CITC 100160 User manual

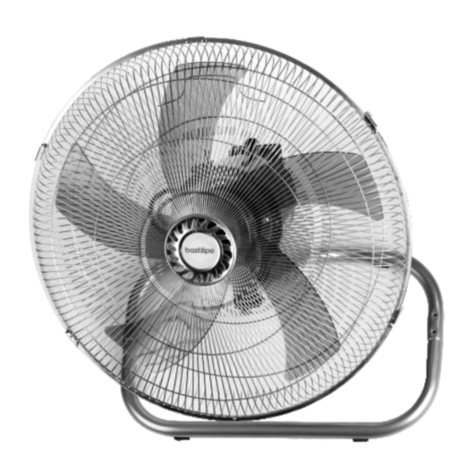

HURRICANE II FANTM

Operating Instructions

P/N 100160 (110V)

P/N 100165 (230V)

1

Thank you for purchasing this Hurricane II FanTM.

oAs you will notice from the table of contents, the manual for your new

fan is quite extensive.

oTo guarantee perfect and successful work with this machine, please

take some time to read the manual carefully.

oAnd finally, we believe you will enjoy many years of dependable,

trouble-free service if you properly install and maintain this powerful

piece of machinery called the Hurricane II FanTM.

CITC

2100 196th St. S.W., Ste. 138

Lynnwood, WA 98036

(888) 786-CITC

www.citcfx.com

2

Contents

1. Set of Equipment Supplied 3

2. Accessories and Parts 3

3. Description 3

4. Safety Instructions 4

5. Operating the Hurricane II FanTM 4

5.1 Unpacking the Hurricane II FanTM

5.2 Electrical Power Requirements

5.3 Running the Hurricane II FanTM

5.4 Transporting the Hurricane II FanTM

5.5 Hanging the Hurricane II FanTM

5.6 Optional Universal DMX Control

5.7 Troubleshooting

5.8 Notes on optional Universal DMX operation

6. Service and Maintenance 7

7. Technical Data 7

8. Warranty Conditions 8

3

1. Set of Equipment Supplied

1 Hurricane II FanTM

1 Bracket with hardware (P/N 600440)

Operating Instructions Booklet

2. Accessories and Parts

C-Clamp w/Baby Spud and Safety Cable (P/N 250140)

Universal DMX for on/off control only (P/N 250041)

DMX Turret (P/N 250350)

Floor plate with baby spud (P/N 250130)

Road Case (P/N 250150)

The following miscellaneous parts are available for the Hurricane II FanTM

600424 Metal Tubular Bracket/Stand - OS

600416 Motor - 120vac, 1hp - OS

600417 Blower Wheel - OS

600418 Motor Mount Bracket - OS

600419 Spider - OS

600420 Switch - OS

600421 Grill Guard - OS

600422 Motor 1/2 hp 120vac - OS

600423 Capacitor for Hurricane - OS

Please check whether all the products you ordered are supplied.

3. Description of the Hurricane II FanTM

o Blow fog, haze, snow, wind to 150’ (45.7m). Tilt 300 degrees, swivel 360 degrees.

Three speeds: three seconds to top speed. Blow massive volumes of air without

motor hum. Continuous output without overheating. Lightweight, portable and

economical. The Hurricane II FanTM is a full hp and can blow to 150’ (45.7m).

o The Hurricane II Fan TM can be on/off controlled with optional Universal DMX control.

o Portable and compact, capable of much more than fans four times its size, the

Hurricane II Fan TM weighs just 49 lbs (23kg).

4

4. Safety Instructions

WARNING: Read and understand all labels and operating instructions

before attempting installation.

o RISK OF ELECTRICAL SHOCK- This fan is supplied with a grounding conductor.

Improper connection of the equipment-grounding conductor can result in a risk of

electric shock. To reduce risk of electrical shock, connect only to a properly grounded,

grounding type receptacle.

o In the event of a malfunction or breakdown, grounding will reduce the risk of electric

shock by providing a path of least resistance for the electric current. Install electrical

hookup in accordance with all local codes and ordinances. Warning: Check with a

qualified electrician if you are in doubt whether the fan is properly grounded.

o To reduce risk of electric shock, disconnect power before servicing this fan.

o SAFETY CABLE- When suspending the fan using the C-Clamps, be sure to attach

the safety cable around the pipe grid and go through the handle of the Hurricane and

attach the cable to itself. It is mandatory to use a safety cable when suspending this

unit!

o C-Clamp- Be sure the Baby Spud has a solid unscrewable connection to the Spud.

When tightening the baby spud in place, always use the washer and cotter key.

Tighten the side lock bolt on the knurled area of the baby spud. Never loosen this lock

bolt to swivel the fan. Always swivel with the loosening of the swivel bolt on the side of

the C-Clamp and spin the entire spud/baby spud together. Tighten the swivel bolt

when in place.

5.Operating the Hurricane II FanTM

5.1 Unpacking the Hurricane II FanTM

Before removing from the box, note the position of the packing material and how the unit

is setting with the sprocket side down for future transport or boxing.

Pull the fan sprocket cover (foam block) and remove the clamping ring with an Allen

wrench. Slide collar over spindle toward fan until seated against the shoulder.

Once the bracket is completely slipped on, reapply the clamping ring until the shaft is

flush to the outside. Tighten securely with an Allen wrench.

5.2 Electrical Power Requirements

Check to see that the power switch on the handle is in the off position. Plug in the cord to

a grounded outlet with sufficient amperage. You may double check the voltage marking,

inside the mouth of the air output. The voltage requirement for this fan is acceptable to

almost all types of single-phase electrical supply. Current consumption is 10 amps at

110vac and 5 amps for the 230 VAC model. Make sure you are using an adequate

extension cord. These fans need at least 12-gauge extension cord for sufficient

amperage supply. Because initial current surge is higher, the fan should have a

5

dedicated circuit with extra capacity (20 amp circuit at 110 VAC. 10 amp circuit at 230

VAC).

5.3 Running the Hurricane II FanTM

1. Quickly turn on then off the power and check to see if the fan is moving easily without

rubbing the edge. Sometimes in shipping the fan may be damaged due to mishandling or

jarring of the unit. Contact your shipper and CITC if damage has occurred in transport.

2. Spin the entire fan to the position you want the air to flow, tightening the lock- down nut

on the spindle to stop it from moving. Use a wrench.

3. Turn on the fan to speed desired, aiming the airflow the direction you want, allowing 25-

30' (7.6-9.1m) of open air space for air movement in front of the fan Your fan is designed

to be left on continuously for 2 years without overheating or failure.

5.4 Transporting the Hurricane II FanTM

When shipping or transporting to another location (not boxed), be sure to set the fan on

the floor, not hanging from the bracket. Damage may occur or you may misalign the fan

unit. Always have the fan lying down on the floor with the bracket up or legs off the floor.

5.5 Hanging the Hurricane II FanTM

1. For hanging, use baby-spud C-Clamp with a washer, cotter key and safety cable.

Place the C-Clamp baby spud onto the attachment on the edge of either of the legs,

placing the cotter key through the pin and tightening the lock screw with a wrench. Adjust

the position by loosening the upper nut and spinning the entire shaft inside the C-Clamp.

Never loosen the tightening screw on the Hurricane IITM bracket while hanging.

2. Attach the safety cable around the pipe grid and through the handle of the Hurricane

and attach the cable to itself. You may now adjust the position of the Hurricane IITM with

the wrench, spinning or tilting as desired. Do not loosen any of the anchor bolts for

movement without the safety cable attached first.

5.6 Optional Universal DMX Control

With DMX control, you will be able to turn the fan on when the slider control reaches

approximately 50%. (See section 5.8).

Lock Bolts

Swivel Lock

Washe

r

Cotter Key

6

5.7 Troubleshooting

DMX doesn’t work: turn on control knob on fan to desired speed setting.

Fan rubs when turning: call CITC for instructions. Do not remove cover.

Motor jumps or is unsteady: check extension cord for low gauge. Turn off any other

loads sharing the same circuit or test in dedicated outlet.

Fan starts slowly: Check extension cord for low gauge. Turn off any other loads sharing

the same circuit or test in dedicated outlet.

5.8 Notes on optional Universal DMX operation

Each DMX’d unit will occupy a unique DMX address on the DMX chain. By adjusting the

dip switches on the side of the machine near the DMX cable plug-ins, the user may

assign one address to the machine, giving you on/off and volume control with one DMX

channel (there is no timer on this DMX).

Step 1). Attach the DMX cable to the upper “in” female connector located on the end of

the fan.

Step 2). The DMX address is configured by adding the dip switch numbers together to

total the number required. For example, DipSwitch 1 + 6 = 33. Your DMX channel would

be 33.

Dip Switch 1 2 3 4 5 6 7 8 9

Channel # 1 2 4 8 16 32 64 128 256

When you move the slide control or digital control to approximately the 50%

position the fan will turn on.

0 – 50% = Off

51– 100% = On

“Input” and “Output” designations on the DMX plugs are arbitrary (i.e., you can use the

input plug for output and visa-versa). It is not necessary to attempt converting your DMX

line’s connector to female/male to match the appropriate socket on the plug. As long as it

is looped in/out, it will work.

7

6. Service and Maintenance

Care of your Hurricane II FanTM will give you years of service. Note:

cleaning your unit is going to pay off in constant good performance.

1. Because air passes through the wiring and blades, it is important not to feed fog or wet

fluids through this unit. It will damage the circuitry.

2. Keeping your unit clean is essential. Use of Filter Foam would be advised if the air is full

of lint or dirt.

3. Wipe down all vent inlets with a clean dry cloth.

4. Never use water around the electrical connections

5. Inspect the cord for damage before each use.

6. Never operate with extension cords that are under 12 awg.

7. Technical Data

Hurricane II FanTM P/N 100160 (230V P/N 100165)

Weight 49lbs (19.3 kg)

Size (with bracket) 17 3/4” x 19 1/2” x 19 1/2”

(45 cm x 49.5 cm x 49.5 cm)

Shipping Weight 55 lbs. (25 kg) without clamp

60 lbs (27.3 kg) with clamp

Shipping Box Size 23” x 23” x 23”

(58.4 cm x 58.4 cm x 58.4 cm)

DMX Optional Universal DMX on/off

control

CFM’s 3000/4000/5000

Wind Speed 3 speeds to 58 mph (93 km/hr)

Wind Range 3 speeds to 150’ (45.7m)

Fan Outlet Opening 5” x 19” (12.7 cm x 48 cm)

Motor 1 hp

Color Black

Positioning 360 degrees

Electrical Supply 110VAC, 10 A, 60 Hz

230 VAC, 5 A, 50 Hz

Limited Warranty One (1) year

Rev. 8/1/03

8

8. Limited Warranty Conditions

for the Hurricane II FanTM

1. Subject to the following conditions we will repair any defect or fault in the unit

if it is caused by a proven factory fault and has been advised immediately

after appearance and within 30 days of delivery to the end user. Insignificant

deviations of the regular product quality does not guarantee replacement

rights, nor do faults or defects caused by water, by generally abnormal

environment conditions or Force Majeure.

2. Limited Warranty Service will be done in the following way: Faulty parts will be

repaired or replaced (our choice) with correct parts. Faulty units have to be

shipped to us or sent to us at customer’s expense. The RMA# has to come

with the faulty unit.

3. The customer loses all rights for limited warranty services, if any repairs or

adjustments are done to the units by unauthorized persons and/or if spare

parts are used, which are not approved by us. Also non-compliance with the

instructions in this manual or mistakes by incorrect handling/treating of the

machine, any faults and damages caused by undue force will lead to a loss of

limited warranty.

4. Freight costs to CITC when under the limited warranty services are the

responsibility of the customer. CITC will pay freight upon return.

5. Limited warranty services do not cause an extension of the limited warranty

time or the start of a new limited warranty time. The warranty of replaced

parts ends with the limited warranty time of the whole unit.

6. If a defect/fault can not be repaired by us in a satisfactory time, we will, within

30 days after sale of the unit, our choice either:

Replace the whole unit for free or

Refund the lesser value or

Take back the whole unit and refund the purchase price, but not more that

the usual market price at the time of refund.

7. Further claims, especially for damages, losses etc. outside the unit are

excluded.

9

If you should send the unit for service, obtain your RMA#

first by calling CITC. Obtain your RMA # by calling CITC.

Payment arrangements for repair must be made before

receiving RMA # in case unit is not covered under Limited

Warranty.

Send unit to:

CITC

RMA # XXXXXXX

2100 196th Street SW Suite #138

Lynnwood, WA 98036

Tel: (888) 786-CITC or (425) 776-4950

Fax: (425) 776-5129

Website: www.citcfx.com

2100 196th St. SW, #138, Lynnwood, WA 98036-7083

425-776-4950 FAX: 425-776-5129

August 1, 2003

This manual suits for next models

2

Table of contents

Other CITC Fan manuals