AeroPlus Air Tractor 502 User manual

110" Air Tractor 502 30-60CC

WING SPAN: 110" (2800mm)

LENGTH: 78.5" (2000mm)

WING AREA: 1704sq in

FLYING WEIGHT: 19-20.9lbs (7100g-7800g)

ENGINE:30-60cc gas

RADIO: 4CH / 6 servos

Features:

Carbon Fiber - Wing Tube, Stab Tube, Main Gear, and Tail gear

Fiberglass Servo Arms and Control Horns

Canister ready Fuse

Adjustable Push rods

Ringed Cowl

Pre-Drilled Hinges

Removable Rudder, 2 Piece Removable Wings and 2 Piece Removable Stabs.

Carbon rods incorporated in fuse and wings to keep airframe stiff

Congratulations on your purchase of your new AeroPlus RC 110”Airtractor 502. We hope that

you will enjoy this plane and that it will exceed your expectations in what a model airplane can

be. Thank you, AeroPlus RC

Unpacking

Carefully unpack the model, when opening the plastic bags make sure you do not to cut any

covering on the model. Inspect each item to make sure there was no damage in shipping. If for

any reason, you are not happy with any part or are unsure please contact the Dealer that you

purchased your plane from.

Covering

Because of the multiple climate zones encountered on the trip from the factory to you, some of

the covering may have wrinkles. We highly recommend that you take time to reseal all covering

edges with an iron and to use a heat gun to remove any wrinkles and retighten the covering. It is

best to do this now before the plane is assembled.

*Note: Be careful not let any heat get near parts like the canopy or cowl as this may cause

damage.

Assembly Tips

We also recommend that you go over all the accessible joints with cyano glue. Wick glue into

areas of high stress around the U/C plate and motor box.

Use a quality Thread-lock on all metal to metal joints. Even if your model is electric powered with

lower levels of vibration the thread-lock will ensure that things do not fall off of your airplane!!

Landing gear:

First, screw the flange nut into the axle, then use the self-locking nut to lock the axle on

the landing gear, remember to use a washer between the self-locking nut and the landing

gear, and then press a plastic gasket, The sequence of the shims is to load the wheel into

the axle, and finally insert the pin into the axle hole to lock the wheel. Repeat for the other

side.

Tail wheel installation:

First attach the rear wheel frame plate with three 3mm screws and washers. Using the hollow

screws and nuts on the tail wheel frame plate. Insert the tail wheel shaft through the hollow

screw (see photos) rear wheel steering seat screws Will be wheel axle locking, tail wheel steering

seat screw to be aligned for the axle to be polished surface. The two springs in the guide angle,

the amount of good spring a little taut length of the T-direction steering seat using self-tapping

screws in the direction (after a good mouth to the screw holes need to fast-drying glue and then

tighten) , And then the length of the hook after the hook in the direction of the steering seat.

Flaps:

The epoxy rudder angle is glued to the wing; the carbon fiber rudder angle is glued to the flap,

with two holes in the middle. The two rudders are then connected using a screw.

Rudder Installation:

The tail wheel must be installed. First, drill the four screw holes with a hand drill and drip CA in

the holes to harden them. Then lock the servo with self-tapping screw. The mounting holes of the

servo mounting plate also need to be fast-dripped and then tightened with self-tapping screws.

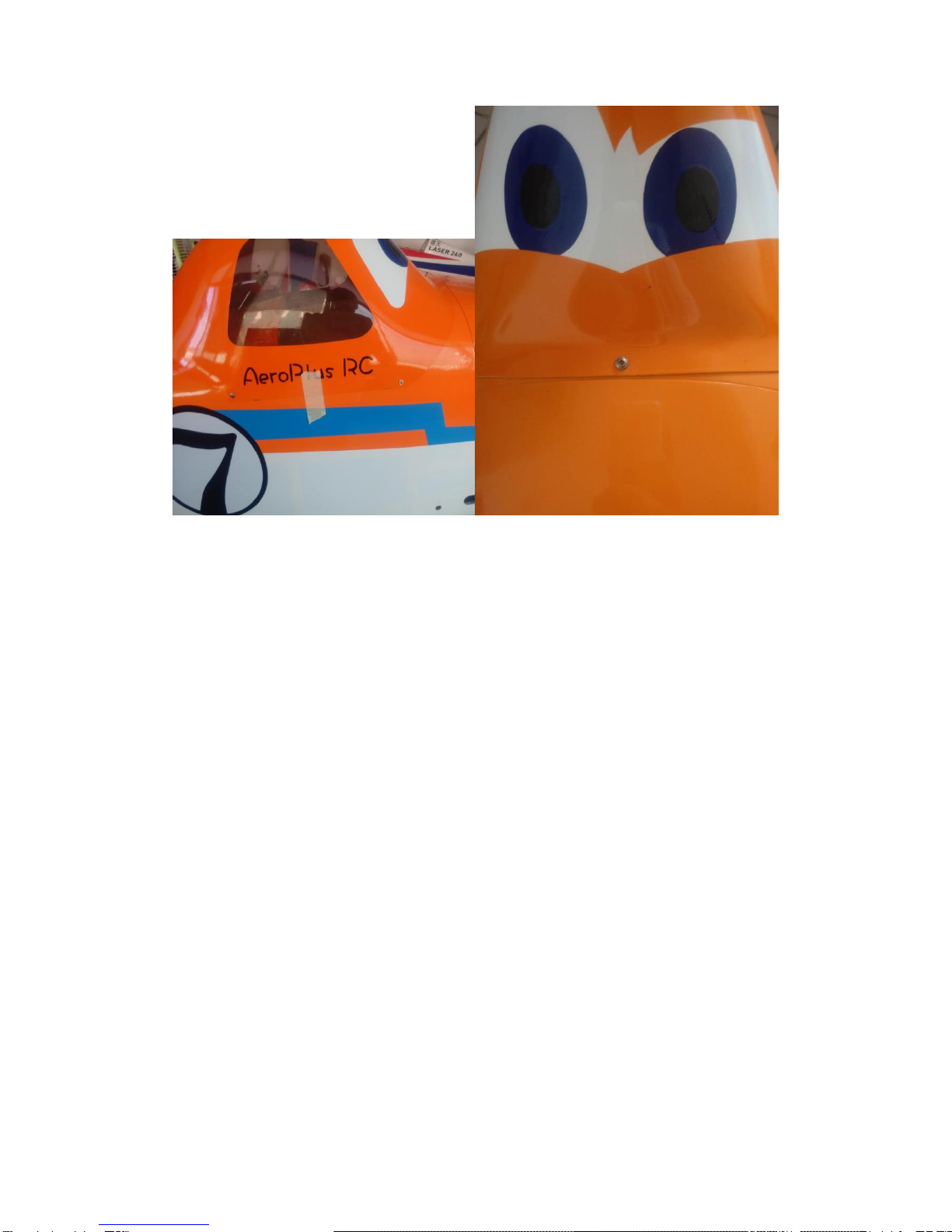

Cockpit cover installation:

find the cockpit suitable placement, use paper tape to be fixed, and then use the drill on the left

and right sides of the two holes to play, before and after the middle position of the play a hole.

Pour a little bit of each hole into the quick-drying glue, and then use the self-tapping screw

locking fixed.

Cowl installation:

Stick a piece of paper tape in the fixed mounting ears, longer than the ear to the fuselage of the

double cut as far as possible with the ear parallel. And then put the paper tape buckle, and then

paste it back to the paper, be careful not to have folds, paste a good tape after the machine from

the machine, the paper tape to the tape, Body tear, in the hood against the punched paper tape

holes can be used to drill a hole in a hand drill. Finally, use hexagon socket head cap screws with

washers.

Before you fly!

We recommend the use of exponential.

Suggested Set up:

Wing flap: Flap are designed for 50 degrees of throw

Aileron: 15-20 degrees 15-20% Expo

Elevator: 15-20 degrees 15-20% Expo

Rudder: 25-30 degrees 15-20% Expo

Aileron: 35-45 degrees 30-60% Expo

Elevator: 40 degrees 30-60% Expo

Rudder: 60 degrees 30-60% Expo

For your maiden flights always use low rates, Also please remember that + and –exponential is

different per manufacturer, check your TX manual. Always range check your model before the

maiden flight. Carry out a short flight then go over everything to make sure nothing has come

loose.

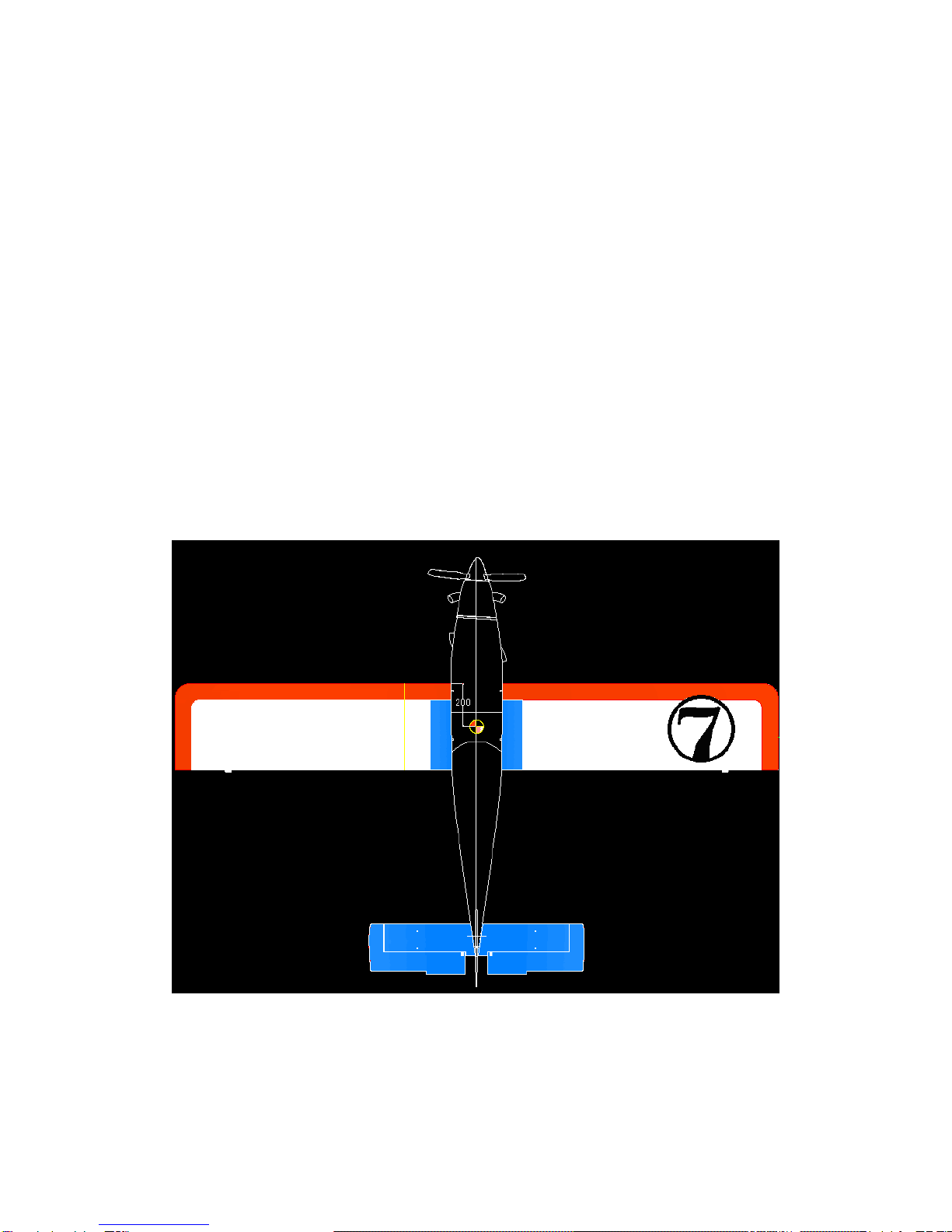

Center of Gravity: 200mm behind the leading edge at the wing root.

Table of contents