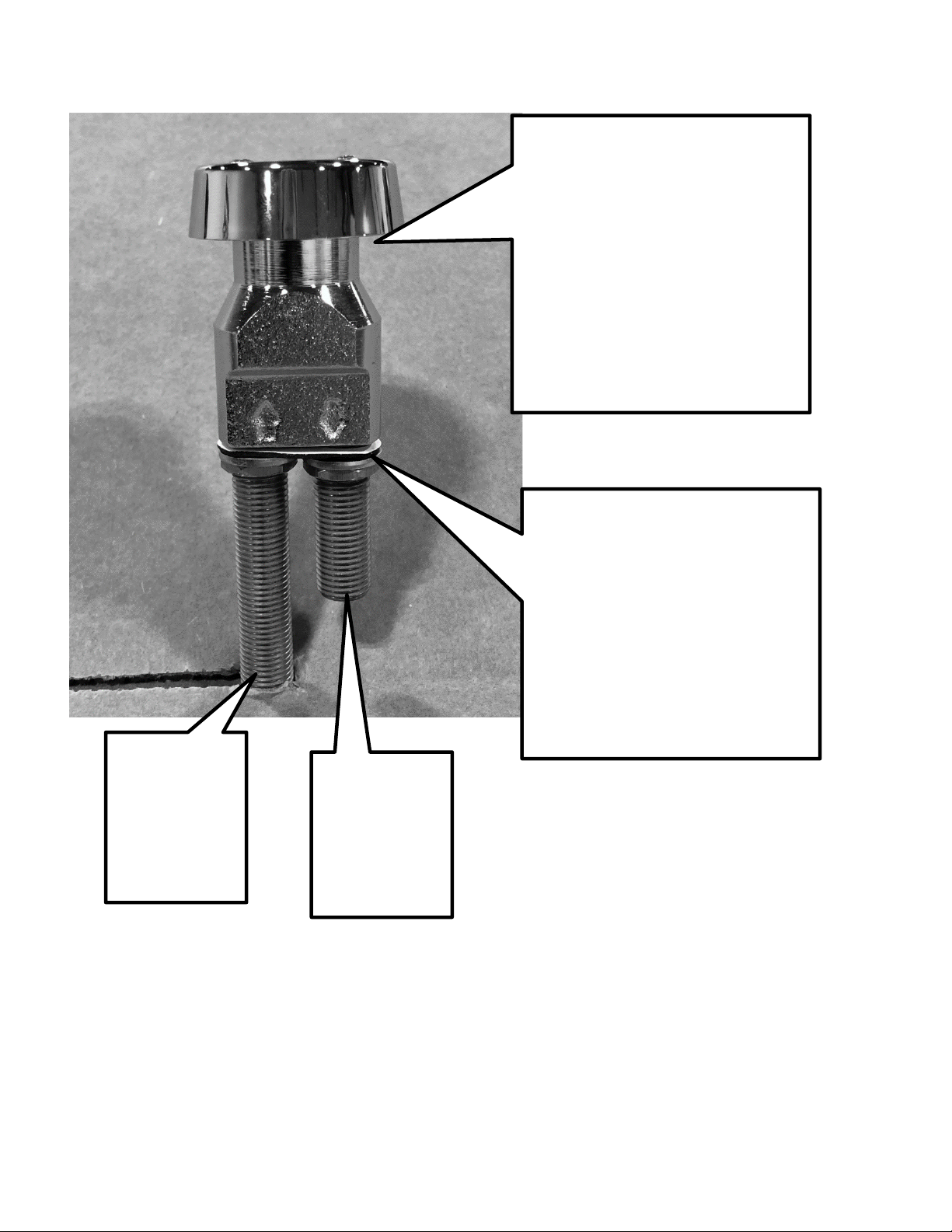

3C. If you have a Comfort Fit bowl with an

integral molded bracket, mount it directly to

the Front Panel with three ¼-20 x 2” bolts

provided.

If you have a bowl with a separate bracket,

Install the sink leveling bolt onto the sink

mounting bracket, then mount the shampoo

bowl on the Sink Mounting Bracket. Be

sure to level the sink to the Front Panel,

secure its position using the leveling bolt

under the sink and properly secure it by

tightening the nut under each side of the

bowl.

3D. elevate the shampoo bowl to its

highest position. Mount the Drain Support

Bracket assembly onto the mounting panel

using the two ¼-20” x ¾” bolts provided.

Make sure the two 5/16” bolts holding the

Drain Clamp Bracket to the Drain

Support Bracket & the hose clamps are

loose enough to make adjustments.

Adjust-A-Sink® E140 System by Accessible Systems Inc. | Minneapolis, MN | 612-238-4600 | www.adjustasink.com

8 of 25

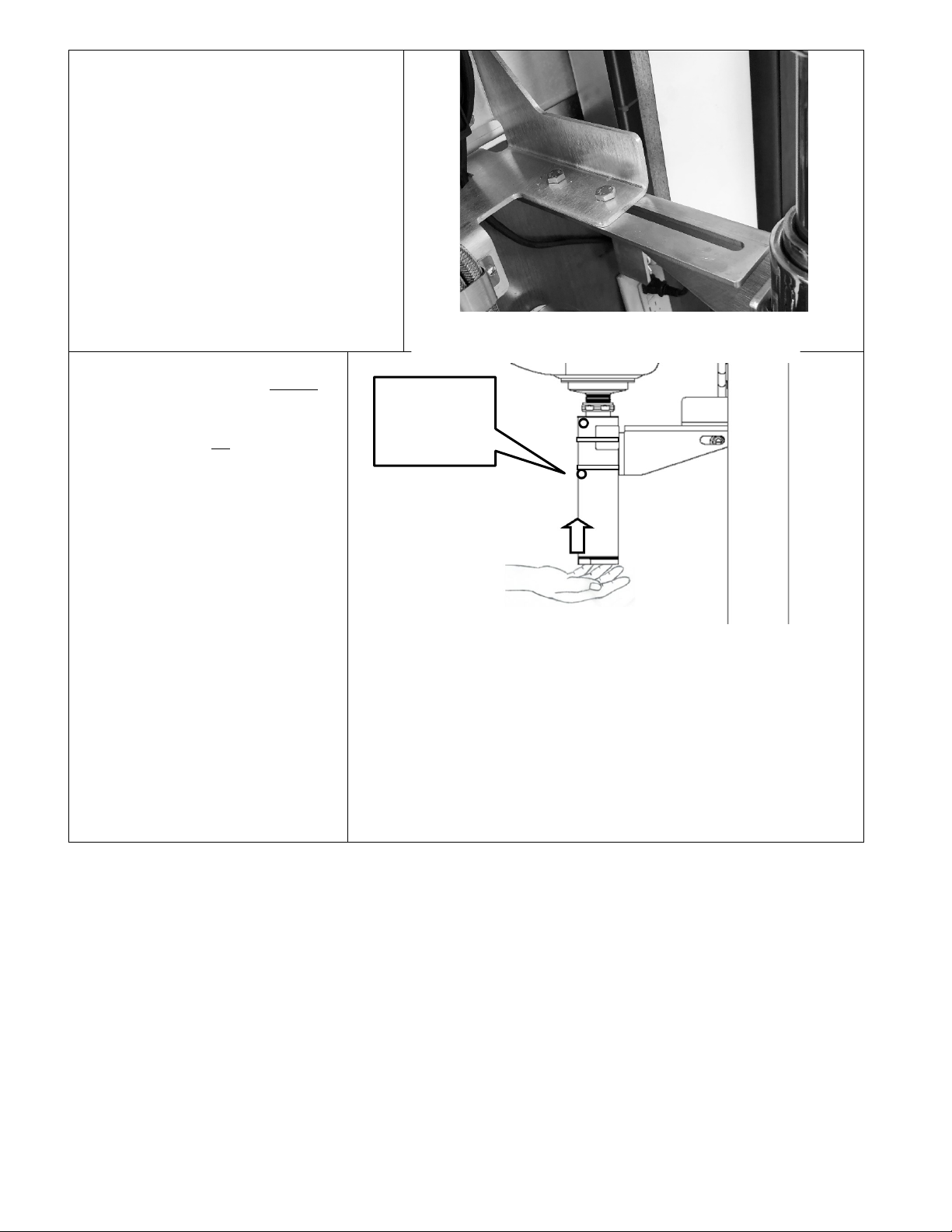

3E. Install the T1514 telescoping drain to

the end of the drain pipe support bracket

with two hose clamps provided.

With the shampoo bowl still at its

highest position extend the Telescoping

drain to the basket strainer. Connect the

slip joint nut to the basket strainer; make

sure to use the vinyl or rubber slip

joint gasket at the joint. Adjust the Drain

Clamp Bracket so that the Telescoping

Drain unit is plumb to the floor and hand

tighten the two 5/16” bolts holding the

bracket together.

NOTE: It is critical to the

proper operation of the

telescopic drain that the bowl

strainer basket is level, front to

back and side to side, and the

telescopic drain is installed

perpendicular to the floor – any

deviation to this will cause

premature wear and possible

failure of the drain system.

3 F . With the sink in its highest position,

pull down on the base of the telescoping

drain so it is fully extended. Using tape, a

marker or other means, mark along the

top of the hose clamp. Tighten one hose

clamp enough so the drain will not slide

for the next step.

Pull down -

Mark above

hose clamps

Adjust-A-Sink® E140 System by Accessible Systems Inc. | Minneapolis, MN | 612-238-4600 | www.adjustasink.com

9 of 25

3G. Now move the unit to the lowest

position and fully tighten the two 5/16”

bolts holding the pipe clamp to the drain

support bracket making sure the drain is

still plumb and parallel. Also make

sure the bracket is aligned with the

bottom section of drain before tightening.

3 H . With the sink in its lowest

position, loosen the hose clamps

enough to slide the base of the

telescoping drain up so it is fully

contracted. Using tape, a marker

or other means, scribe a line on

the drain unit along the bottom of

the hose clamp.

Push up -

Mark below

hose clamps

Adjust-A-Sink® E140 System by Accessible Systems Inc. | Minneapolis, MN | 612-238-4600 | www.adjustasink.com

10 of 25

3 i . Adjust the base section of

the drain unit up about ¼” from

full extension, centering the hose

clamp between the marks made,

and tighten the hose clamps.

Move the sink to both up & down

extremes to check for binding.

Make any minor adjustments to

eliminate any binding before

proceeding.

NOTE: When the unit is installed

at the recommended height, the

bottom of the drain should be

between 11” and 12” from the floor

when correctly positioned.

3J. Dry fit the bottom of the

Telescoping Drain to the

wastewater drain pipe using a

UPC approved P-Trap or a hair

trap (not supplied). The outlet

is 1-1/2” FPT. Use appropriate

plumbing methods to seal and

secure the P-trap to the drain

and the roughed in waste outlet.

Do not glue the P-Trap until

you conduct the Initial Testing

Procedure on the following

page.

CAUTION: Consider proper alignment when performing the final connection of the P-Trap to the

Telescoping Drain and wastewater drain pipe. The Telescoping Drain cannot be allowed to bind; the

motion should be smooth and continuous. After P-Trap installation and proper alignment and smooth

action is achieved, connect the tailpiece nut to the basket strainer and tighten all associated hardware.

Use the included rubber gasket between the tailpiece and basket strainer.

IMPORTANT: Do not trim or alter the Telescopic Drain in any way. All components that make up the

Telescopic Drain Pipe Subassembly are integrated and work together. Altering its design, or removing

the lubricant will cause premature if not total failure of the telescopic drain mechanism and VOID the

warranty.

Secure drain

between the

marks

Adjust-A-Sink® E140 System by Accessible Systems Inc. | Minneapolis, MN | 612-238-4600 | www.adjustasink.com

11 of 25

3K. INITIAL DRAIN ALIGNMENT TESTING PROCEDURE

•Raise and lower the unit all the way up and down several times to be sure it is operating

properly, without binding before and after connecting it to the building drain.

•It is important that the lift system reaches its limits prior to the drain extending to its full range.

You should be able to vertically move the center section of the drain by at least ¼” at both the

upper and lower stops of the lift system. Make any minor adjustments that are needed to keep

the lift system from binding and to ensure that the lift system reaches its end of travel limit prior

to the 3-Stage Telescopic Drain Assembly extending to its full range.

•Now ensure that all of the parts are tightened securely and glue the P-trap to building drain.

Care should be used to ensure you do NOT cause strain or binding on the vertical 3-Stage

Telescoping Drain Assembly.

3L. Connect the provided flexible Water

Supply Lines to both the faucet and the

water supply shutoffs. Use care and good

judgment when installing the flexible lines

so they are free and unobstructed when

traveling with the elevating shampoo bowl.

Start with the unit in its highest position and

secure with tubing clamps and #8 screws

provided. It is recommended that the two

flexible lines be secured to the front panel and

drain bracket such that they have just a little

slack at the uppermost position.

Little to no

supply hose

slack in

highest

position

Adjust-A-Sink® E140 System by Accessible Systems Inc. | Minneapolis, MN | 612-238-4600 | www.adjustasink.com

12 of 25

The hoses should flex and loop up on the left

side of the bowl without snagging at the

lowermost position.

OPTION: If you are installing a mixing valve,

attach the valve to the Drain Support Bracket

with 8-32 screws and spacers provided.

Connect the flexible supply lines directly to the

mixing valve.

3M. FINAL TESTING / LEAK TESTING PROCEDURE

Turn on the faucet and let run for 3-5 minutes at both the highest and lowest height positions.

Check all assembled plumbing joints to verify seals. Take appropriate action to address any leaks.

The telescopic drains are pressure tested per ASME standards prior to shipment–they should not

leak if installed properly.

Supply hoses

loop in lowest

position

4 port

mixing

valve

Adjust-A-Sink® E140 System by Accessible Systems Inc. | Minneapolis, MN | 612-238-4600 | www.adjustasink.com

13 of 25

STEP 4. SHROUD INSTALLATION

4A. With all the plumbing connected and operating smoothly, and prior to installing the Shroud,

observe that the Lift is also operating smoothly by raising and lowering the Shampoo Bowl.

4B. Assemble the two halves of

the front shroud by bolting them

together with the hex head #10

screws and nylock nuts.

Attach the Shroud by hanging the

shroud keyhole slots on the four

10-32 screws with spacers

protruding from the front panel.

Adjust-A-Sink® E140 System by Accessible Systems Inc. | Minneapolis, MN | 612-238-4600 | www.adjustasink.com

14 of 25

TROUBLESHOOTING:

Problem: The sink raises but won’t go down.

The electric lift is capable of lifting hundreds of pounds but as a safety measure, relies on gravity

to lower the sink system. Binding or interference can stop the sink from dropping.

The system may drop very slowly without the bowl and shroud installed since there will be

less weight on the lift. Retry when fully assembled.

The front shroud may be catching on the

trap.

Remove the shroud and retest.

Replumb the trap if it interferes.

The telescoping drain may not be plumb and is binding.

Disconnect the top section from the sink basket and verify alignment as follows.

The telescoping drain may be mounted too high. The

bottom of the drain should be about 11.5” to 12.0”

above the floor.

Adjust the drain for full movement of the sink,

reconstruct the trap.

Interference

Good at lower limit

Good at upper limit

Mis-aligned

Mis-aligned

Adjust-A-Sink® E140 System by Accessible Systems Inc. | Minneapolis, MN | 612-238-4600 | www.adjustasink.com

15 of 25

Problem: Vacuum Breaker Leaks

If it leaks from the cap:

1. Make sure the supply is

connected to the UP arrow

side. Arrows indicate direction

of flow

2. Check that the valve

diaphragm is installed and

undamaged. Loosen the cap

by hand to observe, it is a

plastic component sealed with

an O-ring.

If it leaks from the base:

The brass nipples are tapered pipe

fittings, they require Teflon tape or

thread sealant before assembly.

They are not tightened as supplied

in the fixture kit.

INLET

(UP Arrow)

Connect to

control valve

OUTLET

(DOWN Arrow)

Connect to

spray head

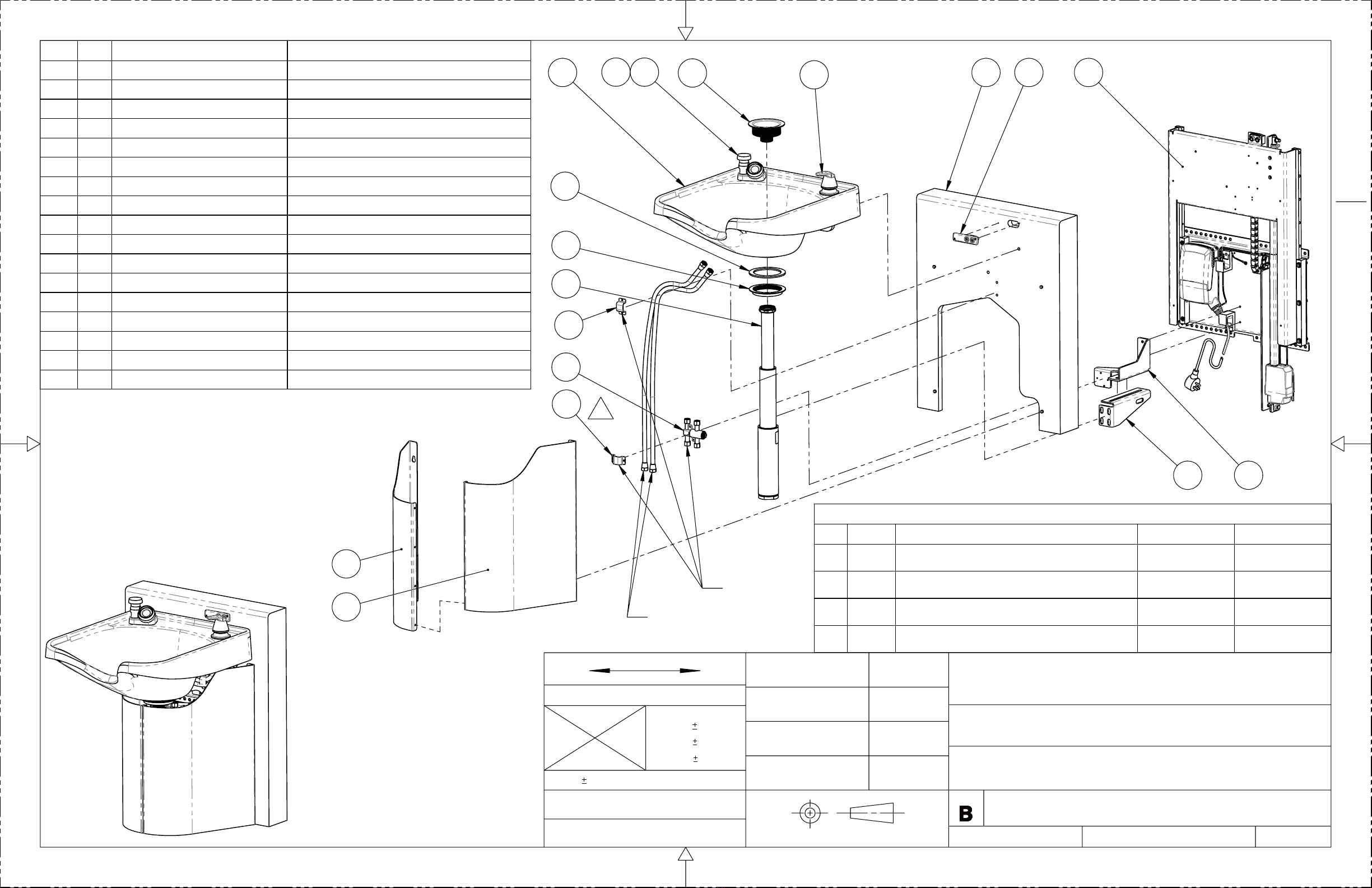

6

4 1

25

3

7

12

9

10

13 11 14

15

16

8

17

8

WATER HOSES (REF)

D

ITEM

QTY

FILE NUMBER

TITLE

1 1 40550

LIFT UNIT - E140

2 1 40340

DRAIN SUPPORT BRACKET

3 1 40360

SHROUD - LH

4 1 40420

FRONT PANEL

5 1 40460

DRAIN CLAMP BRACKET

6 1 40480

SHROUD - RH

7 1 40560

CONTROL ASSEMBLY

8 2 40180

DOUBLE HOSE CLAMP

9 1 650

FIXTURE SET

10 1

VACUUM BREAKER

SUPPLIED WITH 650

11 1

SPRAY HOSE

SUPPLIED WITH 650

12 1

T1514

TELESCOPING DRAIN - MODEL T1514

13 1

3050-2_V4

3050-2 SHAMPOO BOWL

14 1 20260

SINK BASKET STRAINER

15 1

BASKET STRAINER NUT

SUPPLIED WITH 20260

16 1

BASKET STRAINER GASKET

SUPPLIED WITH 20260

17 1

MIXING VALVE

MIXING VALVE (REF)

NOTES:

1. LOWER ITEM 9 (CLAMP) CAN BE USED IF ITEM

17 OPTION (MIXING VALVE) IS NOT SELECTED

SEE NOTE 1

REVISIONS

ZONE

REV.

DESCRIPTION

DATE

APPROVED

A

INITIAL RELEASE

4/2/2017

A.OLSON

B

ADDED MIXING VALVE

3/4/2018

A.OLSON

C

UPDATED BOM ENTRIES, ADDED SHEET 4

3/21/2018

A.OLSON

B3

D

REMOVE ITEM 20 AND USE ITEM 9, UPDATE BOM DETAILS

3/10/2020

A.OLSON

E140

DRAWING NO.

PROPRIETARY AND CONFIDENTIAL

The information contained in this drawing is sole propriety of Accessible Systems, Inc.

Any reproduction in whole or in part without written permission is strictly prohibited.

ACCESSIBLE SYSTEMS, INC.

1 OF 4

9917 13TH AVENUE NORTH - MPLS, MN 55441 PHONE: 612 . 238 . 4600

TITLE

SIZE

DRAWING NO.

DO NOT SCALE DRAWING

WWW.ADJUSTASINK.COM

DATE

DATE

DRAFTER

DESIGNER

DATE

DATE

CUSTOMER APPROVAL

CHECKER

THIRD ANGLE PROJECTION

MM

MM(INCH)

NEXT ASSY

.0

.1

0.5°

ANGLES

MATERIAL

FINISH

25.4MM=1 INCH

TOLERANCES EXCEPT AS NOTED

INCHES

.00

.01

.000

.005

03-12-17

A.OLSON

04-02-17

AJW

TELESCOPING DRAIN - AUTO

E140

34.3 "

32.5 "

TO TOP

OF BACK

PLATE

32.1 "

48.1 "

22.0 "

REFERENCE

WALL SECTION

45.8 "

12.3 "

26.4 "

E140

DRAWING NO.

PROPRIETARY AND CONFIDENTIAL

The information contained in this drawing is sole propriety of Accessible Systems, Inc.

Any reproduction in whole or in part without written permission is strictly prohibited.

ACCESSIBLE SYSTEMS, INC.

2 OF 4

9917 13TH AVENUE NORTH - MPLS, MN 55441 PHONE: 612 . 238 . 4600

TITLE

SIZE

DRAWING NO.

DO NOT SCALE DRAWING

WWW.ADJUSTASINK.COM

DATE

DATE

DRAFTER

DESIGNER

DATE

DATE

CUSTOMER APPROVAL

CHECKER

THIRD ANGLE PROJECTION

MM

MM(INCH)

NEXT ASSY

.0

.1

0.5°

ANGLES

MATERIAL

FINISH

25.4MM=1 INCH

TOLERANCES EXCEPT AS NOTED

INCHES

.00

.01

.000

.005

03-12-17

A.OLSON

04-02-17

AJW

TELESCOPING DRAIN - AUTO

E140

.55 "

THE ADJUSTABlE BACKSPLASH

REQUIRES ADEQUATE CLEARANCE TO

LIFT, ADD SPACER BLOCKS OR PANELS

BEHIND WALL MOUNT PANEL IF

TRIMWORK OR OTHER ELEMENT WILL

INTERFERE.

34 " 34 "

36 "

6 "

STYLIST WORK SPACE STYLIST WORK SPACE

PREFERRED WORK SIDE

ALTERNATE WORK SIDE,

THIS SIDE OF SINK MAY

BE CLOSER TO WALL OR

OBSTACLES IF PREFERRED

SIDE SPACE IS RESERVED

RESERVE WORK SPACE FOR SYLIST

IN SALON PLAN. IF MULTPLE SINKS

ARE BEING INSTALLED ALONG THE SAME

WALL, SPACE AT 54 " OR GREATER ON

CENTER

22.5 " MIN

16 " TYP

6.0 " MAX

CABINET WITH RECESSED AREA FOR SINK MOUNTING

THE ADJUST-A-SINK MAY

BE MOUNTED FLUSH TO A

WALL OR FRONT FACE OF CABINETS.

THE UNIT MAY ALSO BE

RECESSED FROM CABINET

FACE BY A MAXIMUM OF 6 "

E140

DRAWING NO.

PROPRIETARY AND CONFIDENTIAL

The information contained in this drawing is sole propriety of Accessible Systems, Inc.

Any reproduction in whole or in part without written permission is strictly prohibited.

ACCESSIBLE SYSTEMS, INC.

3 OF 4

9917 13TH AVENUE NORTH - MPLS, MN 55441 PHONE: 612 . 238 . 4600

TITLE

SIZE

DRAWING NO.

DO NOT SCALE DRAWING

WWW.ADJUSTASINK.COM

DATE

DATE

DRAFTER

DESIGNER

DATE

DATE

CUSTOMER APPROVAL

CHECKER

THIRD ANGLE PROJECTION

MM

MM(INCH)

NEXT ASSY

.0

.1

0.5°

ANGLES

MATERIAL

FINISH

25.4MM=1 INCH

TOLERANCES EXCEPT AS NOTED

INCHES

.00

.01

.000

.005

03-12-17

A.OLSON

04-02-17

AJW

TELESCOPING DRAIN - AUTO

E140

20.0 "

12.0 "

.75 " (TYP)

19.0 " (REF)

32.5 "

32.0 "

2.5 "

6.5 " MAX

10.0 " MIN

16.0 " MAX

MOUNT BOTH SUPPLIES

ON THE LEFT SIDE

OF THE DRAIN

8.5 "

MAX

12.0 "

MAX

12.0 "

RECOMMENDED

10. 0" MIN

19.0 " MAX

C

L

C

L

FRONT PANEL (REF)

MAINTAIN CLEARANCE

LOCATION FOR E140

MOUNTING PLATE TO

BE INSTALLED

CENTER DRAIN STUB OUT

BELOW SINK CARRIER

MOUNTING PLATE

GFCI PROTECTED

RECEPTACLE REQUIRED

NOTE: RECEPTACLE MAY

BE AVAILABE IN ADJOINING

CABINET

8.0 "

3.0 "

E140 MOUNTING PLATE

(REF)

FINISHED FLOOR (REF)

E140

DRAWING NO.

PROPRIETARY AND CONFIDENTIAL

The information contained in this drawing is sole propriety of Accessible Systems, Inc.

Any reproduction in whole or in part without written permission is strictly prohibited.

ACCESSIBLE SYSTEMS, INC.

4 OF 4

9917 13TH AVENUE NORTH - MPLS, MN 55441 PHONE: 612 . 238 . 4600

TITLE

SIZE

DRAWING NO.

DO NOT SCALE DRAWING

WWW.ADJUSTASINK.COM

DATE

DATE

DRAFTER

DESIGNER

DATE

DATE

CUSTOMER APPROVAL

CHECKER

THIRD ANGLE PROJECTION

MM

MM(INCH)

NEXT ASSY

.0

.1

0.5°

ANGLES

MATERIAL

FINISH

25.4MM=1 INCH

TOLERANCES EXCEPT AS NOTED

INCHES

.00

.01

.000

.005

03-12-17

A.OLSON

04-02-17

AJW

E140 ROUGH-IN

E140

Adjust-A-Sink® E140 System by Accessible Systems Inc. | Minneapolis, MN | 612-238-4600 | www.adjustasink.com

20 of 25

E140 SERIES

TWO YEAR LIMITED WARRANTY

Adjust-a-Sink E140 Series products from Accessible Systems, Inc. have been manufactured

under the highest standards of quality and workmanship. Accessible Systems, Inc. warrants

to the original end-user purchaser this product to be free from defects in material and

workmanship during normal use for two (2) years from date of purchase. A replacement for

any defective part will be supplied for installation by you. Defects or damage caused by the

use of other than genuine Adjust-a-Sink parts are not covered by this warranty. This

warranty shall be effective from the date of purchase shown on the purchaser’s receipt.

This warranty is valid for the original purchaser only and excludes product damage due to

installation error, product abuse, product misuse, wear and tear or stains, whether performed

by a contractor, service company, or end user. Accessible Systems, Inc. will not be

responsible for labor charges, and/or damage incurred in installation, repair or replacement,

nor for incidental, indirect, special, or consequential damages, including without limitation,

damage to, or loss of use of, any equipment, lost sales or profits or delay or failure to perform

this warranty obligation.

This warranty is void if this product is installed incorrectly or in an improper environment,

overloaded, misused, abused, or altered in any manner, or not used under normal operating

conditions or not in accordance with accompanying or relevant instructions, packaging or

labels.

Accessible Systems, Inc. will advise you of the procedure to follow in making warranty

claims. Contact technical support at 612-238-4600 or visit www.adjustasink.com for

assistance diagnosing the problem. Product serial numbers and proof of purchase date are

required.

Table of contents

Other Adjust-a-Sink Plumbing Product manuals

Popular Plumbing Product manuals by other brands

SFA

SFA SANI 2 installation instructions

resideo

resideo Braukmann BA295STN installation instructions

American Standard

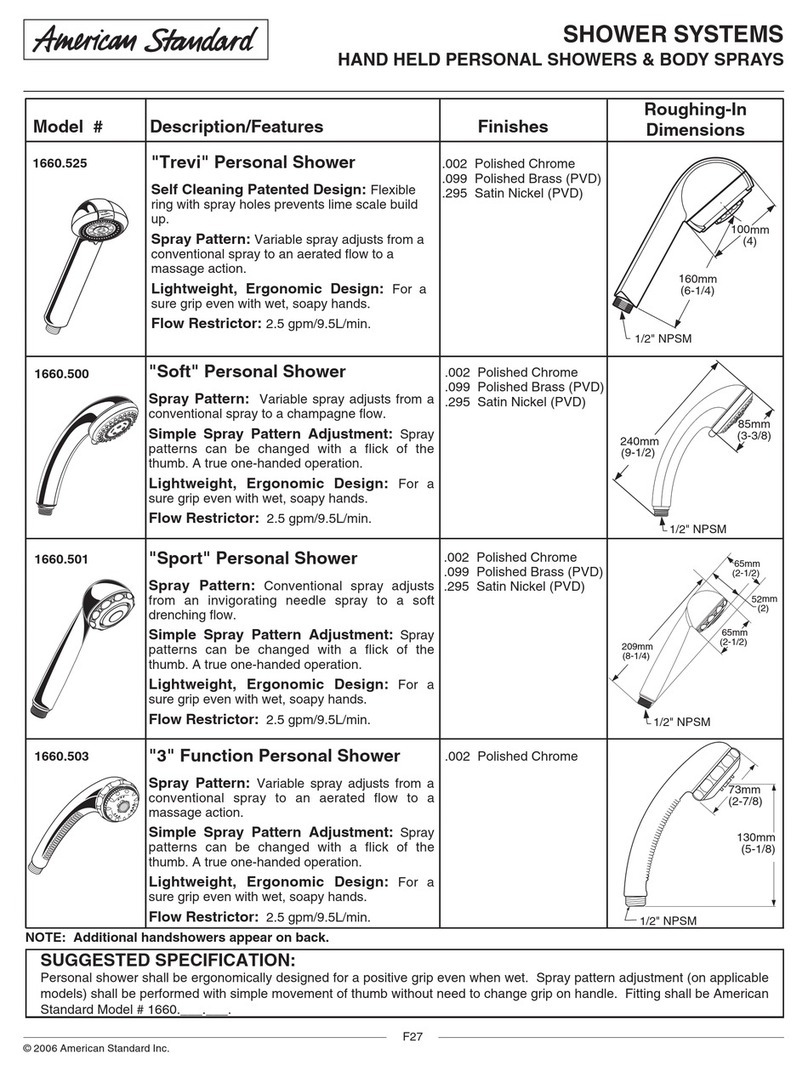

American Standard Shower Systems 1660.525 Specification sheet

Newport Brass

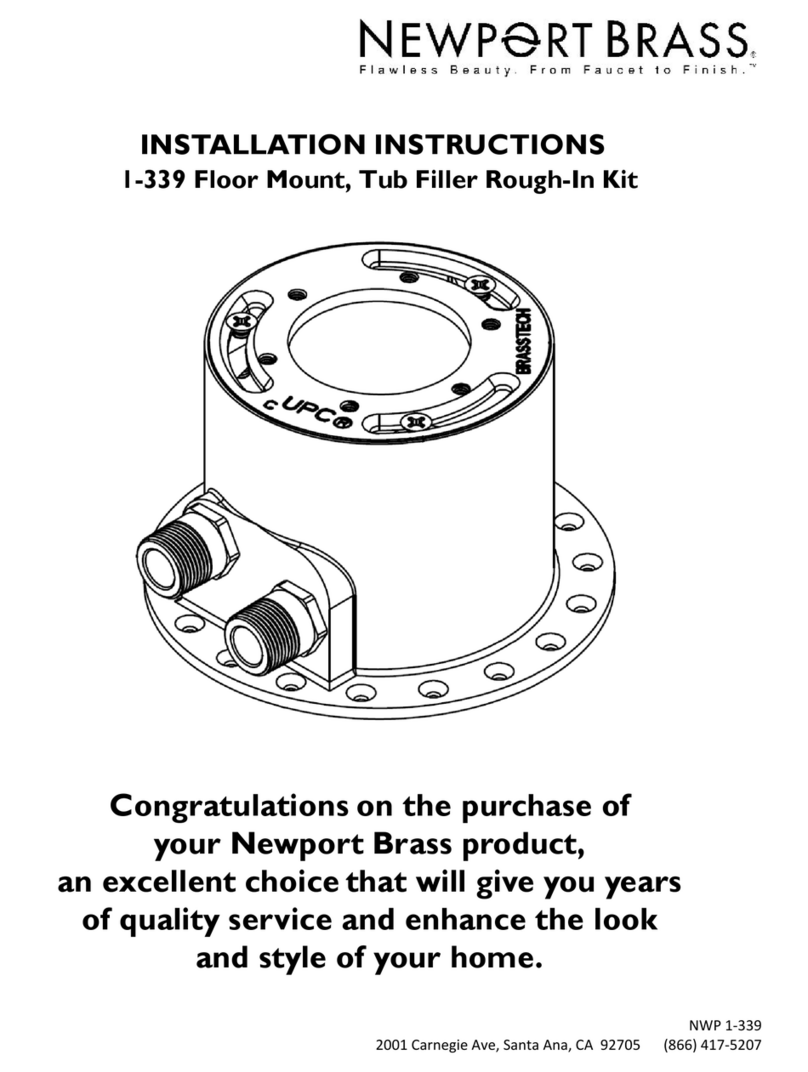

Newport Brass 1-339 installation instructions

Kohler

Kohler K-T45115 Installation and care guide

Axor

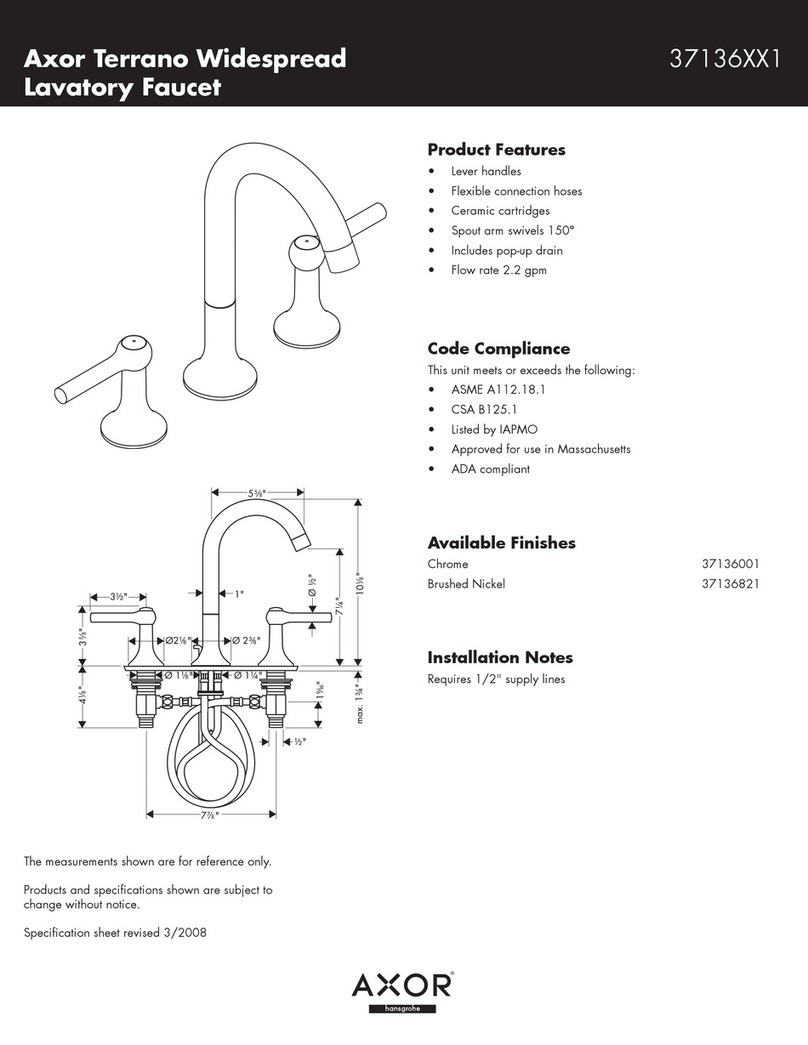

Axor Terrano 37136XX1 Specification sheet

Sterling Plumbing

Sterling Plumbing 11850 Specifications

Kohler

Kohler SUMMON K-24147T-7 Installation & operating instructions

Moen

Moen 64920 manual

Hansgrohe Axor

Hansgrohe Axor Bouroullec 19010000 Instructions for use/assembly instructions

BELLOSTA

BELLOSTA romina 0301/40/26/C installation instructions

Grohe

Grohe Ondus 36 083 Assembly instructions