Admiral 62cc User manual

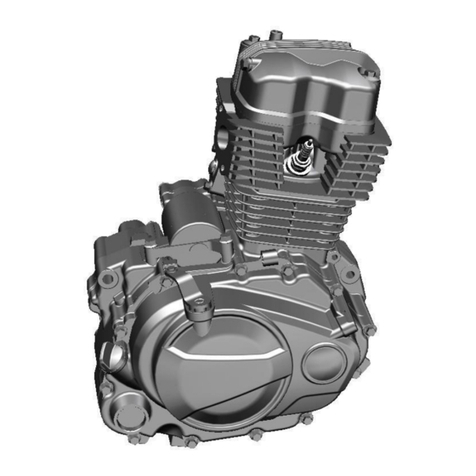

62CC GASOLINE ENGINE

INSTRUCTION MANUAL

ENGLISH

Note:ĞĨŽƌĞŽƉĞƌĂƟŶŐƌĞĂĚƚŚĞŝŶƐƚƌƵĐƟŽŶŵĂŶƵĂůƚŽďĞĐŽŵĞĨĂŵŝůŝĂƌǁŝƚŚƚŚĞĨĞĂƚƵƌĞƐ

ŽĨƚŚĞƉƌŽĚƵĐƚ

Warning: tĞƌĞĐŽŵŵĞŶĚƐŽƉĞƌĂƟŽŶŽĨƚŚŝƐŝƚĞŵďLJĐŚŝůĚƌĞŶŽůĚĞƌƚŚĂŶϭϰLJĞĂƌƐdŚŝƐ

ƉƌŽĚƵĐƚŝƐŶŽƚĂƚŽLJKǁŶĞƌƐĂƌĞƌĞƐƉŽŶƐŝďůĞĨŽƌƚŚĞƐĂĨĞŽƉĞƌĂƟŽŶŽĨƚŚĞĞŶŐŝŶĞƵƐĞ

ĚŝƐĐƌĞƟŽŶĂƚĂůůƟŵĞƐ

Beware: ƌŽƚĂƟŶŐƉƌŽƉĞůůĞƌŝƐĚĂŶŐĞƌŽƵƐĚŽŶŽƚƚŽƵĐŚŽƌĂůůŽǁĂŶLJŽďũĞĐƚƚŽŵĂŬĞ

ĐŽŶƚĂĐƚǁŝƚŚƉƌŽƉĞůůĞƌŽŶŽƚĐƌŽƵĐŚŽǀĞƌƚŚĞĞŶŐŝŶĞǁŚŝůĞŝŶŽƉĞƌĂƟŽŶ

ĂƵƟŽŶDŽĚĞůĞŶŐŝŶĞƐŐĞŶĞƌĂƚĞŚĞĂƚĚŽŶŽƚƚŽƵĐŚĂŶLJƉĂƌƚŽĨƚŚĞĞŶŐŝŶĞƵŶƟůŝƚŚĂƐ

ĐŽŽůĞĚƐĞƌŝŽƵƐďƵƌŶƐŵĂLJƌĞƐƵůƚ

dŚŝƐƉƌŽĚƵĐƚŵƵƐƚŶŽƚďĞĚŝƐƉŽƐĞĚǁŝƚŚ

ŚŽƵƐĞŚŽůĚǁĂƐƚĞ/ƚŝƐƚŚĞƵƐĞƌƐƌĞƐƉŽŶ-

ƐŝďŝůŝƚLJƚŽĚŝƐƉŽƐĞŽĨĞŶŐŝŶĞĐŽŵƉŽŶĞŶƚƐ

ǁŝƚŚĂĚĞƐŝŐŶĂƚĞĚƌĞĐLJĐůŝŶŐƐĞƌǀŝĐĞZĞ-

ĐLJĐůŝŶŐŚĞůƉƐĐŽŶƐĞƌǀĞŶĂƚƵƌĂůƌĞƐŽƵƌĐĞƐ

ĂŶĚĞŶƐƵƌĞƐĂŚĞĂůƚŚLJĞŶǀŝƌŽŶŵĞŶƚ&Žƌ

ŵŽƌĞŝŶĨŽƌŵĂƟŽŶĐŽŶĐĞƌŶŝŶŐƌĞĐLJĐůŝŶŐ

ƉůĞĂƐĞĐŽŶƚĂĐƚLJŽƵƌůŽĐĂůĐŝƚLJŽƌĚŝŶĂŶĐĞ

ŽĸĐĞLJŽƵƌǁĂƐƚĞŵĂŶĂŐĞŵĞŶƚƐĞƌǀŝĐĞ

ŽƌƚŚĞƉůĂĐĞŽĨƉƵƌĐŚĂƐĞ

dŚŝƐƉƌŽĚƵĐƚĐŽŵƉůŝĞƐǁŝƚŚh^ĂŶĚh

ĚŝƌĞĐƟǀĞƐƌĞŐĂƌĚŝŶŐĞƐƐĞŶƟĂůƉƌŽƚĞĐ-

ƟŽŶƌĞƋƵŝƌĞŵĞŶƚƐŽĨĞůĞĐƚƌŽŵĂŐŶĞƟĐ

ĐŽŵƉĂƟďŝůŝƚLJĞĐůĂƌĂƟŽŶŽĨŽŶĨŽƌ-

ŵŝƚLJŝƐĂǀĂŝůĂďůĞ

ENVIRONMENTAL CONCERNS:

DECLARATION OF CONFORMITY

SAFETY INSTRUCTIONS

ENGLISH

INTRODUCTION

INSTALLING THE ENGINE

WARNING:

-

ge.

A: Choke Lever

C: Fuel Inlet

ŽŶŐƌĂƚƵůĂƟŽŶƐfŽƌƉƵrĐŚĂƐŝŶŐŽŶĞŽĨŽƵƌexĐŝƟŶŐŶeǁgĂƐĞŶŐŝŶĞƐdŚĞŝŶŶŽǀĂƟǀĞgĂƐĞŶŐŝŶĞƐĞƌŝĞƐ

ĞŶƐƵrĞĂŚĂƐƐůĞ-frĞĞedžƉĞƌŝĞŶĐĞǁŝƚŚŽƵƚůŽƐƐŽĨƉĞƌfŽƌŵĂŶĐĞŽƌĚƵrĂďŝůŝƚLJƚŚrŽƵŐŚcareĨƵůĚĞƐŝŐŶĂŶĚ

tĞƐƟŶŐdŚŝƐŵĂŶƵĂůǁŝůůŐƵŝĚĞLJŽƵƚŚrŽƵŐŚƚŚĞƐŝŵƉůĞƐteƉƐtŽLJŽƵƌƐƵĐĐĞƐƐǁŚĞŶcareĨƵůůLJrĞĂĚĂŶĚ

followĞĚ

DŽƵŶƟŶŐƚŚĞϲϮŝƐƐŝŵƉůĞǁŝƚŚƚŚĞŽǀĞƌĂůůĚŝŵĞŶƐŝŽŶƐĚĞƐŝŐŶĞĚƚŽĮƚĐƵƌƌĞŶƚŐŝĂŶƚͲƐĐĂůĞŽīĞƌŝŶŐƐ

ĞĐĂƵƐĞŝƚƐƉƌŽƉĞůůĞƌĂŶĚŵƵŋĞƌŵŽƵŶƚŶŐĚŝŵĞŶƐŝŽŶƐŵĂƚĐŚŽƚŚĞƌƉŽƉƵůĂƌϱϬĐĐĂŶĚϲϬĐĐĞŶŐŝŶĞƐ

ƚŚĞϲϮŝƐĂŐŽŽĚĮƚŝŶŵĂŶLJĞdžŝƐƚŶŐϱϬʹϲϬĐĐĂŝƌĨƌĂŵĞƐ

4

ENGLISH

CONNECTING THE THROTTLE LINKAGE

16mm (5/8 in)

1. hƐĞƚŚĞƉƌŽǀŝĚĞĚďĂůůͲůŝŶŬƚŽĂƩĂĐŚƚŚĞƚŚƌŽƩůĞ

2.

3.

4.

5.

6.

the pushrod where it meets this hole.

7. Using pliers, bend the pushrod so there is a 90° bend at the mark.

8. Using a pushrod keeperƐĞĐƵre the pushrod in the servo arm.

9.

10.

CONNECTING THE ELECTRONIC IGNITION

BASELINE NEEDLE SETTINGS

-

gine are 1.5 turns out for the high-speed

needle, and 1.75 turns out for the low-

speed needle.

seat gently— do not forĐĞƚŚĞŵƚŚŝƐĐould

damage the needles or Đarburetor body.

Open the needles the number of turns

listed above.

Low speed needle

High speed needle

5

ENGLISH

FUEL

To properly mix the fuel, add 4.0 oz of high quality 2-stroke oil to one gallon (or 32 mL of oil to one

liter) of 87–93 octane fuel.

We tested primarily with Red Line two-stroke oil. Other high-quality two-stroke oils will also work

well. Mixtures as rich as 25:1 are acceptable.

ENGINE BREAK-IN

-

develop a good seal.

Perform the break-in process with the engine mounted on your airplane. There is no need to

Use a lightly loaded break-in prop to begin your break-in process (22 x 10 or 23 x 9)

• First tank of fuel: Run the engine on the

-

• Second tank of fuel: Do not run at full

sure to mix in some cooling dives and lower-

• Third tank of fuel: Fly the engine at high

up to one minute. This will help the piston

ring and cylinder to expand and contract,

helping the breaking-in process.

• Fourth tank of fuel: Select one of the

recommended propellers for normal opera-

STARTING AND RUNNING THE ENGINE

&ƵĞůƐŚŽƵůĚďĞĮůtered in your fueling system before it enters your model. Failure to prŽƉĞƌůLJĮůter

/ƚŝƐĐƌŝƟĐĂůƚŽƚŚĞƉƌŽƉĞƌŽƉĞƌĂƟŽŶŽĨLJŽƵƌϲϮĐĞŶŐŝŶĞƚŚĂƚLJŽƵƵƐĞƚŚĞŝŶĐůƵĚĞĚĮůƚĞƌĞĚĐůƵŶŬ

ƚŚĞĨƵĞůďĞĨŽƌĞŝƚƌĞĂĐŚĞƐLJŽƵƌĞŶŐŝŶĞĐĂŶŝŶƚƌŽĚƵĐĞĐŽŶƚĂŵŝŶĂƟŽŶŝŶƚŽƚŚĞĨƵĞůƐLJƐƚĞŵ

6

ENGLISH

1. Power ON the radio system but leave the

engine power system OFF.

2. Close the choke valve on the carburetor.

3. -

4. Power ON the engine power system.

5. -

pression. Flip the propeller through com-

6. Open choke valve on the carburetor and

7. Let the engine run at high idle for 30 se-

conds to stabilize the temperatures.

8.

If the engine doesn’t start quickly

9. If the engine appears not to have any fuel,

repeat the priming procedure in step 2—5.

• Check for fuel systems problems. Are there

any holes in the fuel lines (inluding the

clunk line inside the fuel tank) or other pos-

sible sources of air leaks?

If the engine runs

•

charged

1. Remove the spark plug.

2. Cover the cylinder head with a cloth or

paper towel and turn the propeller over to

If you suspect the engine is

expel the excess fuel.

3.

again.

If the engine cannot be turned over easily:

TROUBLESHOOTING GUIDE

• Check and use a new spark plug if needed.

Remove the spark plug and reinstall it into

-

er system ON, move the sensor magnet past

-

nually moving the sensor past the magnet).

You should be able to either see the spark

The engine RPM needs to exceed 180 RPM

plug. Make sure to rapidly move the magnet

past the sensor when checking for proper

• Check fuel lines for damage or kinks. If any

of the lines are restricted, the fuel system

will likely not operate. Clean and intact

properly.

•

turning the engine over.

• Check that the carburetor is correctly

installed and that all gaskets are intact and

undamaged.

•

from any bends or blockages.

If the engine does not start:

A possible cause is the piston is seized in the cylinder: loosen and unscreǁƚŚĞŵƵŋĞƌďŽůƚƐ

Visually inspect the piston and cylinder through the exhaust port.

If there are excessive/deep scratches or grooves in the piston, please contact your local

ƐƵƉƉůŝĞƌĐƵƐƚŽŵĞƌƐĞƌǀŝĐĞĨŽƌŵŽƌĞŝŶĨŽƌŵĂƟŽŶ

Repair of a seized piston/cylinder is mechanical and should not be atempted.

7

ENGLISH

SPECIFICATIONS

Spark Plug Cap

Propeller Bolt

Dimensions

Engine

Mount Di-

mensions

Disp 62cc

Bore 46.0 mm (1.80 in)

Stroke 37.0 mm (1.50 in)

Cylinder Nikasil plated Aluminum

Plug type CM-6

Engine Weight 1483 g (52.3 oz)

M5

1.5 H

1.75 L

PROPELLER SPECIFICATIONS

Propeller Typical Ground RPM

Menz (wood) 22 x 10“ 7000

Menz (wood) 23 x 8“ 7000

Mejzlik (CF) 23 x 8“ 7100

Mejzlik (CF) 23 x 10“ 6900

Mejzlik (CF) 24 x 10“ 6400

8

ENGLISH

EXPLODED VIEW

9

ENGLISH

PARTS LIST

#

1Walbro Carburetor 62

2Front Prop Washer 62

3Rear Prop Washer 62

4Prop Bolt Set (4) M5 x 45 62

5Prop Drive Retaining Bolt 62

6Prop Driver with Key 62

7

8

Front Crankcase with Bearings 62

9

10

11 Crankcase Align Keys (2) 62

12

13

14

15 Conrod Assembly 62

16 Conrod Lower Bearing 62

17 Conrod Retaining Screw 62

18 Piston Pin with Clips 62

19 Piston 62

20 Piston Ring 62

21 Cylinder Gasket 62

22 Crankcase Bolt Set 62

23 Exhaust Flange Gasket (2) 62

24 Cylinder Head 62

25 Rear Crankcase 62

26 Reed Cage Gasket Set 62

27 Aluminum Reed Cage 62

28 Reed Mount Strap (2) 62

29 Intake Reeds (2) 62

30

31

32 Carburetor Gasket Set (3) 62

33 Engine Gasket Set 62

34

35 Carburetor Velocity Stack 62

36 Spark Plug CM6

WŽŽĚƌƵīKey (2) 62

/ŐŶŝƟŽŶWŝĐkup Magnet 62

Front CrankshaŌďĞĂƌŝŶŐϲϮ

Rear CrankshaŌĞĂƌŝŶŐϲϮ

CrankshaŌϲϮ

CrankshaŌstuīer Assembly 62

Carburetor MounƟŶŐůŽĐŬϲϮ

Carburetor MounƟŶŐŽůƚ^et 62

/ŐŶŝƟŽŶ^ĞŶƐŽƌĂŶĚDŽƵnt Set 62

This manual suits for next models

1

Table of contents

Popular Engine manuals by other brands

VM

VM CBF 125 SERVICE MANUAL AND EFI DIAGNOSTIC

Generac Power Systems

Generac Power Systems GN - 320 owner's manual

Volvo Penta

Volvo Penta 13L Operator's manual

Erreka

Erreka SENA installation instructions

Iveco

Iveco Marine Diesel Engines Installation handbook

LinMot

LinMot PS01-48x240F-EX-E installation guide