3

1400500-101 Rev. A

Table of Contents

Warnings & Cautions............................................................................................. 4

Symbol Information ............................................................................................... 7

Introduction............................................................................................................ 8

DENSITY4/5 Introduction................................................................................ 9

DenitionofDensity ........................................................................................ 9

Oscillating U-Tube......................................................................................... 10

Instrument Setup..................................................................................................11

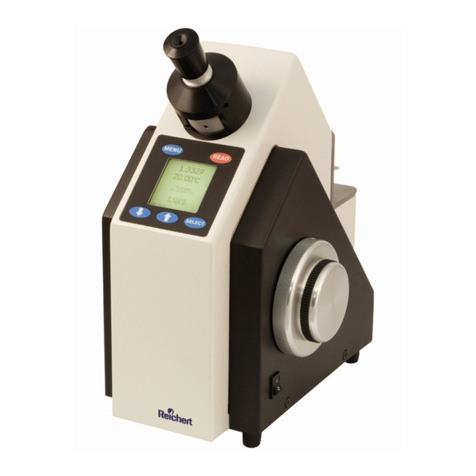

Parts ID ..........................................................................................................11

Accessories................................................................................................... 12

Setting up the DENSITY4/5 .......................................................................... 13

Connecting DENSITY4/5 To Power Supply............................................ 13

Connecting Air Cartridge ........................................................................ 13

Connecting DENSITY4/5 Sample Supply............................................... 14

Connecting Air Pump.............................................................................. 15

Connecting Reichert Universal Display .................................................. 17

Connecting DENSITY4/5 And PC........................................................... 17

Connecting DENSITY4/5 To The Local Network .................................... 17

Instructions for Use ............................................................................................. 18

Starting The DENSITY4/5............................................................................. 18

Keyboards..................................................................................................... 19

Icons ............................................................................................................. 20

Menu Icons ............................................................................................. 20

Status Icons............................................................................................ 20

Main Menu .................................................................................................... 21

Live Data ................................................................................................ 21

Last Measurement.................................................................................. 21

Conguration .......................................................................................... 21

User Interface ......................................................................................... 22

Screen ............................................................................................... 22

Touch Calibration............................................................................... 22

Sound ................................................................................................ 22

Calibration .............................................................................................. 22

Zeroing ................................................................................................... 23

Info And Versions.................................................................................... 23

Measurement ................................................................................................ 24

Measuring With Syringe ......................................................................... 26

DENSITY4/5 And Universal Display ............................................................. 27

Connecting DENSITY4/5 And Universal Display.................................... 27

DENSITY4/5 Remote Mode ................................................................... 28

Update DENSITY4/5 Software ............................................................... 30

Cleaning & Maintenance ..................................................................................... 31

Cleaning........................................................................................................ 31

Cleaning Recommendations .................................................................. 31

Cleaning Process ................................................................................... 31

ChoosingCorrectPurier ....................................................................... 32

Maintenance ................................................................................................. 32

Maintenance Intervals ............................................................................ 32

Maintenance Works................................................................................ 32

Specications ...................................................................................................... 33

TechnicalSpecicationsDENSITY4/5 .......................................................... 33

Minimum System Requirements PC ............................................................. 33

Warranty.............................................................................................................. 34