ff

Load Controller / Single

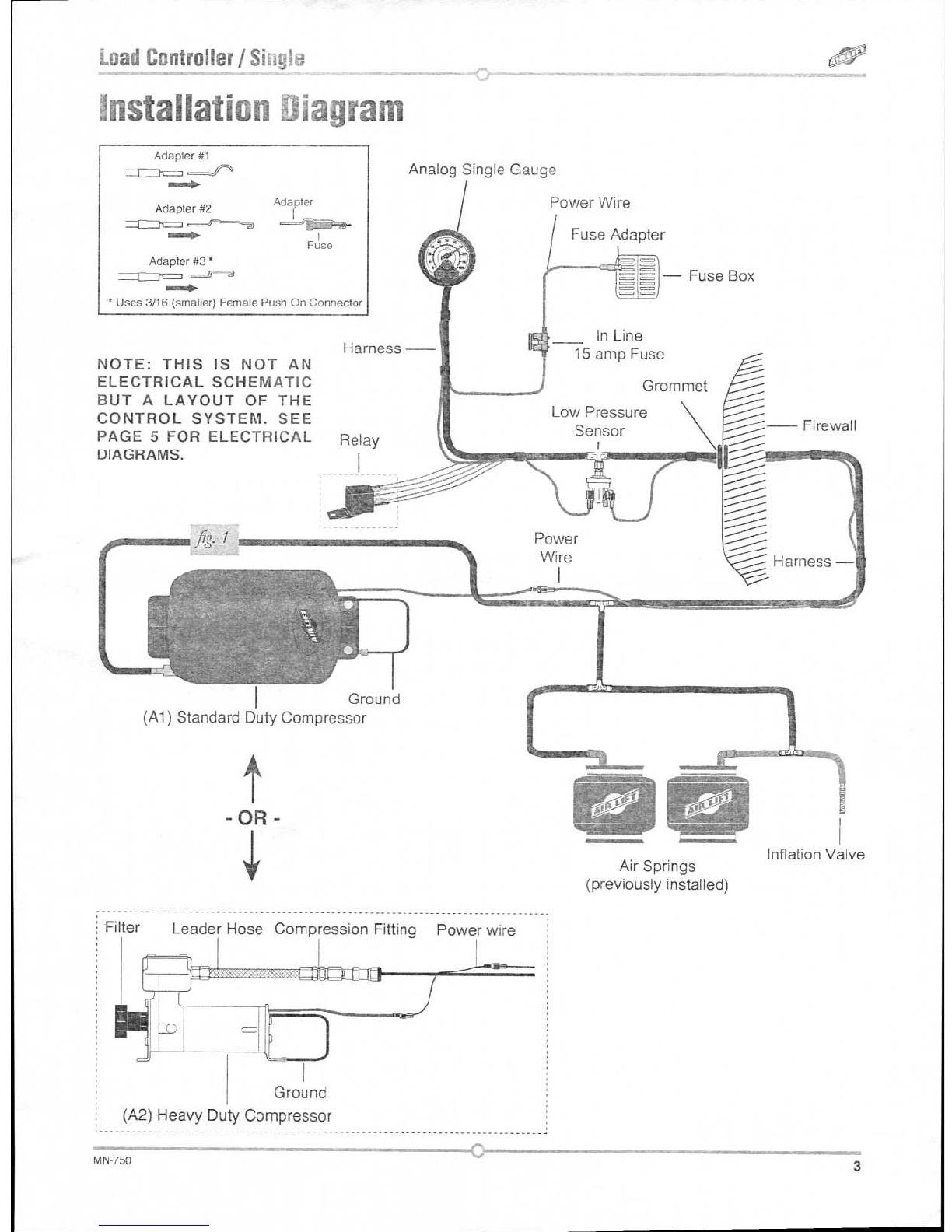

STEP BY STEP INSTALLATION

We recommend that you install the air spring kit first per the instructions provided with the

air spring kit.

J

1111111

fig•

9

Black (ground)

Compressor side

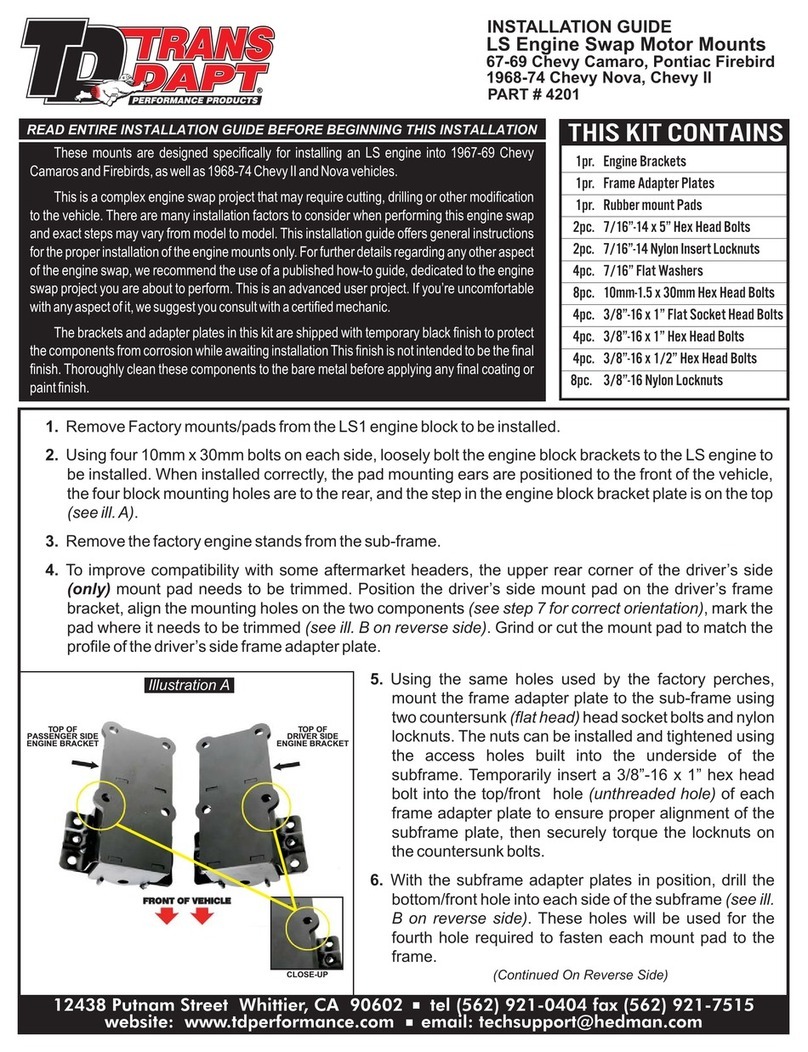

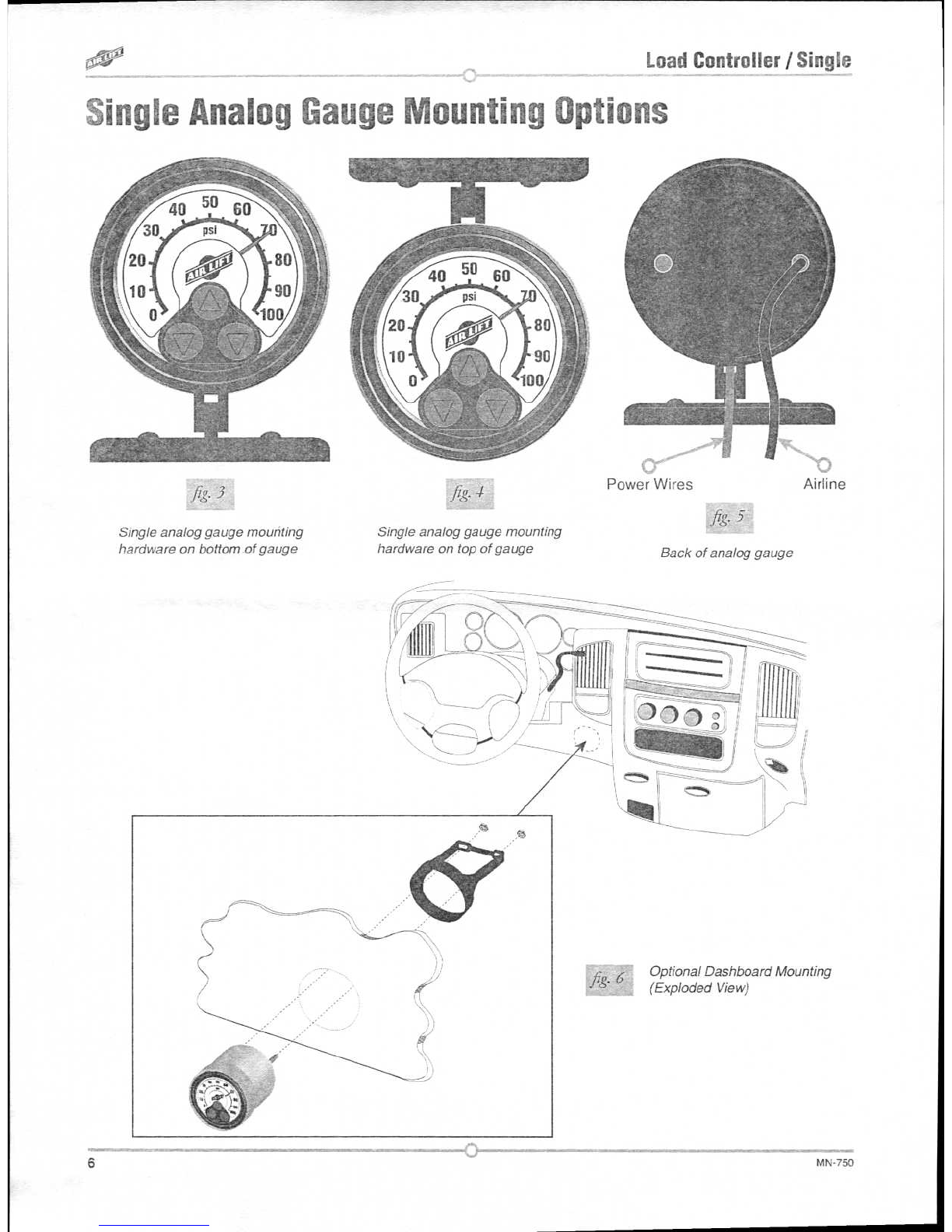

1. Install the gauge pod (figs. 3, 4 & 5). Select a convenient mounting location that has a

sturdy rigid surface. The bottom edge of the dash on either side of the steering wheel is

a good location. Attach the gauge pod to the selected location with the black self-tapping

screws.

NOTE

Optional dash mounting bracket and hardware also included (fig. 6).

2. Connect the harness to the gauge pod.

a.

Connect the color coded wires to the gauge harness as shown in the attached

schematic.

b.

Connect the low pressure switch assemblies as shown in figures 2 and 9.

c.

Do not connect the power wire at this time.

d.

The wiring harnEss also connects the gauge pod to the low pressure sensor assembly.

The low pressure sensor protects the air springs from failure resulting from low

pressure in the unloaded condition. This sensor is preset to maintain a MINIMUM

pressure of 5 psi in the air springs unless the setting was changed in the "Getting

Started" section. The sensor measures the pressure in each spring and turns on the

compressor if the pressure falls below the set psi.

e.

Screw ground eyelet to firewall or other electrical ground in the cab.

NOTE

The sensor should be located under the dash inside the vehicle and secured with the

provided tie straps.

3. Install the compressor unit.

a.

Hold the compressor in the recommended location (fig. 10 or 11).

b.

For box frames: In some cases the frame section will not be wide enough to mount

the compressor legs flat to the rail. Refer to figs. 10 and 11 in this situation.

DO NOT DRILL ANY HOLES INTO THE FRAME OR THE FLOOR BOARD BEFORE

CHECKING FOR HYDRAULIC LINES, GAS LINES, AND/OR ELECTRICAL WIRES

THAT MAY NEED TO BE MOVED ASIDE. ALSO, WHEN ATTACHING TO THE FLOOR

BOARD, IT IS IMPORTANT TO CHECK WHERE THE SCREWS PROTRUDE THROUGH

THE FLOOR BOARD. IT MAY BE NECESSARY TO TRIM OR COVER THE TOP OF THE

SCREWS INSIDE THE VEHICLE. A SEALER SHOULD BE USED AROUND THE SCREW

TO PREVENT THE ELEMENTS FROM ENTERING THE CAB AREA.

A

CAUTION

STANDARD DUTY COMPRESSOR MOUNTING (FIG. 1 - A1, 10)

NOTE

In some cases the mounting area does not provide enough room to use a drill to drive in

the screws. It may be necessary to use the mounting brackets as a template to drill 13/64"

holes through the frame first and then use a 7/16" nut driver to install the self tapping screws.

8

MN-750