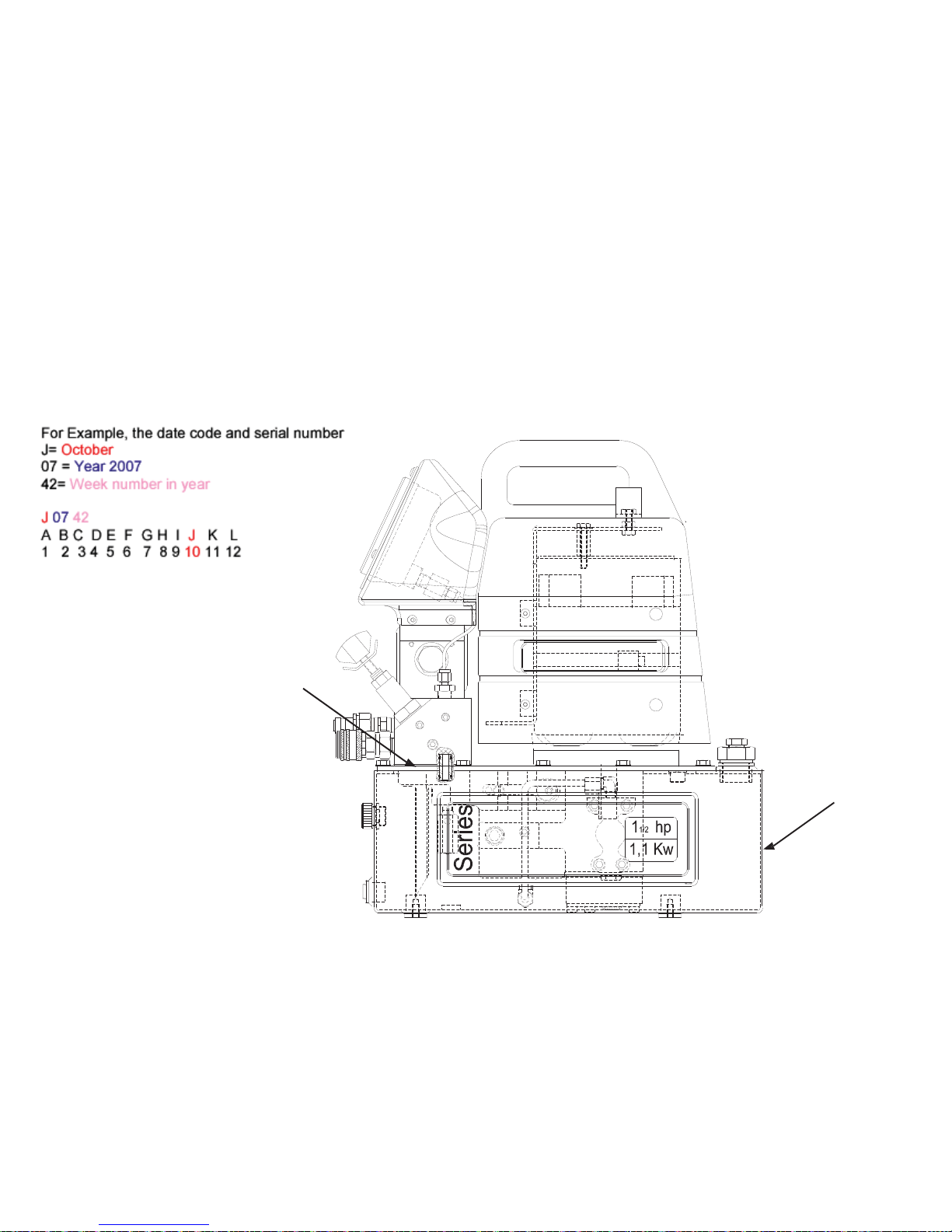

-

IMPORTANT SAFETY INFORMATION ENCLOSED.

READ THIS MANUAL BEFORE OPERATION.

IT IS THE RESPONSIBLITIY OF THE EMPLOYER TO PLACE THE INFORMATION IN THIS MANUAL INTO

THE HANDS OF THE OPERATOR.

FAILURE TO OBSERVE THE FOLLOWING WARNINGS COULD RESULT IN INJURY.

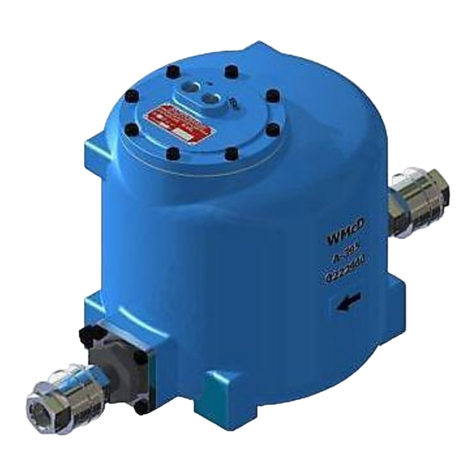

The use of other than genuine TorcUP replacement parts may result in safety hazards, decreased tool

performance, and increased maintenance, and may invalidate all warranties.

Repairs should be made only by authorized personnel. Consult your nearest TorcUP Authorized

Service Center. Refer all communications to the nearest TorcUP Office or Distributor.

FAILURE TO OBSERVE THE FOLLOWING WARNINGS COULD RESULT IN INJURY

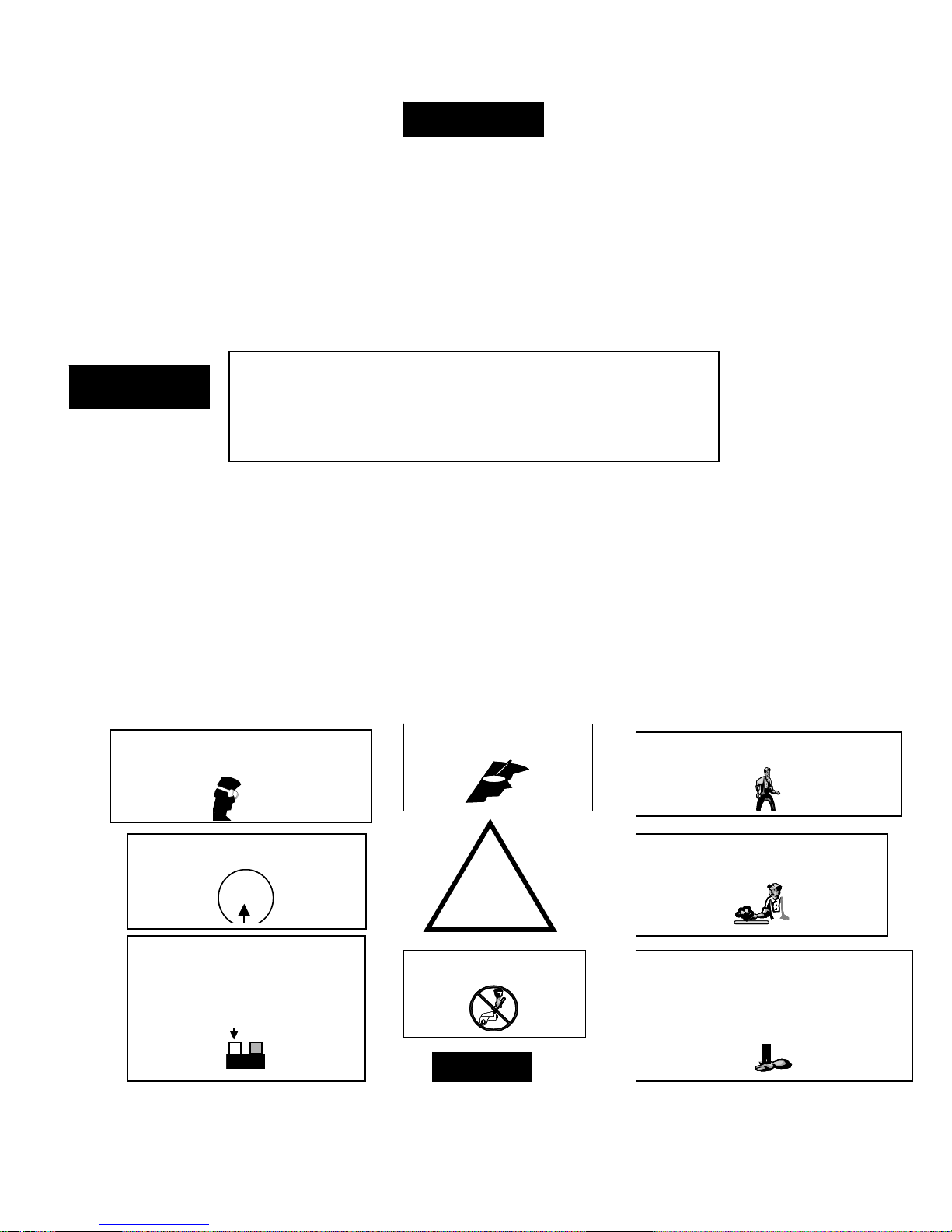

•Keep hands, loose clothing and long hair

away from the reaction arm and working area

during operation. Do not attempt to support the

tool with your hands during operation.

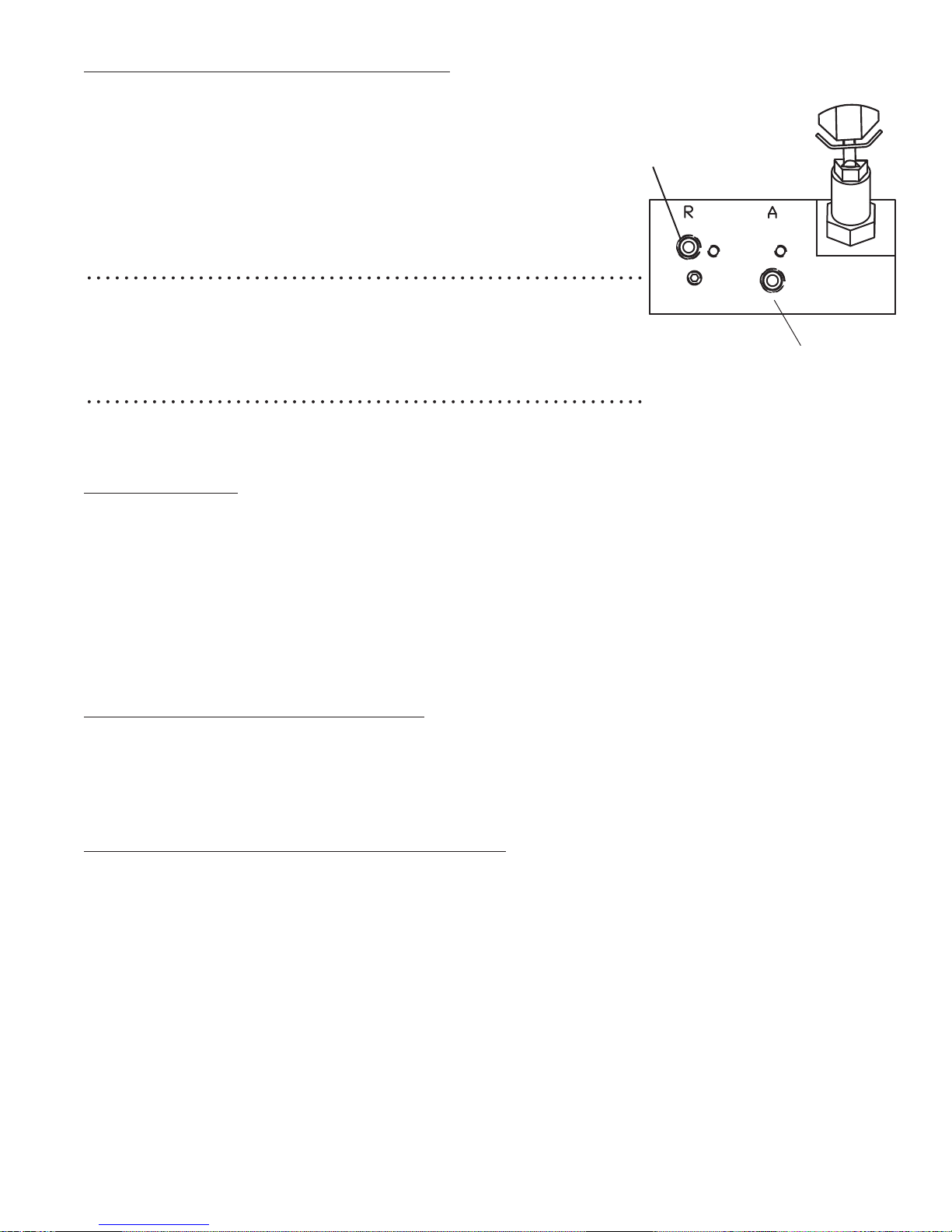

•This tool will exert a strong reaction force.

Use proper mechanical support and correct

reaction arm positioning to control these

forces. Do not position the reaction arm so that

it tilts the tool off the axis of the bolt and never

use the swivel inlets as a reaction stop.

Avoid sharp bends and kinks that will cause

severe back-up pressure in hoses and lead to

premature hose failure.

•Use accessories recommended by TorcUP.

•Use only impact sockets and accessories. Do

not use hand (chrome) sockets or accessories.

•Use only sockets and accesssories that

correctly fit the bolt or nut and function without

tilting the tool off the axis of the bolt.

•This tool is not designed for working in

explosive atmospheres

Do not use damaged, frayed or

deteriorated hydraulic hoses and

fittings.

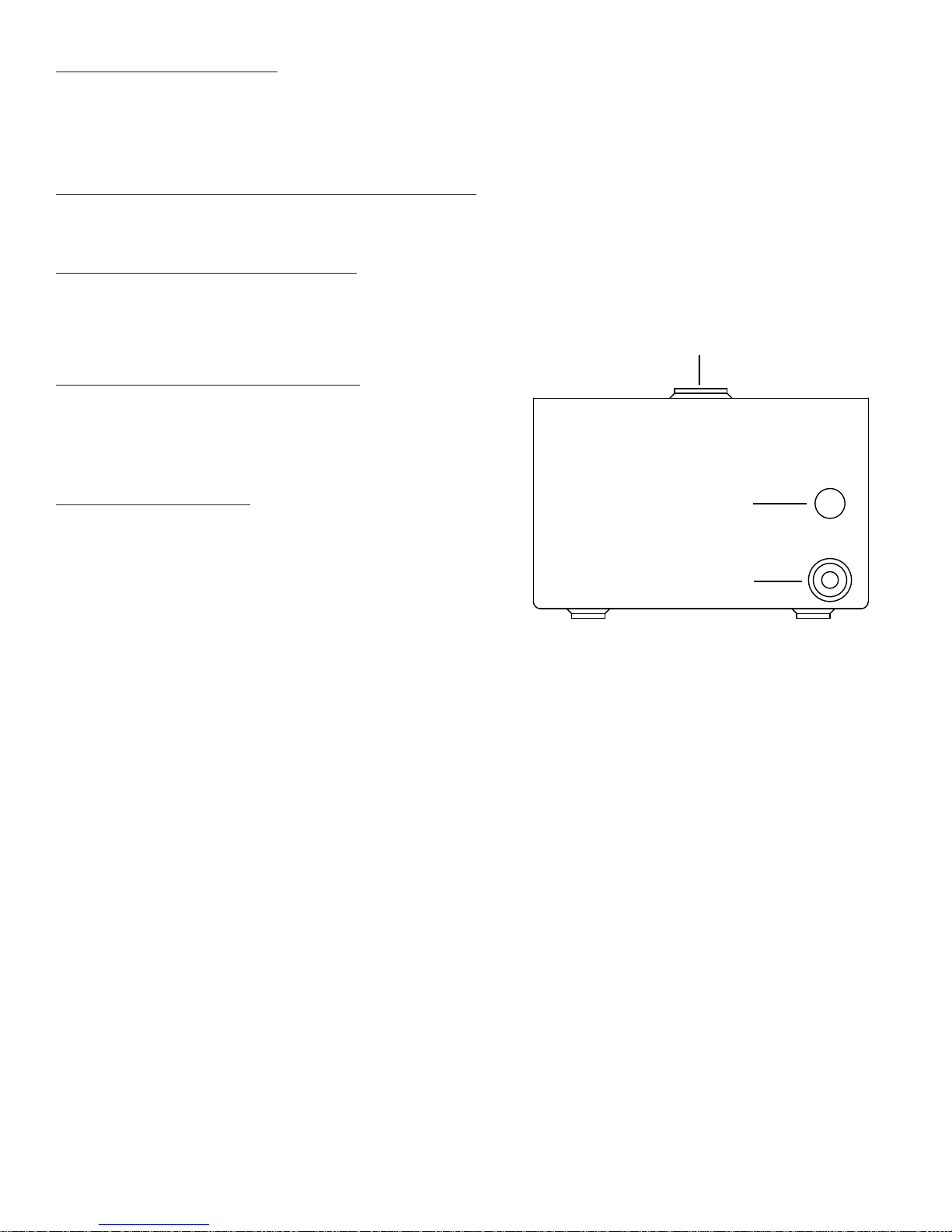

Operate at 10,000 psig (681bar)

maximum pressure.

10,000 psig

(681 bar)

10,000 psig

(681 bar)

The Torque Reaction Arm must be

positioned against a positive stop. Do not

use the Arm as a dead handle. Take all

precautions to make certain the operator’s

hand cannot be pinched between the Arm

and a solid object.

For Technical Support and Information Contact:

TorcUP, Inc.

1025 Conroy Place, Easton, PA 18040

Toll Free: (888) TORCUP-1 Fax: (610) 250-2700

NOTICE

SAVE THESE INSTRUCTIONS. DO NOT DESTROY.

Always wear eye protection when operating

or performing maintenance on this tool.

Always wear eye protection when operating

or performing maintenance on this tool.

!

Always wear ear protection

when operating this tool. Keep body stance balanced and firm. Do

not overreach when operating this tool.

Do not carry the tool by

the hose.

Always turn off the pump and

disconnect the power before

installing, removing, or adjusting

any accessory on this tool, or

before performing any maintenance

on this tool.

POWER

OFF ON

POWER

OFF ON

WARNING

WARNING