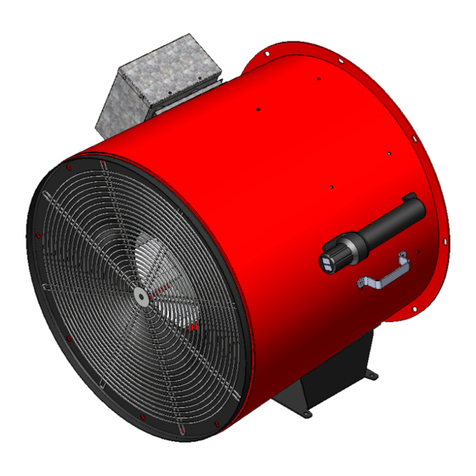

DIRECT DRIVE CENTRIFUGAL FAN – AERATION FAN

8210-30029 R0 3

CONTENTS

1. Introduction ............................................................................................................................................ 5

1.1 General Description................................................................................................................... 5

1.2 Serial Number Location............................................................................................................. 5

2. Safety....................................................................................................................................................... 6

2.1 Safety Alert Symbol and Signal Words...................................................................................... 6

2.2 General Safety Information....................................................................................................... 6

2.3 Fan Safety .................................................................................................................................. 7

2.4 Drives and Lockout/Tagout Safety ............................................................................................ 7

2.4.1 Electric Motor Safety.................................................................................................. 8

2.5 Personal Protective Equipment................................................................................................. 8

2.6 Safety Equipment ...................................................................................................................... 9

2.7 Safety Decals ............................................................................................................................. 9

2.7.1 Decal Installation/Replacement................................................................................. 9

2.7.2 Safety Decal Locations and Details ............................................................................ 9

3. Pre-Installation ..................................................................................................................................... 11

3.1 Receiving and Inspection ........................................................................................................ 11

3.2 Handling the Fan ..................................................................................................................... 11

3.3 Storing the Fan Before Installing............................................................................................. 11

4. Installation ............................................................................................................................................ 12

4.1 Installation Safety.................................................................................................................... 12

4.2 Elevated Fans........................................................................................................................... 13

4.3 Slab Mounted Fans.................................................................................................................. 14

4.4 Vibration Isolators ................................................................................................................... 14

4.5 Ducting Requirements............................................................................................................. 15

5. Operation .............................................................................................................................................. 16

5.1 Operation Safety ..................................................................................................................... 16

5.2 Air Pressure and Suction ......................................................................................................... 16

5.3 Start-Up and Break-In.............................................................................................................. 16

5.4 Fan Rotation and Orientation ................................................................................................. 17

5.5 Emergency Stop....................................................................................................................... 18

5.6 Shutdown ................................................................................................................................ 18

5.7 Storage..................................................................................................................................... 18

6. Maintenance ......................................................................................................................................... 19

6.1 Maintenance Safety ................................................................................................................ 19

6.2 Maintenance Schedule............................................................................................................ 19

6.3 Visually Inspect the Centrifugal Fan........................................................................................ 20

6.4 Cleaning the Fan Blade and Housing ...................................................................................... 20

6.5 Servicing and Part Replacement ............................................................................................. 20

6.5.1 Fan Wheel Replacement .......................................................................................... 21

6.5.2 Fan Wheel/Propeller Balance .................................................................................. 22

6.5.3 Motor Bearings Maintenance .................................................................................. 22

6.6 Replacement Parts .................................................................................................................. 29

7. Troubleshooting.................................................................................................................................... 30

8. Appendix ............................................................................................................................................... 33