Aerosol Magee Scientific Aethalometer AE33 User manual

Aethalometer

Model AE33

_______________________________________________________________________________________________________

Service manual –Ver. 1.0 October 2020 1/60

Aethalometer®Model AE33

Service Manual

Version 1.0

October 2020

Aerosol d.o.o., Ljubljana, Slovenia

Aethalometer

Model AE33

_______________________________________________________________________________________________________

Service manual –Ver. 1.0 October 2020 2/60

Aethalometer® Model AE33 Service Manual

Version 1.0, October 2020

Applicable for Magee Scientific Aethalometer® Model AE33

Copyright 2020 Aerosol d.o.o. Magee Scientific Aethalometer® Service Manual. All Rights

Reserved.

Aerosol d.o.o.

Kamniška 39A

SI-1000 Ljubljana

Slovenia, EU

tel: +386 1 4391 700

fax: +386 59 191 221

www.aerosol.eu

www.mageescientific.com

Aethalometer

Model AE33

_______________________________________________________________________________________________________

Service manual –Ver. 1.0 October 2020 3/60

TABLE OF CONTENTS

1GENERAL INFORMATION ...............................................................................................5

2SAFETY NOTES AND LABELS .........................................................................................6

3SERVICE PROCEDURES ON MAIN PARTS ................................................................10

3.1 ANALYTICAL CORE ASSEMBLY ................................................................................ 10

3.1.1 ANALYTICAL CORE ASSEMBLY REMOVAL PROCEDURE............................... 10

3.1.2 LED OPTICAL SOURCE REPLACEMENT ............................................................... 15

3.1.3 DETECTOR BOARD REPLACEMENT...................................................................... 18

3.1.4 CONTROLLER BOARD REPLACEMENT ................................................................ 21

3.1.5 FLOW SENSOR REPLACEMENT .............................................................................. 22

3.1.6 TAPE SENSOR REPLACEMENT ............................................................................... 25

3.1.7 SAMPLE INLET FLOW PATH CLEANING PROCEDURE...................................... 27

3.2 INTERCONNECTION BOARD ....................................................................................... 30

3.2.1 INTERCONNECTION ELECTRONIC BOARD ......................................................... 30

3.2.2 FUSES............................................................................................................................ 33

3.3 INTERNAL VACUUM PUMP ......................................................................................... 33

3.4 REAR PANEL DATA CONNECTOR PLATE ................................................................ 37

3.5 POWER SUPPLY MODULE............................................................................................ 38

3.6 COMPUTER ...................................................................................................................... 40

3.7 BALL VALVE................................................................................................................... 43

3.8 FRONT DOOR TOUCH-SCREEN MODULE................................................................. 46

4TROUBLESHOOTING.......................................................................................................49

4.1 STARTUP SCREEN CHECKS ......................................................................................... 49

4.2 INSTRUMENT STATUS .................................................................................................. 50

4.3 UNACCEPTABLE QUALITY CONTROL TEST RESULTS......................................... 51

4.4 OTHER ISSUES ................................................................................................................ 52

5SOFTWARE UPGRADE ....................................................................................................54

6DRAWINGS .........................................................................................................................55

Aethalometer

Model AE33

_______________________________________________________________________________________________________

Service manual –Ver. 1.0 October 2020 4/60

7CUSTOMER SERVICE ......................................................................................................58

8RETURNS FOR SERVICE.................................................................................................59

Aethalometer

Model AE33

_______________________________________________________________________________________________________

Service manual –Ver. 1.0 October 2020 5/60

1GENERAL INFORMATION

The Aethalometer® Model AE33.

The ‘Next Generation’ Aethalometer®, Model AE33, is a precision instrument which

incorporates scientific and technical advances to offer improved measurement performance,

user features, communications and interface: and the ability to perform routine performance

tests to verify correct operation. For optimum performance it is essential that the instrument

should be regularly maintained and correctly serviced. The Model AE33 is constructed with a

modular design, so that all sub-units or main parts may be easily serviced. This Manual presents

detailed service and maintenance procedures in a tutorial and illustrative way.

Aethalometer

Model AE33

_______________________________________________________________________________________________________

Service manual –Ver. 1.0 October 2020 6/60

2SAFETY NOTES AND LABELS

CAUTION!

READ THIS CHAPTER VERY CAREFULLY BEFORE SERVICING THE INSTRUMENT.

Instrument service procedure

Service of the instrument must be done only by trained service personnel. Regular

service trainings are offered at the Aerosol d.o.o. premises in Europe; and on-line

arrange a convenient date for training.

INCORRECT service procedures can be DANGEROUS for the service technician.

Unauthorized instrument access and operation

The instrument must not be serviced in any manner which contravenes this Manual. Unauthorized

internal access or incorrect service procedure can be dangerous. The instrument must only be serviced

by trained personnel with suitable technical skills and practical experience, who can ensure its proper

handling and service procedure.

Aethalometer

Model AE33

_______________________________________________________________________________________________________

Service manual –Ver. 1.0 October 2020 7/60

Electric shock

CHECK the A.C. main power supply cord during regular maintenance or other service procedure. If the

supply cable is DAMAGED or FRAYED, ALWAYS replace it with a new one.

Fire and explosion

NEVER install the instrument in explosion-risk areas and never operate the equipment near flammable

substances.

Instrument overheating

ALWAYS provide adequate ventilation. NEVER install the instrument in spaces with limited air

circulation.

UV radiation

The AE33 light source contains ultraviolet (UV) light emitting diodes (LEDs). These LEDs radiate UV and

visible light during operation. Precautions must be taken to prevent looking directly at the UV light with

unaided eyes. NEVER touch or look directly into the AE33 light source!

Aethalometer

Model AE33

_______________________________________________________________________________________________________

Service manual –Ver. 1.0 October 2020 8/60

Instrument service and repair

UNAUTHORISED instrument service and repair procedures will VOID THE WARRANTY. The

instrument must only be serviced by authorized personnel.

Aethalometer

Model AE33

_______________________________________________________________________________________________________

Service manual –Ver. 1.0 October 2020 9/60

Moving parts

During AUTOMATIC tape advance procedure, the measurement chamber is lifted by a motorized lift

mechanism. To prevent any injuries to your fingers, NEVER place your hands or fingers into ANY

mechanical apertures during the automatic tape advance procedure.

During MANUAL chamber lift procedure ALWAYS use the chamber lift locking latch. To prevent any

injuries to your hands or fingers, NEVER place your hands or fingers into ANY mechanical apertures.

Exercise caution when lifting and releasing the chamber against its springs.

Aethalometer

Model AE33

_______________________________________________________________________________________________________

Service manual –Ver. 1.0 October 2020 10/60

3SERVICE PROCEDURES ON MAIN PARTS

3.1 ANALYTICAL CORE ASSEMBLY

3.1.1 ANALYTICAL CORE ASSEMBLY REMOVAL PROCEDURE

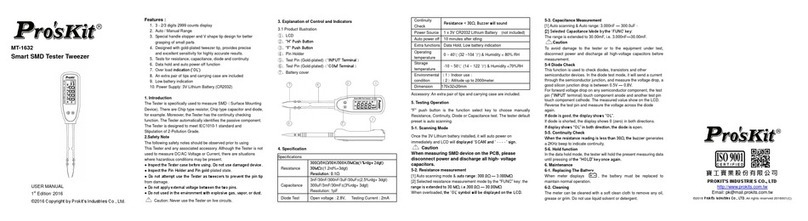

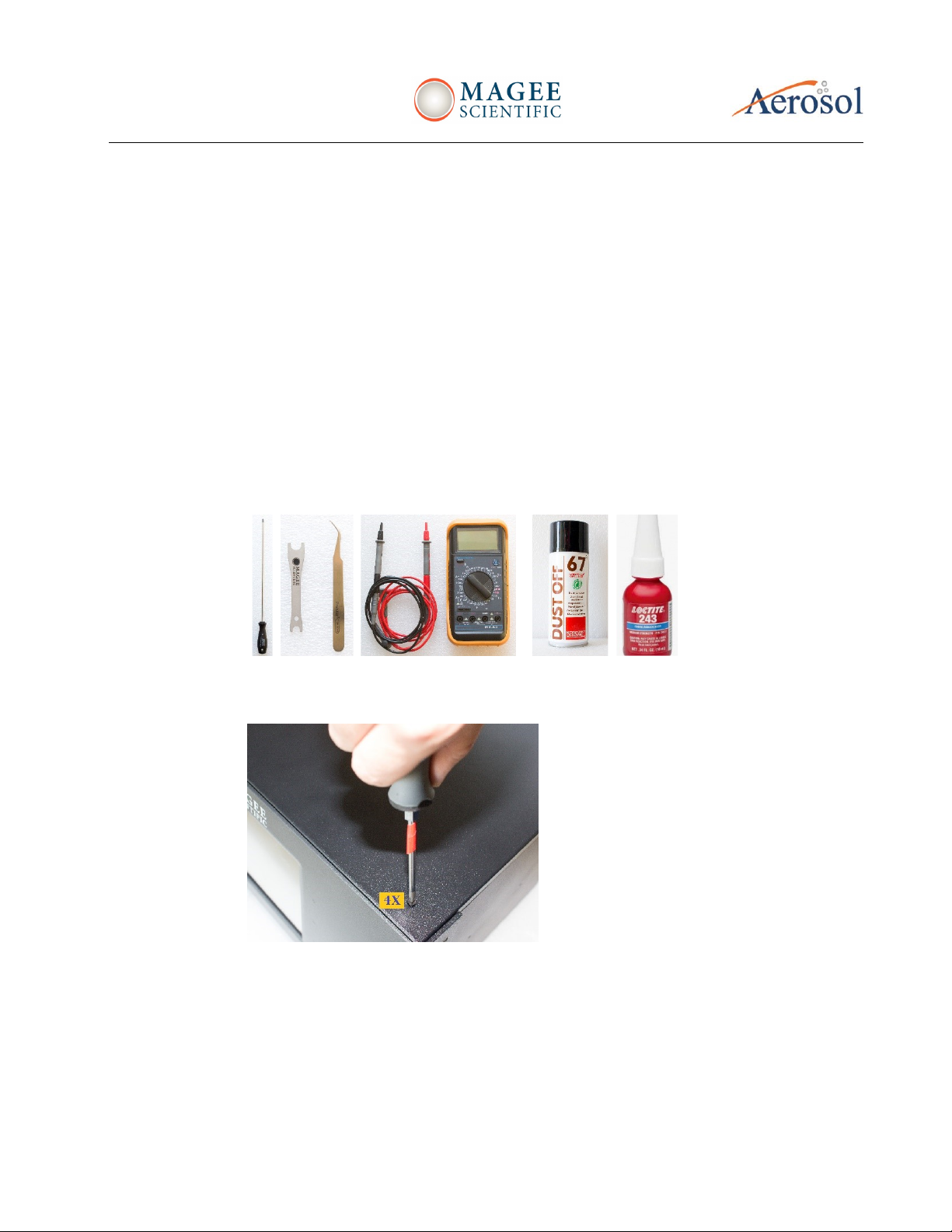

-Tools needed:

•Philips (' + ') screwdriver

•Push to connect tubing fitting tool (supplied in Aethalometer package); or flat (' –')

screwdriver

•Tweezers, long-nose pliers

•Digital voltmeter (for grounding continuity test)

•Screw thread locking adhesive (e.g., 'Loctite 243')

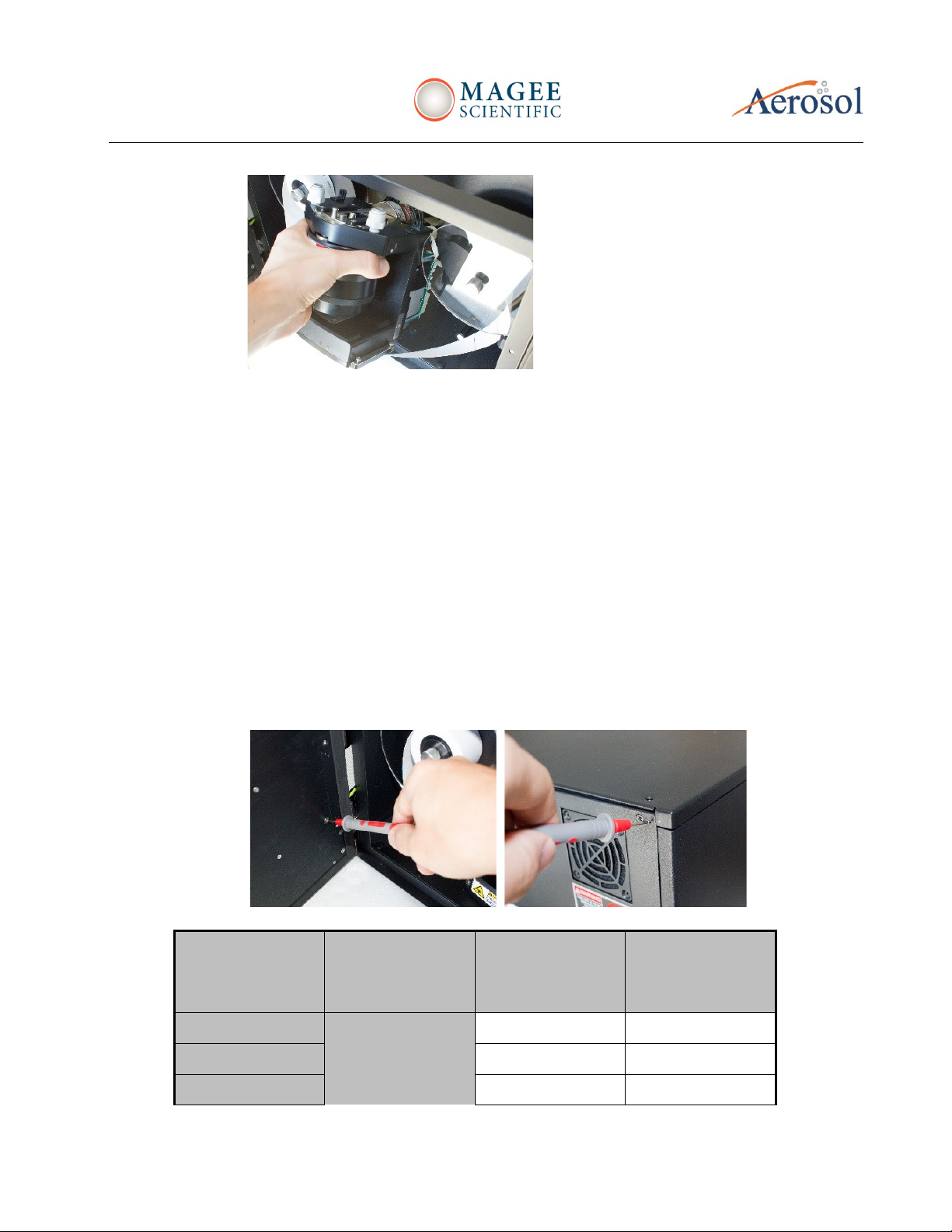

1. Turn OFF the instrument and unplug the power cord. Remove top cover (4 ‘+’ screws,

disconnect ground wire). Remove back cover (6 ‘+’ screws), disconnect ground wire.

Aethalometer

Model AE33

_______________________________________________________________________________________________________

Service manual –Ver. 1.0 October 2020 11/60

2. Please carefully follow the picture steps in the proceeding:

3. Lift the optical chamber up against its springs, lock it into place with the sliding latch

Aethalometer

Model AE33

_______________________________________________________________________________________________________

Service manual –Ver. 1.0 October 2020 12/60

4. Remove cartridge filter (push down on gray fitting rings)

5. Disconnect the optical chamber air sample inlet tube. With one hand hold the light source

housing and with the other hand pull up slowly on the flexible inlet tube.

6. From the rear side of the analytical core unit, disconnect all the tubes and cables except: tape

sensors (4-wire ribbons), solenoid valves (plug with 6 black wires), flow sensors (2x 3-wire

plugs), and LED driver (20-wire ribbon). Do not disconnect the 20-wire ribbon which joins the

base of the controller board to the detector board underneath the base. Carefully disconnect

the tape advance motor (6-wire plug) and the pump (4-wire plug). Apply force only to the

rectangular plug body, never to the wires themselves, as this may pull them out of the contacts.

Aethalometer

Model AE33

_______________________________________________________________________________________________________

Service manual –Ver. 1.0 October 2020 13/60

7. Remove filter tape

8. Unscrew the 6 screws which secure the assembly to the chassis: 3 on each side as shown below

(green circles)

9. Slightly tilt the assembly while removing it from the chassis.

Aethalometer

Model AE33

_______________________________________________________________________________________________________

Service manual –Ver. 1.0 October 2020 14/60

You can now proceed with further service, maintenance/cleaning or procedures

to exchange defective parts on the analytical core assembly.

Analytical core re-installation procedure

1. Clean the threads of the 6 mounting screws and apply a drop of Loctite 243 to each

one. Be sure that the long metal strips are in place between the screws and the

baseplate on either side.

2. Reconnect all cables and make sure they are firmly positioned. Note that each plug

has a different number of contacts: it is not possible to plug the »wrong plug into

the wrong socket«.

3. Make sure the air inlet and outlet tubes are firmly pressed on to the tubing barb

connectors, to avoid leaks.

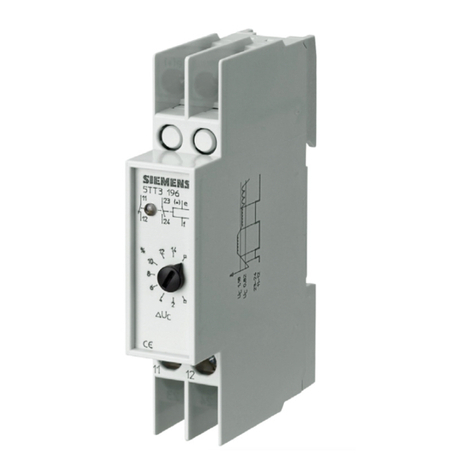

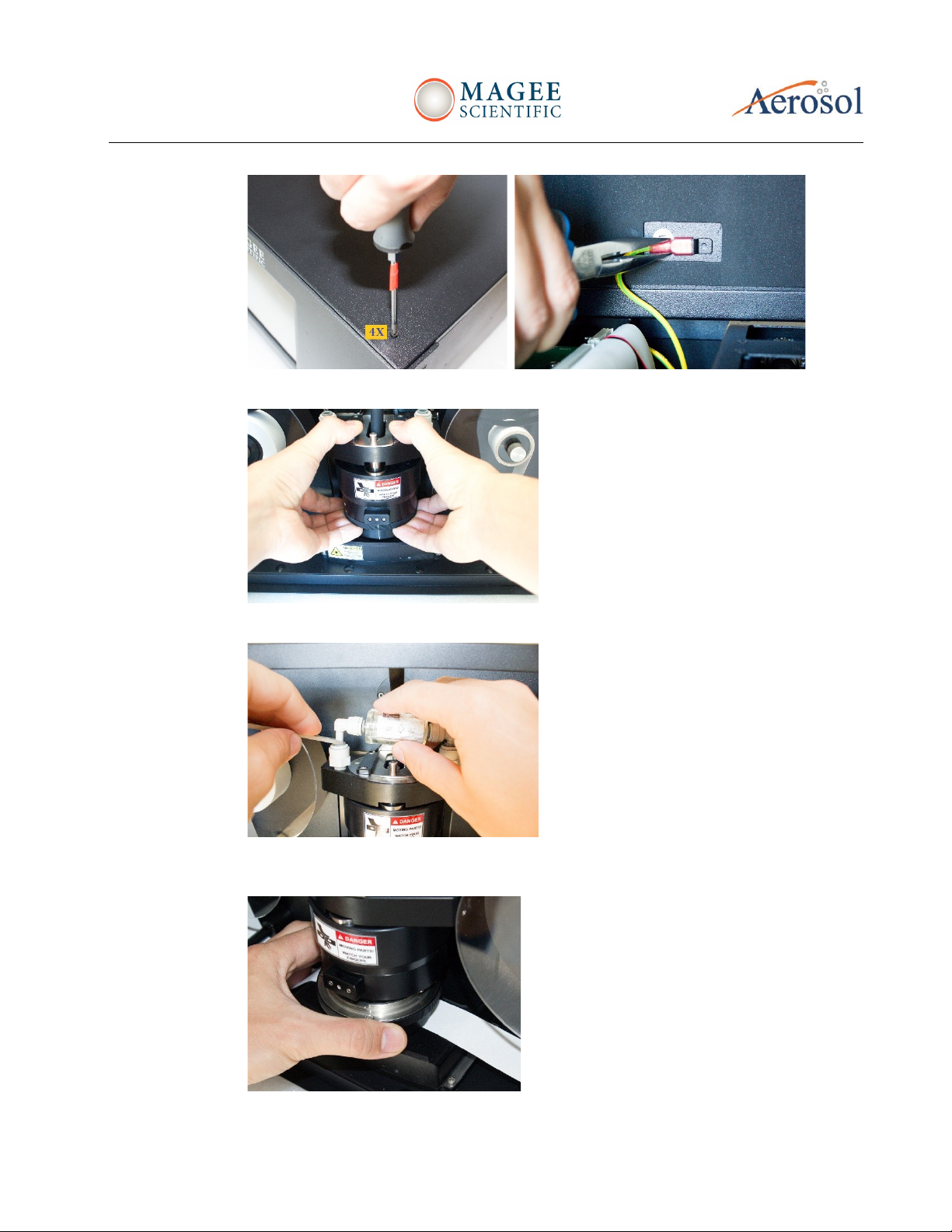

System electrical grounding test

•Electrical safety is provided by connecting the chassis grounding (‘GND’) to the

3rd wire of the power cord. We recommend testing the GND wire connection for

proper grounding as shown below.

Resistance

between the inlet

grounding pin

and

VALUE

MEASURED

CONTINUITY

Top panel

Rear panel

Chassis

< 0.1 Ohm

Aethalometer

Model AE33

_______________________________________________________________________________________________________

Service manual –Ver. 1.0 October 2020 15/60

Front panel

* Older units (units from batch 00 only) have 4 screws on the lower baseplate for attaching the

analytical assembly: but do NOT have the two upper stabilizing screws. All subsequent instruments

have 2 additional screws at the top of the chamber frame.

3.1.2 LED OPTICAL SOURCE REPLACEMENT

-Tools needed

•Medium-size Phillips ('+') screwdriver with a shaft of minimum 6 cm length

•Digital voltmeter (for grounding continuity test)

•Modified power cord for GND continuity test (optional if available), otherwise use

digital multimeter probes to perform this test)

-Spare parts

•AE33 1 05 907_Led driver

•AE33 1 02 901_Led source

•AE33 1 99 022_Led driver board cable

•o-ring_15x1.5

•PH flat head machine screw DIN965A M3x8 zinc plated, quality 8.8

•PH Cross recessed pan head Screw DIN 7985 M2,5x10 A

•PH flat head machine screw DIN965A M2x6 A2

Procedure to disassemble and replace LED optical source

NOTE: it is not necessary to remove the analytical core assembly from the Aethalometer, in order to

simply service the LED source.

1. Turn OFF the instrument and unplug power cord

2. Remove top cover (unscrew 4 screws and disconnect ground wire)

Aethalometer

Model AE33

_______________________________________________________________________________________________________

Service manual –Ver. 1.0 October 2020 16/60

3. Lift the optical chamber up against its springs, lock it into place with the sliding latch

4. Remove cartridge filter (push down on gray fitting rings)

5. Remove lower light guide chamber: press UP on the locking button at the front; turn the

chamber to the left until its bayonet fitting releases.

Aethalometer

Model AE33

_______________________________________________________________________________________________________

Service manual –Ver. 1.0 October 2020 17/60

6. Insert the long '+' screwdriver into the two holes on the upper surface of the chamber top piece.

Unscrew 2 screws from the holder (top left picture). Hold the lower bayonet housing when

detaching the second screw.

7. Remove bayonet housing from the light source housing, disconnect ribbon cable plug from its

socket (it sometimes helps to use a long thin '-' screwdriver to push up on the ribbon plug body

in its socket. DO NOT pull on the ribbon cable itself!) Check the condition of the o-rings.

8. The lowest o-ring fits into the light guide and prevents air leakage. The other o-rings improve

the fitting of the bayonet housing only.

9. From the bayonet housing remove source fixing cover ring (3x '+' screws) and take out the LED

source assembly. This consists of two circular electronics boards connected together by 4x

plugs and sockets and with a thin spacer ring in between.

Aethalometer

Model AE33

_______________________________________________________________________________________________________

Service manual –Ver. 1.0 October 2020 18/60

10. Separate both PCBs (LED source and LED driver) and replace them with new electronics.

Check the orientation of the 4 plugs and sockets –there is only ONE correct way!

LED source assembling

•Put everything back in reverse order (re-attach cover ring, re-connect ribbon

cable, re-insert it into upper chamber, re-attach 2 screws with a long ´+´

screwdriver, re-insert cartridge filter, release the optical chamber and finally

replace the top cover plate). Make sure that the ribbon cable is properly

connected and not squeezed between bayonet and source housing.

System electrical grounding test

Repeat the electrical GND continuity test procedure described in Section 3.1.1.

3.1.3 DETECTOR BOARD REPLACEMENT

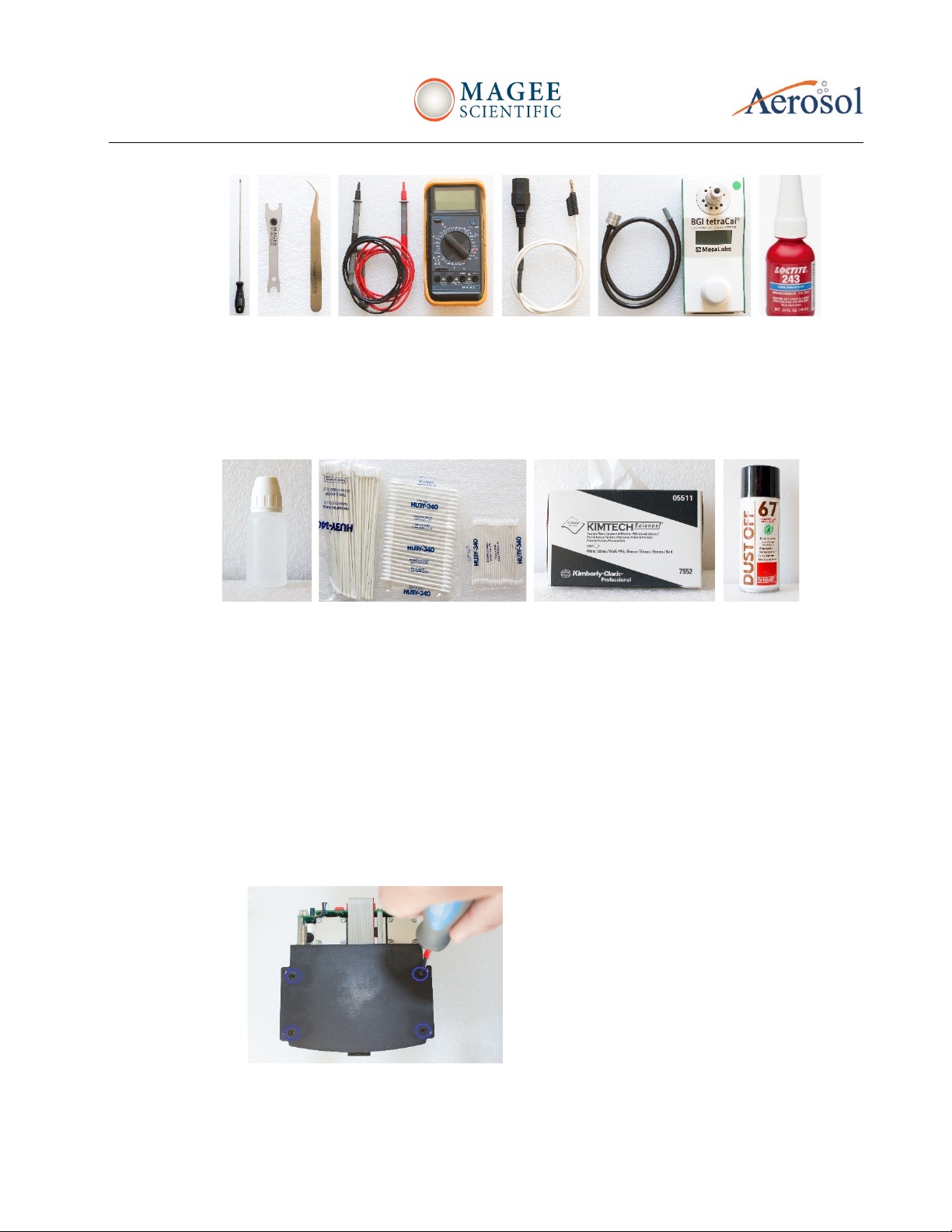

1. Tools needed

•Philips (' + ') screwdriver

•Push to connect tubing fitting tool (supplied in Aethalometer package); or flat (' –')

screwdriver

•Tweezers, long-nose pliers

•Digital voltmeter (for grounding continuity test)

•Can of 'dust removal' pressurized spray with nozzle tube

•Screw thread locking adhesive (e.g., 'Loctite 243')

•Air flow calibrator, e.g. 'BGI TetraCal' (for leak checking)

Aethalometer

Model AE33

_______________________________________________________________________________________________________

Service manual –Ver. 1.0 October 2020 19/60

2. Cleaning equipment

•Ethanol

•Cotton-tipped swab sticks

•Cotton wipe cloths

•Can of 'dust removal' pressurized spray with nozzle tube

3. Spare parts

•AE33 1 03 903_detector board

•AE33 1 99 021_detector board cable

•PH flat head machine screw DIN965A M3x8 zinc plated, quality 8.8

•PH Cross recessed pan head Screw DIN 7985 M2,5x6 A2

•PH Cross recessed pan head Screw DIN 7985 M2,5x10 A2

4. Detector Board service procedure

1. TURN OFF the instrument and unplug the power cord

2. See Section 3.1.1 and follow the procedure to remove the analytical core

3. Turn the unit upside down and remove the detector cover baseplate

Aethalometer

Model AE33

_______________________________________________________________________________________________________

Service manual –Ver. 1.0 October 2020 20/60

4. Remove 5 screws from the detector board and pull it out holding the connector

(Note: you may need to pry it gently at each mounting hole, if it is pressed firmly

into place.)

5. Detector board replacement

•Before installing the new detector board, make sure that the front glass

lenses on all of the photodiodes are completely clean of any greasy stains,

scratches, fingerprints or dirt. Also check the cylindrical light guide tubes in

the detector housing base. Clean with swabs and alcohol if necessary.

•When re-installing the mounting screws of the detector board, do not over-

tighten the central screw: use finger-tight torque only.

6. Analytical core assembly re-installation procedure

Follow the instructions in Section 3.1.1

7. Recommended leakage test

Table of contents

Popular Measuring Instrument manuals by other brands

Keysight

Keysight M9703A Series Startup guide

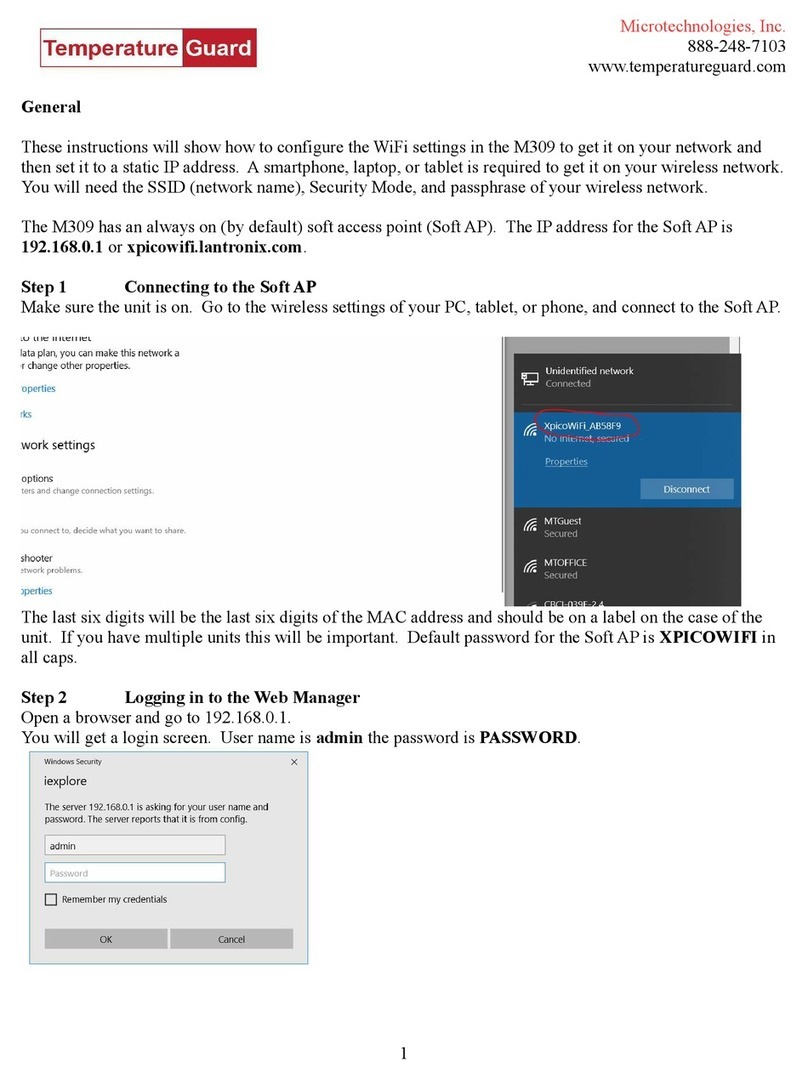

Temperature Guard

Temperature Guard M309 instructions

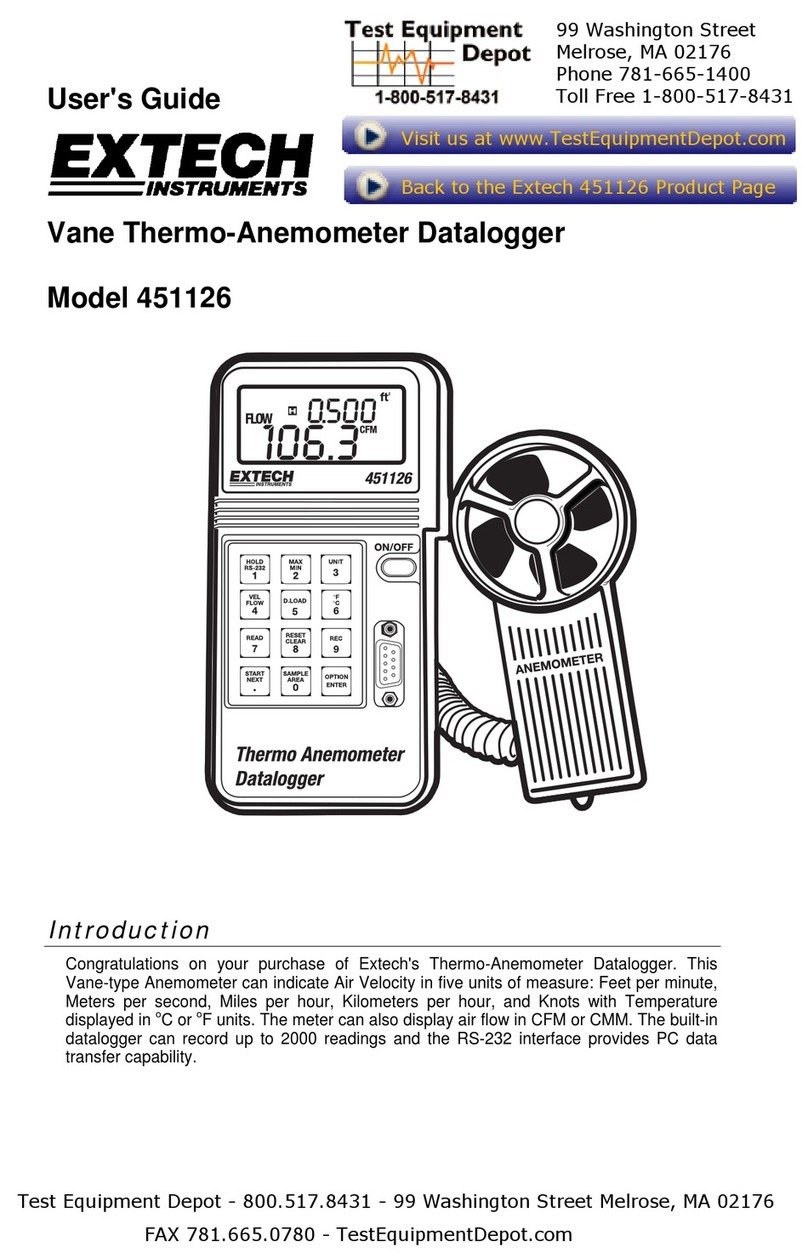

Extech Instruments

Extech Instruments NON-DISPLAY PORTABLE user guide

NIVELCO

NIVELCO THERMOCONT TXP-1 Series user manual

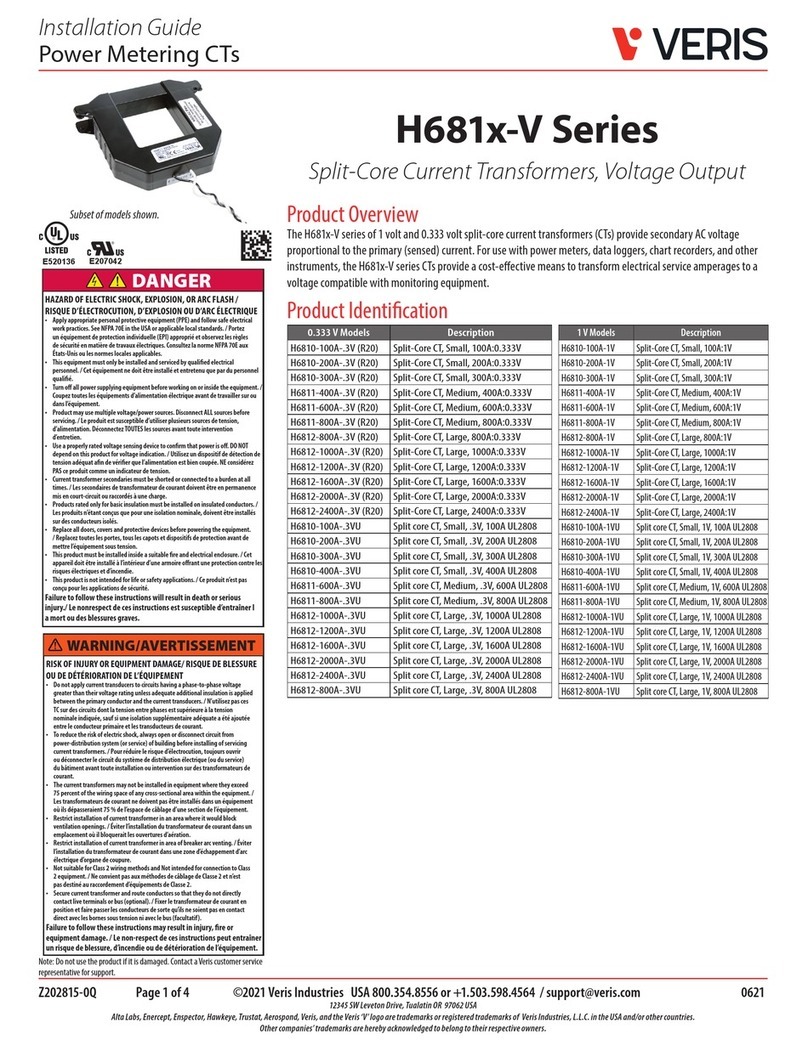

Veris

Veris H681-V Series installation guide

Hanna Instruments

Hanna Instruments HI96709C instruction manual