Aeroel HWS.1 User manual

AEROEL s.r.l. - via Pier Paolo Pasolini 35/3, 33040 - PRADAMANO (UD) - ITALY -+39 0432 671301 (671543)

http://www.aeroel.it e-mail: [email protected]

HWS.1

Handy Wire Scanner

USER’S MANUAL

ENGLISH

HW 240HW01V00

SW 600V00L02 B2798_E – 1.1

VALIDAZIONE ANNULLAMENTO

numero DTE:

B2798_E – 1.0

foglio: 1 di tot: 36

Rif.: 240HW01V00

Redatto: PS

Ai sensi di legge, il contenuto

di questo documento non può

essere riprodotto o comunicato

a terzi senza approvazione

scritta di Aeroel s.r.l.

HWS.1 Handy Wire Scanner - 240HW01V00

B2798_E 1.1, 2016-04-08 3

INDEX

1. PRELIMINARY INFORMATION ......................................................................................................................... 5

1.1 THANKS................................................................................................................................................................. 5

1.2 WARRANTY TERMS............................................................................................................................................... 5

1.3 CONFORMITY TO THE NORMATIVES IN FORCE..................................................................................................... 6

1.4 SAFETY INFORMATIONS ....................................................................................................................................... 6

1.5 GENERAL SAFETY RULES ....................................................................................................................................... 6

1.6 SPECIFIC SAFETY PROVISIONS............................................................................................................................... 7

1.7 INTENDED USE...................................................................................................................................................... 8

1.8 PROHIBITED USES ................................................................................................................................................. 8

1.9 PRECAUTIONS FOR USE ........................................................................................................................................ 8

1.10 EQUIPMENT DISPOSAL .................................................................................................................................... 9

2. TECHNICAL INFO ........................................................................................................................................... 10

2.1 FEATURES AND PERFORMANCE ......................................................................................................................... 10

2.2 DESCRIPTION ...................................................................................................................................................... 11

2.3 PROTECTION....................................................................................................................................................... 12

2.4 PORTABLE TAG (OPTIONAL) ............................................................................................................................... 13

2.5 FIXTURE FOR THE ON-LINE MEASUREMENT (OPTIONAL) .................................................................................. 13

2.6 PULLEY SET FOR WIRE GUIDANCE, WITH ADJUSTING WHEEL (OPTIONAL DEVICE) .......................................... 14

2.7 FRONT PULLEY FOR WIRE GUIDANCE (OPTIONAL DEVICE)................................................................................ 16

2.8 CHARGING THE BATTERY .................................................................................................................................... 16

2.9 TURNING ON AND OFF ....................................................................................................................................... 17

2.10 AUTOMATIC SWITCH OFF .............................................................................................................................. 18

2.11 MAINTENANCE .............................................................................................................................................. 18

2.12 DISPLAY.......................................................................................................................................................... 18

2.13 SETUP MENU ................................................................................................................................................. 20

2.14 MEASURE SETUP............................................................................................................................................ 21

2.15 HWS.1 SETUP ................................................................................................................................................ 22

3. MEASURING A PRODUCT .............................................................................................................................. 24

3.1 GENERAL INDICATIONS ...................................................................................................................................... 24

3.2 PRODUCT POSITIONING ..................................................................................................................................... 24

3.3 AVERAGING MODE ............................................................................................................................................. 27

3.4 GLASS LOGIC ....................................................................................................................................................... 28

3.5 MEASURING APRODUCT.................................................................................................................................... 29

3.6 ON-LINE MEASUREMENT WITH FIXTURE DEVICE (OPTIONAL) ........................................................................... 30

3.7 OFFSET CALIBRATION ......................................................................................................................................... 31

4. APPENDIX..................................................................................................................................................... 33

4.1 FIXTURE DIMENSIONS ........................................................................................................................................ 33

4.2 INSTRUCTIONS TO REMOVE THE BATTERY ......................................................................................................... 34

AEROEL s.r.l. - PRADAMANO (UD) - ITALY

4 B2798_E 1.1, 2016-04-08

HWS.1 Handy Wire Scanner - 240HW01V00

B2798_E 1.1, 2016-04-08 5

1. PRELIMINARY INFORMATION

1.1 THANKS

We wish to thank you and to congratulate you for choosing an AEROEL product. We are sure that you will fully appreciate

the reliability and the accuracy that our equipment can grant.

We did our best effort to give you a top quality product, by carefully selecting the employed components and by adopting

strict quality control procedures, both during the assembling and the final testing.

Although unlikely, it is nevertheless possible that during the operative life of the instrument some minor inconvenience

may occur, possibly due to an unforeseeable hidden defect, or to component wear, or to some special event that may

cause the use of the instrument in anomalous conditions.

In this case our After Sales Technical Assistance Department is always at your disposition, to assure a quick and accurate

repair of the gauge or to supply installation assistance or operational advice. Please, carefully review the enclosed warranty

terms and do not hesitate to contact us, should any doubt or problem arise!

Once again we thank you for your choice and we hope that we shall continue to be of your service for many more years.

1.2 WARRANTY TERMS

All AEROEL products are covered by a 36 month warranty, starting from the date on which the equipment actually

leaves our facilities. This warranty also covers any AEROEL-designed software installed inside the AEROEL device,

which is necessary for its operation.

Any software produced by AEROEL for installation on devices that are manufactured by others (e.g. Personal

Computers), even if supplied by AEROEL, are LICENSED FOR USE only and are guaranteed for a period of 90 days

from installation thereof, and however not over 180 days from the date of delivery to the customer.

Any instrument, component, interface or parts in general sold, but not manufactured by AEROEL (e.g. Personal

Computers, Interfaces, Printers and other peripherals, etc.) will be covered by 12 months warranty, starting from

the delivery date.

WARRANTY CONDITIONS

During the guarantee period AEROEL will replace or repair, free of charge, any defective part or component, as well as

other parts or components that do not conform to performance specifications. These operations will be carried out at

our main plant or at any branch of ours; shipping and packaging costs are charged to the CUSTOMER. Whenever the

dimensions or the type of instrument are such that it cannot be easily shipped, AEROEL will dispatch spare parts and

service personnel to the buyer's facilities at its own expense. The CUSTOMER will cover the shipping cost of the

material and the travelling and accommodation costs of the personnel. The CUSTOMER will leave the defective unit at

our disposal for all the time required for the repair.

VOIDANCE OF WARRANTY

This warranty shall automatically become void if the product has been tampered with, modified and/or

repaired by the customer or other person without the prior written authorization of AEROEL.

Tampering and modification also means the installation of software, modification or upgrading of

operating systems, use of boards and/or peripherals and/or other interfaces on equipment produced by

other manufacturers and sold by AEROEL (e.g. Personal Computers) when not explicitly authorized by

AEROEL in writing.

WARRANTY EXCLUSIONS

Excluded from this warranty is any damage caused to the product by carelessness, incorrect or improper use,

inadequate installation, electrical power supply that does not conform to the specifications, force majeure and, in any

case, events of an extraordinary nature that lie beyond the normal use thereof.

AEROEL excludes, for any reason, compensation for any damage, direct or indirect, of any nature, to

individuals or property as a result of the use or suspension of use of our equipment or software.

AEROEL s.r.l. - PRADAMANO (UD) - ITALY

6 B2798_E 1.1, 2016-04-08

1.3 CONFORMITY TO THE NORMATIVES IN FORCE

The product complies with the applicable European directives and technical standards in force at

the production date, as reported in the Declaration of Conformity supplied with the product.

SEE CE DECLARATION OF CONFORMITY CE

The product is intended to be used in a basic electromagnetic environment

This equipment has been designed and tested to CISPR 11 Class A. In a domestic environment it may cause radio

interference, in which case, you may need to take measures to mitigate the interference

1.4 SAFETY INFORMATIONS

Read all safety warnings and all instructions. Failure to follow the warnings and instructions may result in

dangerous situations and / or serious injury.

Save all warnings and instructions for future reference.

In this manual, the measuring instrument HWS.1 - Handy Wire Scanner will be hereinafter referred to as "HWS.1" or

"scanner" or "instrument" or "gun"

While using the instrument used the precautions described in the following chapters

1.5 GENERAL SAFETY RULES

To minimize the risks in the working area it is advisable to use the following general precautions:

Work Area Safety

•Keep your work area clean and well lit. Cluttered or dark areas invite accidents.

•Do not operate equipment in explosive atmospheres, such as in the presence of flammable liquids, gases or

dust.

•Keep children and by-standers away while operating equipment. Distractions can cause you to lose control.

Electrical Safety

•Avoid body contact with earthed or grounded surfaces such as pipes, radiators, ranges and refrigerators.

There is an increased risk of electrical shock if your body is earthed or grounded.

•Do not expose equipment to rain or wet conditions. Water entering equipment will increase the risk of

electrical shock.

Personal Safety

•Stay alert, watch what you are doing and use common sense when operating equipment. Do not use

equipment while you are tired or under the influence of drugs, alcohol or medication. A moment of

inattention while operating equipment may result in serious personal injury.

•Use personal protective equipment. Always wear eye protection. Protective equipment such as dust mask,

non-skid safety shoes, hard hat, or hearing protection used for appropriate conditions will reduce personal

injuries.

•Do not overreach. Keep proper footing and balance at all times. This enables better control of the power tool

in unexpected situations.

HWS.1 Handy Wire Scanner - 240HW01V00

B2798_E 1.1, 2016-04-08 7

Equipment Use and Care

•Do not force equipment. Use the correct equipment for your application. The correct equipment will do the

job better and safer at the rate for which it is designed.

•Store idle equipment out of the reach of children and do not allow persons unfamiliar with the equipment or

these instructions to operate the equipment. Equipment can be dangerous in the hands of untrained users.

•Maintain equipment. Check for misalignment or binding of moving parts, missing parts, breakage of parts

and any other condition that may affect the equipment's operation. If damaged, have the equipment

repaired before use. Many accidents are caused by poorly maintained equipment.

•Use the equipment and accessories in accordance with these instructions, taking into account the working

conditions and the work to be performed. Use of the equipment for operations different from those

intended could result in a hazardous situation.

•Use only accessories that are recommended by the manufacturer for your equipment. Accessories that may

be suitable for one piece of equipment may become hazardous when used with other equipment.

•Keep handle dry and clean; free from oil and grease. Allows for better control of the equipment.

Service

•Have your equipment serviced by a qualified repair person using only identical replacement parts. This will

ensure that the safety of the tool is maintained.

1.6 SPECIFIC SAFETY PROVISIONS

To use safely the HWS.1 - Handy Wire Scanner, please follow the special precautions listed below:

Measuring moving parts

•Avoid the measurement of moving products without the use of appropriate accessories and protections

described in the following chapters of this manual: in any case avoid contact even accidentally, with the

product or moving parts

•Avoid measuring moving products if the type of product, its size, its speed or its temperature be likely to

cause damage to the instrument, to the user, to third parties or other tools and / or equipments in case of

accidental contact with the product itself. The accidental contact involves hazards due to breakage of the

measured product, the break of the instrument, the dragging of the gun, the expulsion and thrown of

objects.

•Use the protective hand guard and the shield for the optics supplied with the instrument.

•Use the appropriate personal protective equipment

•Follow the safety measures provided in the workplace and for the machines in the vicinity of whom you are

performing measurements

•Take appropriate precautions when working near electrical, moving or hot parts. Close contact may cause

electrical shock, entanglement, burns and other serious injury. Protective equipment may be required.

Transport

•The HWS-1 Handy Wire Scanner contains 1 (one) non-removable, rechargeable Ion Lithium Cell, mounted

inside the instrument. The above mentioned Ion Lithium Cell is type NCR18650B manufactured by

PANASONIC, it has a rated capacity of 3350 mAh and a Voltage of 3.6 V , corresponding to a capacity of 12

Wh.The contained lithium-ion rechargeable cell is subject to the Dangerous Goods Legislation requirements.

The user can transport the batteries by road without further requirements. When being transported by third

parties (e.g.: air transport or forwarding agency), special requirements on packaging and labelling must be

observed. The regulations in this field are constantly changing: for preparation of the item being shipped, it

might be necessary consulting an expert for hazardous material is required.

AEROEL s.r.l. - PRADAMANO (UD) - ITALY

8 B2798_E 1.1, 2016-04-08

1.7 INTENDED USE

HWS.1 - Wire Handy Scanner is a portable optical micrometer whose intended use is the measurement of the

diameter of products with round cross section, such as:

•metallic wire

•fiber optics

•electric cables

The measurement can be performed on a continuous product both under static and dynamic conditions (moving

product) using the instrument with the appropriate accessories and protections.

When measuring moving products, you must consider the possibility that accidental contact with the product can

cause damage to the instrument, to the user, to third parties or to other tools and/or equipments.

The accidental contact involves hazards due to breakage of the measured product, the break of the instrument, the

dragging of the instrument, expulsion and thrown of objects.

In such cases avoid measuring moving products !

SEE CHAPTER 1.6 SPECIFIC SAFETY PROVISIONS

1.8 PROHIBITED USES

Inappropriate use of the HWS.1 portable micrometer renders the product warranty void and can cause direct or

indirect damage to people and/or objects.

The following uses are prohibited:

•use of the HWS.1 portable micrometer in an environment other than air;

•use of the HWS.1 portable micrometer in areas classified according to the directive 99/92/EC (environment

with an explosive atmosphere);

•use of the HWS.1 portable micrometer in environmental conditions that are different from those specified in

the technical data;

•use of the HWS.1 portable micrometer as a "fail-safe" device;

•use of the HWS.1 portable micrometer on transport means, in life support devices and in any other system in

which any malfunctioning of the micrometer could provoke direct or indirect damage to human life.

The aforementioned list is not to be considered complete.

Should there be any doubt on the correct use of the HWS.1 portable micrometer, please contact AEROEL

for further information.

1.9 PRECAUTIONS FOR USE

Attention !

The cleaning of optical prisms MUST be performed with the instrument SWITCHED OFF.

If cleaning is carried out with the gun switched on, this has to be cycled ( switched off and on again ) to

prevent invalid measurement values.

Attention:

The trigger is magnetically operated: avoid operating in the presence of strong magnetic fields and/or do

not use magnets close to the gun. The presence of magnetic fields may cause malfunction of the trigger.

HWS.1 Handy Wire Scanner - 240HW01V00

B2798_E 1.1, 2016-04-08 9

1.10 EQUIPMENT DISPOSAL

European Directives requires that the equipment bearing this symbol on the product and/or

its packaging must not be disposed of with unsorted municipal waste. The symbol indicates

that this product should be disposed of separately from regular household waste streams. It

is your responsibility to dispose of this and other electric and electronic equipment via

designated collection facilities appointed by the government or local authorities. Correct

disposal and recycling will help prevent potential negative consequences to the

environment and human health.

For more detailed information about the disposal of your old equipment, please contact

your local authorities, waste disposal service, or the dealer where you purchased the

product.

Should a new piece of equipment be purchased to replace a similar one manufactured by Aeroel, within the European

Union, Aeroel may take-in the used equipment and dispose of it in compliance with the laws in force in matters of

waste disposal without any additional cost to the Customer, except for transport costs (from the Customer’s site to

Aeroel’s premises), which will be at the Customer’s expense.

The equipment must not be demolished and/or dismantled in any way whatsoever inasmuch as

potentially hazardous substances are contained therein, which could damage the environment if not

handled with due care and in strict compliance with the waste disposal laws in force in the associated

country. Offenders shall be subjected to a fine at various levels according to their State of origin.

Disposing of damaged or exhausted batteries

The instrument contains a rechargeable Li-ion cell that must be removed and disposed separately.

Do not dispose of discarded batteries together into ordinary household waste, fire or water. In accordance with the

law, damaged or exhausted batteries must be taken to the nearest collection point for batteries or a battery

management company. Failure to comply with these regulations may render you liable to fine or other penalty.

Attention

The instructions for removing the lithium-ion battery from the instrument are shown in the Appendix of

this manual

SEE APPENDIX

AEROEL s.r.l. - PRADAMANO (UD) - ITALY

10 B2798_E 1.1, 2016-04-08

2. TECHNICAL INFO

2.1 FEATURES AND PERFORMANCE

HWS.1 - Handy Wire Scanner is a fully portable optical micrometer for non-contact measurement of wires, cables and

other similar products. The instrument has a LED and CCD technology, with 2 crossed linear sensor to automatically

compensate positioning errors (Patent pending). Thanks to a powerful single chip microprocessor, the micrometer is

linearized and compensated to obtain the maximum precision in the entire field of measurement, regardless of an

accurate positioning of the wire.

To measure the diameter of a product just press the trigger of the gun: the light generated by a green LED light

illuminates the product through superior optics; the shadow cast on the lower optics is detected by 2 CCD sensors

and allows the measurement of the diameter of the product.

The software "YesWeGun" for PC Windows is available in the CD-ROM supplied with HWS.1. The program allows the

management of HWS.1 connected to a PC via an USB cable. This software is the only tool that allows communication

between HWS.1 and a PC.

PLEASE REFER TO THE MANUAL OF HWS MANAGEMENT SOFTWARE ON PC “YESWEGUN”

Measuring Field

10 mm

Measurable Diameters

0.1 - 6 mm

Frequency

1282 Hz

Repeatability

1 µm

Accuracy

2 µm

Battery Life (working)

4 h

Dimensions

191 x 210 x 79 mm

Weight

850 g

Operating Temperature Range

0 - 50° C

Storage Temperature

Atmospheric humidity

Max 85% (non-condensing)

Rechargeable battery

PANASONIC NCR18650B

•Type

Li-Ion cell

•Nominal voltage

3,6V

•Capacity

3350 mAh (12Wh)

•charging temperature

10 - 45°C

•charging time(1500mAh)

3 hours

•charging time (500 mAh)

8 hours

Power Supply

FRIWO GPP USB (1895382)

•Input voltage

100-240 V; 50-60 Hz

•Output voltage

5 V

•Output current

1500 mA

•Operating Temperature Range

0 - 40° C

HWS.1 Handy Wire Scanner - 240HW01V00

B2798_E 1.1, 2016-04-08 11

2.2 DESCRIPTION

Main parts

Display

Function keys

Functio

UBS

Connector

Upper optics

Lower optics

Handle

Product being

measured

Safe/Arm

Trigger

USB Connector

Info and CE marking

Fixing holes

Display

Function keys

LED battery status

Magnets

Reference sphere

Optical prisms

Magnets

Reference spheres

AEROEL s.r.l. - PRADAMANO (UD) - ITALY

12 B2798_E 1.1, 2016-04-08

2.3 PROTECTION

HWS.1 is supplied with removable protections for the optics and for the operator’s hand.

Protection for

optics

Handguard

Protection for

optics

Handguard

The optics protection is useful to protect the surface of the optical prisms

against any accidental contact with the product.

It is simply fixed to the instrument through the magnets that are located

on the external faces of the optics (lower and upper).

The correct positioning and locking of the protection is also guaranteed by

the holes in which the reference spheres are inserted. (see figure at right).

To unlock the protection, just pull it out and remove it from the magnet

blocks.

This protection is used as an alternative to the fixture for on-line

measurement (see next section).

The handguard is designed to protect the operator's hand from hazards due to accidental contact with the product to

be measured (especially with moving product )

It is fixed by means of screws (supplied) using the following procedure:

Fasten the two screws at the lower

optical protection without tightening.

Place the handguard so that the two

screws are inserted into the upper

slots.

Secure the bottom screw and tighten

the two upper screws.

HWS.1 Handy Wire Scanner - 240HW01V00

B2798_E 1.1, 2016-04-08 13

2.4 PORTABLE TAG (OPTIONAL)

The HWS.1 scanner has been designed to use an external TAG that identifies the

machine and which is read by the instrument at the time of measurement: the

measurement data saved in memory will be associated to the identification number

of the line/machine given by the Tag inserted in the fixture. This TAG is always

embedded in the fixture for the on-line measurement (SEE NEXT CHAPTER), but

there is also available in a portable version that can be left next to the machine to

associate the production line to measurements taken without the support.

fig. 1

To use the portable TAG, plug it into the top slot of the scanner and take the measurement: the measurement data

saved in memory will be associated to the TAG identification number (figs. 2-4).

fig. 2

fig. 3

fig. 4

2.5 FIXTURE FOR THE ON-LINE MEASUREMENT (OPTIONAL)

The scanner has been designed to fit into a special holder (optional) to be fixed on the machine, the holder contains a

TAG that identifies the machine and which is read by the instrument at the time of measurement.

The support allows to easily and quickly place the scanner, also for the measurement of moving products and it

guarantees maximum precision of measurement. It is therefore possible, mounting a support on each line,

periodically monitor the production of all machines with just one micrometre: the measurement data saved in

memory will be associated to the identification number of the line/machine given by the Tag inserted in the fixture.

The fixture consists of two main parts:

•a fixed part, with holes for M6 screws, which must be installed properly on the production line. The

positioning must be done so that the product to be measured is in the centre of the measuring field of the

instrument.

•a mobile part that can be raised so as to allow easy access to the product. In this part, when positioned

horizontally, insert the scanner HWS.1 for measurement. The movable part can be locked by means of a

retaining screw.

The following drawing shows the main dimensions and, in red, the position of the product for a correct measurement

AEROEL s.r.l. - PRADAMANO (UD) - ITALY

14 B2798_E 1.1, 2016-04-08

Attention!

The positioning of the fixture must be done in order to allow easy access for the measurement without

risks for the operator. For instructions, please contact the customer service Aeroel

Attention!

For the dimensions of the mounting holes see drawing in Appendix

SEE APPENDIX

For the measuring mode using the fixture

PLEASE REFER TO CHAPTER 3.6 ON-LINE MEASUREMENT WITH FIXTURE DEVICE (OPTIONAL)

2.6 PULLEY SET FOR WIRE GUIDANCE, WITH ADJUSTING WHEEL (OPTIONAL DEVICE)

The fixture for the on-line measurement (optional) can be completed with a pulley set (optional) very useful to centre

and guide the wire (see figure)

Fixing

rail

Wire guiding

pulleys

Presetting

wheel

Gun

holder

Wire to be

measured

The wire guiding system is composed by

•1 rail type ITEM 6 30x30 (ITEM 0.0.419.01)

•Assembly of 2 ceramic pulleys and 1 pre-setting wheel with 6 pre-setting positions (from 0.5 to 5.6 mm wire

diameter). The wheel must be rotated to pre-set the distance from the gun holder following the diameter to

check.

•Sliding nuts for fixing the assembly to the rail ITEM 6 with M6 screws (ITEM 0.0.419.40)

The rail and the pulley assembly can also be supplied separately

The rail must be fixed on the machine to let the wire be guided by the pulleys. The pre-setting wheel must be rotated

following the diameter of the wire (approximately) and then the gun holder must be fixed to the rail and stop against

the pre-setting wheel, in order to be at the right position. The pre-setting wheel allows 5 mm displacement range (6x

steps by 1 mm, from 0.5 (or smaller) to 5.5 (or greater)

The docking o the components to the rail is made using the nuts (supplied with) sliding in the groove of the rail.

HWS.1 Handy Wire Scanner - 240HW01V00

B2798_E 1.1, 2016-04-08 15

Follow the instructions below:

Fix the rail on-line, in a suitable position, depending

upon the wire axis position .

To get the rail dimensions please check the drawing

above

Insert from the bottom the pulley assembly , using

the nuts sliding inside the rail groove

Position the pulley assembly in order to apply a slight

tension to the wire : the pulley should rotate when the

wire moves.

Now lock the assembly to the rail by fastening the

screws .

Rotate the pre-setting wheel to get on top the

figure which is closer to the actual wire diameter (pre-

settable values are 0.5/1.5/2.5/3.5/4.5/5.5 mm)

Insert from the top, into the rail, the gun holder

and let it touch the pre-setting wheel

AEROEL s.r.l. - PRADAMANO (UD) - ITALY

16 B2798_E 1.1, 2016-04-08

When the gun holder is in the right position, lock it

to the rail by fastening the 2 screws

When you change the wire diameter by a significant

amount, loosen the 2 screws , rotate the pre-setting

wheel to the new value, position the gun holder

against the pre-setting wheel and fasten again the 2

screws

2.7 FRONT PULLEY FOR WIRE GUIDANCE (OPTIONAL DEVICE)

The front pulley for wire guidance are useful for the quick

centering of the moving products. They can only be used with

electrical cable

They can be used only for the measurement of electric cable or

plastic products (optical fiber, tubes, extruded products, etc..).

They must not be used for the measurement of metal products or

moving products with speed exceeding 300 m/min.

The front pulleys cannot be used with the fixture for on-line

measurement

ATTENTION!

Do not use the front pulley with metal products, with

products moving with speed exceeding 300m/min or

with very high vibrations. In these cases there may be

hazards due to breakage of the measured product,

the break of the instrument, the dragging of the gun,

the expulsion and thrown of objects.

The front pulley are simply fixed to the instrument through the magnets that

are located on the external faces of the optics (lower and upper).

The correct positioning and locking of the protection is also guaranteed by

the holes in which the reference spheres are inserted. (see figure at right).

To unlock the pulley, just pull them out and remove them from the magnet

blocks.

Using the pulleys during the measurement is very simple: the product

(moving or still) is perfectly centered in the measurement field when it is

positioned in the pulleys grooves. At this point start the measurement by

pressing the trigger.

2.8 CHARGING THE BATTERY

HWS.1 is equipped with a rechargeable lithium-ion cell, PANASONIC NCR18650B, 3.6V, 3350 mAh, 12 Wh capacity.

At first use, the battery should be fully charged and you should fully charge the battery before any prolonged use of

the instrument.

The fully charged battery allows continuous operation for about 4 hours.

To preserve the life of the battery, you should avoid deep discharge of the battery.

The battery is nevertheless protected from deep discharge. An integrated protective circuit automatically turns the

device off when the battery is discharged.

HWS.1 Handy Wire Scanner - 240HW01V00

B2798_E 1.1, 2016-04-08 17

When the instrument is in operation, the state of charge of the battery is indicated by a special icon on the display

PLEASE REFER TO CHAPTER 2.12 DISPLAY

When you try to turn on the instrument and the state of charge of the battery is low, the battery LED indicator lights

up with three long flashes.

To charge the battery use the power supply and USB cable provided:

•Check that the voltage indicated on the identification plate corresponds to the mains voltage available.

•Plug the charger into the socket and connect the USB cable to the corresponding connector USB-A

•Open the door under the handle of the instrument and connect the USB cable to the corresponding

connector USB-B

•The charging process starts as soon as the charging cable is connected to the jack.

•The charging indicator LED under the display flashes to indicate that the battery is charging.

•After charging the LED indicator remains lit

The charging time with the charger supplied (1500 mA) is about 3 hours.

To be recharged, HWS.1 can also be connected to the USB socket of a PC (500 mA), in this case the duration of the full

charge is approximately 8 hours.

During charging, if the instrument is turned on, the icon of the state of charge of the battery indicates the type of

charging in progress

PLEASE REFER TO CHAPTER 2.12 DISPLAY

Attention!

During the charging process the handle can be heated a bit, but this is completely normal.

Attention !

If battery charging is not possible, check that there is mains voltage on the socket; that there is good

contact along the charging cable

In use, when the battery charge power is low, the device will automatically turn off after a warning message on the

display (5 seconds).

2.9 TURNING ON AND OFF

To turn the instrument on, set the Safe/Arm in position A (Armed) and push the trigger for more than 3 seconds: a

long beep will accompany the lighting of the display.

At the start up, the instrument performs an initialization/self-calibration procedure of the CCD (about 3 seconds)

during which there must be NO object in the measurement field and NO dirt on the optical windows.

We suggest to clean the optics before switching the device on

If the initialization is not performed correctly for one of these reasons, on the display will show an error message INIT

CCD FAIL! REMOVE PIECE FROM THE FIELD. In this case, remove the piece from the measuring field and press a

function key to restart the instrument.

At startup is also made a test to find dirt on the optical windows. If dirt is detected the following message appears on

the display DIRTY DETECTED POWER OFF & CLEAN

At this point, using the function keys, you can choose:

F1 - Ignore Start the gun ignoring the message of dirt

F4 - Power Off Turn off the instrument for cleaning of optical windows

If you decide to ignore the message about the dirt, the gun will start normally, but the measurements may be not

accurate. In this case the display will show the icon . The number on the icon indicates the type of detected dirty:

1 = smooth dirty, 2 = localized dirty, 3 = smooth and localized dirty.

To switch off, press and hold (> 2 sec) the F3 key (Power Off) and then the F1 key as indicated on the display.

Attention!

In case of malfunction of the gun, the instrument can be reset by pushin

g the trigger for 45 seconds,

ignoring any error messages that appear on the screen.

AEROEL s.r.l. - PRADAMANO (UD) - ITALY

18 B2798_E 1.1, 2016-04-08

2.10 AUTOMATIC SWITCH OFF

The instrument is programmed to automatically turn off after a specified period of inactivity The activation and

programming of the automatic shut-off must be made in the instrument setup

PLEASE REFER TO CHAPTER 2.15 HWS.1 SETUP

From the measuring window, press the F1 key (Setup) to enter the setup screen of the instrument.

Use the arrow keys (F2 and F3) to navigate through the various options. The selected row is highlighted in blue.

To select the option, press the Enter key (F1)

To exit or return to the previous level, press Exit (F4)

Select the item Setup HWS.1 with the Enter key (F1).

Use the arrow keys (F2 and F3) to select the Power Management option and press the Enter key (F1).

Access the Power Off item and to the choice of the inactivity time that must pass before the instrument will

automatically switch off

You can choose between the following values:

OFF (NO automatic power off), 30 sec, 1 min, 2 min, 3 min, 5 min, 10 min, 15 min

Select the desired value using the arrow keys (F2 and F3) and the Enter key (F1).

2.11 MAINTENANCE

For the right maintenance, you have to do, when needed, the cleaning of of the deflecting prisms. This operation has

to be done by using a clean cloth, eventually dampened with ether or pure ethylic alcohol, by paying attention not to

scratch the of the prism surface

Attention !

The cleaning of optical prisms MUST be performed with the instrument SWITCHED OFF.

If cleaning is carried out with the gun switched on, this has to be cycled (switched off and on again) to

prevent invalid measurement values.

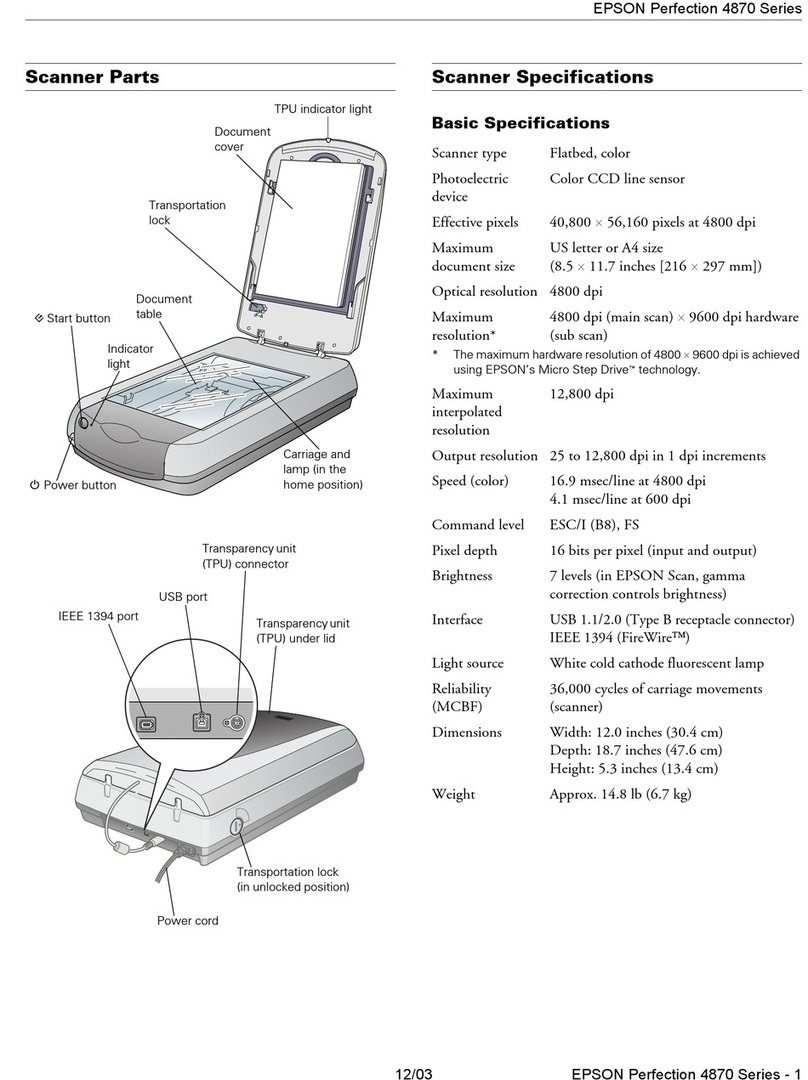

2.12 DISPLAY

- Line identification Tag,

time and date

- Data recording icon

- Offset icon

- Glass Logic icon

- Battery status

- Dirty optics icon

- Reference bar for

the horizontal

position of the

product

- Measured value box

- Labels of the

function keys

- Line identification Tag, date and time

Information related to the line identification Tag inserted in the fixture for the on-line measurement

PLEASE REFER TO CHAPTER 2.15 HWS.1 SETUP

Displaying of the time and date: the format can be chosen in the set-up: hh: mm and dd/mm/yyyy or hh: mm

and yyyy/mm/dd. The hour "flashes" on first use when no setting has not been made, or in the case of complete

battery discharge.

For information on setting the time and date:

PLEASE REFER TO CHAPTER 2.15 HWS.1 SETUP

HWS.1 Handy Wire Scanner - 240HW01V00

B2798_E 1.1, 2016-04-08 19

- Data recording icon

Info about the status of the data saving in the device memory

Data recording ACTIVE

Data recording STOPPED (low battery)

PLEASE REFER TO CHAPTER 2.14 MEASURE SETUP

- Offset icon

Icon shown when an offset value has been programmed in the Calibration menu

Icon offset active

PLEASE REFER TO CHAPTER 2.15 HWS.1 SETUP

- Glass Logic Icon

Icon shown when enabled the Glass Logic for the measurement of transparent products

Icon Glass Logic active

PLEASE REFER TO CHAPTER 3.4 GLASS LOGIC

- Battery status

Info about the charging status of the battery

Battery charge status

Only 20% of charge left

Low battery

Reading the type of battery charger

1500 mA battery charger connected + battery charge status

500 mA battery charger (USB standard) connected + battery charge stat

us

PLEASE REFER TO CHAPTER 2.8 CHARGING THE BATTERY

- Dirty Optics Icon

The icon is active when the instrument is used despite a warning of dirty on the optics. The number on the icon

indicates the type of detected dirt:

1 = smooth dirty, 2 = localized dirty, 3 = smooth and localized dirty.

Dirty Optics Icon

PLEASE REFER TO CHAPTER 2.9 TURNING ON AND OFF

- Reference bar for the horizontal position of the product

The green bar indicates the horizontal position of the product in the field of measurement.

The 2 green marks on the sides indicate the horizontal

center of the measurement range. The

bar moves upward when the product goes out from the field of measurement and down when

it enters. The

color of the bar indicates that the product is in or out of the measuring range:

green (inside the field), yellow (on the edge of the field), red (off the field).

PLEASE REFER TO CHAPTER 3.2 PRODUCT POSITIONING

AEROEL s.r.l. - PRADAMANO (UD) - ITALY

20 B2798_E 1.1, 2016-04-08

- Measured value box

In the box it is shown the measured value and the directions about the vertical position and the alignment of the

product

No product in the measuring field

Indication of the vertical position of the product: the offset of the two parts of

the frame decreases to zero by placing the product in the vertical

center of the

measuring range

Indication of over misalignment of the product (in the horizontal plane): the two

arrows appear in case of excessive misalignment of the product and invite to

rotate the instrument clockwise or counter

-clockwise.

Diameter of the product properly positioned in the field of measurement

(trigger is not pressed)

Frozen diameter of the product (after trigger pressure)

PLEASE REFER TO CHAPTER 3.2 PRODUCT POSITIONING

- Labels of the function keys

They indicate the menu or action that is obtained by pressing the respective function key from F1 to F4. In this

case, pressing F1 you enter the Setup menu of the instrument and pressing F3 in the Power off menu

2.13 SETUP MENU

From the measuring window, press the F1 key (Setup) to enter the setup

screen of the instrument.

The programming is done through menus consisting of a title (yellow field)

and a list of options.

Use the arrow keys (F2 and F3) to navigate through the various options.

The selected row is highlighted in blue.

To select the option, press the Enter key (F1)

To exit or return to the previous level, press Exit (F4)

In the event that the options to be selected are not all shown in the window, on the right side the a symbols

indicate the presence of other options in the list.

The initial menu contains the following options:

Measure Setup Setting of some parameters about the measurement and display function

HWS.1 Setup Basic instrument setup

Info Hardware and software info

Table of contents

Popular Scanner manuals by other brands

Bell and Howell

Bell and Howell Spectrum XF Maintenance manual

Digital Research Technologies

Digital Research Technologies DRSCAN36EPPR user manual

AGFA

AGFA SnapScan e25 owner's guide

Uniden

Uniden BC72XLT Manual Del Usuario

Canon

Canon imageFORMULA DR-M160 Service manual

Honeywell

Honeywell Voyager 1450g Series user guide