be of 20-30 grades.

- At the end of the weld bead, bring the end of the electrode backward, in order to fill the weld crater, quickly lift the

electrode from the weld pool to extinguish the arc.

7. MAINTENANCE

WARNING! BEFORE CARRYING OUT MAINTENANCE OPERATIONS MAKE SURE THE WELDING

MACHINE IS SWITCHED OFF AND DISCONNECTED FROM THE MAIN POWER SUPPLY.

7.1 EXTRAORDINARY MAINTENANCE MUST ONLY BE CARRIED OUT BY TECHNICIANS WHO ARE EXPERT OR

QUALIFIED IN THE ELECTRIC-MECHANICAL FIELD

Checks inside the welding machine while it is on, may cause serious electric shock due to the direct contact with live

parts and/or injury due to direct contact with moving parts.

- Inspect the welding machine regularly, with a frequency depending on use and the dustiness of the environment, and

remove the dust deposited on the transformer, reactance and rectifier using a jet of dry compressed air (max. 10bar).

- Do not direct the jet of compressed air on the electronic boards; these can be cleaned with a very soft brush or

suitable solvents.

- At the same time make sure the electrical connections are tight and check the wiring for the insulation damage.

- At the end of these operations, re-assemble the panels of the welding machine and screw the fastening screws right

down.

- Never carry out welding operations while the welding machine is open.

- After having carried out maintenance or repairs, restore the connections and wiring as they were before, making sure

they do not come into contact with moving parts or parts that can reach high temperatures. Tie all the wires as they

were before, be careful to keep the high voltage connections of the primary transformer separate from the low voltage

ones of the secondary transformer.

Use original washers and screws when closing the casing.

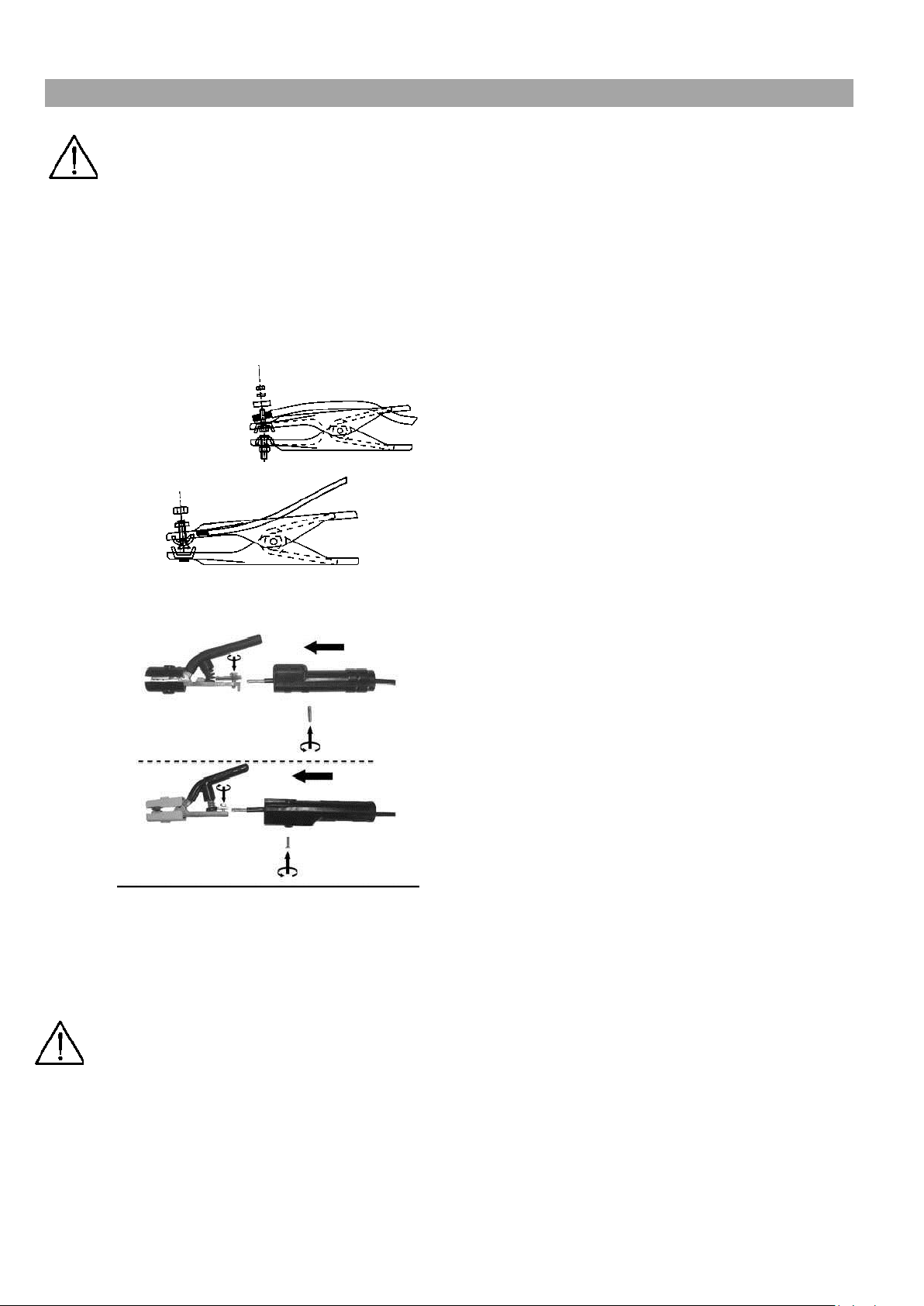

7.2 Maintenance of cables and clamps

- Do not touch hot objects with the cable and the clamp.

- Periodically check leak tightness of gas connections.

- Check contacts and connections of the welding cables and the clamps.

- Before each operation, check the electrodes and the clamps.

8. TROUBLESHOOTING

IN CASE OF UNSATISFACTORY FUNCTIONING, BEFORE SERVICING MACHINE OR REQUESTING

ASSISTANCE, CARRY OUT THE FOLLOWING CHECK:

- Check that the welding current, which is regulated by the potentiometer with a graduated amp scale, is correct for the

diameter and electrode type in use.

- Check that when general switch is ON, the corresponding lamp is ON too. If this is not the case then the problem is

located on the mains (cables, plugs, outlets, fuses, etc.).

- Check that the yellow led (ie. thermal protection interruption - either over or undervoltage or short circuit) is not lit.

- Check that the nominal intermittence ratio is correct. In case there is a thermal protection interruption, wait for the

machine to cool down, check if the fan is working properly.

- Check the mains voltage: if the value is too high or too low the welding machine will be stopped.

- Check that there is no short-circuit at the output of the machine.

- Check that all connections of the welding circuit are correct, particularly that the work clamp is well attached to the

workpiece, with no interfering material or surface-coverings (ie. Paint).

- Protective gas must be of appropriate type (Argon 99.5%) and quantity.