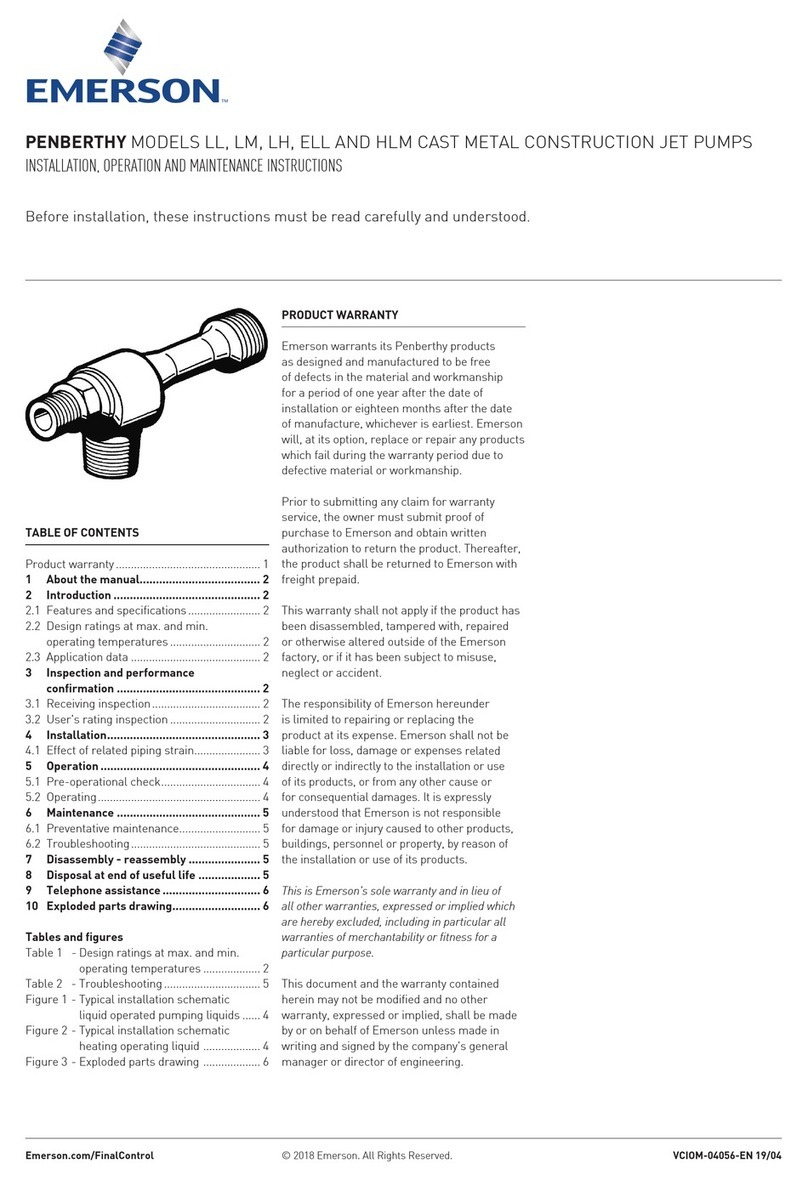

INSTALLATION & OPERATINGINSTRUCTIONS

YourEvolutionpumphasbeen qualitybuiltand

engineeredtogivemaximumefficiencyunder

normalwaterpumpingconditions.Consultthe

manufacturer for anyotherapplications.

INSTALLATION

I. LOCATION OFPUMP

Forbestpumpperformance,locatethe systemas

closetothe watersourceaspossible.Provide

adequateaccessaround thepumpforinspection

and maintenance.Placepumpon afirmlevel

surface.Pumpneed notbebolted downunless

required bylocalcode.

II. MODELSWITH TRAP

Avoid excessivetighteningofpipeorfittingsinany

areaswherethreadedconnectionsareused.For

NPTthreaded connections,useQuick-Seal Teflon

Thread Sealing Compound,Plasto-JointStick orany

othersealantsformulatedspecificallyfor plastics.

OPERATION

I. STARTING& PRIMINGPUMP

Donotrun unitdry.Alwaysbecertain thatthepump

casingand/ortrapisfilledwithwaterbeforestarting

the unit. Allowareasonableamountoftimefor

priming.Ifpumpwill notstart,orwill notprime,see

troubleshooting sectionofthis manual.

II. MAINTENANCE

The trap basketshouldbe inspected frequentlyand

keptclean.Toavoid damagetothe basket, do not

strikewhen cleaning.Inspecttrap coverO-ring

regularlyandreplaceasnecessary.

CAUTION:Donotremovehairand lintstrainer

lidwhilepumpisrunning orunderpressure!Lid

isheldinplace bylock handles,which can be

removed ortightened byhand.Basketmustbe

keptclearofleaves anddebrisatall times.Keep

motorclean.Insurethatlouvered openings are

free from debrisand obstructions.Overaperiod

oftime,theshaft sealsmaybecomedamaged or

wornandmust be replaced.

III. WINTERIZATION

Topreventdamageduringfreezing conditions,turn

off allelectricalpower. Drainthoroughlyandclean

outanydebris.Protectpumpandmotorfrom

elementsbycovering orifpossible,storein drywell

ventilated room.

MOTOR

Yourpumpis equipped withapermanently

lubricated,maintenance-free, heavy-dutyindustrial

qualitymotorespeciallydesigned towithstand the

heavy-dutyrequirementsofwatergarden

application.Wiringconnection mustagreewith

incoming line voltage.Improperwiring cancause

seriousinjuriesand damagetothe motor, voiding

warranty.(Forwiring instructions,seediagramon

motor rating plate.)

NOTE: Motoris designed towithstand the effectsof

normal rainfall.To increasethe lifeofyourmotor

observethe following:

1.) Donotfloodthemotororsubmergein water. To

do sovoidswarranty.

2.) Provide ample crossventilation,minimumof6”at

all points.

3.) Keep motorand surrounding area clean.

4.) Avoid sweeping orstirring dustnearmotorwhile

it isrunning.

5.) Avoid storingorspilling drychemicals,powders,

etc.nearmotor.

6.) Provide protectionagainst theelements.

7.) Locatemotoron aslightelevation sowaterwill

drain awayfrommotor.

8.) Avoid spillingordripping liquidchemicalsonor

nearmotor.

9.) Avoid splashing waterorhosing area nearmotor.

Waterdamagevoidswarranty.Forreplacements

contactyourlocalsupplierorauthorized

serviceman.