Aerfast TS55-AC User manual

MODEL: TS55-AC

WARNING Read all safety warnings and instructions. Failure to follow

the warnings and instructions may result in electric shock, fire and/or serious

injury.

Save all warnings and instructions for future reference.

The term ″power tool″ in the warnings refers to your mains-operated

(corded) power tool or battery-operated (cordless) power tool.

1) Work area safety

a) Keep work area clean and well lit. Cluttered or dark areas invite

accidents.

b) Do not operate power tools in explosive atmospheres, such as in

the presence of flammable liquids, gases or dust. Power tools create

sparks which may ignite the dust or fumes.

c) Keep children and bystanders away while operating a power

tool. Distractions can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet. Never modify the plug in

any way. Do not use any adapter plugs with earthed (grounded)

power tools. Unmodified plugs and matching outlets will reduce risk of

electric shock.

b) Avoid body contact with earthed or grounded surfaces such as

pipes, radiators, ranges and refrigerators. There is an increased risk

of electric shock if your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water

entering a power tool will increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling

or unplugging the power tool. Keep cord away from heat, oil,

sharp edges or moving parts.

Damaged or entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord

suitable for outdoor use. Use of a cord suitable for outdoor use

reduces the risk of electric shock.

f) If operating a power tool in a damp location is unavoidable, use

a residual current device (RCD) protected supply. Use of an RCD

reduces the risk of electric shock.

1BOPERATING INSTRUCTIONSOPERATING INSTRUCTIONS

AUTOFEED SCREW DRIVER MODEL TS55-AC

1

NOTE The term ″residual current device (RCD)″ may be replaced by

the term ″ground fault circuit

interrupter (GFCI)″ or ″earth leakage circuit breaker (ELCB)″.

3) Personal safety

a) Stay alert, watch what you are doing and use common sense

when operating a power tool. Do not use a power tool while you are

tired or under the influence of drugs, alcohol or medication. A

moment of inattention while operating power tools may result in serious

personal injury.

b) Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask, non-skid safety

shoes, hard hat, or hearing protection used for appropriate conditions

will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the

off-position before connecting to power source and/or battery

pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or energising power

tools that have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power

tool on. A wrench or a key left attached to a rotating part of the power

tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at all times.

This enables better control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewellery. Keep

your hair, clothing and gloves away from moving parts. Loose

clothes, jewellery or long hair can be caught in moving parts.

g) If devices are provided for the connection of dust extraction and

collection facilities, ensure these are connected and properly used.

Use of dust collection can reduce dust-related hazards.

4) Power tool use and care

a) Do not force the power tool. Use the correct power tool for

your application. The correct power tool will do the job better and

safer at the rate for which it was designed.

2

b) Do not use the power tool if the switch does not turn it on and

off. Any power tool that cannot be controlled with the switch is

dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the battery

pack from the power tool before making any adjustments,

changing accessories, or storing power tools. Such preventive

safety measures reduce the risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do not

allow persons unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of

moving parts, breakage of parts and any other condition that

may aect the power tool’s operation. If damaged, have the

power tool repaired before use. Many accidents are caused by

poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting

tools with sharp cutting edges are less likely to bind and are easier to

control.

g) Use the power tool, accessories and tool bits etc. in

accordance with these instructions, taking into account the

working conditions and the work to be performed. Use of the

power tool for operations dierent from those intended could result in

a hazardous situation.

5) Service

a) Have your power tool serviced by a qualified repair person using only

identical replacement parts. This will ensure that the safety of the power

tool is maintained.

Hold power tool by insulated gripping surfaces, when

performing an operation where the fastener may contact hidden wiring or

its own cord. Fasteners contacting a ”live” wire may make exposed metal parts

of the power tool ”live” and cold give the operator an electric shock.

3

△,!WARNING

Operational Precautions

General Safety Instructions

1. Consider work area environment. Do not expose tools to rain. Do not

use tools in damp or wet locations:Keep work area clean and well lit. Do

not use tools in the present of flammable liquids or gases.

2. Guard against electric shock. Avoid body contact with earthed or

grounded surfaces.

3. Keep children away. Do not let visitors touch the tools or extension cord.

All visitors should be kept away from work area.

4. Store idle tools. When not in use, tool should be stored in a dry locked

up place, out of reach of children.

5. Do not force the tool. It will do the job better and safer at the rate for

which it was intended.

6. Stay alert. Watch out what you are doing:Use common sense. Do not

operate tool when you are tired. Check damaged parts. Before further

use of the tool, a guard or other part is damaged should be carefully

checked to determine that it will operate properly and perform its

intended function.

7. Check for alignment of moving parts, blinding of moving parts, breakage

of parts, mounting and any other condition that may affect its operation.

8. A guard or other parts that is damaged should be properly repaired or

replaced by an authorized service center unless otherwise indicated in

this instruction manual. Have defective switches replaced by an

authorized service center. Do not use tool if switch does not turn it on.

9. To ensure the designed operational integrity of power tools, do not

remove installed cover or screws.

10. Use your tool at lower input than specified on the nameplate, otherwise,

the finish may be spoiled and working efficiency reduced by motor

overload.

11. Do not wipe plastic parts with solvent. Solvents such as gasoline,

thinner, benzene, carbon tetrachloride, alcohol, ammonia and oil

containing chloric annex may damage and crack plastic parts. Do not

wipe them with such solvent. Wipe plastic parts with a soft cloth lightly

dampened with soap water.

12. Dress properly. Do not wear loose clothing or jewelry. Contain long hair

keep your hair, clothing, and gloves away from moving parts.

13. Use safety equipment. Always wear eye protection, non-skid safety

shoes, hard hat, or hearing protection.

14. Do not overreach. Proper footing and balance enables better control of

the tool in unexpected situations.

4

△,!WARNING

1.

To ensure the designed operational integrity of power tools, do not

remove installed cover or screws.

2.

Use your tool at lower input than specified on the nameplate, otherwise,

the finish may be spoiled and working efficiency reduced by motor

overload.

3.

Do not wipe plastic parts with solvent. Solvents such as gasoline,

thinner, benzene, carbon tetrachloride, alcohol, ammonia and oil

containing chloric annex may damage and crack plastic parts. Wipe

plastic parts with a soft cloth lightly dampened with soap water.

4.

Use clamps or other practical way to secure and support the work piece

to a stable platform. Holding the work by hand or against your body is

unstable and may lead to a loss of control.

Product Safety Instructions

5.Use only accessories that are recommended by the manufacturer for

your model. Accessories that may be suitable for one tool may create a

risk of injury when used on another tool.

Specific Safety Rules and/or Symbols

--------Recycle

--------Do Not Throw In Garbage

------Class II Tool

V--------Volts

a.c.------Alternating Current Hz-------Hertz

W--------Watts

mm------Millimeter

kg-cm--Kilograms Per Centimeter

kg-------Kilograms

d.c. -----Direct Current

ft-lb------Foot-Pound

/

min-----Revolutions or Reciprocations Per Minute

5

View of the Major Components

Reverse Button

Forward/Reverse Rod

Main Switch

Conduction Ass’y

Power Cord

Carbon Brush Panel

Anti-slip Pad

Depth Control Knob

Screw Length Adjust Button

Specifications

Model No. TS55-AC

Voltage 220V a.c.

No-Load Speed 4200 r.p.m(/min)

Max. Torque 80 kg-cm/7.8 N-m/5.8ft-lb

Tool Weight 1.9kg

Volume L430 x W80 x H190mm

Fastener Range 25-55 mm length

Bit Spec 1/4” x 173Lmm

Quick Release Button

6

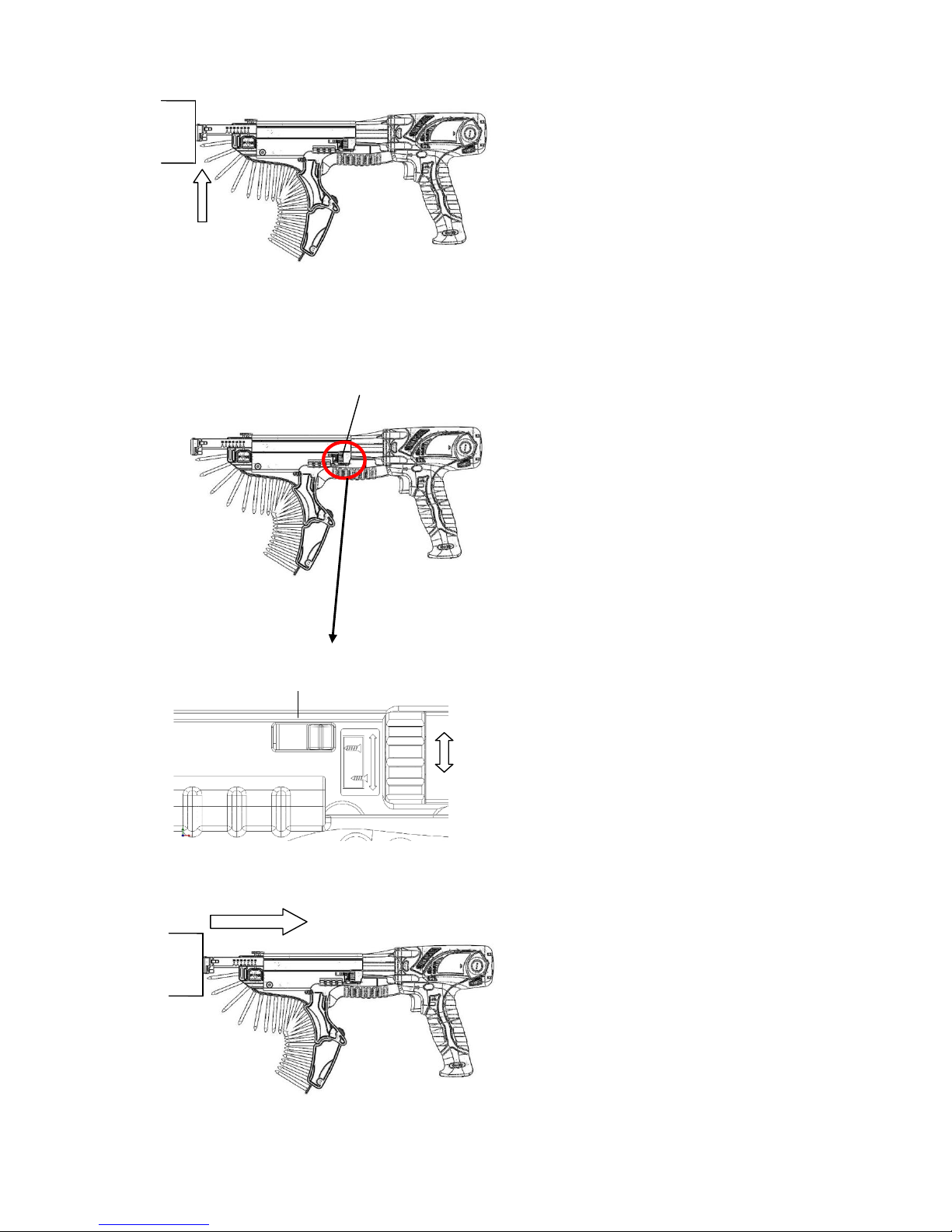

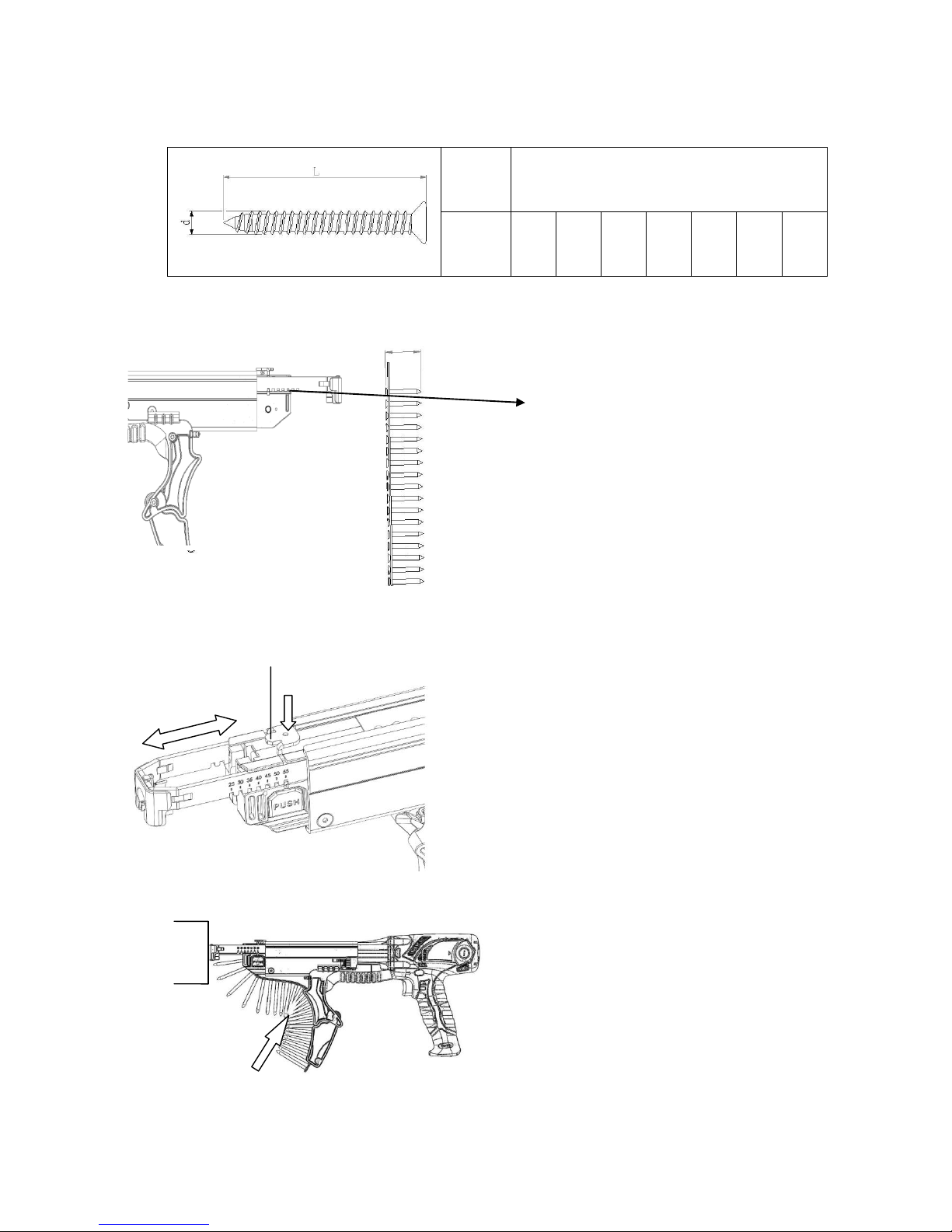

2BStrip Installation

1.Check the scale of the adjust is

totally consistent with length of the

screw.

2.Press the screw length adjust knob

for the correct length of the screw.

Release the knob when the auto feed

assembly has adjusted to the proper

position. Please adjust the length of

screw first. Do not adjust the length

when the collated screw is on.

This tool can be used in the following screw sizes.:

d(mm)

Φ3.5~Φ4.5mm

(#6~#8)

L(mm)

25

30

35

40

45

50

55

3. Feed the strip into the strip guide.

Screw Length

Screw Length Adjust Knob

Scale

Press

7

Tool Operation

4. Move the strip forward until the

2nd empty slot is aligned with

the bit. This will allow for the

proper strip advancement once

the nosepiece is depressed.

2. Whenever possible, hold the

tool at a right angle to the

work surface.

1. Make sure the forward/reverse

rod direction ( )。

Forward/Reverse Rod

(2)

3.

(1)Pull the main switch to start

the motor.

(2)Press the conduction,with

constant force, against the

work surface.

Do not remove the tool from

the work surface until the

clutch disengages and the

bit stops rotating, signaling a

fully driven screw.

(1)

Main Switch

8

Depth Control Knob

6. This tool has a depth sensing

clutch.When the screw is

countersunk to the pre-set

depth,it automatically

disengages and makes a

click or racheting sound. This

is normal and signals

completion of the drive.

4.Continue to allow the motor

to run.The next screw will be

automatically fed into place

when the tool is depressed

against the work surface.(3)

5. The depth display shows the

depth level. Adjust the depth

control knob for appropriate

depth. Please do not adjust the

depth control knob when the

depth display shows the

maximum level.

(3)

Depth Display

9

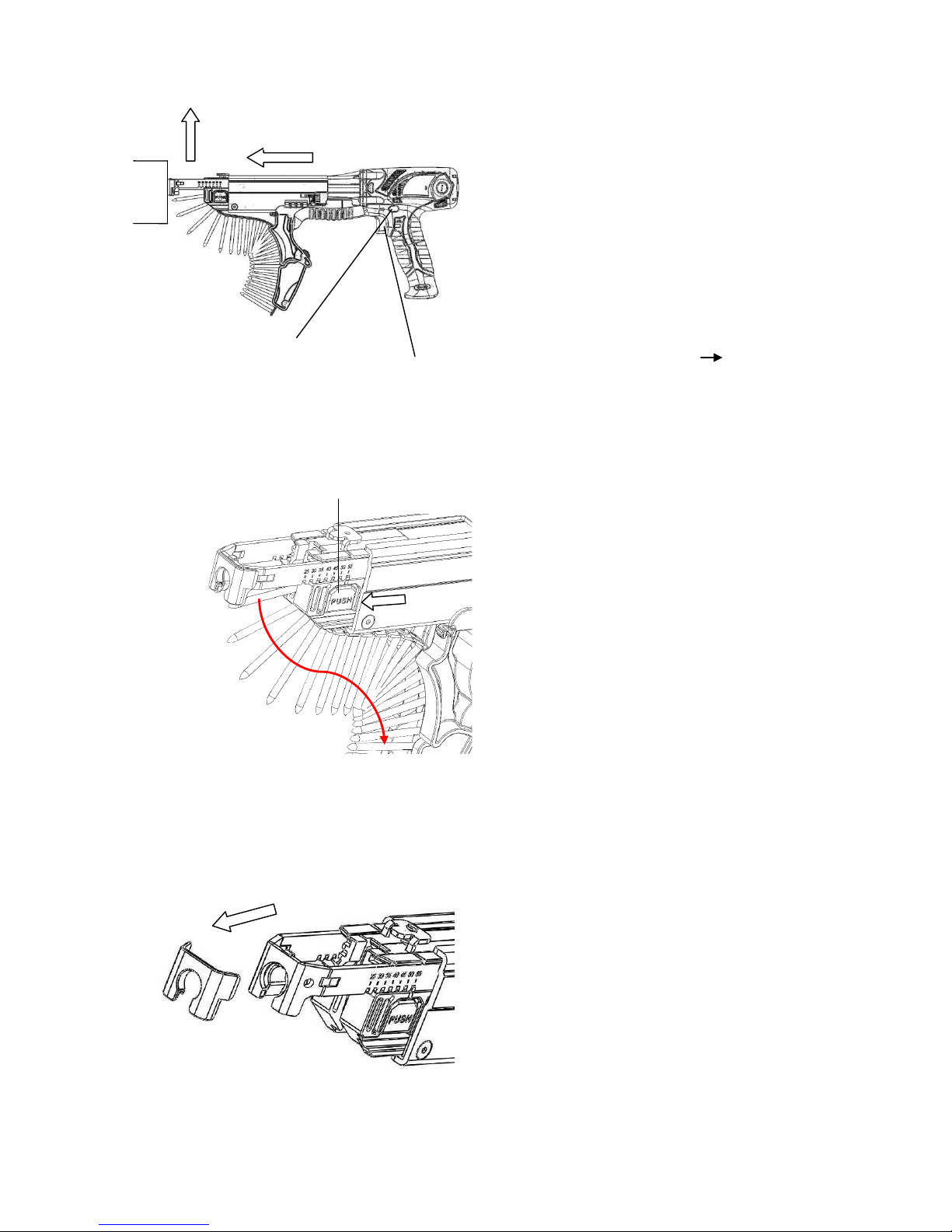

To Remove the Screws

Replaceable Non Slip Pad

Reverse direction

Reverse knob

Press

1.

(1)Remove the strip, pull it through

from the top of the nosepiece.

Pull the collated screw upward

for removing.When the screw

is out of position or stuck, push

the reverse knob while pulling

the collated screw downward at

the same time.

Push the forward / reverse rod

to reverse side ( ).

Depress nose piece while

inserting bit into screw.

(2)Maintain forward pressure on

tool.

(3)Pull the main switch to start

motor. Continue operation until

screw is completely

disengaged.

(3)

Main Switch

Forward /Reverse Rod

(2)

(1)

1.The non slip pad is self

replaceable if damaged or

dirty.

10

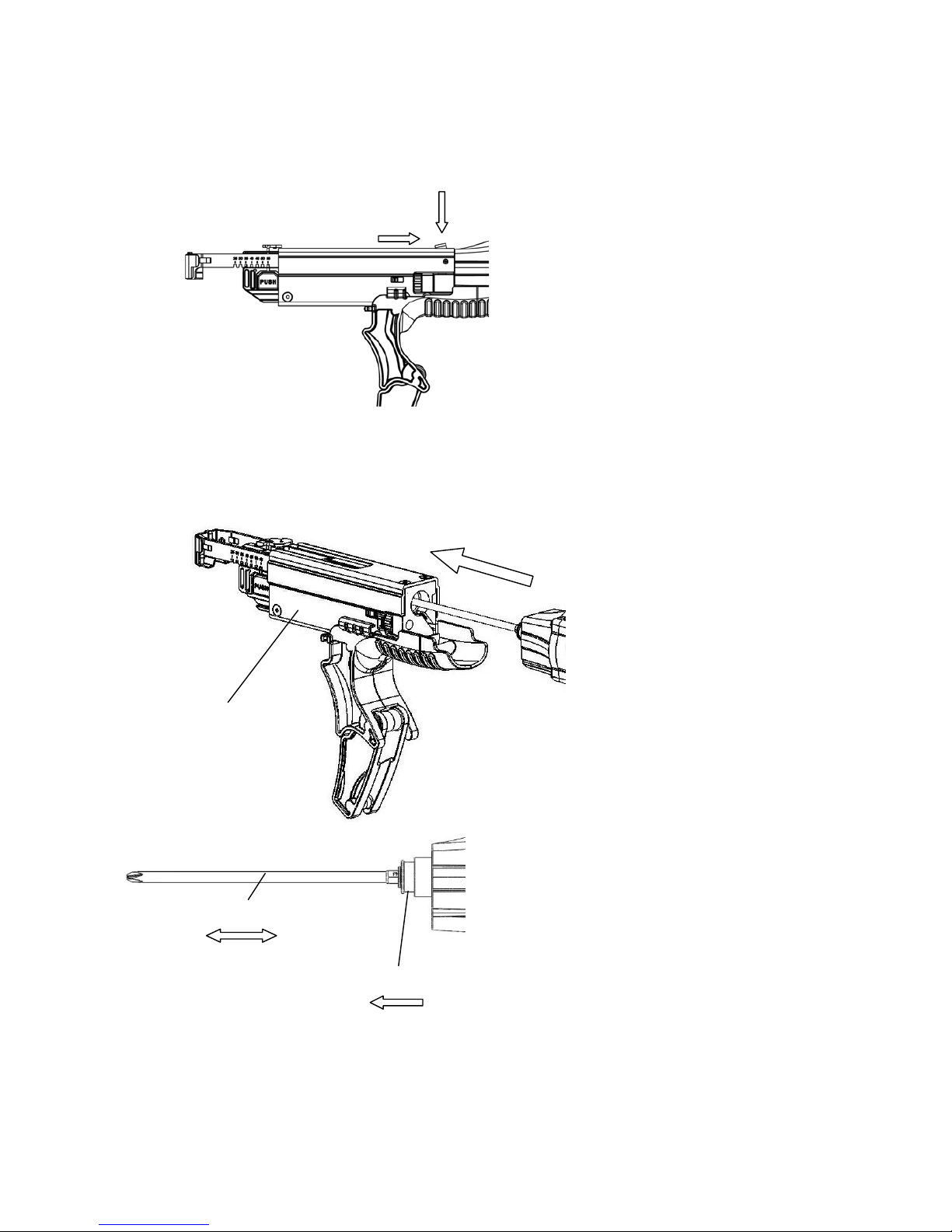

Change the Driving Bit

Note: Use the bit provided by the manufacturer.

1.

(1) Push the quick release button

backward first.

(2) then press down to loose

conduction ass'y.

2. Remove conduction

ass’y.

3. Pull the ring-pull and

replace the bit.

After replacement ﹐

assemble conduction

ass’y and lock in

screw.

Conduction Ass’y

Bit

Ring-Pull

(1) (2)

11

Installing Extended Rod Ass’y

1.. Remove conducti

ass’y and bit.

Conduction Ass’y Bit

3.

(1) Push the ring backward.

(2) Inject the bit.

2.

(1) Pull the ring-pull.

(2) Inject the extended

spindle.

(3) Inject the extended

rod.

※Pull the ring-pull of

the extended rod

can separate the

extended rod.

(2) (1)

Bit Ring

Ring-pull

(2) (1)

(3)

Extended Rod

Ring-pull

Conduction Ass’y

Extended Rod

Handle

4.. Inject the conducti

ass’y .

The handle can be

adjusted 360 degrees,

based on the user's setting

(to tighten: clockwise/ to

loose: anti-clockwise)

Extended Spindle

12

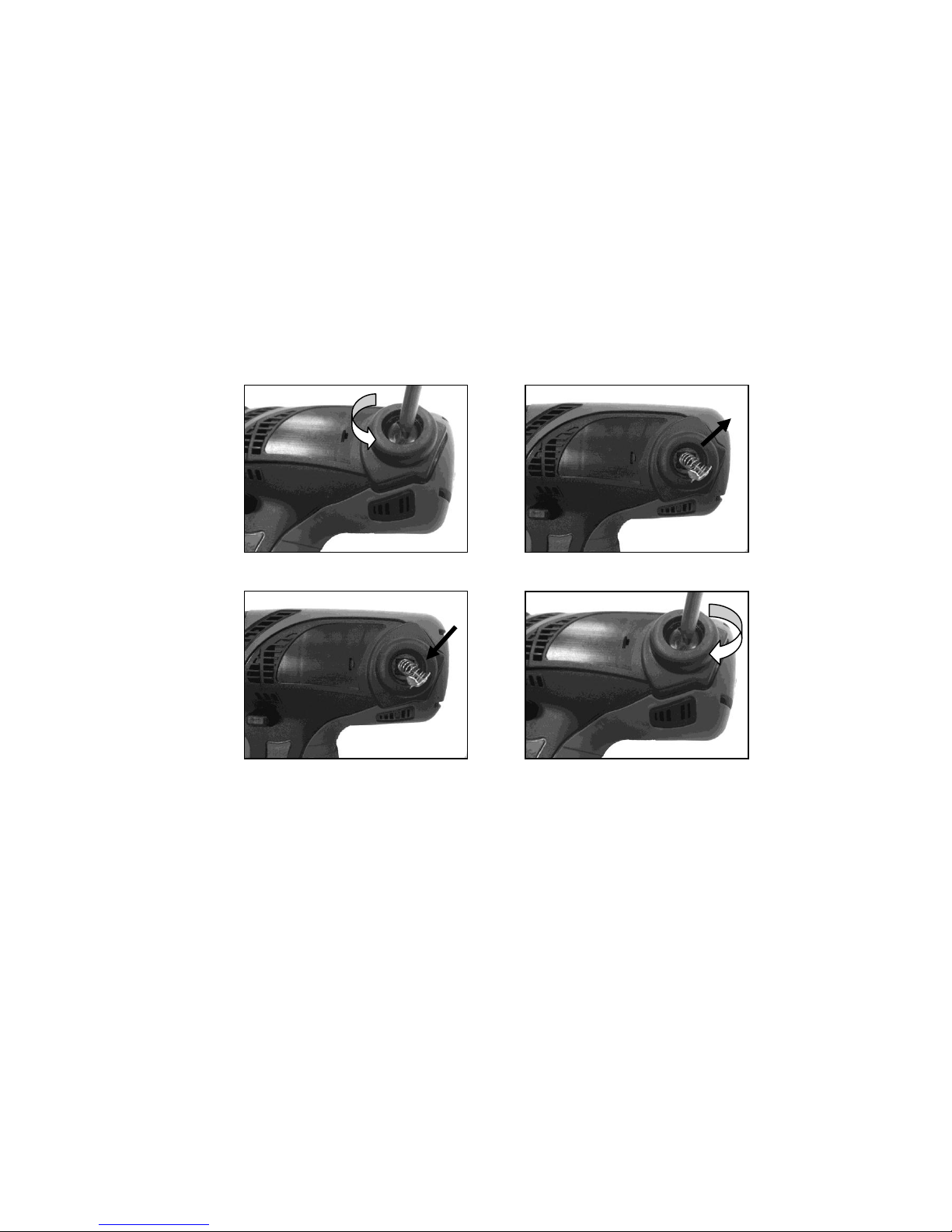

Replaceable Carbon Brush

1. Replace the new carbon brush, while the motor is not rotated and the

carbon brush is run out.(Change the new motor after the carbon brush has

been replaced 2~3 times)

2. Replacement procedure is as follows:

Loose the carbon brush panel counterclockwise by using slotted

bit.(Fig.1).

Take out the carbon brush ( Fig.2 ).

Put the new carbon brush and carbon brush panel back into the housing

in proper order. (Fig.3)

Lock the carbon brush panel back clockwise by using slotted bit. (Fig. 4)

Caution

Always be sure that the machine is switched off and is unplugged from the

power outlet removed before carrying out any work on the machine.

To maintain product safety and reliability, repairs, maintenance or adjustment

should be carried out by an authorized service center.

Fig.3

Fig.1

Fig.2

Fig.4

13

PRECAUTION

Lire ce manuel utilisateur avant d’utiliser la machine. Une mauvaise utilisation

pourrait entrâiner des risques de blessure.

Conserver ce manuel pour un éventuel besoin future.

Les termes “appareil “ ou « machine » ou « outil » employé ci-après

désigne la visseuse automatique.

1) Zone de travail

a) Garder la zone de travail propre, éclairée correctement et dégagée.

b) Ne pas utiliser l’outil en atmosphère potentiellement explosive,

comme en présence de liquide ou gaz inflammables.

Un appareil électrique peut en effet produire des étincelles.

c) Tenir les enfants et les personnes non nécessaires au chantier à

distance.

2) Sécurité électrique

a) La fiche électrique doit être compatible avec la prise réseau

disponible. Ne jamais modifier une prise électrique.

c) Ne pas exposer l’appareil à la pluie ou le plonger dans l’eau. De

l’eau entrant dans un appareil électrique accroît le risque de chocs

électriques.

d) Ne jamais détériorer le cordon. Ne pas utiliser le cordon pour porter,

tirer ou débrancher l’appareil du réseau électrique. Préserver le cordon

de la chaleur, des produits pétroliers, angles vifs coupants ou pièces

en mouvement.

e) En cas d’utilisation en extérieur, utiliser une rallonge électrique

adaptée à une telle utilisation.

3) Sécurité individuelle

a) Rester vigilant et attentif avec un outil en main.

b) Porter tout EPI (Equipement de Protection Individuel) requis par le

type de travail effectué.

1

INSTRUCTIONS UTILISATEUR TS55-AC

1BOPERATING INSTRUCTIONS

Visseuse automatique 230V pour vis en bandes.

c) Prévenir toute mise en route intempestive de l’outil.

S’assurer que l’interrupteur est en position « coupé » avant de

connecter l’appareil à la source d’énergie.

Porter un appareil avec le doigt sur la gâchette augmente le risque

d’accident.

d) Retirer toute clé ou outil de l’appareil avant la mise en route. Un outil

resté en place sur une partie tournante de l’appareil pourrait présenter

un danger pour les personnes présentes aux environs.

e) Garder l’équilibre et de bons appuis en toutes circonstances.

f) Porter une tenue adaptée au travail à effectuer. En présence de

partie rotative, veiller à ne pas laisser d’habits ou de longs cheveux

flotter dans la zone de travail.

4) Utilisation et soin de l’appareil

a) Ne pas forcer sur l’outil. Utiliser le bon outil adapté à

l’application.

b) Ne pas utiliser la machine si l’interrupteur général ne permet pas

d’allumer ou d’éteindre la machine.

Prévoir dans ce cas une réparation par une personne qualifiée.

c) Pour toute intervention sur la machine il est impératif de la

déconnecter de la source d’énergie (230V ou batterie).

Ceci s’applique au montage / démontage d’accessoires, au

changement d’embout, au réglage de profondeur ou retrait de bande.

d) Stocker les machines hors de portée des enfants. Ne pas laisser

des personnes non formées à son utilisation, à se servir de l’appareil.

Tout outil est potentiellement dangereux pour qui ne sait pas s’en servir.

e) Entretenir le matériel. Vérifier avant l’usage l’outil et faire réparer

tout ce qui est ou semble défectueux.

g) Utiliser le matériel et ses accessoires en accord avec ces

instructions. Prendre en considération l’environnement et les

conditions de la zone de travail.

2

5) Service

a) Effectuer la maintenance régulière par un personnel qualifié, avec

des pièces d’origine ou recommandées par le constructreur.

Tenir la visseuse par les zones prévues à cet effet en cours

d’utilisation. Ainsi en cas de placement inopiné d’une vis sur le

cordon de la machine, vous éviterez un choc électrique

désagréable et potentiellement dangereux pour vous.

ATTENTION !

1. Afin d'assurer l'intégrité opérationnelle de vos outils électriques, ne pas

retirer le couvercle ou les vis prévues.

2. Utiliser votre outil en dehors des spécifications indiquées sur la plaque

signalétique, peut dégrader le résultat et l'efficacité du travail et

engendrer une détérioration du moteur.

3. Ne pas essuyer les parties en plastique avec du solvant. Les solvants

tels que l'essence, de diluant, le benzène, le tétrachlorure de carbone,

l'alcool, de l'ammoniac et de l'huile contenant une additif chloré peut

endommager et fissurer les parties en plastique. Ne pas les essuyer

avec un tel solvant. Essuyer les parties en plastique avec un chiffon

légèrement humidifié avec de l'eau savonneuse.

Précautions de sécurité

3

Symboles

--------Recycler ------Appareil classe II

V--------Volts

Hz-------Hertz

kg-------Kilogramme

DC -----Courant continu

--------Ne pas jeter

AC.------Courant alternatif

W--------Watts

mm------Millimètre

kg-cm--Kilogramme cm

t

/mn-----tour par minute

4.Utiliser des pinces ou un autre moyen pratique de fixation et maintenir la

pièce à une plate-forme stable de travail. Tenir la pièce avec la main ou

contre son corps est instable et peut engendrer une perte de contrôle.

5.N'utiliser que les accessoires recommandés par le fabricant pour le

modèle. Des accessoires qui peuvent convenir à un outil pourraient créer

un risque de blessure lorsque utilisés sur un autre outil.

Principaux composants

Avant / arrière

Gâchette

Ensemble adaptateur

Cordon électrique

Embout

anti-glisse

Déverrouillage anti-retour

Réglage prof.

de vissage

Bouton réglage lg de vis

Logement des charbons

Spécifications

Modèle TS55-AC

Voltage 220V

Vitesse à vide 4200 t/mn

Couple maxi 80 kg-cm/7.8 N-m/5.8ft-lb

Poids 1.9kg

Dimensions Long 430 x larg 80 x Haut 190mm

Gamme de vis 25-55 mm

Longueur embout 1/4"x173L mm

Bouton de séparation rapide

4

Mise en place de la bande

1. Vérifier sur les graduations

que le réglage correspond

exactement à la longueur de

vis voulue

2. Appuyer sur le bouton de réglage

et déplacer le nez jusqu’à la position

voulue.

Relâcher ensuite le bouton.

Attention: ce réglage doit être fait à

vide, sans vis.

Tailles compatibles.:

d(mm)

Φ3.5 à Φ4.5mm

L(mm)

25

30

35

40

45

50

55

3. Engager la bande de vis dans le

guide.

Longueur de vis

Régler la longueur de vis

Graduation

s

Appuyer

5

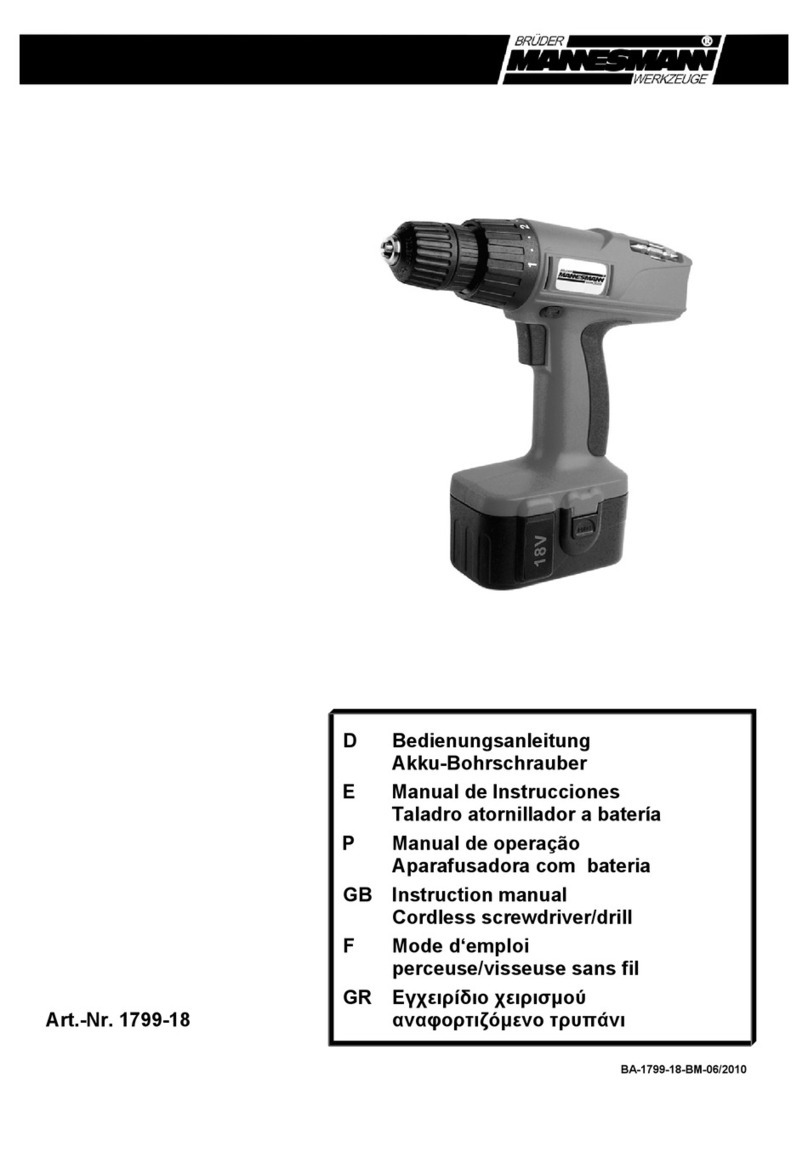

This manual suits for next models

1

Table of contents

Languages:

Popular Power Screwdriver manuals by other brands

Mannesmann

Mannesmann 1799-18 instruction manual

Hyundai power products

Hyundai power products HPV20V Original instructions

Black & Decker

Black & Decker PLR36NC-XE instruction manual

Atlas Copco

Atlas Copco QMC41-250-I06 Product instructions

Sumake

Sumake ACP48 quick start guide

Mannesmann Demag

Mannesmann Demag RRI-150 operating manual

Makita

Makita XSF01 instruction manual

Festool

Festool DWC 18-2500 instruction manual

Deprag

Deprag 345-308U Operating instruction booklet

EINHELL

EINHELL bavaria BUSS 18 operating instructions

Dixon Automatic Tool

Dixon Automatic Tool SKC-PTA-B60 Operation and maintenance manual

Hammerhead

Hammerhead HCSD040 user guide