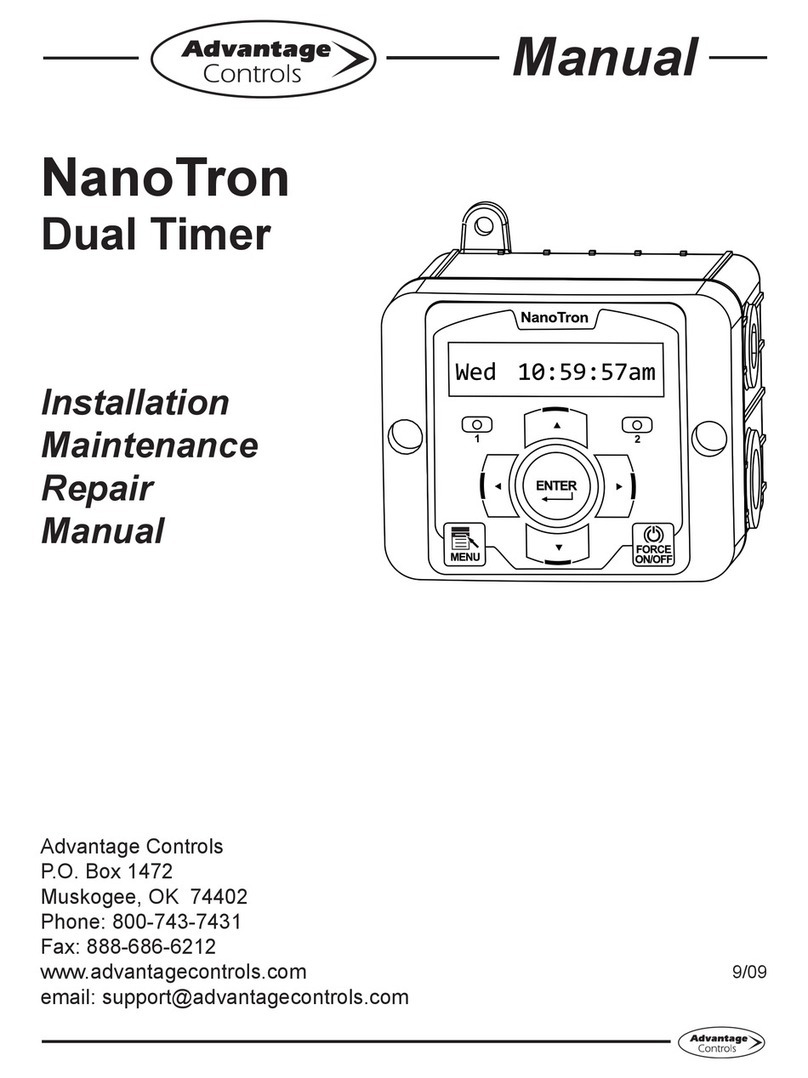

Advantage Controls NanoTron User manual

1

Manual

NanoTron

Dual Timer

Installation

Maintenance

Repair

Manual

Advantage Controls

4700 Harold Abitz Dr.

Muskogee, OK 74402

Phone: 918-686-6211

Fax: 888-686-6212

www.advantagecontrols.com

email: [email protected]

04/2019

ENTER

2

Table of Contents

Contents Page

I. Introduction................................................................................. 2

II. Description.................................................................................. 3

NanoTron-F2 Features ............................................................... 3

III. Installation

Electrical Wiring.......................................................................... 3

Logic and Relay Cards ............................................................... 4

Mounting Instructions ................................................................. 4

IV. Front Panel Description.............................................................. 5

V. NanoTron-F2 Menu Map ............................................................ 6

VI. Warranty & 30 Day Billing Memo Policy ..................................... 8

I. Introduction

NanoTron microprocessor based controllers are designed to provide a wide range of control functions for

recirculating water treatment systems. The controller is programmed through a front panel keypad and can

be congured to provide a customized control system for your application. Your particular unit’s functions can

be determined by comparing the units model number to the model numbering table listed below.

Model Numbering

NanoTron units have several base system control functions and unit optional features. Your unit may be

supplied with one or more of the features described in this manual. To determine what features apply to your

unit check the model number label located on the controller enclosure.

Base Control Function

F2 - Two Feed Timers

Whole Unit Optional Features

A- Conduit Connections

A3 - Conduit with CE

E- Flow Switch

Y- ETL Listing / Approvals

3

II. Description

NanoTron units are designed to automate the addition of various chemicals or activate other devices via a

relay output.

Nano-F2 units include:

• Two totalizing water meter inputs that can be congured for contacting head or hall eect meter inputs.

• Two drum level inputs that can be set to disable the relay outputs.

• Two mechanical relay outputs with normally open and normally closed contacts that can be congured

for powered or dry contact relay operation (see page 4).

• A “force on” timer that allows for manual activation of the relays for a user dened amount of time.

Each of the 2 timers in a NanoTron-F2 can be individually programmed as one of the following types:

1. Pulse Timer – Accepts dry contact pulses from a water meter (supplied separately). It can accumulate

1-9999 pulses to activate the timer to run from 0-99 minutes, 59 seconds in minutes and seconds.

Timer will store up to 5 additional activations during an individual run time.

2. Recycle Timer – Provides a user dened “o” cycle in HH:MM and a user dened “on” cycle in

MM:SS that is repeated constantly.

3. 28-Day Timer - 28-day feed timers, typically used for biocide feed are based on a 28-day cycle with

two independent programmable feed cycles allowing for feed on selectable days and weeks.

4. Batch Timer - Timer activated by the Force On/O key for a user dened run time.

5. Utility - Relay is on as long as it is not a ow or drum alarm.

6. After Timer 1 - This allows Timer 2 to run after Timer 1.

III. Installation

Electrical Wiring

The controller has an internal regulated power supply that will operate in the range of approximately 100 to

240 VAC on the incoming wiring. Output relay(s) are protected with a replaceable fuse. Relay output voltage

will equal the incoming line voltage.

Prewired units are supplied with a 16 AWG cable with a 3-wire grounded USA 120 volt plug for incoming power

and 18 AWG 3-wire grounded receptacle cords for all control relay outputs. Conduit units are supplied with

liquid tights and adaptors for easy hard wiring to supplied connector.

NOTES:

1. Liquid tight

fittings and some

labeled signal leads

are provided for

signal (low voltage)

connections, such as

water meter inputs.

2. Hall eect meters

that require +12 VDC

must use an external

power supply (TFS-

PWR).

CAUTION

1. There are live circuits inside the controller even when the power switch on the front panel is in

the OFF position. Never open the front panel without rst disconnecting power from the outlet.

Prewired controllers are supplied with an 8 foot, 18 AWG power cord with USA style plug. A #1

Phillips driver is required to open the front panel.

2. Low voltage signal wires (probes, ow switch, water meter, etc.) should never be run

in conduit with high voltage (like 115VAC) wires.

3. Never attempt to land connections to the controller without rst disconnecting power from the outlet.

4. Do not block access to disconnect power during mounting and installation.

5. The controller should be connected to its own isolated circuit breaker, and for best

results, the ground should be a true earth ground, not shared. Any attempt to bypass the grounding

will compromise the safety of users and property.

6. The electrical installation of the controller must be performed by trained personnel only and

conform to all applicable National, State and Local codes.

7. Operation of this product in a manner not specied by Advantage Controls may result in damage

to equipment or persons.

8. Avoid mounting in locations that expose the controller to direct sunlight, vapors, vibration,

liquid spills or extreme temperatures; less than 0°F (-17.8°C) or greater than 120°F (50°C).

EMI(electromagnetic interference) from radio transmissions and electric motors can also cause

damage or interference and should be avoided.

! !

4

Mounting Instructions

Select a mounting location that provides the operator easy access to the unit and a clear view of the

controls through the cover of the controller. The location should be convenient to grounded electrical

connections, the needed sample line plumbing and is on a stable vertical surface.

Logic and Relay Cards

+5 VDC

Ground

Conductivity

Temp

NanoCond

PWA Rev G

R B W G

Conductivity Probe

mA

Output

-

+

P S G

Meter

+-

Flow

+-

Level

Signal

Note 1: Contacting head water meters just use signal

and ground. The +5 VDC is used with hall effect meters.

-

Alarm Dry

Contact Output

+

Note 2: The alarm dry

contact output is normal

open. 12 VDC max be

connected to output.

FUSE

FUSE

Ground

Relay 1

Power Supply

Relay 2

Neutral

Hot

Neutral

Ground

N/O

N/C

Neutral

Ground

N/O

N/C

Relay 1 Out Relay 2 Out

Power In

Powered relay

output jumper

configuration

Dry contact relay

output jumper

configuration

Relay Card

NanoTron-C & B2 Logic Card

Contrast

Adjust

Note: Use GND and N.O.

for N.O. dry contact relay or

use GND and N.C. for N.C.

dry contact relay.

1 2 3

4 5

ON

OFF

Reset

Battery

1 2 3

4 5

ON

OFF

+5 VDC

Ground

+

-

Power

P S G

Meter 1

P S G

Meter 2

+

-

Flow

+

-

Level 2

+

-

Level 1

Signal

Note: Contacting head water meters

just use signal and ground. The +5 VDC

is used with hall effect meters.

FUSE

FUSE

Ground

Relay 1

Power Supply

Relay 2

Neutral

Hot

Neutral

Ground

N/O

N/C

Neutral

Ground

N/O

N/C

Relay 1 Out Relay 2 Out

Power In

Powered relay

output jumper

configuration

Dry contact relay

output jumper

configuration

Relay Card

NanoTron-F2 Logic Card

Contrast

Adjust

Note: Use GND and N.O.

for N.O. dry contact relay or

use GND and N.C. for N.C.

dry contact relay.

Switch # Position Function

1 OFF Backlight normally o; ashes on w/ alarm

1 ON Backlight normally on; ashes o w/ alarm

2 OFF Normal Operation

2 ON “Burn-in” Mode

3 OFF Normal Operation

3 ON Clear Memory (Resets to factory defaults)

4 OFF N/A

4 ON N/A

5 OFF Set for 1x6 LCD (Normal)

5 ON Set for 4x20 LCD (Debug @ Factory)

5

IV. Front Panel Description

Timer1 Set Timer2 Set Configure Force Set

Water Meters Clock Set

Set Time

Set Date

Day & Week

Pulse Recycle

On in 0001 gal

Run Time mm:ss

Off Time hh:mm

Run Time mm:ss

28-Day (Bio)

Every Day

A:

All Weeks

A:

Start 05:00a

A:

Run Time hh:mm

A:

Every Day

B:

All Weeks

B:

Start 05:00a

B:

Run Time hh:mm

B:

-options-

No Week

Week 1

Week 2

Week 3

Week 4

Odd Weeks

Even Weeks

All Weeks

-Day Options-

No Day; Sun; Mon

Tue; Wed; Thu; Fri;

M, W, F

T, Th, S

Mon-Fri

Sat & Sun

Alternate

Everyday

Flow SW: Open

Drum Lvls On

NanoTron

Firmware

Password 0000

Meter 1 Units

Meter1 Debounce

Meter 1 Value

Timer 2 Enabled Timeout1 mm:ss

Set Force On/Off

key action here as:

Ask, Both, Relay 1,

Relay 2 or None.

Set Timeout values

to desired Forced

On time for each

relay. If a timer is a

Batch it will run for

the Batch timer’s

run time when the

Force On/Off is

pressed.

Timers go back to

auto mode after

Force On/Off time

has expired.

Enter to access, timer type

shown, press Enter again to

change type or to settings.

If water meter

input Units is

gallons or liters

per pulse the

accumulator is

the volume desired

before activation.

If Units is pulses

per gallon/liter

accumulator is

number of gallons

or liters before

activation.

Reset Meter1?

Meter2 Enabled

FORCE

ON/OFF

MENU

1 2

Wed10:59:57am

MENU

FORCE

ON/OFF

ENTER

Press MENU to access menus or go back

one layer in menu structure.

Press FORCE to activate relays manually

again for Off and a third time back to auto.

Press ENTER to go a layer deeper in menu,

to initiate a setting change and to set change.

Use up or down arrows to navigate through

menu selections or setting options.

Use left or right arrows to move cursor

while making a numerical value change.

Main Menu

Circle

Tmr1 Meter1

Tmr2 WM1+2

Disabled

if 0000.

Notes:

1. If Menu is pressed while changing a value

the value on screen will be the new value.

2. If Timer 2 is “After Timer 1” it will activate it’s

Run each time Timer 1 completes a Run cycle.

3. Meter units and values must be set in the

Water Meter menu for Pulse timers to work.

Select which meter(s)

contacts activate timer.

Timer 2 has a fourth type selection;

“After Timer 1” for sequential timers.

See note 2 below.

Batch

Run Time mm:ss

Batch timers are

activated by the

Force On/Off

key and will run

for the time set

here.

Force On: Ask

Timeout2 mm:ss

Increase value to

prevent false

contacts from

water meter.

Set debounce to

0 for paddle

wheel meters.

ENTER

V. System Operation Overview

Description of Menus

NanoTron controllers have three modes of operation, Run, Menu and Force. All menus are circular. Pressing

the DOWN key will display the next line of information on the display.

Run - This mode is for normal operation. The control relays will only be automatically active in this

mode. In the Run mode, the display will read system values. If an alarm is present, the display

ashes with the alarm status.

The Run menu will display values such as day, time, date and other values depending upon the

features present on the unit. The unit will automatically return to the Run mode if no keys are

pressed for three minutes.

Menu - This mode is used to make adjustments to settings and readings on the controller. To access

the Menu mode from the run screen, press the Menu key. Use the up or down arrow to scroll

through the various menus. When you want to access a specic menu, press the Enter key.

Once you have entered a sub-menu you will be able to step through that menu’s options with

the up or down arrow key.

Force - Relays may be forced on or o for a user dened amount of time. Press the Force key to force

relays on for the time congured in the Menu’s force sub-menu. Press it a second time to force

them o for the same amount of time. Press a third time to go back to automatic Run mode.

Unit returns to the Run mode automatically when the force time has elapsed.

6

V. NanoTron-F2 Menu Map

Timer2 Set Configure Force Set

Water Meters Clock Set

Set Time

Set Date

Day & Week

Flow SW: Open

Drum Lvls On

NanoTron

Firmware

Password 0000

Meter 1 Units

Meter1 Debounce

Meter 1 Value

Timer 2 Enabled Timeout1 mm:ss

Set Force On/Off

key action here as:

Ask, Both, Relay 1,

Relay 2 or None.

Set Timeout values

to desired Forced

On time for each

relay. If a timer is a

Batch it will run for

the Batch timer’s

run time when the

Force On/Off is

pressed.

Timers go back to

auto mode after

Force On/Off time

has expired.

If Units is pulses

per gallon/liter

accumulator is

number of gallons

or liters before

activation.

Reset Meter1?

Meter2 Enabled

FORCE

ON/OFF

MENU

1 2

Wed10:59:57am

MENU

FORCE

ON/OFF

ENTER

Press MENU to access menus or go back

one layer in menu structure.

Press FORCE to activate relays manually

again for Off and a third time back to auto.

Press ENTER to go a layer deeper in menu,

to initiate a setting change and to set change.

Use up or down arrows to navigate through

menu selections or setting options.

Use left or right arrows to move cursor

while making a numerical value change.

Tmr1 Meter1

Tmr2 WM1+2

Disabled

if 0000.

Notes:

1. If Menu is pressed while changing a value

the value on screen will be the new value.

2. If Timer 2 is “After Timer 1” it will activate it’s

Run each time Timer 1 completes a Run cycle.

3. Meter units and values must be set in the

Water Meter menu for Pulse timers to work.

Select which meter(s)

contacts activate timer.

Timer 2 has a fourth type selection;

“After Timer 1” for sequential timers.

See note 2 below.

Enter to access, timer type

shown, press Enter again to

change type or to settings.

Force On: Ask

Timeout2 mm:ss

Increase value to

prevent false

contacts from

water meter.

Set debounce to

0 for paddle

wheel meters.

ENTER

Timer1 Set

Pulse Recycle

Run After 0100 gl

Run Time mm:ss

O Time hh:mm

Run Time mm:ss

28-Day (Bio)

Every Day

A:

All Weeks

A:

Start 05:00a

A:

Run Time hh:mm

A:

Every Day

B:

All Weeks

B:

Start 05:00a

B:

Run Time hh:mm

B:

-options-

No Week

Week 1

Week 2

Week 3

Week 4

Odd Weeks

Even Weeks

All Weeks

-Day Options-

No Day; Sun; Mon

Tue; Wed; Thu; Fri;

M, W, F

T, Th, S

Mon-Fri

Sat & Sun

Alternate

Everyday

Disabled

Batch Utility

If the Water

Meter input

has just been

set to Just

Pulses the

timer will run

after the set

number of

pulses.

Relay is always on

unless disabled by

ow input

Run Time mm:ss

Batch timers are

activated by the

Force On/Off

key and will run

for the time set

here.

Main Menu

Circle

7

Timer2 Set Configure Force Set

Water Meters Clock Set

Set Time

Set Date

Day & Week

Flow SW: Open

Drum Lvls On

NanoTron

Firmware

Password 0000

Meter 1 Units

Meter1 Debounce

Meter 1 Value

Timer 2 Enabled Timeout1 mm:ss

Set Force On/Off

key action here as:

Ask, Both, Relay 1,

Relay 2 or None.

Set Timeout values

to desired Forced

On time for each

relay. If a timer is a

Batch it will run for

the Batch timer’s

run time when the

Force On/Off is

pressed.

Timers go back to

auto mode after

Force On/Off time

has expired.

If Units is pulses

per gallon/liter

accumulator is

number of gallons

or liters before

activation.

Reset Meter1?

Meter2 Enabled

FORCE

ON/OFF

MENU

1 2

Wed10:59:57am

MENU

FORCE

ON/OFF

ENTER

Press MENU to access menus or go back

one layer in menu structure.

Press FORCE to activate relays manually

again for Off and a third time back to auto.

Press ENTER to go a layer deeper in menu,

to initiate a setting change and to set change.

Use up or down arrows to navigate through

menu selections or setting options.

Use left or right arrows to move cursor

while making a numerical value change.

Tmr1 Meter1

Tmr2 WM1+2

Disabled

if 0000.

Notes:

1. If Menu is pressed while changing a value

the value on screen will be the new value.

2. If Timer 2 is “After Timer 1” it will activate it’s

Run each time Timer 1 completes a Run cycle.

3. Meter units and values must be set in the

Water Meter menu for Pulse timers to work.

Select which meter(s)

contacts activate timer.

Timer 2 has a fourth type selection;

“After Timer 1” for sequential timers.

See note 2 below.

Enter to access, timer type

shown, press Enter again to

change type or to settings.

Force On: Ask

Timeout2 mm:ss

Increase value to

prevent false

contacts from

water meter.

Set debounce to

0 for paddle

wheel meters.

ENTER

Timer1 Set

Pulse Recycle

Run After 0100 gl

Run Time mm:ss

O Time hh:mm

Run Time mm:ss

28-Day (Bio)

Every Day

A:

All Weeks

A:

Start 05:00a

A:

Run Time hh:mm

A:

Every Day

B:

All Weeks

B:

Start 05:00a

B:

Run Time hh:mm

B:

-options-

No Week

Week 1

Week 2

Week 3

Week 4

Odd Weeks

Even Weeks

All Weeks

-Day Options-

No Day; Sun; Mon

Tue; Wed; Thu; Fri;

M, W, F

T, Th, S

Mon-Fri

Sat & Sun

Alternate

Everyday

Disabled

Batch Utility

If the Water

Meter input

has just been

set to Just

Pulses the

timer will run

after the set

number of

pulses.

Relay is always on

unless disabled by

ow input

Run Time mm:ss

Batch timers are

activated by the

Force On/Off

key and will run

for the time set

here.

Main Menu

Circle

8

VI. Manufacturer’s Product Warranty

Advantage Controls warrants units of its manufacture to be free of defects in material or

workmanship. Liability under this policy extends for 24 months from date of installation. Liability is limited

to repair or replacement of any failed equipment or part proven defective in material or workmanship upon

manufacturer’s examination. Removal and installation costs are not included under this warranty.

Manufacturer’s liability shall never exceed the selling price of equipment or part in question.

Advantage disclaims all liability for damage caused by its products by improper installation,

maintenance, use or attempts to operate products beyond their intended functionality, intentionally or

otherwise, or any unauthorized repair. Advantage is not responsible for damages, injuries or expense

incurred through the use of its products.

The above warranty is in lieu of other warranties, either expressed or implied. No agent of ours is

authorized to provide any warranty other than the above.

30 Day Billing Memo Policy

Advantage Controls maintains a unique factory exchange program to ensure uninterrupted service

with minimum downtime. If your unit malfunctions, call 1-800-743-7431, and provide our technician with

Model and Serial Number information. If we are unable to diagnose and solve your problem over the phone,

a fully warranted replacement unit will be shipped, usually within 48 hours, on a 30 Day Billing Memo.

This service requires a purchase order and the replacement unit is billed to your regular account for

payment.

The replacement unit will be billed at current list price for that model less any applicable resale

discount. Upon return of your old unit, credit will be issued to your account if the unit is in warranty. If the unit

is out of warranty or the damage not covered, a partial credit will be applied based upon a prorated

replacement price schedule dependent on the age of the unit. Any exchange covers only the controller

or pump. Electrodes, liquid end components and other external accessories are not included.

FCC Warning

This equipment generates and uses radio frequency energy and if not installed and used properly,

that is, in strict accordance with the manufacturer’s instruction, may cause interference to radio

communications. It has been type tested and found to comply with the limits for a class A computing

device pursuant to subpart J of part 15 of FCC Rules, which are designed to provide reasonable

protection against such interference when operated in a commercial or industrial environment.

Operation of this equipment in a residential area is likely to cause interference in which case the user,

at his own expense, will be required to take whatever measures necessary to correct the interference.

Table of contents

Other Advantage Controls Timer manuals

Popular Timer manuals by other brands

Hama

Hama 00223302 operating instructions

Alarm SAF

Alarm SAF UT-10 installation instructions

mr. steam

mr. steam 99216DIG Installation and operating manual

Timeguard

Timeguard ETU17 Installation & operating instructions

FLORABEST

FLORABEST FBC 7 A1 operating instructions

CO/Tech

CO/Tech EMT448ET Original instruction