Airetool ATP III User manual

For additional product information visit our website at http://www.apextoolgroup.com

Instruction Manual

PL19-6000EN

05/15/2015

ATP III

Electric/Hydraulic Pump

Airetool®

Page 2

PL19-6000EN

05/15/2015

Airetool®

Specifications

Pump Model 5526244 (ATP III)

Motor 1.7 hp (1,25 kW) Electric Motor

Motor Voltage 115 VAC, Single Phase, 50/60 Hz

Motor RPM 1,750

Maximum Current Draw 20 Amps

100 psi (7 bar) = 700 in

3

/min (11,5 l/min)

700 psi (50 bar) = 535 in

3

/min (8,8 l/min)

5,000 psi (350 bar) = 76 in

3

/min (1,2 l/min)

10,000 psi (700 bar) = 60 in

3

/min (1,0 l/min)

Relief Valve Adjusment Range 1,400-10,000 psi (70-700 bar)

Sound Level 85-90 dBA

Reservoir Capacity 2 gallons (8 liters)

Weight (with oil) 70 lbs. (31.8 kg)

ATP III Electric/Hydraulic Pump Specifications

Output Flow Rate *

* Note: Output flow rate shown is at 60 Hz.

Flow rate will be approximately 5/6 of shown values at 50 Hz.

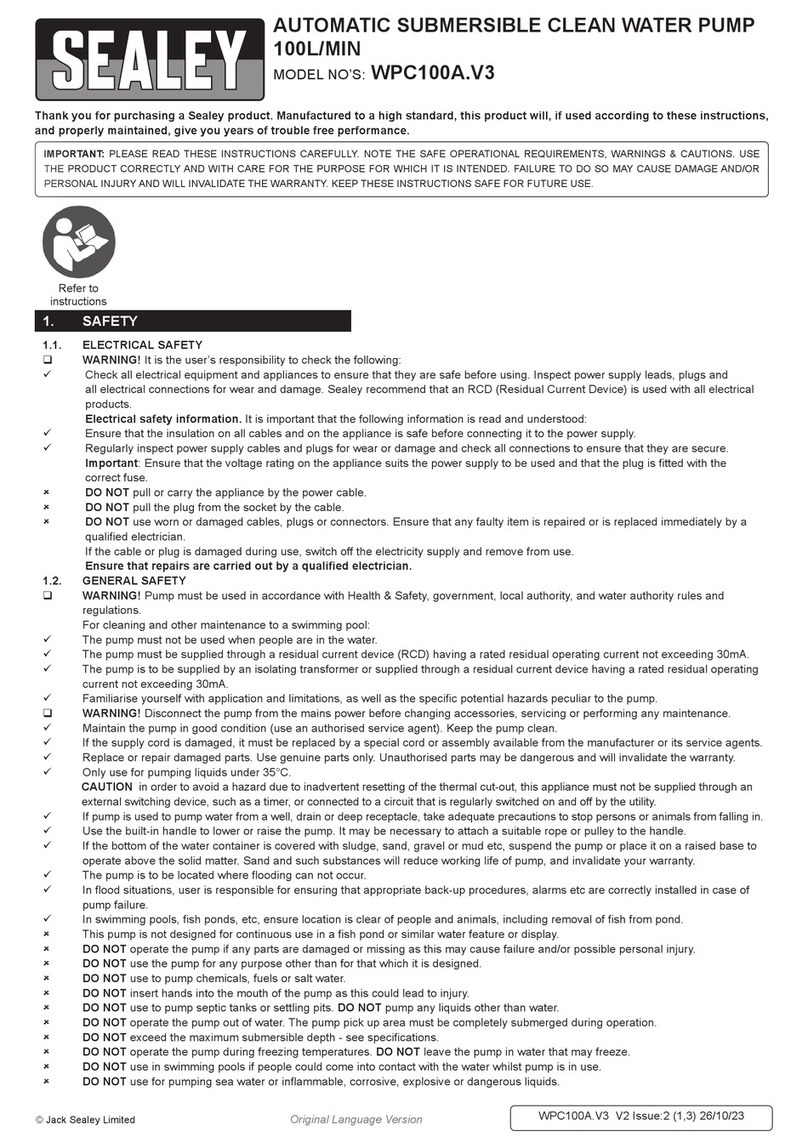

Figure 1

Page 3

PL19-6000EN

05/15/2015

Airetool®

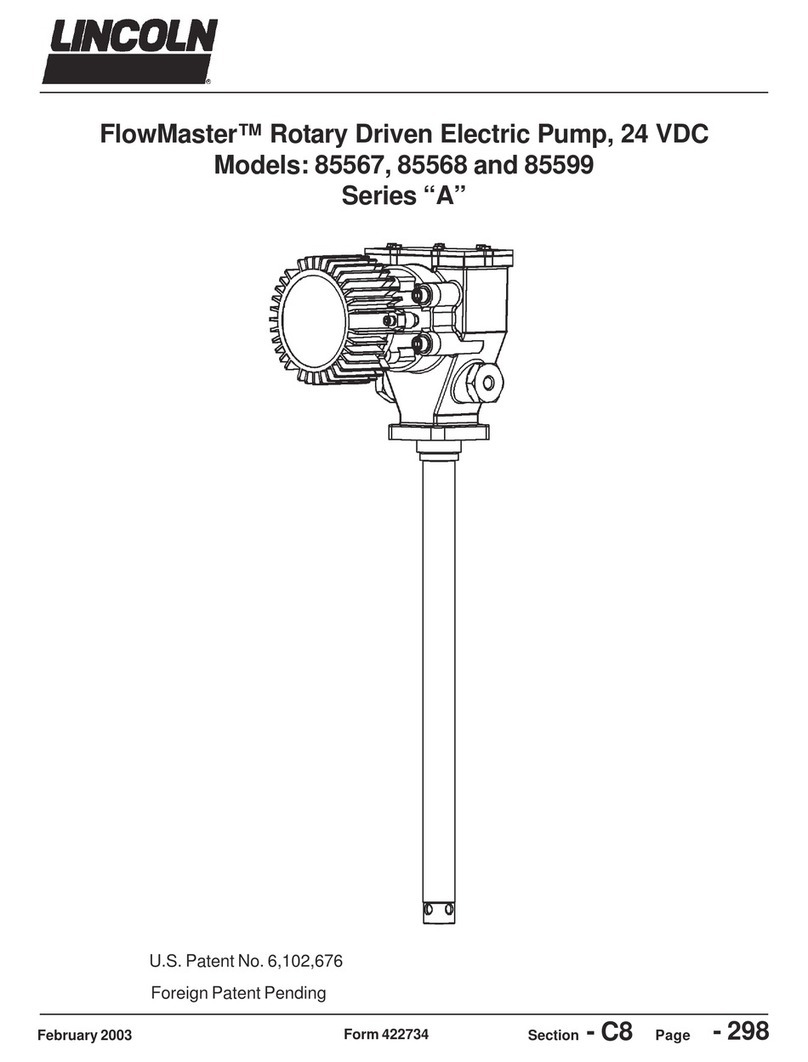

System Configuration

Carefully plan your system by selecting components designed to perform the intended operation

and which will adequately perform with existing equipment.

Always check the product limitations regarding pressure ranges, load capacities and set-up

requirements. The system operating pressure must not exceed the pressure rating of the lowest

rated component in the system.

Read all CAUTIONS, WARNINGS, and INSTRUCTIONS included with or attached to each

product. Follow all safety precautions to avoid personal injury or property damage during system

operation.

IMPORTANT RECEIVING INSTRUCTIONS:

Visually inspect all components for shipping damage. If any shipping damage is found, notify

the carrier at once. Shipping damage is NOT covered under the Apex Tool Group warranty. The

carrier is responsible for all repair or replacement cost resulting from damage during shipment.

Figure 2

Page 4

PL19-6000EN

05/15/2015

Language Version:

This Parts Manual is the “Original Instructions” intended

for all persons who will use or repair these tools.

Noise and Vibration:

The ATP III Pump operates at 85-90 dBA.

General Description:

An electric powered hydraulic pump mounted in a

wheeled roll cage, with an integrated handle, to facilitate

safely and easily moving the pump from one job location

to another.

Intended Use:

This pump is designed to work as an integrated tube

pulling system in conjunction with the Airetool ATP III

gripper type pullers. The Airetool HDQ III gripper type

pullers, RAV III and HDP III spear type tube pullers can

also be used with this pump.

Use only for the designated purpose. Do not use in any

improper manner that can cause equipment damage

and operator injury.

Copyright protection:

Apex Tool Group, LLC reserves the right to modify,

supplement or improve this document or the product

without prior notice. This document may not be

reproduced in any way, shape or form, in full or parts

thereof, or copied to another natural or machine readable

language or to a data carrier, whether electronic,

mechanical, optical or otherwise without the express

permission of Apex Tool Group, LLC.

Airetool®

Description

Page 5

PL19-6000EN

05/15/2015

Safety Precautions:

Read all instructions, warnings and

cautions carefully. Follow all safety

precautions to avoid personal injury or

property damage during system operation.

Apex Tool Group cannot be responsible

for damage or injury resulting from unsafe

product use, lack of maintenance or

incorrect product and/or system operation.

Contact Apex Tool Group when in doubt as

to the safety precautions and operations of

this equipment.

Failure to comply with the following cautions and

warnings could cause equipment damage and/or

personal injury.

A CAUTION is used to indicate correct operating or

maintenance procedures and practices to prevent

damage to, or destruction of, equipment or other

property.

A WARNING indicates a potential danger that requires

correct procedures or practices to avoid personal injury.

A DANGER is only used when your action, or lack of

action, may cause serious personal injury or

even death.

WARNING: Wear proper personal

protective gear when operating hydraulic

equipment.

WARNING: The system operating

pressure must not exceed the pressure

rating of the lowest rated component in

the system. Install pressure gauges in the

system to monitor operating pressure.

Avoid damaging the hydraulic hoses.

Avoid sharp bends and kinks when routing

the hydraulic hoses. Using a bent or kinked

hose will cause severe back-pressure.

Sharp bends or kinks will internally damage

the hose leading to premature failure.

DO NOT drop heavy objects on the

hoses. A sharp impact may cause internal

damage to the hose wire strands. Applying

pressure to a damaged hose may cause it

to rupture.

IMPORTANT: Do not lift hydraulic

equipment by the hoses or swivel couplers.

Use the integrated handle and wheeled

cage to safely move the pump.

Keep hydraulic equipment away from

ames and heat. Excessive heat will

soften packing and seals, resulting in uid

leaks. Heat also weakens hose materials

and packing. For optimum performance

do not expose equipment to temperatures

of 150° F (65° C) or higher. Protect hoses

and cylinders from weld spatter.

Do not handle pressurized hoses.

Escaping oil under pressure can penetrate

the skin, causing serious injury. If oil is

injected under the skin, see a doctor

immediately.

IMPORTANT: Hydraulic equipment must

only be serviced by a qualied hydraulic

technician. To protect your warranty, use

only manufactured recommended oil.

Immediately replace worn or damaged

parts with genuine manufacturer’s parts.

Standard grade parts will break causing

property damage and/or personal injury.

Manufacturer’s parts are designed to t

properly and withstand high loads.

Do not use electric pumps in an explosive

environment.Adhere to al local and national

electrical codes. A qualied electrician

must do installation and modication on

this equipment.

These pumps have internal factory

adjusted relief valves, which must not be

repaired or adjusted except by a factory

authorized service location.

To prevent damage to the pump’s electric

motor, check specications. An incorrect

power source will cause damage to the

motor.

Airetool®

Safety First

Page 6

PL19-6000EN

05/15/2015

Installation:

Position the pump to ensure that air ow around the

motor and pump is not obstructed. Keep the motor clean

to ensure maximum cooling during operation.

Fluid Level:

Check the oil level of the pump prior to start-up. If

necessary add oil by removing the SAE #10 plug from

the cover plate, Figure 3.

The reservoir is full when the oil level reaches the top of

the sight glass, Figure 4.

IMPORTANT: Add oil only when all system components

are fully retracted, or the system will contain more oil

than the reservoir can hold.

Operation:

Check the oil level of the pump and add oil if necessary,

as shown in Figures 3 and 4.

Connect power to the unit and wait until “OK” is displayed

on the LCD before pressing any button on the shroud or

pendent (if equipped).

NOTE: During the boot sequence, the micro processor

identies any button operation as a potential malfunction

and prevents the motor from starting. You can reset by

disconnecting the power for 10 seconds.

Start the motor and operate the tube puller by pressing

and releasing the ON/OFF button. The LCD will show

the pressure in the retract circuit (B-port bypass),

approximately 2500-2800 psi (173-193 bar).

As the motor starts, the valve shifts

automatically, retracting the tube puller.

Verify the tube puller is positioned to avoid

personal injury or equipment damage

before starting motor.

Shut off the motor by pressing the ON/OFF button. If

no buttons are pressed within a continuous 20 second

period, the pump’s built in timer will automatically shut

the motor off.

NOTE: When the motor is turned off, as the motor stops

turning, the valves will automatically cycle to release all

pressure in both the advance and retract hoses.

NOTE: Units equipped with heat exchangers allow the

timer to automatically shut off the pump. During any idle

period, the pump is circulating 90% of its oil ow through

the heat exchanger to reduce oil temperature.

Setting Pump Pressure:

This pump model provides the operator with two methods

of limiting the Advance (A port) pressure to the tube

puller: “User Adjustable Relief Valve” and “Auto Cycle”.

Airetool®

General Instructions

Figure 3: Oil Fill Plug

SAE #10

Plug

Figure 4: Oil Full Level

Reservoir

Full Level

Figure 5: Relief Valve

Control

Handle

Locking

Nut

Page 7

PL19-6000EN

05/15/2015

User Adjustable Relief Valve:

Limits the pressure by opening the relief valve to redirect

the pump’s oil ow to the reservoir at the desired

pressure value. Pressure will remain in the Advance

circuit (A port) while the Pendant “Up” button is pressed.

To adjust the pressure valve, Figure 5:

1. Verify “Auto Mode” is Off or “Set Pres” value is a

minimum 100 psi (7 bar) higher than the desired

relief valve setting.

2. Loosen the relief valve locking nut and turn the relief

valve control handle counter-clockwise until there

is a light drag when turning, this will decrease the

pressure value.

3. Start the pump to allow the oil to warm above 32°

F (0° C).

4. Press and hold the pendant Up button to build

pressure in the advance circuit. Turn relief valve

control handle clockwise to increase pressure to

desired value. NOTE: To get an accurate setting,

decrease the pressure to a point below the nal

setting and then slowly increase the pressure

until it reaches the nal setting.

5. Tighten the relief valve locking nut at the desired

pressure value.

6. Release the pendant Up button to allow the system

pressure to return to the B-port by-pass setting.

7. Recheck the nal pressure setting by shifting the

valve and pressurizing the system.

Auto Cycle:

Limits the pressure by automatically changing the tube

pulling operation from Advance to Retract at the desired

pressure value. When the Retract pressure reaches a

factory-preset value of approximately 2,000 psi (138

bar), the pump automatically changes tube pulling

operation from Retract back to Advance. The pump

microprocessor does this by shifting the electric control

valve to redirect the pump’s oil ow between ports. This

automatic cycling will continue while the pendant Up

button is pressed.

To activate Auto Cycle and adjust the pressure value:

1. Activate Auto Cycle by displaying the “Automode”

menu and toggling the setting to “On” using the

shroud arrow buttons. Save by pressing the Menu

button once.

2. Set the desired Advance pressure by displaying the

“Set Pres” menu and adjusting the value by using

the shroud arrow buttons. Save and return to the

“OK” display by pressing and holding the Menu

button for 2 seconds.

3. Turn on the pump by pressing the pendant On/Off

button.

4. Press and hold the pendant Up button to Auto Cycle

the tube puller.

5. If the tube puller does not Auto Cycle or does so

erratically, increase the User Adjustable Relief Valve

setting to a minimum value of 100 psi (7 bar) higher

than the desired Auto Cycle value.

NOTE: Maximum Retract pressure (B port),

also known as B port by-pass, is factory set at

approximately 2,500-2,800 psi (173-193 bar) and

cannot be adjusted.

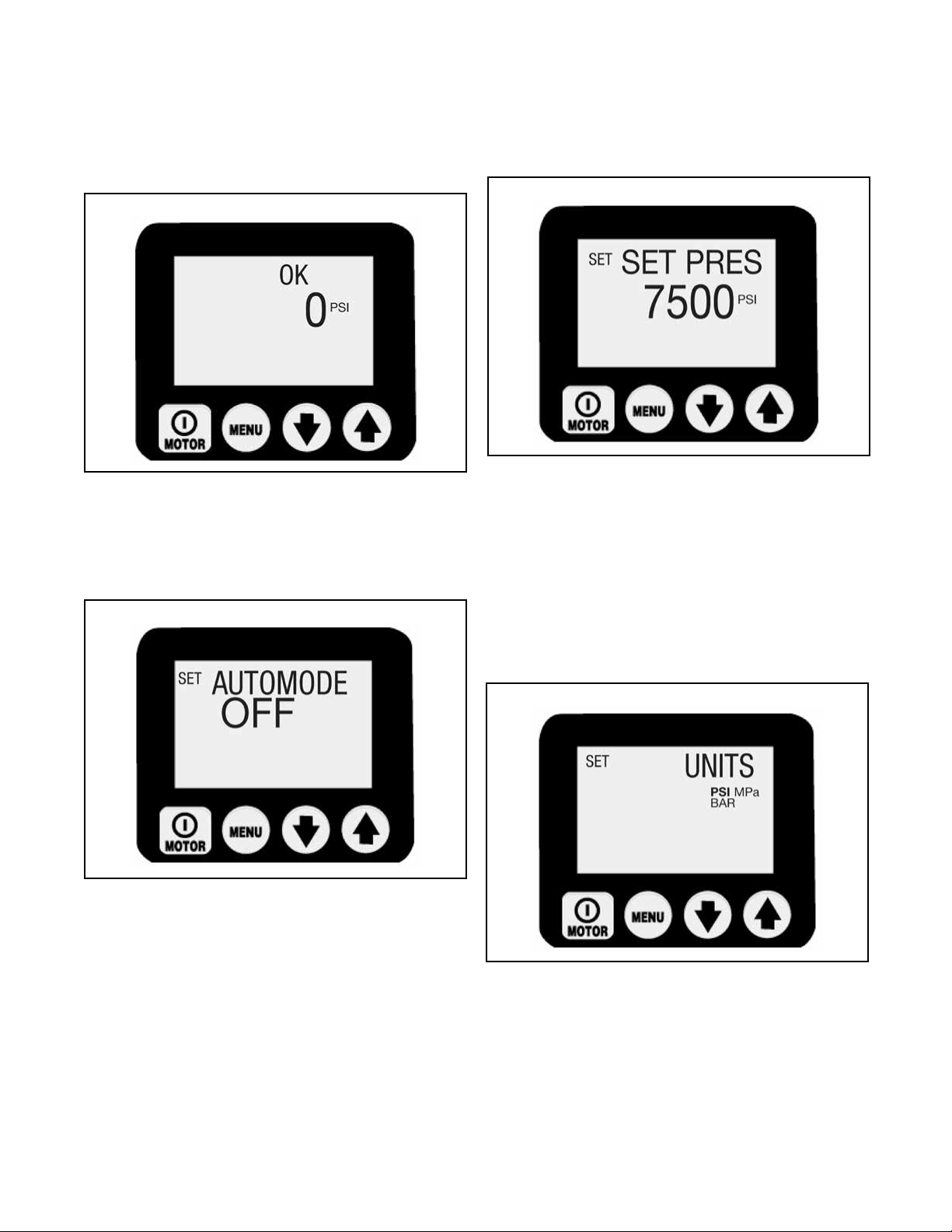

LCD Function:

Besides the Pendant, which is used to switch the motor

on/off and operate the valves, the Control Board with its

four-button switches is the main interface between the

operator and the pump. With the use of these four-button

switches all functions and settings that are described in

the following can be activated.

Make sure that all the plastic overlay, that

protects the LCD screen and the button

switches, is not broken or otherwise

damaged. Never punch the button switches

with a sharp or pointed instrument, user

ngertips only. Clean the overlay regularly

with a damp cloth; never use an aggressive

or abrasive detergent.

Airetool®

General Instructions

Figure 6: LCD Screen

Number

Display

Text

Display

Page 8

PL19-6000EN

05/15/2015

A. Boot Sequence:

Firmware 5.5 and earlier: When the pump is

connected to electrical power the LCD screen will show:

“FIRMWARE x.x” for 2 seconds.

Firmware 5.6 and later: When the pump is connected to

electrical power the LCD screen will show: “FIRMWARE

x.x” for 1 second, then “Model xx” for 0.5 seconds, and

then “MOTOR UN/1P/3P” for 0.5 seconds.

This is setup information about your pump that may

be needed for service. The boot sequence is nished

successfully when the text display on the LCD screen

shows “OK” (sequence takes approximately 2 seconds).

The micro-controller will automatically recognize the

optional pressure transducer built into the pump. The

reading after the boot process is “OK” in the text display

and the current pump pressure on the numeric display.

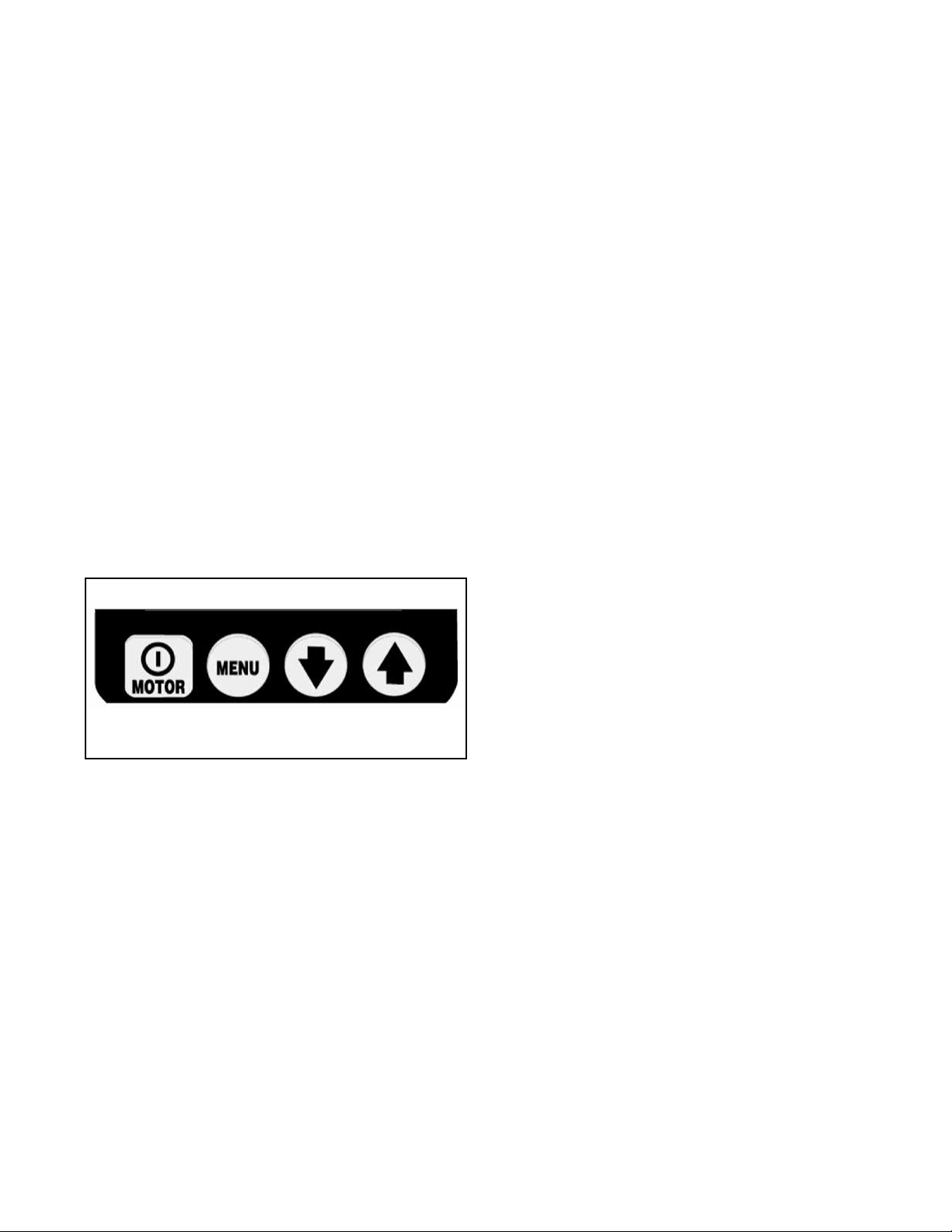

B. LCD Operational Buttons:

The control board is equipped with four button switches,

from left to right; On/Off, Menu, Down Arrow, Up Arrow,

see Figure 7.

• The On/Off button toggles the motor OFF. The

motor OFF function is available on this button even

if the pump is NOT in the local mode but is operated

by using the pendant control.

• The Menu button enables the operator to step from

normal operational mode into menus. With repeated

pressing the operator steps through the various

menus. Pressing the Menu button also saves any

changes made. To return to the normal operational

mode, press and hold the Menu button for two

seconds or don’t push any button for 60 seconds.

• The Down Arrow and Up Arrow buttons serve

two purposes. When the display shows one of the

menus, the Down Arrow and Up Arrow buttons are

used to step through the menu’s options. When the

pump is placed in Local Mode the UP Arrow button

switches the B and A electric solenoids (the pendant

is non-operational in local mode).

C. Menus Available:

The software provides the operator with the following

Menus:

• Automode: Set tube puller Auto Cycle mode ON

or OFF. With Automode OFF, the menu Set Pres

(Firmware 5.5 and earlier) or HI PRESS (Firmware

5.6 and later) will not be available and the Set Pres

or HI PRESS pressure value has no effect on the

pump.

• Set Pres or HI PRESS: (Only available with

Automode ON) Set the Advance port pressure

value the tub puller will Auto Cycle at. Changes in

increments of 50 psi (3.5 bar), maximum pressure

value is 10,000 psi (700 bar). NOTE: Firmware 5.5

and earlier - the hidden calibration menu for the

digital gauge is accessed from this menu.

• Units: Set the pressure units to PSI / BAR / MPa,

with psi being the default setting. NOTE: Firmware

5.6 and later - the hidden calibration menu for

the digital gauge is accessed from this menu.

• Motor: Display the motor hour meter and on/off

cycle counter (can not be reset).

• Low Volt: Display the low voltage hour-meter (can

not be reset).

• Advance: Display the Advance solenoid hour meter

and on/off cycle counter (can not be reset).

• Retract: Display the Retract solenoid hour meter

and on/off cycle counter (can not be reset).

• Local: Set the pump local mode on/off

• Language: Set the language of the display to

English / Spanish / French / Italian / German /

Portuguese, with English being the default setting.

• Diagnose: Display to show input signals from the

pendant control and other electrical accessories.

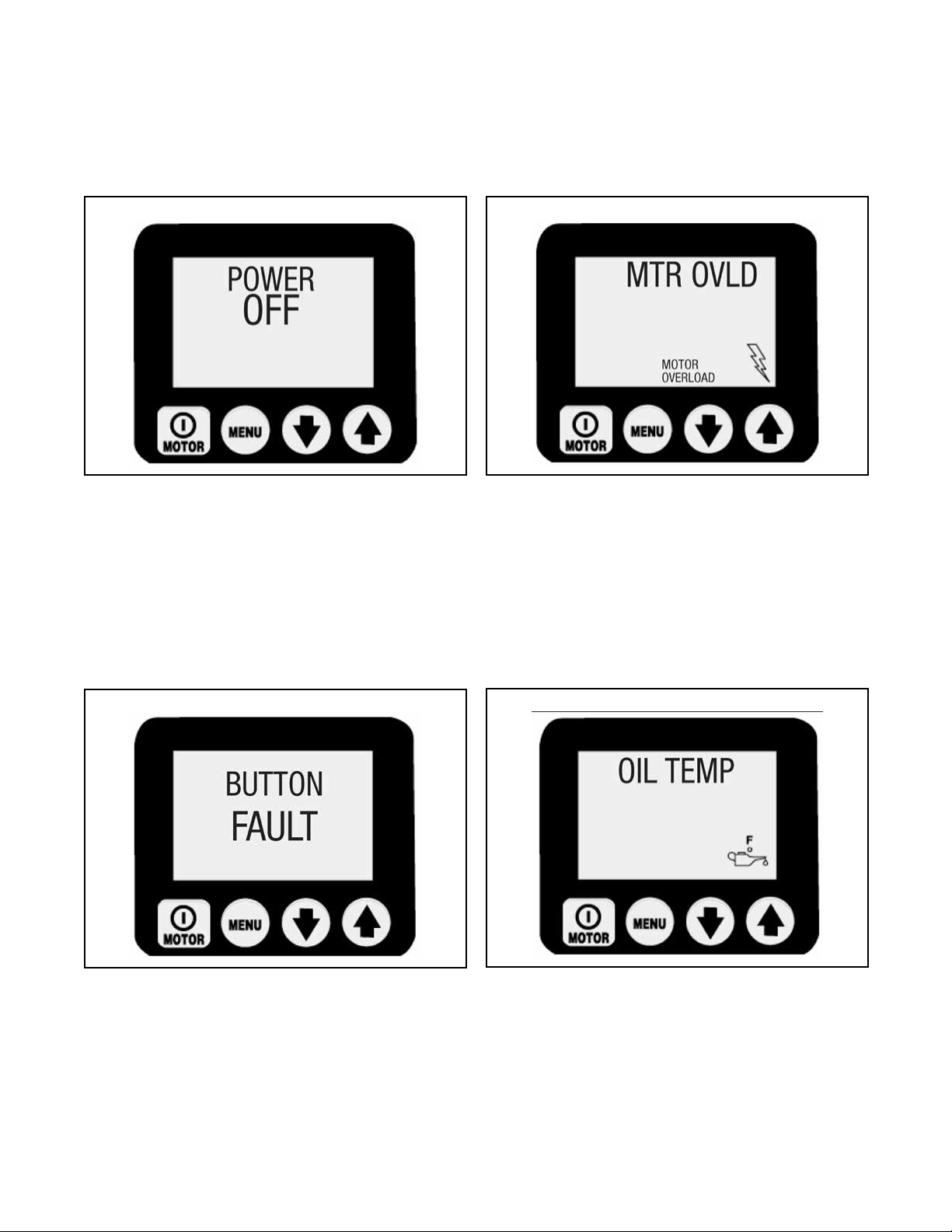

Fault Conditions:

Any fault will shut down and prevent the pump from

starting:

A. Clearing a Fault Condition from the LCD:

After the fault causing the problem has been corrected,

clear the fault message from the LCD by disconnecting

electrical power from the pump, wait until all characters

clear the LCD (approximately 10 seconds), then

reconnect the electrical power.

Airetool®

General Instructions

Figure 7: Operational Buttons

On/Off Menu Down

Arrow

Up

Arrow

Page 9

PL19-6000EN

05/15/2015

B. Power Failure:

Display: “POWER OFF”

The Power Off fault is displayed when the main power

supply drops to 65% or less of nominal voltage. The

pump will automatically shut off the valves and the

motor, and display “Power Off” on the LCD.

NOTE: “Power Off” is also displayed for several

seconds after the unit is disconnected from the

electrical supply.

C. Button Fault:

Display: “Button Fault”

The Button Fault is displayed when the micro processor

detects any button press during the boot sequence or

if the shroud on/off button is held in for more than 3

seconds.

D. Motor Overload:

Display: “MTR OVLD”

The Motor Overload fault is displayed when the electric

current drawn by the motor exceeds the pre-set limit of

the internal circuit breaker. The internal circuit breaker

will automatically reset once the condition has been

corrected; however, the operator must clear the fault and

then press the motor on/off button to restart the motor.

E. Oil Temperature (requires optional oat/temperature

switch)

Display: “OIL TEMP”

The Oil Temperature fault is displayed when the

temperature of the oil inside the reservoir exceeds 175°

F (80° C).

Airetool®

General Instructions

Figure 8: Power Off

Figure 9: Button Fault

Figure 10: Motor Overload

Figure 11: Oil Temperature

Page 10

PL19-6000EN

05/15/2015

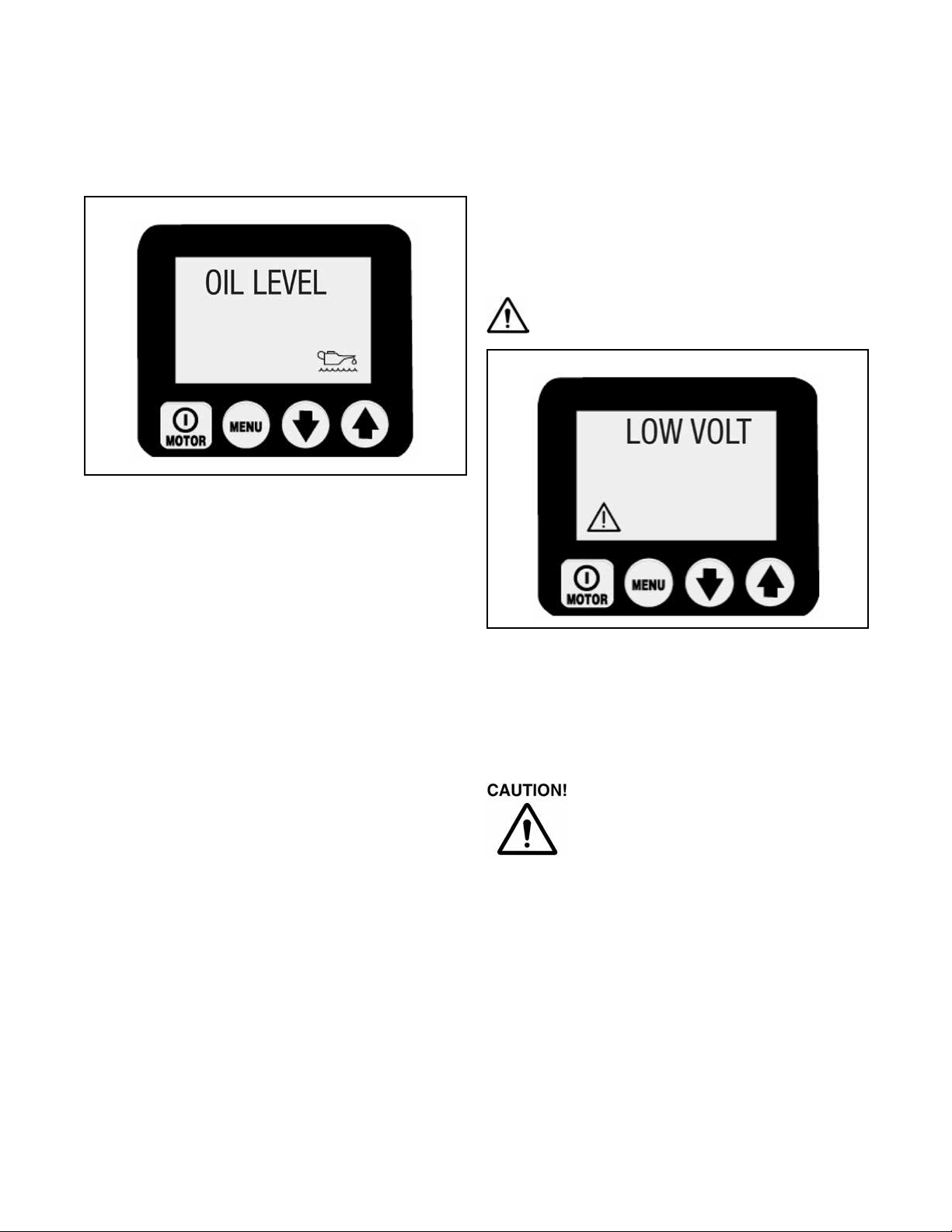

F. Oil Level (requires optional oat/temperature switch)

Display: “OIL LEVEL”

The Oil Level fault is displayed when the oil level inside

the reservoir drops below 1.3” (34mm) from bottom.

Warning Conditions:

All warnings notify the operator of an abnormal operating

condition, however, allow pump to continue operating.

Warnings will automatically clear once the issue has

been resolved.

A. Low Voltage:

Display: “LOW VOLT”

Low Voltage

A Low Voltage condition is dened as an operating

condition when the main power supply is at or below

80% of nominal voltage. While running the pump under

this condition, the “Low Voltage” signal will ash on the

LCD and the Low Voltage hours will be counted and

stored on the control board. Normal pump operation is

still provided.

For optimized pump performance it is

recommended NOT to run the pump at a

Low Voltage condition.

Airetool®

General Instructions

Figure 12: Oil Level

Figure 13: Low Voltage

Page 11

PL19-6000EN

05/15/2015

LCD Menus:

A. Normal Operation Menu:

The Normal Operation LCD screen indicates that

the control board has booted successfully (OK); the

pressure reading is 0 psi. The operator can now enter

into the menus by pressing the “Menu” button.

B. Auto Mode Menu:

This screen allows the operator to toggle the tube puller

Auto Cycle mode ON or OFF. With Automode OFF, the

menu Set Pres (Firmware 5.5 and earlier) or HI PRESS

(Firmware 5.6 and later) will not be available and the Set

Press / HI PRESS pressure value has no effect on the

pump. Switch it ON or OFF by pressing either the Down

or Up Arrow buttons.

NOTE: Firmware 5.6 and later - Setting the value to

ON also changes the Normal Operations menu text

message from “OK” to “AUTO”. Save the setting

and step forward by pressing the Menu button.

C. Set Press or High Press Menu (only available with

Automode ON):

This screen allows the operator to set the Advance

port pressure value the tube puller will Auto Cycle at.

Changes in increments of 50 psi (3.5 bar) by pressing

either the Down or Up Arrow button or keep either button

pressed for speed setting. Maximum pressure value is

10,000 psi (700 bar). Save the setting and step forward

by pressing the Menu button.

NOTE: Firmware 5.5 and earlier: The hidden

calibration menu for the digital gauge is accessed

from this menu.

D. Units Menu:

This screen allows the operator to set the unit of

pressure-measurement by pressing either the Down or

Up Arrow button. The options available are PSI, BAR,

Mpa with PSI being the default. Save the setting and

step forward by pressing the Menu button.

NOTE: Firmware 5.6 and later: The hidden calibration

menu for the digital gauge is accessed from this

menu.

Airetool®

General Instructions

Figure 14: Normal Operation Menu

Figure 15: Auto Mode Menu

Figure 16: Set Press or HI PRESS Menu

Figure 17: Units Menu

Page 12

PL19-6000EN

05/15/2015

E. Motor Menu:

This screen allows the operator to read the number of

hours (ON / OFF cycles) the motor has been operated.

Toggle between hours and cycles by pushing either the

Down or Up Arrow buttons. Step forward by pressing the

Menu button.

General note for all hour and cycle displays:

Hours Displayed

• up to 9999.9 the display will show decimal hours

• between 10,000 - 99,999 whole hours will be

displayed (decimal “.” is not displayed)

• over 99,999 hours the meter starts over at 0.0

reading decimal hours.

Cycles Displayed

• over 99,999 cycles the meter starts over at 0

F. Low Volt Menu:

This screen allows the operator to read the number

of hours the pump has been operated in low-voltage

condition. Step forward by pressing the Menu button.

G. Advance Menu:

This screen allows the operator to read the number of

hours (On / Off cycles) the Advance solenoid has been

operated. Toggle between hours and cycles by pushing

either the Down or Up Arrow buttons. Step forward by

pressing the Menu button.

H. Retract Menu:

This screen allows the operator to read the number of

hours (On / Off cycles) the Retract solenoid has been

operated. Toggle between hours and cycles by pushing

either the Down or Up Arrow buttons. Step forward by

pressing the Menu button.

Airetool®

General Instructions

Figure 18: Motor Menu

Figure 19: Low Volt Menu

Figure 20: Advance Menu

Figure 21: Retract Menu

Page 13

PL19-6000EN

05/15/2015

I. Local Menu:

This screen allows the operator to toggle the LOCAL

mode ON or OFF, default is OFF. With LOCAL mode

ON, the shroud buttons replace the pendant control

buttons as the method to operate the pump.

NOTE: The word LOCAL replaces OK on the Normal

Operations display and the pendant control buttons

become deactivated.

LOCAL mode will provide operation of the pump if the

pendant control or pendant control cable is damaged.

Toggle LOCAL mode ON or OFF by pressing the Down

or Up Arrow buttons. Save the setting and step forward

by pressing the Menu button.

J. Language Menu:

With a language shown on the text display the operator

can change the display language by pressing the Down

or Up Arrow buttons. Save the setting and step forward

by pressing the Menu button.

K. Diagnose Menu:

This screen allows the operator to trouble shoot several

pendant problems by displaying if the microprocessor

has received a signal from the pendant control button.

No signal indicates the problem is most likely with the

pendant keypad or pendant cord. Use LOCAL mode to

operate the pump until the problem can be corrected.

Airetool®

General Instructions

Figure 22: Local Menu

Figure 23: Language Menu

Figure 24: Diagnose Menu

not used

Fan

Pendant Down Arrow button

Pendant Up Arrow button

Pendant ON / OFF button

Figure 25: Diagnose Menu

ON / OFF (Motor)

button pushed

Up Arrow (Advance)

button pushed

Page 14

PL19-6000EN

05/15/2015

LCD Hidden Menus:

(available when the pressure transducer is installed)

A. Calibration Menu:

This screen allows the operator to adjust the pressure

value shown on the LCD to match a master gauge. To

access this menu:

Firmware 5.5 and earlier: Set AUTOMODE to ON and

go to the “Set Pres” menu.

Firmware 5.6 and later: Go to the UNITS menu

Then press and hold the ON / OFF button for 7 seconds,

ENTRY CODE will appear. Then press and hold both the

Down Arrow and Up Arrow buttons for 7 seconds.

Refer to Table A for Pump Calibration sequence.

Airetool®

General Instructions

Figure 26: Calibration Menu

Page 15

PL19-6000EN

05/15/2015

Step Operator Action Comments

1

Connect master gauge to port A (Advance port) - Also

connect hand pump if applicable, see comments

Note: There are two methods of producing the

needed pressure in steps 11 and 15, using the pumps

"motor" or separate "hand pump". Connect a hand

pump only if it will be used to create pressure in steps

11 and 15, and verify the pump's user adjustable

relief valve is set higher than maximum pressure

used in step 15.

2 Connect electrical power to pump FIRMWARE x.x, then "OK" 0 psi Boot-sequence

3

Firmware 5.5 and earlier: In the OK mode, press the

Menu button once and set Automode ON

AUTOMODE ON

If Automode is OFF, press one of the Arrow buttons

once to select ON

3.1

Firmware 5.5 and earlier: At main screen, press the

Menu button once to display screen "SET PRES",

skip step 4

SET PRES xxxx psi xxxx psi is the current pressure value of SET PRES

4

Firmware 5.6 and later: At main screen, press the

Menu button once to display screen "UNITS", skip

steps 3 and 3.1

UNITS psi psi is the current unit of pressure measurement

5 Press and hold the ON / OFF button for 7 seconds ENTRY CODE Step into the hidden calibration mode

6Press and hold the Up Arrow and Down Arrow

buttons together for 7 seconds

CAL PT A 0 psi (0 bar)

Start of calibration process. The advance-solenoid

will be powered up to access the pressure transducer

through valve-port A.

7.a

"Motor" method - Open the pump's user adjustable

relief valve and verify both pump LCD and master

gauge read zero.

CAP PT A 0 psi (0 bar) Calibrate the zero-offset, point "A"

7.b

"Hand Pump" method - Open the hand pump's user

control valve and verify both pump LCD and master

gauge read zero.

CAP PT A 0 psi (0 bar) Calibrate the zero-offset, point "A"

8

Press the Menu button to accept the pressure value

into temporary memory

SAVE A no

9

Press one Arrow button to change from "NO" to

"YES"

SAVE A yes

Confirm the pressure data should be stored to

memory

10 Press the Menu button once CAL PT B 2000 psi (138 bar)

Calibrating gain is done with two points, starting with

point "B"

11.a

"Motor" method - Press and release the shroud's ON

/ Off motor button to switch the pump motor on.

Reading the master gauge, apply a pressure of 2,000

psi (138 bar) by closing the pump's user adjustable

relief valve.

CAL PT B 2000 psi (138 bar)

CAL PT B can be set at any pressure value greater

than zero. First obtain the pressure value on the

master gauge (ie 2250 psi) (155 bar) then use the

arrow buttons to match the LCD value to the master

gauge.

11.b

"Hand Pump" method - Close the hand pump's

control valve. Reading the master gauge, apply a

pressure of 2,000 psi (138 bar)

CAL PT B 2000 psi (138 bar)

CAL PT B can be set ay any pressure value greater

than zero. First obtain the pressure value on the

master gauge (ie 2250 psi) (155 bar) then use the

arrow buttons to match the LCD value to the master

gauge.

12

Press the Menu button to accept the pressure value

into temporary memory

SAVE B no

13

Press one Arrow button to change from "NO" to

"YES"

SAVE B yes

Confirm the pressure data should be stored to

memory

14 Press the Menu button once CAL PT C 8000 psi (548 bar)

Calibrating gain is done with two points, finishing with

point "C"

15

Reading the master gauge, apply a pressure of 8,000

psi (548 bar) CAL PT C 8000 psi (548 bar)

CAL PT C can be set at any pressure value greater

than CAL PT B. First obtain the pressure value on the

master gauge (ie 7500 psi) (515 bar) then use the

arrow buttons to match the LCD value to the master

gauge.

16

Press the Menu button to accept the pressure value

into temporary memory

SAVE C no

17

Press one Arrow button to change from "NO" to

"YES"

SAVE C yes

Confirm the pressure data should be stored to

memory

18 Press the Menu button once USE DFLT off

Re-confirm calibration data. Leave "off" to proceed

with new calibratin data. Only set to "on" to change

calibration data back to factory default settings. Press

Arrow button to change.

19 Press the Menu button once CAL PT A 0 psi (0 bar) Save calibration data to permanent memory.

20

Press and hold the Menu button for 3 seconds to step

out of the calibration mode.

OK 0 psi (0 bar) Calibration complete

Table A - Pump Calibration

LCD Reading

Airetool®

General Instructions

Page 16

PL19-6000EN

05/15/2015

Maintenance:

Frequently inspect all system components for leaks

or damage. Electrical components (example; power

cord) may only be repaired or replaced by a qualied

electrician, adhering to all applicable local and national

codes.

Check Oil Level:

Check the oil level of the pump prior to start-up, and add

oil, if necessary, by removing the oil ll plug. Always be

sure the cylinders are fully retracted before adding oil to

the reservoir.

Change Oil and Clean Reservoir:

The ATP III pump oil is a crisp blue color. Frequently

check the oil condition for contamination by comparing

the reservoir oil to new unused oil. As a general rule,

completely drain an clean the reservoir every 250 hours

of use, or more frequently if used in dirty environments

NOTE: This procedure requires that you remove the

pump from the reservoir. Work on a clean bench and

dispose of used oil according to local codes.

1. Unscrew the 13 bolts holding the cover plate to the

reservoir and lift the pump unit out of the reservoir.

Be careful not to damage the lter screen.

2. Pour all oil out of the reservoir.

3. Thoroughly clean the reservoir and magnet with a

suitable cleaning agent.

4. Remove the pick-up lter screen for cleaning.

CAUTION: Do not pull on the screen or the

bottom of the intake to avoid possible damage.

Clean the screen with solvent and a soft brush.

Reinstall the lter screen.

5. Reassemble the pump and reservoir, installing a

new reservoir gasket.

6. Fill the reservoir with clean manufacturer

recommended hydraulic oil. The reservoir is full

when the oil level is in the middle of the sight gauge,

see Figure 28.

Troubleshooting Guide (see Table B):

Only qualied factory technicians should service the

pump or system components. A system failure may or

may not be the result of a pump malfunction. To determine

the cause of the problem, the complete system must be

included in any diagnostic procedure.

The information contained in Table B is intended for use

as an aid in determining if a problem exists. For repair

service, contact your Apex Tool Group representative.

Airetool®

General Instructions

Figure 27: Oil Fill Plug

Oil Fill

Plug

Figure 28: Oil Full Level

Reservoir

Full Level

Page 17

PL19-6000EN

05/15/2015

Problem Possible Cause

Pump will not start No power or wrong voltage

Pump in LOCAL mode

Pendant damaged

Motor stalls under load Low voltage

No power or wrong voltage

Valve out of adjustment

Solenoid cable disconnected or damaged

Low oil level

External system leak

Internal leak in pump

Internal leak in valve

Internal leak in system component

Relief valve set too low

Low oil level

External system leak

Internal leak in pump

Internal leak in valve

Internal leak in system component

Relief valve set too low

Quick coupler not connected properly

Defective quick connector on pump or hand piece

Defective directional valve

External system leak

Internal leak in system component

Valve malfunction

Return flow or coupler restricted

Leaky seal(s) in hand piece

Couplings assembled backwards

Auto Cycle mode set to OFF

Relief valve setting at or below "SET PRES" or "HI

PRESS" value

SET PRES value below 2,900 psi (200 bar) -

Firmware 5.5 and earlier

HI PRESS value below 1,400 psi (96 bar) - Firmware

5.6 and later

Retract flow restricted or blocked

Valve malfunction

Advance or retract flol restricted

High ambient temperature

Pump runs hot

Tube puller does not Auto Cycle or Auto Cycles

erratically

Table B - Trouble Shooting Guide

Pump builds less than full pressure

Pump builds full pressure but does not move cylinder

Tube puller will not retract

Cylinder drifts back on its own

Cylinder will not return

Electric valve will not operate

Pump fails to build pressure

Pendant does not function

Airetool®

General Instructions

Page 18

PL19-6000EN

05/15/2015

Page 18

Figure 29

1

Airetool®

Electric/Hydraulic Pump Assembly

2

PL19-6000EN

05/15/2015

Page 19

EN

Description

1 2902536 1 EDHP III Electric/Hydraulic Pump Assembly (Factory repair only)

2 ------ Serviceable Electrical Components

2994951 1 HDP 31 20 Receptacle

8567132 1 A 100 82 Reverse Switch

2983261 2 ATS 8835 Cable Clamp

2991255 1 ATP 9046 Cord Plug

2990688 1 A 100 95 Plug

2902574 1 PATP3 9 Plate

2902575 1 PATP3 4 BL Blank Box

8011043 4 4-20 x 3/8 Screw

2990308 1 A 100 66 Strain Relief

8010464 1 30 071 Wire Nut

8566942 1 AART 2 Receptacle

0981264PT 1 DAS2 Blank Box

2902576 1 ATP3 2 Switch

3 ------ Pump Mobility Parts mounted to Roll Cage (not shown)

2902841 1 ATP3 14 Axle

2902842 8 ATP3 15 U-Bolt

2902843 16 ATP3 16 Cap

2902844 2 ATP3 17 Caster

2902845 1 ATP3 18 Caster Bracket

2902846 2 ATP3 19 Wheel

(#) Quantity

(X) Recommended Spare Parts

Figure 29

Ref Number # X

Airetool®

Electric/Hydraulic Pump Assembly

Please note that all locations may not service all products.

Contact the nearest Apex Tool Group Sales & Service Center for the appropriate facility

to handle your service requirements.

POWER TOOLS SALES & SERVICE CENTERS

Apex Tool Group, LLC

1000 Lufkin Road

Apex, NC 27539

Phone: +1 (919) 387-0099

Fax: +1 (919) 387-2614

www.apexpowertools.com

England

Apex Tool Group

GmbH & Co. OHG

C/O Spline Gauges

Piccadilly, Tamworth

Staffordshire B78 2ER

United Kingdom

Phone: +44 1827 8727 71

Fax: +44 1827 8741 28

EUROPE | MIDDLE EAST | AFRICA

France

Apex Tool Group S.A.S.

25 rue Maurice Chevalier

B.P. 28

77831 Ozoir-La-Ferrière

Cedex, France

Phone: +33 1 64 43 22 00

Fax: +33 1 64 43 17 17

Germany

Apex Tool Group

GmbH & Co. OHG

Industriestraße 1

73463 Westhausen

Germany

Phone: +49 (0) 73 63 81 0

Fax: +49 (0) 73 63 81 222

Hungary

Apex Tool Group

Hungária Kft.

Platánfa u. 2

9027 Györ

Hungary

Phone: +36 96 66 1383

Fax: +36 96 66 1135

NORTH AMERICA | SOUTH AMERICA

Lexington, South Carolina

Apex Tool Group

670 Industrial Drive

Lexington, SC 29072

Phone: +1 (800) 845-5629

Phone: +1 (919) 387-0099

Fax: +1 (803) 358-7681

Canada

Apex Tool Canada, Ltd.

7631 Bath Road

Mississauga, Ontario L4T 3T1

Canada

Phone: (866) 691-6212

Fax: (905) 673-4400

Mexico

Apex Tool Group

Manufacturing México

S. de R.L. de C.V.

Vialidad El Pueblito #103

Parque Industrial Querétaro

Querétaro, QRO 76220

Mexico

Phone: +52 (442) 211 3800

Fax: +52 (800) 685 5560

Detroit, Michigan

Apex Tool Group

2630 Superior Court

Auburn Hills, MI 48236

Phone: +1 (248) 393-5640

Fax: +1 (248) 391-6295

Brazil

Apex Tool Group

Ind. Com. Ferram, Ltda.

Av. Liberdade, 4055

Zona Industrial Iporanga

Sorocaba, São Paulo

CEP# 18087-170

Brazil

Phone: +55 15 3238 3820

Fax: +55 15 3238 3938

Louisville, Kentucky

Apex Tool Group

1000 Glengarry Drive

Suite 150

Fairdale, KY 40118

apexpowertools.com/service

ASIA PACIFIC

India

Apex Power Tools India

Private Limited

Gala No. 1, Plot No. 5

S. No. 234, 235 & 245

Indialand Global

Industrial Park

Taluka-Mulsi, Phase I

Hinjawadi, Pune 411057

Maharashtra, India

Phone: +91 020 66761111

Australia

Apex Tool Group

519 Nurigong Street, Albury

NSW 2640

Australia

Phone: +61 2 6058 0300

China

Apex Power Tool Trading

(Shanghai) Co., Ltd

Building A8, No. 38

Dongsheng Road

Pudong, Shanghai

China 201201

Phone: +86 21 60880320

Fax: +86 21 60880298

Japan

Apex Tool Group Japan

Korin-Kaikan 5F,

3-6-23 Shibakoen, Minato-Ku,

Tokyo 105-0011, JAPAN

Phone: +81-3-6450-1840

Fax: +81-3-6450-1841

Korea

Apex Tool Group Korea

#1503, Hibrand Living Bldg.,

215 Yangjae-dong,

Seocho-gu, Seoul 137-924,

Korea

Phone: +82-2-2155-0250

Fax: +82-2-2155-0252

PL19-6000EN | 0515 | © 2015 Apex Tool Group, LLC | Printed in USA

Airetool®

Table of contents

Other Airetool Water Pump manuals

Popular Water Pump manuals by other brands

Graco

Graco BLUE DEVIL 260410 Instructions-parts list

Aqueon

Aqueon QuietFlow 10 instructions

laguna

laguna TABLETOP instructions

Summit

Summit 2175 Series Installation, operation and maintenance manual

Ruhrpumpen

Ruhrpumpen CPP21 Installation, operation and maintenance manual

Zehnder Pumpen

Zehnder Pumpen Drain Inox 50 MA operating instructions