Caution

1. Open or close the valve slowly.

Rapidly opening or closing the valve when there is a pressure difference

between the upstream and downstream sides of the valve may damage the

Storage

Caution

1. Store the flowmeter away from fire and direct sunlight.

2. Keep the flowmeter away from combustible, inflammable, and/or heating

materials.

3. Store the flowmeter in a place where the surrounding temperature is -25 to

Piping

Caution

1. Install an object which disturbs the flow (e.g., flow regulating valve)

atthedownstream side of the flowmeter.

2. For a new piping system, thoroughly wash it before installation.

3. Vertical piping is recommended when a large amount of mist and dust is

contained in the fluid. For horizontal piping, be sure to install the flowmeter so

that the display portion faces up.

4. Do not install the flowmeter where a strong compression or tension force

isapplied to it.

5. Lay pipes in accordance with the flow direction indicated on the flowmeter.

6. Do not drop, hit, or apply an excessive impact to the flowmeter.

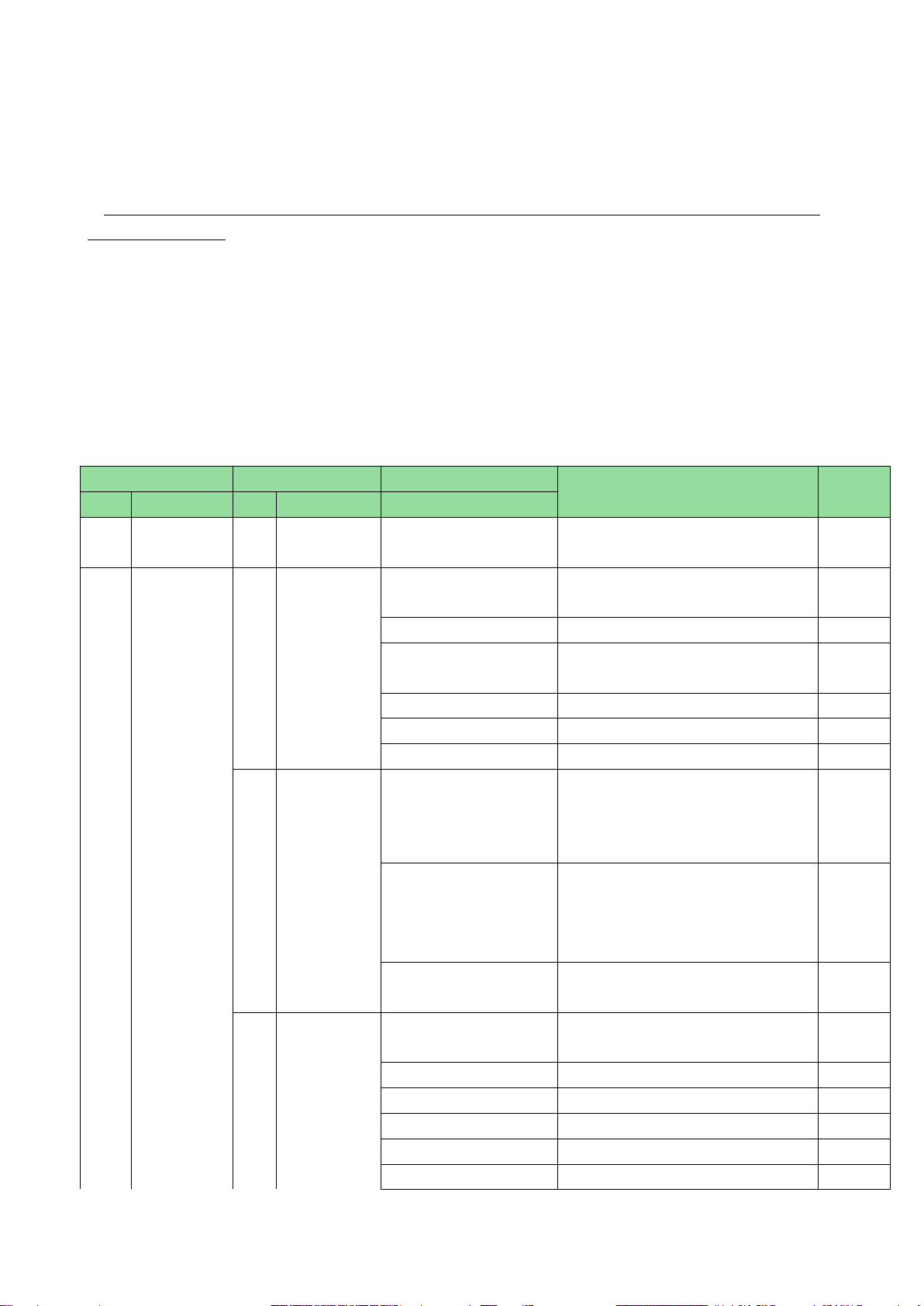

7. When rotating the display portion, do not apply a force in any other

directionthan the rotation direction.

8. Do not touch the ultrasonic sensor.

Wiring

Danger

1. Observe the instructions given in this manual for wiring.

2. Observe the rated range. Do not use the flowmeter under a voltage

exceeding the rated load.

Caution

1. Keep the cables away from the power and motor cable.

2. Do not apply an excessive tension to the external connection cables.

3. Be careful so that the tip of an external connection cable is submerged

duringthe wiring work.

4. When connecting the power cable to an external power supply, be sure to

prevent a short-circuit. Use an external power supply with a short-circuit

prevention function.

5. Turn off the external power supply at the time of wiring.

6. Do not perform operation and wiring work with wet hands.

Disassembly and inspection

Caution

1. Do not disassemble the flowmeter.

2. Presence of fluid flow wakes a pilot lamp blink in a normal state If it does

notblink, contact us.

3. When a large amount of mist and dust is contained in the fluid, regularly

remove the flowmeter and check and clean foreign substances as necessary

the inside for.

Remove the flowmeter from the pipe, cover one of the connection port, and

then wash the inside with water or spindle oil. (For details, refer to "ALARM1

turns on" in "After deployment" in "11. Troubleshooting".)

Do not touch the ultrasonic sensor during inspection.

Disposal

Warning

1. Since this product contains lithium batteries it cannot be disposed as

domestic waste.

2. Never throw the flowmeter into fire. Combustion or explosion may occur.