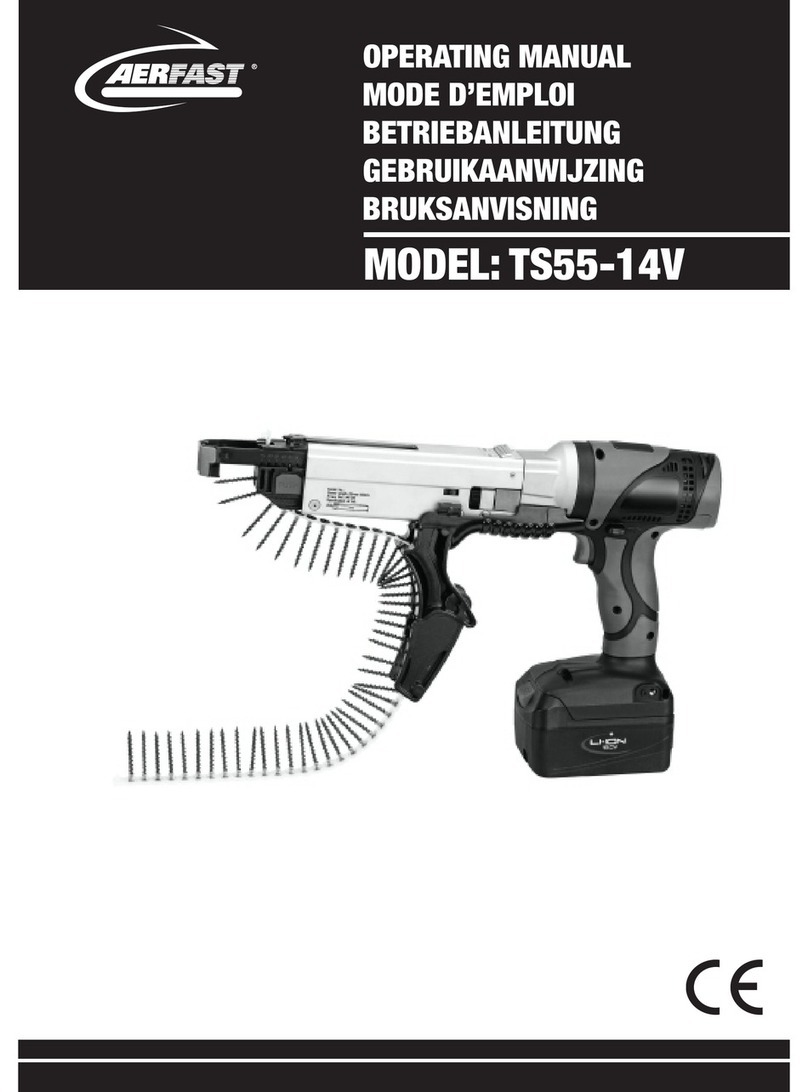

Aerfast TS55-14V User manual

MODEL: TS55-14V

1

DÉCLARATION «CE » DE CONFORMITÉ

NOTIFICATION OF EC CONFORMITY

EG-KONFORMITÄTSERKLÄRUNG

Le constructeur / l’importateur / le responsable de la mise sur le marché :

Der Verkaüfer / der Importeur / der Verantwortliche für die Einführung auf dem Markt

The manufacturer / the importer / the person in charge of marketing

SOFRAGRAF

29, rue de la Gare

Saint Amé

88125 Vagney Cedex –France

Nous déclarons sous notre propre responsabilité que l’appareil désigné ci-dessous

We declare on our own responsibility, that the undermentioned tool

Wir erklären unter unserer eigenen Verantwortung, daß das nachstehend bezeichnete Gerät

Marque / Trademark / Marke / Merk :Aerfast

Type / Type / Typ /TS55-14V -AFK0000

Visseuse à batterie /Cordless screwgun

Matricule ; Seriennummer ; Number : ------

Année de construction ; Baujahr ; Year of construction

est conforme aux dispositions des Directives suivantes :

is in accordance with the following specifications and standardised documents :

mit den folgenden harmonisierten Normen und Unterlagen übereinstimmt :

2004/108 CE

2006/42 CE

2002/95 CE

Saint Amé, le :26 mai 2011

Nom du signataire : Estelle THIRIET

Fonction :Service qualité / Quality Department

Signature :

Processus : Sécurité, environnement, réglementation Page 1/1

Sous processus :Indice C

Document : Déclaration de conformité "CE" Par : E. Thiriet

2

0BOperating

4BInstructions

1BCORDLESS AUTOFEED SCREW DRIVER

MODEL :

TS55-14V

3

△,!WARNING

Operational Precautions

General Safety Instructions

1. Consider work area environment. Do not expose tools to rain. Do not

use tools in damp or wet locations:Keep work area clean and well lit. Do

not use tools in the present of flammable liquids or gases.

2. Guard against electric shock. Avoid body contact with earthed or

grounded surfaces.

3. Keep children away. Do not let visitors touch the tools or extension cord.

All visitors should be kept away from work area.

4. Store idle tools. When not in use, tool should be stored in a dry locked

up place, out of reach of children.

5. Do not force the tool. It will do the job better and safer at the rate for

which it was intended.

6. Stay alert. Watch out what you are doing:Use common sense. Do not

operate tool when you are tired. Check damaged parts. Before further

use of the tool, a guard or other part is damaged should be carefully

checked to determine that it will operate properly and perform its

intended function.

7. Check for alignment of moving parts, blinding of moving parts, breakage

of parts, mounting and any other condition that may affect its operation.

8. A guard or other parts that is damaged should be properly repaired or

replaced by an authorized service center unless otherwise indicated in

this instruction manual. Have defective switches replaced by an

authorized service center. Do not use tool if switch does not turn it on.

9. To ensure the designed operational integrity of power tools, do not

remove installed cover or screws.

10. Use your tool at lower input than specified on the nameplate, otherwise,

the finish may be spoiled and working efficiency reduced by motor

overload.

11. Do not wipe plastic parts with solvent. Solvents such as gasoline,

thinner, benzene, carbon tetrachloride, alcohol, ammonia and oil

containing chloric annex may damage and crack plastic parts. Do not

wipe them with such solvent. Wipe plastic parts with a soft cloth lightly

dampened with soap water.

12. Dress properly. Do not wear loose clothing or jewelry. Contain long hair

keep your hair, clothing, and gloves away from moving parts.

13. Use safety equipment. Always wear eye protection, non-skid safety

shoes, hard hat, or hearing protection.

14. Do not overreach. Proper footing and balance enables better control of

the tool in unexpected situations.

4

△,!WARNING

1. Disconnect battery pack from tool or place the main switch in the locked

or off position before making any adjustments, changing accessories, or

storing the tool. Such preventative safety measures reduce the risk of

starting the tool accidentally.

2. Remove adjusting keys or wenches before turning the tool on . A wrench

or a key that is left attached to a rotating part of the tool may result in

personal injury.

3. Use clamps or other practical way to secure and support the work piece

to a stable platform. Holding the work by hand or against your body is

unstable and may lead to a loss of control.

4. Maintain tools with care. Keep cutting tools sharp and clean. Properly

maintained tools, with sharp cutting edges are less likely to bind and are

easier to control.

5. Use only accessories that are recommended by the manufacturer for

your model. Accessories that may be suitable for one tool may create a

risk of injury when used on another tool.

Product Safety Instructions

△,!WARNING

1. Caution:To reduce risk of injury, charge only specific type rechargeable

battery packs. Other types of battery packs may burst causing personal

injury and damage.

2. Before using charger, read all instructions and cautionary markings on

battery packs and chargers.

3. Do not expose charger to rain or snow.

4. To reduce the risk of damage to electric plug and cord, pull by plug

rather than cord when disconnecting charger.

5. Use of an attachment not recommended or sold by the charger

manufacture may result in a risk of fire, electric shock, or injury to

persons.

6. Make sure cord is located so that it will not be stepped on, tripped on,

tripped over, or otherwise subjected damage or stress.

7. Do not operate charger with damaged cord or plug. Replace them

immediately.

8. Do not operate charger if it has received a sharp blow, been dropped, or

otherwise damage in any way, take it to qualified center.

9. To reduce risk of electric shock, unplug charger from outlet before

attempting any maintenance or cleaning. Turning off controls will not

reduce this risk.

10. Do not disassemble charger or battery pack, take it to a qualified service

center while repair is required. Incorrect reassembling may result in a

risk of electric shock or fire.

Important Safety Instructions for Charger & Battery Pack

5

△,!WARNING

1. Do not charge battery pack when temperature is below 10°C (50°F) or

above 40°C (104°F).

2. Do not attempt to use a set-up transformer, an engine generator or DC

power receptacle.

3. Do not allow anything to cover or clog the charger vents.

4. Always cover the battery pack terminals with the battery pack cover

when the battery pack: is not used.

5. Do not short the battery pack:

6. Do not touch the terminals with any conductive material.

7. Avoid storing battery pack in a container with other metal objects

such as nails, coins, etc.

8. Do not expose battery pack to water or rain, A battery pack short can

use large current flow, overheating, possible burns and even a

breakdown.

9. Do not store the machine and battery pack in locations where the

temperature may reach or exceed 50°C (122°F)

10. Do not incinerate the battery pack even if it is severely damaged or

completely worn out. The battery pack can explode in a fire.

11. Be careful not drop, shake or strike battery pack.

12. Do not charge inside a box or container of any kind. The battery pack

must be placed in a well ventilated area during charging.

13. For extension of the battery lifetime, the lithium-ion battery is designed

with the protection function to stop the output.

In the case of described below, when using this product, even if you are

pulling the switch, the motor may stop.

This is not malfunction but the result of protection function.

When the battery power remaining runs out, the motor stops.

If the tool is overloaded, the motor may stop.

In this case, release the switch of tool and eliminate causes of

overloading. After that you can use it again.

If the battery is overheated under overload work, the battery power

may stop. In this case stop using the battery and let the battery cool.

After that you can use it again.

14. Do not leave batteries unused for extended period of time. Recharge

the battery every 3~6 months and bring Li-Ion battery to 40~80%

charge level before storage.

15. Li-Ion batteries are sensitive to high temperature and should be kept in

a cool, dry and out of direct light exposure. Ideal temperature for

operation and storage is below 77°F.

Additional Safety Rules for Charger & Battery Pack

6

Specifications

Model No.

TS55-14V

Voltage

14.4 V d.c.

No-Load Speed

4500 r.p.m(/min)

Max Torque

17.6 kg-cm(1.27ft-lb)

Size

L376 x W80 x H254 mm

Tool Weight

(With Battery)

2.17 kg

(Battery0.53kg)

Fastener Range

25-55 mm length

Bit Spec.

1/4”x154L mm

Charging Time

1 Hour Auto Cut-Off

Specific Safety Rules and/or Symbols

--------Recycle ------Class II Tool

--------Do Not Throw In Garbage V--------Volts

a.c.------Alternating Current Hz-------Hertz

W--------Watts kg-------Kilograms

mm------Millimeter d.c. -----Direct Current

kg-cm--Kilograms Per Centimeter ft-lb------Foot-Pound

/min-----Revolutions or Reciprocations Per Minute

7

6BView of the Major Components

Accessories

Forward/Reverse Rod

Battery Pack

Main Switch

Battery Knob

Conduction Ass’y

Bit

Wrench

Hook

Hook Screw

Charger

Screw Length Adjust Knob

Non Slip Pad

Reverse Knob

Depth Control Knob

8

Operating Instructions (Slide-In)

Installing or Removing Battery Pack

(See Fig.1 Fig.2 )

1. Always switch off the machine before insertion or

removal of the battery pack.

2. To remove the battery pack, push the button on the

battery pack and pull the tool unit from the battery

pack in the direction.

3. To insert the battery pack, align the tool unit slides

with the battery pack sliding groove and push the tool

unit into place.

The tool unit can be slide into battery pack in two

directions.

4. Do not force the battery pack in sliding it into tool unit.

If the battery pack does not slide in easily, it is not

being inserted correctly.

Charging the Battery Pack (See Fig.3)

1. Plug the fast charger into the power source.

2. Slide the battery pack into the charger as the arrow

direction shown on the charger.

3. Push the battery pack into place and make sure the

red light on the charger is “ON”. The battery pack is

now starting the charging cycle.

4. After finish the charging cycle, the light will turn into

green. The battery pack is now ready for use.

5. Your new battery pack is not charged. You need to

charge it before use.

6. If you try to charge a battery pack from a just-operated

machine, sometimes the charging light will not come

on. If this occurs, let the battery pack cool for a while

then re-insert it and try to charge again.

7. When you charge a new battery pack or a battery

pack which has not been used for a long period, it

may not accept a full charge. This is a normal

condition and does not indicate a problem. You can

recharge the battery pack fully after discharging it

completely a couple of times.

8. While charging the second battery, allow the charger

to cool down for 15 minutes before start the second

charging process.

9. Unplug the charger from the power source after finish

the charge.

Fig.1

Fig.2

Fig.3

1

2

9

LED Indication Function

The Battery Pack has a “SW” button and 4-step green LEDs for indicating

remaining capacity status and Over temperature condition.

The remaining capacity (RC) and temperature protection status green LED

indications ( 3 second ) when the “SW” button is momentarily pressed.

Power On (Green light flashes slowly)

Battery Low (Red light stays illuminated)

Battery charged 80% (Green light flashes rapidly)

Battery charged 100% (Green light stays illuminated)

Battery Pack temperature is too hot or too cold (Red light flashes slowly)

Battery Pack malfunction (Red and Green lights stay illuminated)

Remaining Capacity LED Indication

RC Status

LED 1 (green)

0%- 25%

LED 1, 2 (green)

26%-50%

LED 1, 2, 3 (green)

51%-75%

LED 1, 2, 3, 4 (green)

76%-100%

LED 1 Blinking (0.25Sec/green)

Fully Depleted

LED 1, 2, 3, 4 Blinking (0.5sec/ green)

Over Temperature condition

The LED Light on the Charger

10

△,!WARNING

1. Charger is plugged into a 100-240V a.c outlet only.

2. If the battery pack is too hot or too cold, the charger will not fast charge the

battery pack and the red Indicator light is “blinking”. When the battery pack

temperature returns to between 0°C (32°F) and 50°C(122°F), The charger

will automatically begin charging.

3. If both red and green indicator lights are “ON” the battery pack either does not

comply or is defective. Please contact your retailer.

4. Do not charge the battery pack in the rain, snow or high temperature

environment.

5. Do not charge battery pack when environment temperature is below

0°C (32°F)or above 40°C(104°F).

6. While charge the cool battery pack (below 0°C(32°F) in the warm indoor, keep the

battery pack in the room for one hour to warm up before starting the battery

pack.

A cool battery may charge unsaturated.

7. Remove the plug after finishing the charge.

8. The charger should be cooled at least one hour after continue charging three

times.

9. Do not use generator for charging the battery pack.

11

2BStrip Installation

1.Check the scale of the adjust is

totally consistent with length of the

screw.

This tool can be used in the following screw sizes.:

d(mm)

Φ3.5~Φ4.5mm

(#6~#8)

L(mm)

25

30

35

40

45

50

55

3. Feed the strip into the strip guide.

Screw Length

Screw Length Adjust Knob

Scale

Press

2.Press the screw length adjust knob

for the correct length of the screw.

Release the knob when the auto feed

assembly has adjusted to the proper

position. Please adjust the length of

screw first. Do not adjust the length

when the collated screw is on.

12

Tool Operation

4. Move the strip forward until the

2nd empty slot is aligned with

the bit. This will allow for the

proper strip advancement once

the nosepiece is depressed.

2. Whenever possible, hold the

tool at a right angle to the

work surface.

Forward/Reverse Rod

(2)

(1)

Main Switch

1. Make sure the forward/reverse

rod direction ( )。

3.

(1)Pull the main switch to start

the motor.

(2)Press the conduction, with

constant force, against the

work surface.

Do not remove the tool from

the work surface until the

clutch disengages and the

bit stops rotating, signaling a

fully driven screw.

13

Depth Control Knob

6. This tool has a depth sensing

clutch. When the screw is

countersunk to the pre-set

depth, it automatically

disengages and makes a

click or racheting sound. This

is normal and signals

completion of the drive.

4.Continue to allow the motor

to run.The next screw will be

automatically fed into place

when the tool is depressed

against the work surface.(3)

(3)

Depth Display

5. The depth display shows the

depth level. Adjust the depth

control knob for appropriate

depth. Please do not adjust

the depth control knob when

the depth display shows the

maximum level.

14

To Remove the Screws

Replaceable Non Slip Pad

Caution

When the battery pack is low or the drive requires too much torque, the

tool may stall at the bottom of the drive (before the clutch can disengage).

Continuous operation in this manner can cause over-heating and

permanent damage.

Reverse direction

Reverse knob

Press

1.

(1)Remove the strip, pull it through

from the top of the nosepiece.

Pull the collated screw upward

for removing.When the screw

is out of position or stuck, push

the reverse knob while pulling

the collated screw downward at

the same time.

Push the forward / reverse rod

to reverse side ( ).

Depress nose piece while

inserting bit into screw.

(2)Maintain forward pressure on

tool.

(3)Pull the main switch to start

motor. Continue operation until

screw is completely

disengaged.

(2)

(1)

(3)

Main Switch

Forward /Reverse Rod

1. The non slip pad is self

replaceable if damaged or

dirty.

15

Change the Driving Bit

Note: Use the bit provided by the manufacturer.

`

1. Use 4mm hex wrench to

loose screw.

2. Remove conduction

ass’y.

3. Pull the ring-pull and

replace the bit.

After replacement

assemble conduction

ass’y and lock in

screw.

Conduction Ass’y

Screw

Bit

Ring-Pull

4. Hex wrench can be

placed here after use.

16

Installing Or Removing Hook

1. Installing Hook:

Use Phillips or slotted bit size bit and tighten in clockwise.

2. Removing Hook:

Use Phillips or slotted bit size bit to loosen the hook.

(1)

(2)

17

18

4BInstructions

utilisateur

1BVVisseuse automatique à batterie pour vis

en bandes.

19

PRECAUTIONS

Lire ce manuel utilisateur avant d’utiliser la machine. Une mauvaise utilisation

pourrait entraîner des risques de blessure.

Conserver ce manuel pour un éventuel besoin future.

Les termes “appareil “ ou « machine » ou « outil » employé ci-après désigne

la visseuse automatique.

1) Zone de travail

a) Garder la zone de travail propre, éclairée correctement et dégagée.

b) Ne pas utiliser l’outil en atmosphère potentiellement explosive,

comme en présence de liquide ou gaz inflammables.

Un appareil électrique peut en effet produire des étincelles.

c) Tenir les enfants et les personnes non nécessaires au chantier à

distance.

2) Sécurité électrique

a) La fiche électrique doit être compatible avec la prise réseau

disponible. Ne jamais modifier une prise électrique.

b) Ne pas exposer l’appareil à la pluie ou le plonger dans l’eau. De

l’eau entrant dans un ajpareil électrique accroît le risque de chocs

électriques.

c) Ne jamais détériorer le cordon. Ne pas utiliser le cordon pour porter,

tirer ou débrancher l’appareil du réseau électrique. Préserver le cordon

de la chaleur, des produits pétroliers, angles vifs coupants ou pièces

en mouvement.

d) En cas d’utilisation en extérieur, utiliser une rallonge électrique

adaptée à une telle utilisation.

3) Sécurité individuelle

a) Rester vigilant et attentif avec un outil en main.

b) Porter tout EPI (Equipement de Protection Individuel) requis par le

type de travail effectué.

20

Other manuals for TS55-14V

1

Table of contents

Languages:

Other Aerfast Nail Gun manuals

Popular Nail Gun manuals by other brands

BEA

BEA 71/16-421S Additional instructions

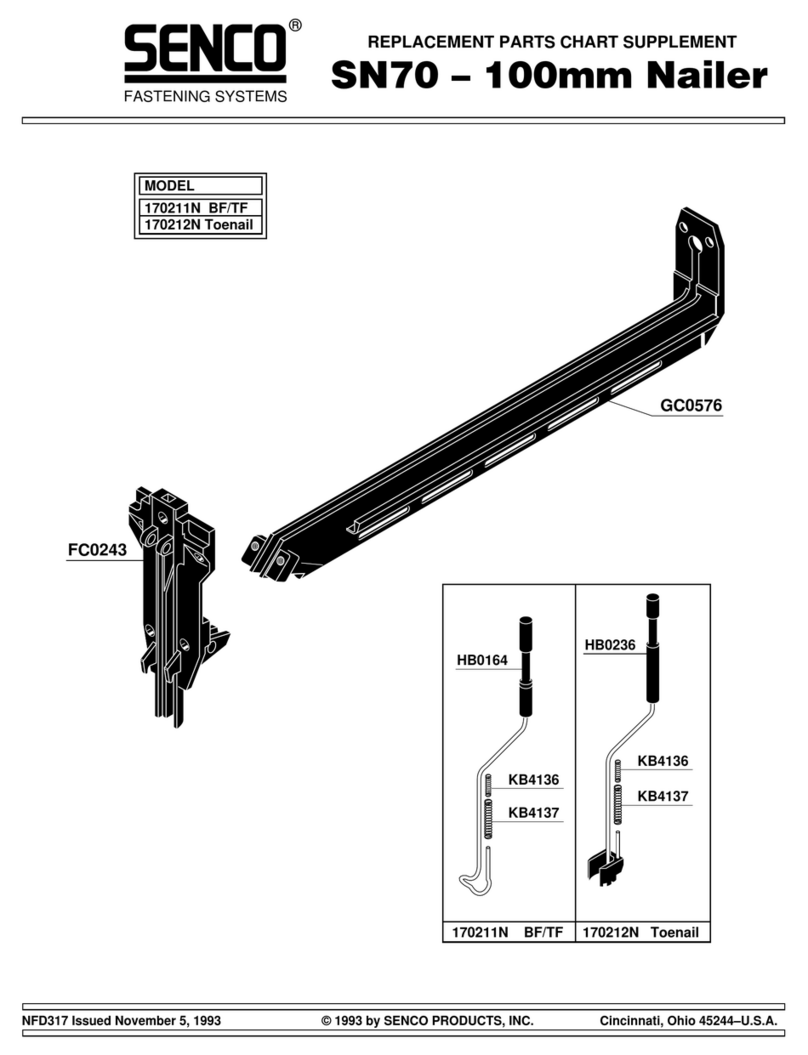

Senco

Senco 100mm nailer SN70 Replacement parts

Campbell Hausfeld

Campbell Hausfeld IN180300AV Specifications and parts list

Bostitch

Bostitch N79WW Operation and maintenance manual

Bosch

Bosch FNH180K-16 Operating/safety instructions

Husky

Husky H125BN Operator's manual

Schneider Airsystems

Schneider Airsystems KLG 90-40 SYS Original operating manual

Senco

Senco Fusion F-15XP operating instructions

DeWalt

DeWalt DWFP12569 instruction manual

Bostitch

Bostitch N62FN Operation and maintenance manual

Asist

Asist AE2ST03DN Instructions for use

Campbell Hausfeld

Campbell Hausfeld SB504000 operating instructions