AFL IDEAA 144F User manual

1

INSTALLATION INSTRUCTIONS

IDEAA®Interior Distribution Cabinet 144F

TABLE OF CONTENTS

GENERAL ........................................................................................................................................................................ 2

SPECIFICATIONS............................................................................................................................................................ 2

PACKAGE CONTENTS.................................................................................................................................................... 2

PACKAGE CONTENTS: ACCESSORIES........................................................................................................................ 3

REQUIRED TOOLS ......................................................................................................................................................... 3

ADD-ON COMPONENTS................................................................................................................................................. 3

CABINET MOUNTING – WALL MOUNT BRACKET ATTACHMENT............................................................................... 3

CABINET MOUNTING – WALL MOUNT.......................................................................................................................... 3

LOCK AND UNLOCK EXTERIOR DOORS...................................................................................................................... 4

DOOR REMOVAL AND RE-INSTALLATION.................................................................................................................... 4

CABLE PREPARATION .................................................................................................................................................. 4

CABLE INSTALLATION ................................................................................................................................................... 5

COMPRESSION FITTING INSTALLATION ..................................................................................................................... 5

DISASSEMBLE COMPRESSION FITTING – CABLE REPLACEMENT ........................................................................ 6

SPLICING......................................................................................................................................................................... 6

DISTRIBUTION CABLE INSTALLATION – MPO DISTRIBUTION CABLE...................................................................... 6

DISTRIBUTION CABLE INSTALLATION – MPO PIGTAIL SPLICING............................................................................. 8

IDEAA SPLITTER MODULE INSTALLATION – MOUNT IDEAA SPLITTER MODULE ................................................... 9

IDEAA SPLITTER MODULE INSTALLATION – ACTIVATE IDEAA SPLITTER MODULE ............................................... 9

IDEAA SPLITTER MODULE INSTALLATION – CONNECT DISTRIBUTION FIBER......................................................11

MDU DROP CABLE INSTALLATION – 4.8 MM CABLE ................................................................................................ 12

PASS THROUGH CONNECTION.................................................................................................................................. 14

2

INSTALLATION INSTRUCTIONS

IDEAA®Interior Distribution Cabinet

© 2016, AFL, all rights reserved. Revision C, 3.3.17

Specications are subject to change without notice.

GENERAL

SPECIFICATIONS

The IDEAA Interior Distribution Cabinet (IDC) provides a convenient modular approach to centralized ber distribution in

medium to large Multiple Dwelling Units (MDU). All sizes of the IDC utilize the IDEAA splitter module to enable versatility

across the platform. The IDC utilizes innovative jumper routing to enable efcient ber management utilizing equal length

pigtails for the entire cabinet. The IDEAA IDC provides MDU ber distribution in an extremely compact size.

Parameter Value

Splitter Capacity Up to 5 Modules

Input/Pass Through Ports 12

Dimensions - (L x W x H) in. (cm) 21.7 x 19.0 x 12.5 (55.12 x 48.26 x 31.75)

PACKAGE CONTENTS

A. IDEAA Interior Distribution Cabinet

B. Fiber Input Pigtail

C. Input Splice Tray

D. Fiber Distribution Jumpers

3

INSTALLATION INSTRUCTIONS

IDEAA®Interior Distribution Cabinet

© 2016, AFL, all rights reserved. Revision C, 3.3.17

Specications are subject to change without notice.

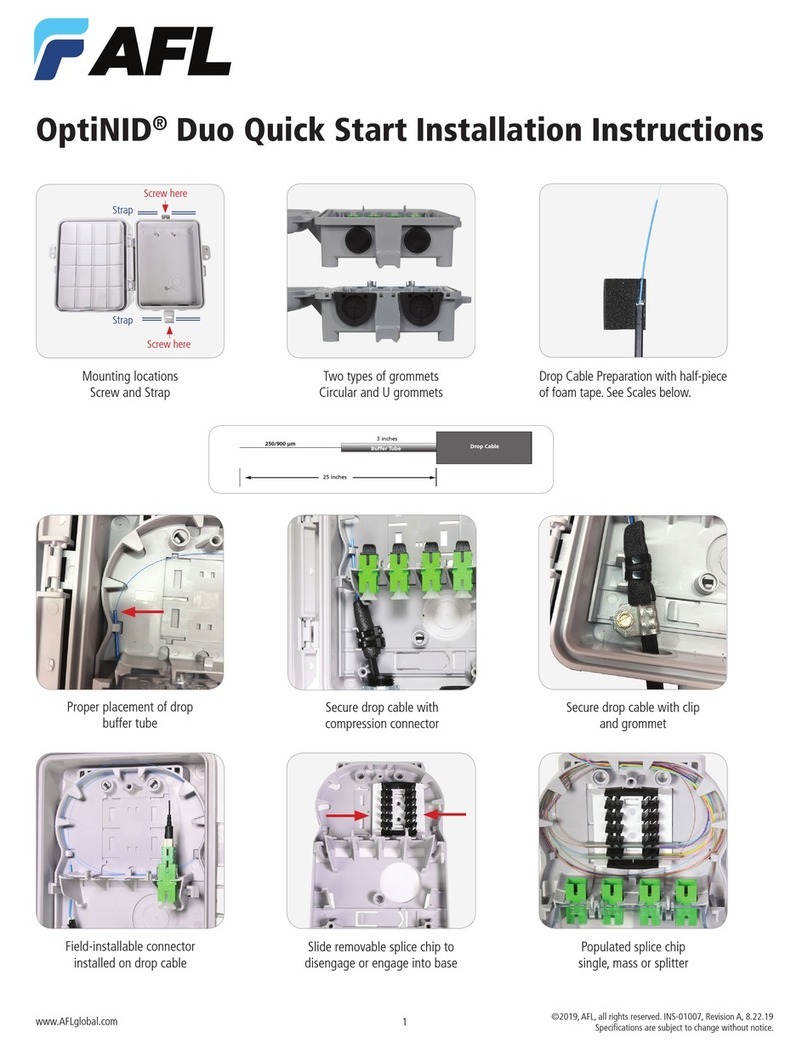

1. Using local engineering practices, determine the

mounting position of the cabinet on the wall.

2. Mark the three mounting points to be pre-drilled for

cabinet placement.

3. Using local accepted practices and approved

hardware, insert a lag screw into each of the three

pre-drilled mounting holes. Screw the lag screws

half-way into the wall.

Note: For best practice, it is recommended that

the lag screws hex head is wider than the key

slots of the cabinet mounts. Also, ensure that

the shaft of the screws is smaller than the actual

mounting slots for ease of installation.

4. Mount the cabinet over the pre-installed lag screws.

5. Secure the cabinet to the wall by tightening the three

lag screws. Before the lag screws are completely

tightened a level may be used to ensure that the

cabinet is in the desired position.

REQUIRED TOOLS

216 style Socket Tool

Phillips Head Screwdriver

1. Locate the three bracket mounting positions on the

back of the 144F IDC. (Figure 1)

2. Using a standard 216 style tool, or similar, attach

the three wall mount brackets included in the Wall

Mounting Hardware Kit. (Figure 2)

PACKAGE CONTENTS:

ACCESSORIES

Wall Mounting Hardware Kit

LGX-118 Mounting Bracket Kit

Replacement Door Label Kit

Input Compression Fitting Kit

ADD-ON COMPONENTS

SC IDEAA Module – 1 x 32

Universal Splice Tray

Compression Fitting Kit

FUSEConnect®MPO Splice-On Connector

FASTConnect®Mechanical Connectors

MPO Pigtail Kit

One-Click®SC Cleaner

One-Click®MPO Cleaner

CABINET MOUNTING – WALL

MOUNT BRACKET ATTACHMENT

CABINET MOUNTING – WALL MOUNT

Bracket

Positions

Figure 1

Figure 2

4

INSTALLATION INSTRUCTIONS

IDEAA®Interior Distribution Cabinet

© 2016, AFL, all rights reserved. Revision C, 3.3.17

Specications are subject to change without notice.

LOCK AND UNLOCK EXTERIOR DOORS

1. Using a standard 216 style tool, or similar, turn the locking bolt located at the center of the IDC door

a ¼ turn clockwise to unlock and counter clockwise to lock the cabinet..

Note: A pad lock, not provided, may be utilized if additional security is desired.

DOOR REMOVAL AND RE-INSTALLATION

The IDC was designed so that the door may be installed on either side of the cabinet for applications where there are

space restrictions.

1. Lift up on the cabinet door to release it from the hinge pins.

3. Using local engineering practices determine which side of the cabinet the door is to be placed. Install the enclosure

door over the appropriate hinge pins.

3. Review the label and diagram orientation on the IDC door. If necessary, apply the included Replacement Door Label

Kit in the appropriate positioning.

4. Using a standard 216 style socket tool, or similar, lock the cabinet.

CABLE PREPARATION

Caution: Fiber optic cable is susceptible to damage

from excessive bending, pulling or crushing forces.

At every stage of the installation process ensure that

loose buffer tubes, ribbon or Wrapping Tube Cable

(WTC) with Spider Web® Ribbon (SWR) bers are

free from unintentional cuts, knick or bends to avoid

potential ber damage.

1. Mark the cable to have a minimum 60"(152.4 cm) opening.

2. Use local accepted practice to remove the cable sheath.

3. Using wire cutters cut the central strength member back to the sheath opening.

Note: For best practice, when working with WTC it

is recommended accepted local practices be used

to protect the SWR ber before continuing to the

cable installation.

60"(152.4 cm)

5

INSTALLATION INSTRUCTIONS

IDEAA®Interior Distribution Cabinet

© 2016, AFL, all rights reserved. Revision C, 3.3.17

Specications are subject to change without notice.

1. Using a standard 216 style tool, or similar, remove the

shipping screws from each side of the swing down tray.

A total of two screws will be removed. (Figure 3)

2. Using a standard 216 style tool, or similar, loosen the

shipping screw from the swing down splice tray holder

in order to begin splicing. Do not remove this screw

from the swing down splice tray holder. (Figure 4)

3. Determine the appropriate compression tting

for the application.

4. Located at the lower right side of the cabinet, knock

out the appropriate mounting hole to accommodate

the compression tting. (Figure 5)

5. Install the compression tting, reference the

Compression Fitting Installation section of this

document. (Figure 6)

6. Using local engineering practices determine which

bers will be unused for the input splicing and separate

the bundles from the bers that will be routed to the

splice tray.

7. Route the unused buffer tubes through the ber

management rings located on the side wall of the IDC.

(Figure 7)

CABLE INSTALLATION

COMPRESSION FITTING

INSTALLATION

Caution: In order to avoid micro bends or ber damage do not over-tighten the compression tting

around the ber cable.

1. Ensure that the mounting hole is free from burrs and that the cabinet surface is smooth and free of debris.

2. Place the hex portion on the body (not the sealing nut) into the mounting hole.

3. Insert the cable through the tting to the desired position.

Note: For best practice, it is recommended that when working with the 9-port compression tting that the

multi-port grommet be removed from the tting body. Slit each of the application appropriate ports and align

the grommet around the cables. Once all required cables are seated in the grommet, insert both the cables

and grommet back into the tting body.

4. Tighten the sealing nut to hand-tight.

5. Using a wrench hold the body hex stationary while tightening the sealing nut with a second wrench.

Tighten until the cable is held securely in place.

6. Check to ensure that the tting body is still screwed tightly into the panel.

Shipping Screws

Figure 3

Shipping Screw

Figure 4

Figure 5

Figure 7Figure 6

6

INSTALLATION INSTRUCTIONS

IDEAA®Interior Distribution Cabinet

© 2016, AFL, all rights reserved. Revision C, 3.3.17

Specications are subject to change without notice.

SPLICING

1. Prior to splicing, ensure that adequate slack for both

the feeder ber and the input pigtail ber is stored

within the splice tray. Mark bers for splicing.

2. Clean the individual ber per accepted local practice

using an approved ber cleaner.

3. Follow accepted local practice for preparing and

splicing feeder bers and input pigtail bers.

4. Once all splicing is complete, route the exposed bers

inside the splice tray. (Figure 8)

Note: Thick foam pads may be used to help

organize loose tube bare bers within the

splice tray.

5. Replace the splice tray cover.

6. Secure the splice tray to the swing down splice tray

holder with the hook and loop band.

7. The ber management rings on the side wall of the IDC

may be used for slack storage. (Figure 9)

8. Return the swing down splice tray holder to the upright

position and secure the shipping screw.

DISTRIBUTION CABLE INSTALLATION - MPO DISTRIBUTION CABLE

The top plate of the 144F IDC may be removed to aid in

the distribution cable installation process.

Note: For distribution cable entry from the bottom

of the cabinet, reference the Cable Installation

section of this document before continuing on

to Step 7.

1. Remove the ve caps to expose the nuts on the top

of the 144F IDC.

2. Using a standard 216 style tool, or similar, remove the

ve nuts that secure the top plate to the cabinet body.

(Figure 10)

DISASSEMBLE COMPRESSION FITTING – CABLE REPLACEMENT

1. To disassemble for cable replacement, loosen the sealing nut.

2. Grip the disconnected cable and pull while turning the cable in the counter-clockwise direction.

Figure 8

Figure 9

Figure 10

7

INSTALLATION INSTRUCTIONS

IDEAA®Interior Distribution Cabinet

© 2016, AFL, all rights reserved. Revision C, 3.3.17

Specications are subject to change without notice.

3. Remove the top plate.

4. Determine the appropriate compression tting

for the application.

5. Knock out the appropriate mounting hole

to accommodate the compression tting.

6. Install the appropriate compression tting.

Reference the Compression Fitting Installation

section of this document.

7. Using local engineering practices, determine the

port to be used on the MPO eld for the MPO

distribution cable.

8. Use local accepted practices to clean the connector

end face and plug the connector into the appropriate

port. (Figure 11)

9. Use the ber management rings to route the

MPO distribution cable through the back side of the

144F IDC. (Figure 12)

Note: A FUSEConnect®MPO Splice-On Connector

may be spliced onto a non-connectorized

distribution cable. The FUSEConnect®MPO

Splice-On Connector application will utilize the

same cable installation and routing techniques

outlined in steps 1-7. Reference the installation

instructions provided with the FUSEConnect®

MPO Splice-On Connector. The document will

include the following:

•Fiber Preparation

•Fiber Splicing

•Connector Assembly

10. Use local accepted practices to label the MPO

distribution ber connection in the appropriate space

on the door label, as applicable.

11. Repeat Steps 7 – 10 for each MPO distribution cable

to be installed.

Distribution

Drop

Figure 11

Figure 12

8

INSTALLATION INSTRUCTIONS

IDEAA®Interior Distribution Cabinet

© 2016, AFL, all rights reserved. Revision C, 3.3.17

Specications are subject to change without notice.

DISTRIBUTION CABLE INSTALLATION - MPO PIGTAIL SPLICING

When a non-connectorized distribution cable is utilized a MPO pigtail may be spliced onto the distribution cable.

Note: For distribution cable entry from the bottom of the cabinet, reference the Cable Installation section

of this document before continuing on to step 7.

1. Remove the ve caps to expose the nuts on the top side of the 144F IDC.

2. Using a standard 216 style tool, or similar, remove the ve nuts that secure the top plate

to the cabinet body. (Figure 10)

3. Remove the top plate.

4. Determine the appropriate compression tting for the application.

5. Knock out the appropriate mounting hole to accommodate the compression tting.

6. Install the appropriate compression tting. Reference the Compression Fitting Installation section

of this document.

7. Using a standard 216 style tool, or similar, loosen the shipping screw from the swing down splice tray holder

in order to begin splicing. Do not remove this screw from the swing down tray holder. (Figure 4)

8. Prior to splicing, ensure that adequate slack for both the distribution ber and the MPO pigtail ber

is stored within the splice tray. Mark bers for splicing.

9. Clean the ber per accepted local practice using an approved ber cleaner.

10. Follow accepted local practice for preparing and splicing distribution bers and MPO pigtail bers.

11. Once all splicing is complete, route the exposed bers inside the splice tray. (Figure 8)

12. Replace the splice tray cover.

13. Secure the splice tray to the swing down splice tray

holder with the hook and loop band.

14. The ber management rings on the side wall

of the IDC may be used for slack storage. (Figure 9)

15. Using local engineering practices, determine the

port to be used on the MPO eld for the

MPO distribution cable.

16. Use local accepted practices to clean the connector

end face and plug the connector into

the appropriate port. (Figure 11)

17. Use the ber management rings to route the

MPO pigtail ber through the back side of the

144F IDC. (Figure 13)

18. Return the swing down splice tray holder to the upright

position and secure the shipping screw.

Distribution

Pigtail

Figure 13

9

INSTALLATION INSTRUCTIONS

IDEAA®Interior Distribution Cabinet

© 2016, AFL, all rights reserved. Revision C, 3.3.17

Specications are subject to change without notice.

1. Using local engineering practices, determine the

location of the IDEAA Splitter Module to be installed

within the IDC.

2. Using the provided hex-head screws, attach the

mounting bracket to the bottom side of the IDEAA

Splitter Module. (Figure 14)

3. Install the IDEAA LGX-118 Rack Mount Bracket into

the LGX-118 mounting xture by pressing in the two

nylatch plungers. (Figure 16)

4. Repeat Steps 1 – 3 for each IDEAA Splitter Module

to be mounted.

IDEAA SPLITTER MODULE INSTALLATION

MOUNT IDEAA SPLITTER MODULE

Nylatch Plunger

Nylatch Plunger

ACTIVATE IDEAA SPLITTER MODULE

An IDEAA Splitter Module that has been mounted into

the IDC is not active until it has been connected to the

Input Field.

Caution: When working with ber optics, do

not look directly into the end of the ber cable

or adapter port. A power meter may be used to

determine if the cable or port is dark. Or use

locally accepted ber optic safety practices.

1. Use local accepted practices to clean the connector

end face at both ends of the jumper provided with the

IDEAA Splitter Module.

2. Plug the jumper cable into the black input port on

the IDEAA Splitter Module. Use the foam ber relief

to route the jumper cable to the ber routing section

of the IDC. (Figure 16)

Note: When mounted on the LGX-118 mounting

xture the black input port will be located in the

bottom right corner of the module adapter eld.

Figure 14

Figure 15

Figure 16

10

INSTALLATION INSTRUCTIONS

IDEAA®Interior Distribution Cabinet

© 2016, AFL, all rights reserved. Revision C, 3.3.17

Specications are subject to change without notice.

3. Using local engineering practices, determine the port

to be used on the input panel for activating the IDEAA

Splitter Module. Plug the opposite end of the jumper

into the desired port on the input panel. Use the foam

ber relief to route the jumper cable to the ber routing

section of the IDC. (Figure 17)

4. Route the remaining jumper slack through the ber

routing section of the IDC. (Figure 18)

5. Use local accepted practices to label the input ber

connection in the appropriate space on the door label,

as applicable.

6. Repeat Steps 1 – 5 for each IDEAA Splitter Module

that needs to be activated.

Splitter

Input Jumper

Figure 17

Figure 18

11

INSTALLATION INSTRUCTIONS

IDEAA®Interior Distribution Cabinet

© 2016, AFL, all rights reserved. Revision C, 3.3.17

Specications are subject to change without notice.

CONNECT DISTRIBUTION FIBER

1. If not already removed, remove the shipping screws from each side of the swing down tray. A total of two screws

will be removed. (Figure 3)

2. Using local engineering practices, determine the appropriate distribution ber to be connected. Remove the

corresponding ber storage cartridge from the swing down tray by pushing in and pulling up on the cartridge arms.

(Figure 19)

Note: The cartridges and distribution bers are numbered to assist in ber identication.

Additionally, distribution bers may be identied by placing a red light on the customer side of the ber

and locating the ber on the swing down tray. (Figure 19)

3. Remove the desired distribution ber from the cartridge by sliding the connector out of the housing location

and continue to route the cable out of the cartridge.

4. For best practice, it is recommended that the distribution ber be removed from

all Velcro and routed back to the cable transition.

Ensuring the distribution ber has a clear path to the ber routing section of the IDC.

5. Use local accepted practices to clean the distribution ber connector end face.

6. Connect the distribution ber to the appropriate port on the IDEAA Splitter Module.

Use the foam ber relief to route the distribution ber to the ber routing section

of the IDC, employing a similar technique to that used with the input

jumper cable. (Figure 20)

Figure 19

Figure 20

12

INSTALLATION INSTRUCTIONS

IDEAA®Interior Distribution Cabinet

© 2016, AFL, all rights reserved. Revision C, 3.3.17

Specications are subject to change without notice.

7. Route the remaining distribution ber slack through the

ber routing section of the IDC. (Figure 21)

8. Use local accepted practices to label the distribution

ber connection in the appropriate space on the door

label, as applicable.

9. Repeat Steps 2 – 8 for each addition distribution ber

needing to be connected.

Note: Unused bers should remain in the ber

storage cartridge until needed.

MDU DROP CABLE INSTALLATION - 4.8MM CABLE

The 144F IDC is capable of supporting up to (72) direct connections to the living unit through the use of a MDU drop cable

for applications in which the interconnect panel will be bypassed.

Caution: Fiber optic cable is susceptible to damage from excessive bending, pulling or crushing forces.

At every stage of the installation process ensure that the bers are free from unintentional cuts, knick or

bends to avoid potential ber damage.

1. Remove the two caps to expose the nuts on the MDU drop access plate, located in the lower left corner

of the cabinet.

2. Using a standard 216 style tool, or similar, remove the two nuts that secure the MDU drop access plate

to the cabinet body. (Figure 22)

3. Remove the MDU drop access plate. (Figure 23)

4. Use local accepted practices to remove the cable sheath.

Distribution

Jumper

Figure 21

13

INSTALLATION INSTRUCTIONS

IDEAA®Interior Distribution Cabinet

© 2016, AFL, all rights reserved. Revision C, 3.3.17

Specications are subject to change without notice.

7. Ensure that the exposed 900 µm ber is long enough

to reach the desired IDEAA Splitter Module port.

8. Repeat steps 4 – 7 for all desired MDU drop cables.

9. Once all MDU drop cables have been installed, replace

the drop access plate.

10. Using a standard 216 style tool, or similar, replace the

two nuts that secure the MDU drop access plate to the

cabinet body and cover with caps. (Figure 25)

11. Install FASTConnect®Mechanical Connector.

Reference the installation instructions provided with the

FASTConnect®Mechanical Connector. The document

will include the following:

• Fiber Preparation

• Fiber Termination

• Connector Assembly

12. Using local engineering practices, determine which

port on the IDEAA Splitter Module will be used for

the MDU drop connection.

13. Use local accepted practices to clean the distribution

ber connector end face.

14. Connect the distribution ber to the appropriate port on

the IDEAA Splitter Module. Use the foam ber relief to

route the distribution ber to the ber routing section

of the IDC, employing a similar technique to that used

with the input jumper cable. (Figure 26)

6. Slide the 4.8 mm drop cable to the backmost position within the drop retention bracket.

Recommendation: For best practice no more than 35" (88.9 cm) of 900 µm ber be exposed for the MDU

drop cable installation process. This length will optimize the routing capability within the IDC and prevent

excessive lengths of 900 µm ber from collecting within the cabinet.

5. Insert the 4.8mm jacket into the drop retention bracket. (Figure 24)

Figure 22 Figure 23 Figure 24

Replace

Nuts & Caps

Figure 25

Figure 26

14

INSTALLATION INSTRUCTIONS

IDEAA®Interior Distribution Cabinet

© 2016, AFL, all rights reserved. Revision C, 3.3.17

Specications are subject to change without notice.

15. Route the remaining distribution ber slack through the ber routing section of the IDC. (Figure 27)

16. Use local accepted practices to label the distribution ber connection in the appropriate space on the door label,

as applicable.

17. Repeat Steps 10 – 16 for each addition distribution ber needing to be connected.

PASS THROUGH CONNECTION

1. Using local engineering practices, determine the appropriate distribution ber to be used for a pass through

connection. Remove the corresponding ber storage cartridge from the swing down tray by pushing in and

pulling up on the cartridge arms.

2. Remove the desired distribution ber from the cartridge by sliding the connector out of the housing location

and continue to route the cable out of the cartridge.

3. For best practice, it is recommended that the distribution ber be routed back to the cable transition.

Ensuring the distribution ber has a clear path to the ber routing section of the IDC.

4. Use local accepted practices to clean the distribution ber connector end face.

5. Connect the distribution ber to the appropriate port on the input eld.

6. Use the foam ber relief to route the distribution ber to the ber routing section of the IDC.

Employing a similar technique to that used with the jumper cable.

7. Route the remaining distribution ber slack through the ber routing section of the IDC.

8. Repeat Steps 1 – 7 for each addition pass through connection.

Note: Unused bers should remain in the ber storage cartridge until needed.

4.8 mm Drop

Figure 27

Table of contents

Other AFL Enclosure manuals