www.advancedco.com

2

Table of Contents Page

1INTRODUCTION / OVERVIEW............................................................................................................................4

1.1LIMITATIONS OF FIRE ALARM SYSTEMS ...........................................................................................................4

1.2GENERAL INSTALLATION NOTES .....................................................................................................................4

2PROGRAMMING..................................................................................................................................................5

2.1INTRODUCTION ...............................................................................................................................................5

2.1.1Access Levels ..........................................................................................................................................5

2.2MEMORY LOCK...............................................................................................................................................6

2.3STARTING POINT ............................................................................................................................................7

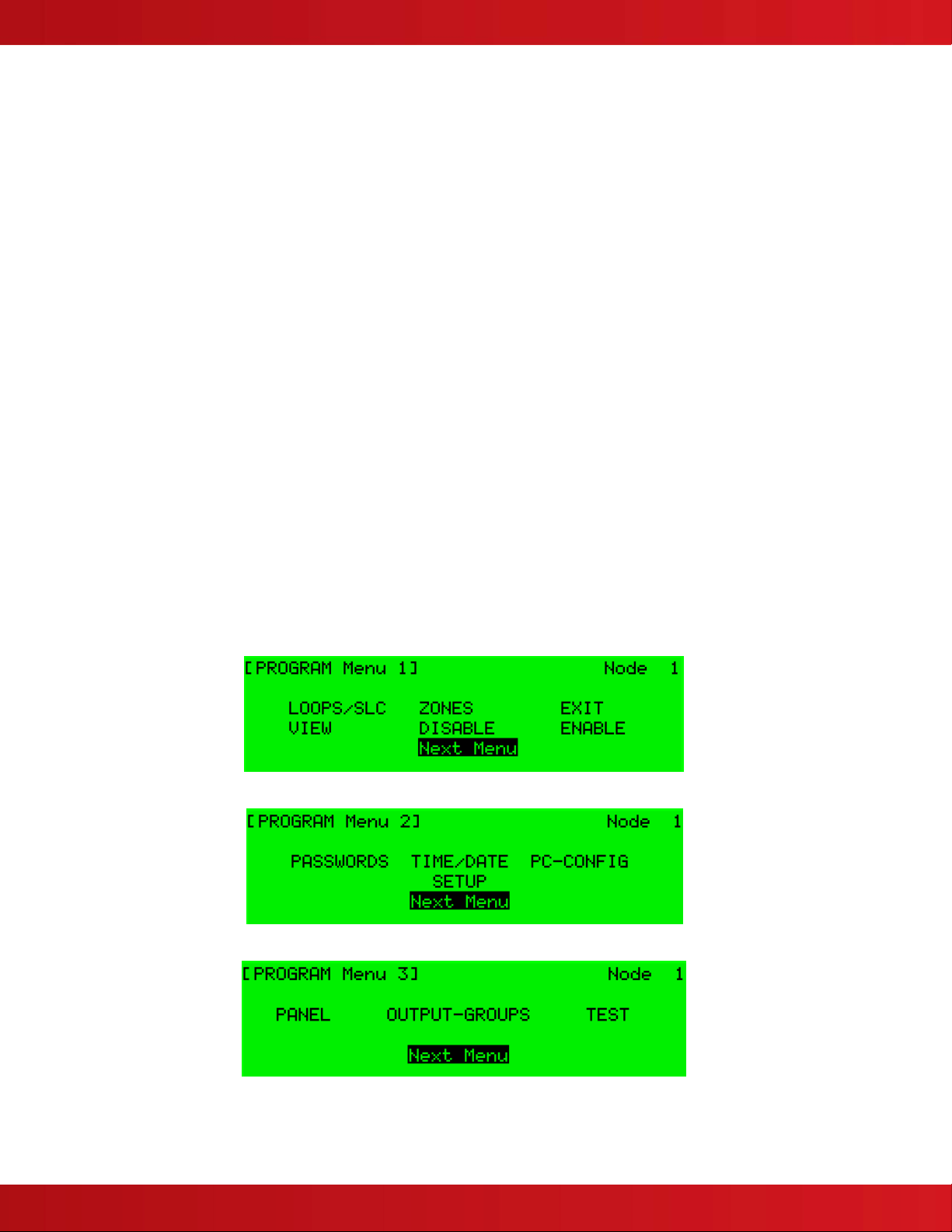

2.3.1Program Menu Screens ...........................................................................................................................8

2.3.2Navigating Through Menus......................................................................................................................9

2.3.3Changing Text Descriptions.....................................................................................................................9

2.3.4Numeric data entry.................................................................................................................................11

2.4RECOMMENDED PROGRAMMING PROCEDURE ................................................................................................11

2.4.1Loops/SLC .............................................................................................................................................13

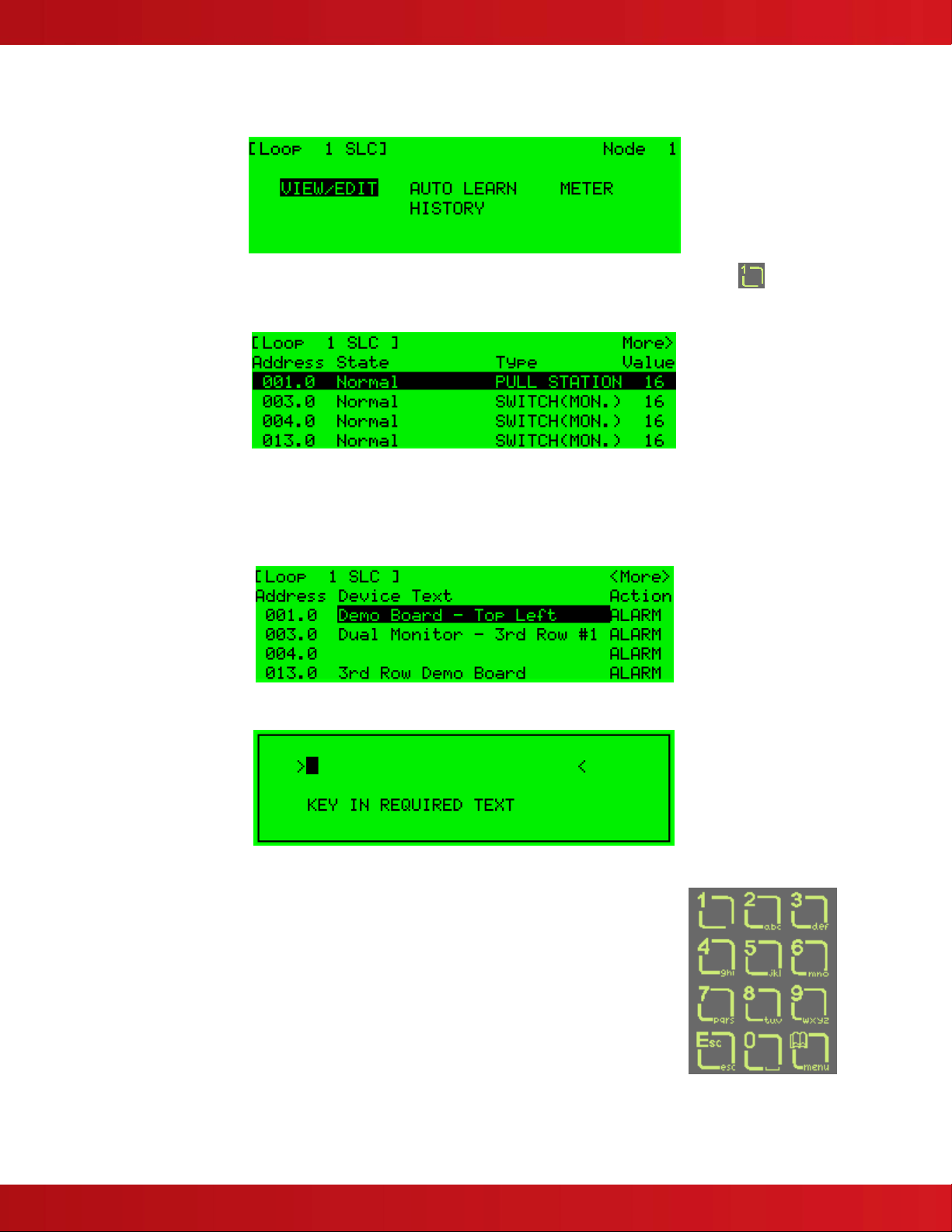

2.4.1.1Loop – View/Edit...........................................................................................................................................13

2.4.1.1.1Address Parameter..................................................................................................................................13

2.4.1.1.2State Parameter.......................................................................................................................................13

2.4.1.1.3Type.........................................................................................................................................................13

2.4.1.1.4Value Parameter......................................................................................................................................14

2.4.1.1.5Zone Parameter.......................................................................................................................................14

2.4.1.1.6Device Text Parameter ............................................................................................................................14

2.4.1.1.7Action Parameter.....................................................................................................................................14

2.4.1.1.8Sensitivity Parameter...............................................................................................................................15

2.4.1.1.9O/P Group ...............................................................................................................................................18

2.4.1.1.10Additional Info.........................................................................................................................................18

2.4.1.1.11Detector Testing .....................................................................................................................................19

2.4.1.2Loop – Auto Learn........................................................................................................................................20

2.4.1.2.1Normal Procedure / Auto Learn ...............................................................................................................20

2.4.1.2.2Procedure if the Panel finds Devices Missing..........................................................................................20

2.4.1.2.3Procedure if the Panel finds Devices Added............................................................................................21

2.4.1.2.4Procedure if the Panel finds Devices Changed........................................................................................21

2.4.1.3Loop – Meter ................................................................................................................................................22

2.4.1.4Loop – History ..............................................................................................................................................22

2.4.2Zones .....................................................................................................................................................22

2.4.3Exit .........................................................................................................................................................23

2.4.4View........................................................................................................................................................23

2.4.5Disable ...................................................................................................................................................23

2.4.6Enable ....................................................................................................................................................23

2.4.7Passwords..............................................................................................................................................24

2.4.8Time and Date........................................................................................................................................24

2.4.9PC Config...............................................................................................................................................25

2.4.10Setup..................................................................................................................................................25

2.4.10.1Network ........................................................................................................................................................25

2.4.10.2Panel Zone ...................................................................................................................................................25

2.4.10.3Onboard NACs .............................................................................................................................................25

2.4.10.4Service Number............................................................................................................................................25

2.4.10.5Service Due Date .........................................................................................................................................25

2.4.10.6Trace Logging Mode.....................................................................................................................................26

2.4.10.7Detector Blinking ..........................................................................................................................................26

2.4.10.8Ground Monitoring........................................................................................................................................26

2.4.10.9DACT............................................................................................................................................................27

2.4.10.10DACT AC Trouble Delay..........................................................................................................................27

2.4.10.11Resound Upon.........................................................................................................................................27

2.4.10.12CONFIG Data ..........................................................................................................................................27

2.4.11Panel..................................................................................................................................................27

2.4.12Output-Groups ...................................................................................................................................28

2.4.12.1Default Output Settings ................................................................................................................................28