Garnet SeeLevel 710-JS User manual

Page 1SeeLeveL Sender Installation Manual 710-JS / 710-ES / 710-SS

HOLDING TANK MONITOR

710-JS-ES-SS Manual_v1.0 - 05-Jul-2022

WCAUTION: explains safety information that could cause

damage to the product, including data loss.

WWARNING: explains dangers that might result in

personal injury or death.

WNOTE: expands on information for any procedures.

SAFETY SYMBOLS INFORMATION

CANADA

Garnet Instruments

286 Kaska Road

Sherwood Park, AB T8A 4G7

USA

Garnet US Inc.

5360 Old Granbury Road

Granbury, TX 76049

SENDER MANUAL

710-JS | 710-ES | 710-SS

The SeeLeveL Senders 710-JS, 710-ES, 710-SS are used with SeeLeveL II

Tank Monitoring systems that can monitor either two, three or four tanks.

The 710-JS sender is 6" high (not including tabs) and has a resolution of

1/4". This model can measure tanks from 5" to 7.5" high tanks and cannot

be stacked. The higher resolution is optimal for low-prole tanks.

The 710-ES sender is 12" high (not including tabs) with a resolution of 3/8"

and can measure tanks from 5.5" to 14" high with a single sender, and up

to 26" with double-stacked senders.

The 710-SS sender is 16" high (not including tabs) and has a resolution

of 1/2". This model can measure tanks from 7" to 18" high with a single

sender, and up to 34.5" with double-stacked senders.

The senders are mounted on the outside of the holding tanks and can

be stacked to t taller tanks. They work on most plastic or polyethylene

holding tanks that contain water-soluble uids. They are not compatible

with metal holding tanks.

See more information about sender lengths on page 3.

The communication protocol used between our senders and displays is

proprietary allowing us to control the accuracy and functionality of our

systems ensuring our customers experience reliable operation.

INTRODUCTION

Page 2SeeLeveL Sender Installation Manual 710-JS / 710-ES / 710-SS

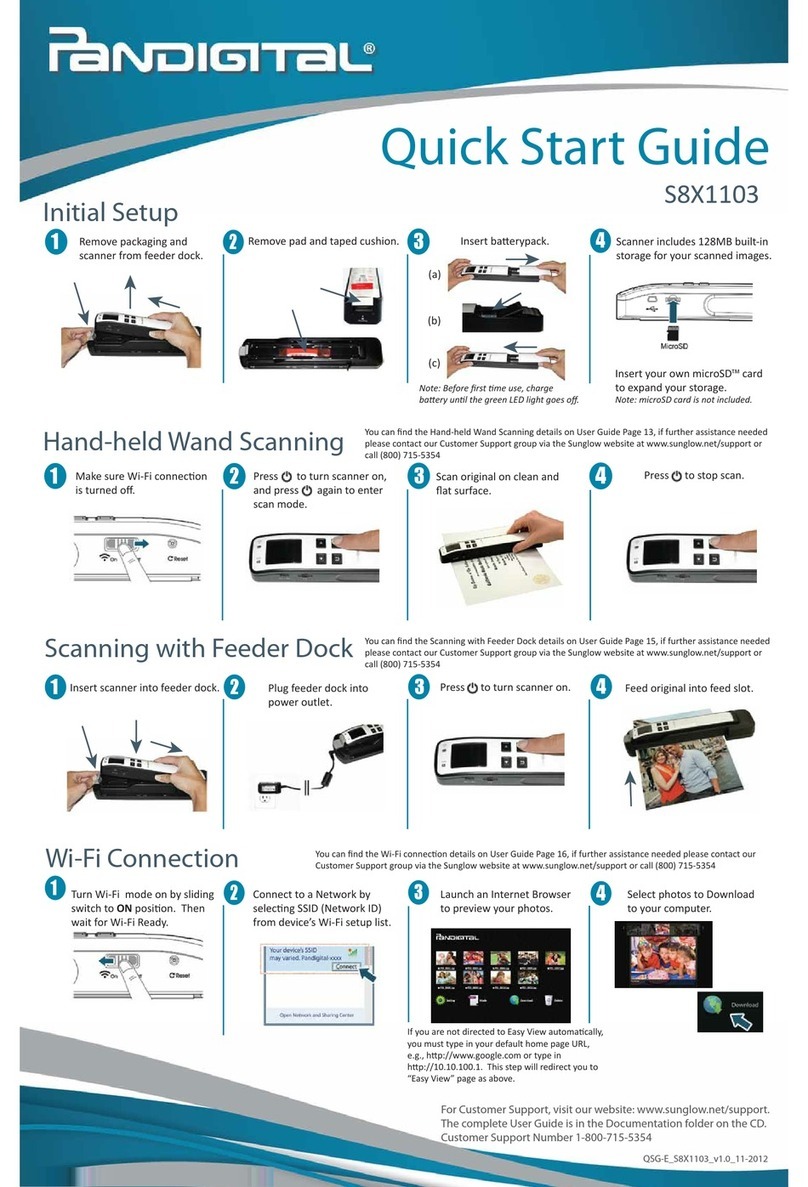

DETERMINE BEST CONFIGURATION & LOCATION

Tools and equipment required:

□Wire cutters/stripper

□Wire crimper

□Scissors or hole punch

□Acetone/rubbing alcohol

□Duct tape or tie-wraps for securing wires

□Non aggressive tape (painters, masking)

□Electrical tape

□Butt connectors

INSTALLATION INFORMATION

The installation for the complete system consists of mounting the display

inside the RV, cutting and mounting the senders to the sides of the tanks,

connecting the wiring, and programming the display.

This manual provides information on how to install the SeeLeveL 710-JS,

710-ES, and 710-SS senders.

Before senders are installed the display should be installed rst.

Refer to the Display Installation Guide and User Manual for the model

you've purchased for all installation and connection details. Manuals can

be found at our online Resource Library from our website at:

http://https://www.garnetinstruments.com/holding-tanks-resource-library/

WCAUTION: 710-JS Senders cannot be double-stacked.

DO NOT mix sender types when stacking senders.

The senders will need to have a at area on the side of the tank large

enough so the whole width of the sender is in contact with the side of the

tank.

Make sure that any metal is at least 1” away from either side, top and

bottom of the sender, and at least 2” away from the face of the sender.

Some tanks may have

irregular shapes. DO NOT

wrap the corners over the top

or bottom of the tank.

See placement examples to

the right.

WCAUTION: Bending the

sender sharply will damage the

circuit on the sender.

Sender Placement

Tank

Height

Sender Options

Best Resolution Other Possible

5” - 5.5" 710-JS single -

5.5” - 7” 710-JS single 710-ES single

7” - 13” 710-ES single 710-SS single

13” - 17” 710-ES stacked 710-SS single

17” - 25” 710-ES stacked 710-SS stacked

25” - 33” 710-SS stacked -

To determine which sender conguration you need, measure the height of

your tanks, then nd out the measurable space (see following page). The

measurable space is the “ideal” position of the sender on the tank. This

will determine what length the senders should be. If a sender is too long,

it will need to be cut. The following table has recommended senders and

congurations for various tank heights.

Sender Conguration

WNOTE: The new 710-AR, 710-ES2 can be combined with old sender models 710-ES,

710-JS, 710-SS.

Page 3SeeLeveL Sender Installation Manual 710-JS / 710-ES / 710-SS

DETERMINE MEASURABLE SPACE ON TANKS

gap

gap

gap

gap

gap

Measure the height of the tank from top to bottom then determine

measurable space.

• The minimum gap is 1/4", however, we recommend that the

senders be installed 1/2" from the top and 1/2" from the bottom

of the tank. Depending on the characteristics of the tank the gap

can be a little more or less (see note below and installation tips

on page 12). This gap ensures that the sender can read properly

through the tank wall as the corners or rounded edges of the tanks

can be too thick for the sender to read through.

• Subtract the gap space from the overall tank height. This will result

in your measurable space. Use the calculation formula at the right.

Measurable

Space

Tank Height

1/2” gap

WNOTE: If senders do not t full height of the tank, to

optimize the level you can justify sender location to be

either closer to the top or bottom, depending on the type

of liquid (Fresh or Grey/Black).

FRESH = closer to bottom as it is preferable that this tank is

not empty!

GREY/BLACK = closer to top as it is preferable that these

tanks are not full!

WNOTE: This is not a static formula that can be used on every tank. With some fresh

tanks, the outlet for the pump feed may sit more than 1 inch above the bottom of the

tank. Your water pump may begin to suck air before the tank is completely empty. In

these cases, you want to install the fresh tank sender above the outlet for the pump

feed. This will ensure that the monitor reads “0” before the pump begins to suck air. WNOTE: Both senders in a double-stacked

conguration should be approximately the same length.

WCAUTION: Installing a sender outside of the recommended measurable space

may aect your readings.

Find Measurable Space

WNOTE: Although

the recommended

gap at the top and

bottom of the tank

is 1/2" the minimum

gap can be 1/4".

The maximum gap

for the 710-JS is 3/4",

the 710-ES is 1", and

the 710-SS is 1.25".

See recommended

sender options table

on page 2.

Stacked conguration

Two senders may be required for taller tanks and

additional senders may be purchased for this

application. There needs to be a gap of 1/16”

to 1/8” between the double stacked senders.

Calculate what the total length of measurable

space for both senders will be:

1. Measure the height of the tank.

2. Tank height = ______________

3. Calculate the recommended measurable space

4. Tank height −top gap −bottom gap −middle

gap =measurable space. *See note regarding

gap recommendations.\\\

Single conguration

1. Measure the height of the tank.

2. Tank height = ______________

3. Calculate the recommended measurable

space as follows:

Tank height −top gap −bottom gap =

measurable space. *See note regarding gap

recommendations.

1/2” gap

Page 4SeeLeveL Sender Installation Manual 710-JS / 710-ES / 710-SS

710-JS Sender

2"

6"

SENDER SPECIFICATIONS

710-ES Sender

2"

12"

Blue

signal wire

Black

ground wire

Continuous

pad

Segmented

pads

710-SS Sender

2"

16"

Segmented

pads

Segmented

pads

Continuous

pad

Continuous

pad

Page 5SeeLeveL Sender Installation Manual 710-JS / 710-ES / 710-SS

CUTTING SENDERS

The senders need to be cut to the required length to match the height of

the measurable space of the tank.

The cut must be between the sender segmented pads. Senders have a

minimum length they can be cut. The minimum length for the 710-ES and

710-SS is after the rst three segmented pads and the 710-JS minimum is

four segmented pads. Once this has been determined, cut the sender with

a pair of scissors.

3 pad

Minimum

length

Only cut

between

pads

PROGRAMMING THE SENDERS

Senders are programmed by cutting o the tabs at the top of each sender

to tell it which tank it will be mounted on, or if in a stacked conguration,

whether they are on the top or bottom. A pair of scissors or a hole punch

can be used to cut the sender tabs.

The senders can be programmed for FRESH, GREY, BLACK, and GALLEY

tanks. The tabs are labeled at the top to show you which tab or tabs to

cut for which tanks. Cut the middle tab labeled "TOP" for double-stacking

senders (top sender only).

TANK TYPE TABS TO CUT

FRESH No tab cut

GREY GRY

BLACK BLK

GALLEY GRY + TOP

FRESH TOP TOP

GREY TOP GRY + TOP

BLACK TOP BLK + TOP

GALLEY TOP see note

For examples of programming for each tank types refer to the table

at the bottom and the illustrations on the next page.

TABS

GRY BLKTOP

GBC TC

WNOTE: For systems that have a Galley

button. Cut the GRY and the TOP tabs. The

GALLEY and the GREY tanks can only have one

sender, so no programming is possible for the

number of senders.

4 pad

Minimum

length

Only cut

between

pads

710-ES & 710-SS

710-JS

Page 6SeeLeveL Sender Installation Manual 710-JS / 710-ES / 710-SS

PROGRAMMING THE SENDERS 710-ES AND 710-SS

FRESH

Senders tabs to cut for single sender or bottom sender if double-stacked.

GREY

GRY

BLACK

BLK

For a double-stacked tank conguration, the top sender requires an additional tab to be cut.

GALLEY

GRY TOP

FRESH TOP GREY TOP

GRY

BLACK TOP

BLKTOP TOP TOP

Examples for correcting cuts made in error.

FRESH TOP

TOP

(GRY or BLK tab cut by mistake)

GRY BLK

GREY SINGLE

OR BOTTOM

BLK

(BLK tab cut by mistake)

FRESH SINGLE

OR BOTTOM

TOP

(TOP tab cut by mistake)

No Tabs cut

WCAUTION: TABS CUT IN ERROR

If the “GRY” tab has been removed and it should be a black

tank sender, or if the “BLK” tab has been removed and it should

be a grey tank sender, then cut out the recessed grey-black

correction tab that says “GBC” next to it. This reverses the eect

of the grey and black tabs.

If either the “GRY” or “BLK” tabs have been removed and it

should be for a fresh tank, then remove the other “GRY” or

“BLK” tab. When both the “GRY” and “BLK” tabs are removed, it

becomes a fresh tank sender.

WNOTE: For systems that have a

Galley button. Cut the GRY and the TOP

tabs. The GALLEY and the GREY tanks can

only have one sender, so no programming

is possible for the number of senders.

Page 7SeeLeveL Sender Installation Manual 710-JS / 710-ES / 710-SS

FRESH

Senders tabs to cut for single senders.

GREY

GRY

BLACK

BLK

No Tabs cut

GALLEY

(4-Tank systems)

GRY ALT

Examples for correcting cuts made in error.

FRESH

(GRY or BLK tab cut by mistake)

GRY BLK

GRY BLKALT

PROGRAMMING THE SENDER 710-JS

710-JS Sender Tabs

WCAUTION: 710-JS Senders cannot be double-stacked.

Page 8SeeLeveL Sender Installation Manual 710-JS / 710-ES / 710-SS

PREPARE SENDER FOR INSTALLATION

❶Clean the tank

Clean area throughly where the sender will be

mounted making sure there is no dust, grease

and oil.

Acetone or rubbing alcohol will remove sticky

residue. Once the sender is cut and programmed, temporarily tape the sender

to the tank wall. Place a piece along the length of both sides of the

sender and perform a test to verify operation.

❷

WCAUTION: Route wires to the right, away

from the senders. The wires indicate the top

of the sender.

WCAUTION: DO NOT SKIP THE FOLLOWING STEPS. Removing the sender

from the tank after the sender has been permanently installed will cause damage

to the sender that is NOT covered under warranty.

Use a non aggressive

tape like painters tape

or masking tape.

Temporarily tape sender on tank

Page 9SeeLeveL Sender Installation Manual 710-JS / 710-ES / 710-SS

WIRING THE SENDER

❸Connect the wiring to the pigtail

The following diagram shows the wiring from the sender to the display pigtail. Other wiring

connections may apply for each display model. All wiring diagrams are available on the website.

GROUND

TO

+12V POWER

TO PUMP

INDICATOR

PIGTAIL

HARNESS

GALLEY BLACK GREY

FRESH STACKED

WCAUTION: It is very important that the display

and senders have the same ground. Make sure the

sender ground connection is connected back to the

display ground or breaker panel ground.

WCAUTION: Wires are to be routed to the RIGHT

side of the sender, away from the sender. Never

route the wires to the left of the sender. If they

drape over the sender they could aect the reading.

Example of stacked

sender wiring

Page 10SeeLeveL Sender Installation Manual 710-JS / 710-ES / 710-SS

❹Verify operation before permanently sticking the sender to the tank.

Tank levels operation test

For the initial test, have the tank at least 1/4 full of

water or sewage.

Verify that the percent level reading on the display

panel looks correct.

Signal strength test

The signal power is an indication of how much

signal is being transmitted through the tank wall

and picked up by the receiver part of the sender.

Typical signal power should be 50% to 60%. The

gauge will work with minimum signal strength as

low as 20%, but it is good to have at least 50% to

60% at installation so that there is some margin

available for buildup in the tank. P00 = 100%.

FRESH

LEVEL IN PERCENT

2 5

.

.

SENDER TEST

Page 11SeeLeveL Sender Installation Manual 710-JS / 710-ES / 710-SS

Once proper operation has been conrmed,

the sender will be ready to permanently

stick to the tank wall.

Remove one side of the tape.

Permanently adhere sender to the tank

Fold the sender over so it is still attached

with one side of the tape.

Carefully fold the sender back and press the

sender down to the tank so that all of the

adhesive is contacting the tank wall. Make

sure there are no air gaps between the sender

and the tank. Remove the other side of the

temporary tape.

Slowly peel the backing paper o the

adhesive.

Secure the wires

❻

Secure the wires with duct tape, tie wraps, or

something similar so that the wires do not rattle or

press against the sender, this may result in sender

damage or wires breaking over time.

Apply undercoating to the senders

On installations where the holding tank is exposed

to under chassis road spray and ying rocks etc. We

recommend the use of a rubberized undercoating.

Recommended brands:

3M 03584 Professional Grade Rubberized Undercoating

Gravel Guard Rocker Guard Coating By Dominion Sure Seal

❼

MOUNTING THE SENDER

WCAUTION: Be careful not to bend the senders excessively or you

could damage the circuits. You only have one shot at this. If you try

to peel it o the tank once it is stuck the sender may be damaged

by the sharp bending. Removing the sender after it's been adhered

voids the warranty.

❺

Page 12SeeLeveL Sender Installation Manual 710-JS / 710-ES / 710-SS

INSTALLATION TIPS

This manual suits for next models

4

Table of contents

Popular Scanner manuals by other brands

Epson

Epson Perfection 1670 Photo Brochure & specs

Ambir

Ambir ImageScan Pro 800ix series Installation and setup guide

SICK

SICK S300 Mini Mounting instructions

Epson

Epson Perfection 610 Scanner Supplemental information

Canon

Canon imageFORMULA DR-M160II user manual

GTCO CalComp

GTCO CalComp SCANstation brochure