2.3. HANDLING THE GOODS

Before off-loading the goods please ensure that a suitable means of transport/lifting to accommodate the

weight and size of the equipment is available.

The weight of the equipment is displayed on the manufacturing label fitted on the outside of the packaging, on

the equipment control panel door and on the documentation provided at the time of order confirmation. Please

check the weight of the unit before attempting to handle it.

For products delivered in pallets or with integral base frame the use of a fork-lift or pallet truck is recommended.

If the equipment needs to be lifted with straps it is recommended to use spreaders to avoid damage to the

casing.

Manual lifting between floor and shoulder level is acceptable only up to a maximum weight of 20kg

(89/391/CEE).

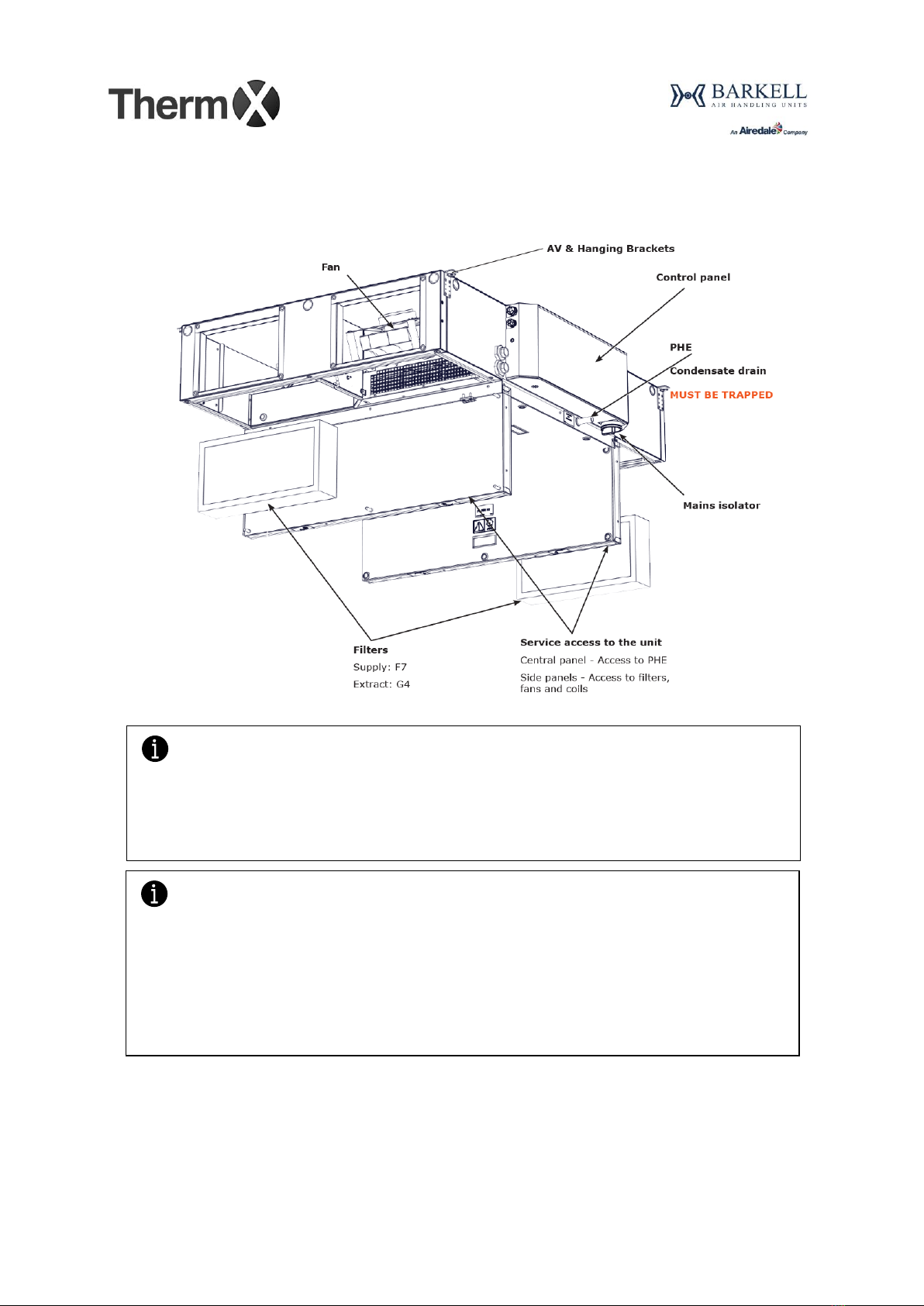

Take care when handling the equipment to ensure that damage to coil pipe work connections, spigots, drain

trays, etc. is avoided.

3. STORAGE

Should it be required to store the products on site for any period of time prior to installation they should be

stored in a clean, dry and secure area with an ambient temperature between 5°C and 35°C.

Inlet and discharge openings, pipe connections and filters should be sealed to avoid moisture ingress.

The equipment should be inspected on a regular basis and its packaging repaired if damaged.

The equipment should not be stored in areas where there is excessive vibration as this could damage fan

motor bearings.

If access panels are removed for inspection purposes or to carry out work on site they should be refitted and

made secure.

Small items delivered with the equipment such as sensors, controllers, etc… shall be stored safely from

unauthorized access, damage and the weather.

Crated or palletized horizontal mounting ceiling products (HRFL2) can be stacked on top of each other for

transport up to a maximum of 2 units high. For long term storage the maximum allowable stacking will depend

on the size of the unit, please contact our offices for more information.

Free standing units (HR85, HR95) cannot be stacked.