CHAPTER 1

GENERAL INSTALLATION AND OPERATING INSTRIUCTIONS

1.0 Important information

To ensure safety and correct operation please read and observe the following instructions carefully before proceeding.

Important information is specified in the maintenance section on filter changes and necessary cleaning and maintenance

activities. The user usually carries out maintenance work. The chapter “Installation” with important installation

tips and basic unit adjustments is intended for the specialised installer.

The electrical connection must be fully isolated from the supply up to the finalassembly!

This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities,

or lack of experience and knowledge, unless they have been given supervision or instruction concerning use of the appliance by

a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

The planning office provides the planning documents necessary for system calculations. Additional information can be

requested ex works. Keep the installation and operating instructions as a reference at the device. After the final assembly,

the document must be handed out to the operator (tenant/owner).

1.1 Warning and safety instructions

The adjacent symbol is a safety-relevant prominent warning symbol. All safety regulations and/or symbols must

be absolutely adhered to, so that any dangerous situation is avoided.

1.2 Warranty claims –Exclusion of liability

If the preceding instructions are not observed, all warranty claims and accommodation treatment are excluded. This

also applies to any liability claims extended to the manufacturer.

The use of accessories not offered or recommended by AERA is not permitted. Potential damages are not covered by

warranty.

1.3 Regulations –Guidelines

If the product is installed correctly and used to its intended purpose, it conforms to all applicable CE standards

at its date of manufacture. The AERA AZURE WHEEL ventilation units in this series are compliant with Eco-Design 2018.

1.4 Storage

When storing for a prolonged time the following steps are to be taken to avoid damaging influences:

Protection by dry, air- dustproof packing. The storage place must be water protected, vibration-free and free of temperature

variations. (Ambient temperature limit, min/max, 0°C/ +40°C) Damages due to improper transportation, storage or putting into

operation are not covered by warranty.

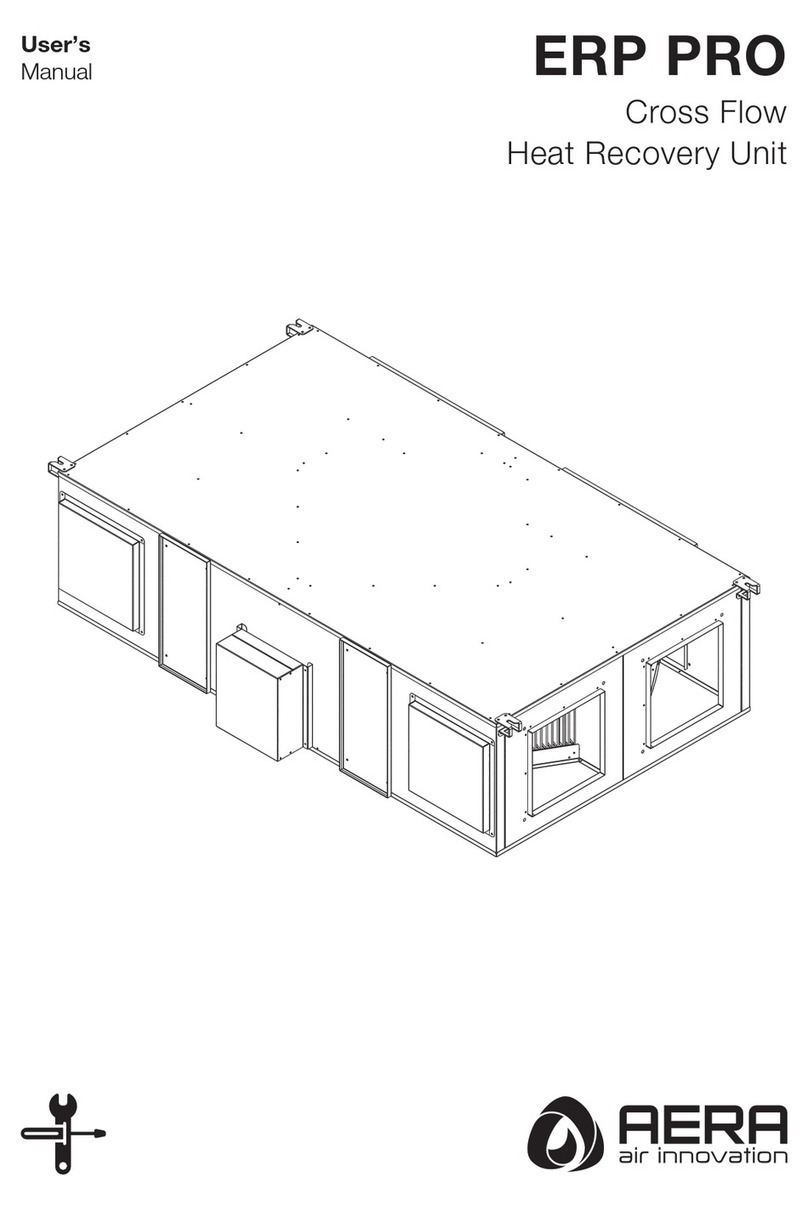

1.5 Transport

The unit is packed ex works in a timber frame so that it is protected against normal transport strain. Carry out the shipping

carefully. It is recommended to leave the unit in the original packaging until installation to avoid possible damages

and soiling.

The transport must be carried out by trained and experienced personnel and the necessary safety precautions should be taken

to prevent overturning and slipping of the device. During transport of the devices it should be ensured that the weight is evenly

distributed over the four corners.

Danger due to overhead loads –risk of grave injuries ordeath!

- Never stand beneath suspended loads, since there is always a risk that the lifting gear, tackle, ropes or slings are faulty or

damaged.